Waterproof non-inflammable cable fireproof groove box and manufacturing method thereof

A technology of fireproof slots and slot boxes, which is applied in the direction of electrical components, etc., to achieve the effect of strong heat insulation performance, high strength, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

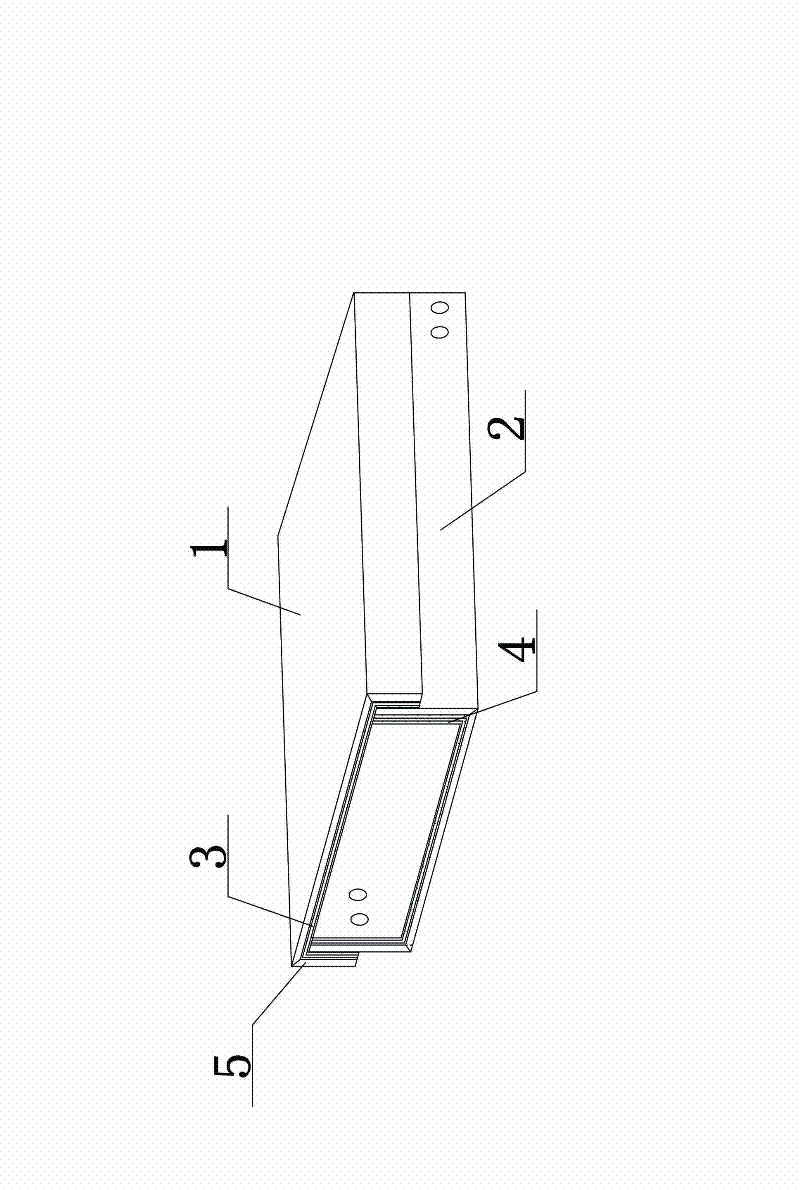

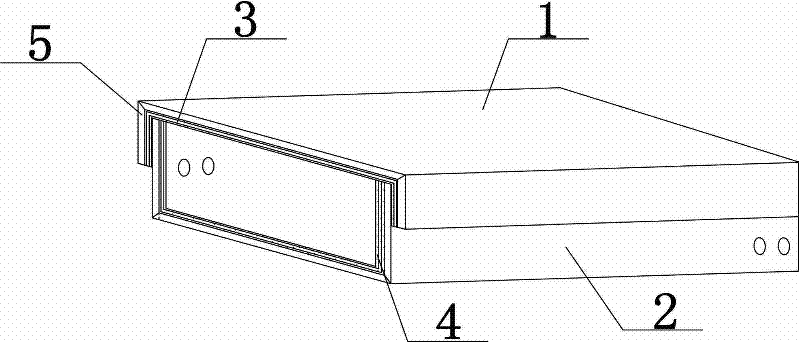

[0023] Embodiment one, by figure 1 It can be seen that the water-resistant and non-combustible cable fireproof tank box is mainly composed of two parts: the tank box cover plate 1 and the tray 2, and is formed by an extrusion production line mechanism. Put it in the barrel of the extrusion production line equipment, cover a layer of glass fiber cloth with a layer of cement, set a metal mesh shielding layer 3 between the cement layer and glass fiber cloth, start extrusion production, and extrude composite molding materials , Put the extruded material into the mold, cover the material in the mold with two layers of film, and cure it into the tank box cover plate 1 and the tray 2. The reaction is controlled at a temperature of 20°C and a humidity of 70%. The curing reaction can be demoulded within 12 hours. After demoulding, the product is removed, punched, and trimmed until it passes the acceptance test. The inner side of the tank box cover plate 1 and the tray 2 are all waterp...

Embodiment 2

[0024] Embodiment 2, the manufacturing process is the same as Embodiment 1, but the weight ratio of the components of the cement is: magnesium oxide: 36%; magnesium chloride: 21%; talcum powder: 12%; perlite: 4%; saw foam: 5.2%; Modifier: 2.3%; phosphoric acid: 0.07%; waterproof powder: 19.43%.

Embodiment 3

[0025] Embodiment 3, the manufacturing process is the same as Embodiment 1, but the weight ratio of the components of the cement layer is: magnesium oxide: 35%; magnesium chloride: 22%; talcum powder: 13%; perlite: 4.44%; saw foam: 4% ; Modifier: 2.3%; Phosphoric acid: 0.04%; Waterproof powder: 19.22%.

[0026] The physical and chemical performance indicators, water resistance and fire resistance performance indicators of this product are shown in the table below.

[0027] project unit Technical indicators Exterior The surface of the tank box is flat Bulk density kg / m 3 1.67*10 3 Thermal Conductivity W / (m·k) ≤0.5 Dry flexural strength MPa ≥31 Water absorption saturated flexural strength MPa ≥37 Moisture deformation rate % ≤0.13 water resistance d ≥3, no swelling, no cracking oil resistance d ≥3, no swelling, no cracking Moisture resistance h ≥120, no cracking, no pulverization Freeze-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com