Concrete material for high-performance structural engineering and preparation method and application thereof

A technology for structural engineering and concrete, which is applied in the field of concrete materials for structural engineering and its preparation, which can solve the problems of poor pouring and tamping quality, difficult construction, unmatched systems, etc., and achieve the effect of convenient construction and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

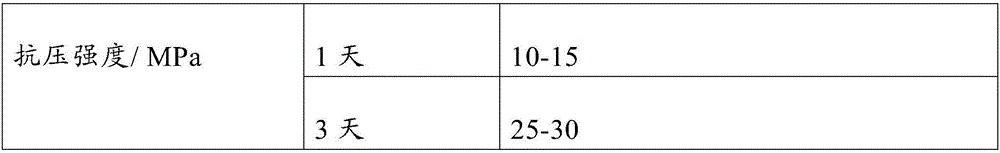

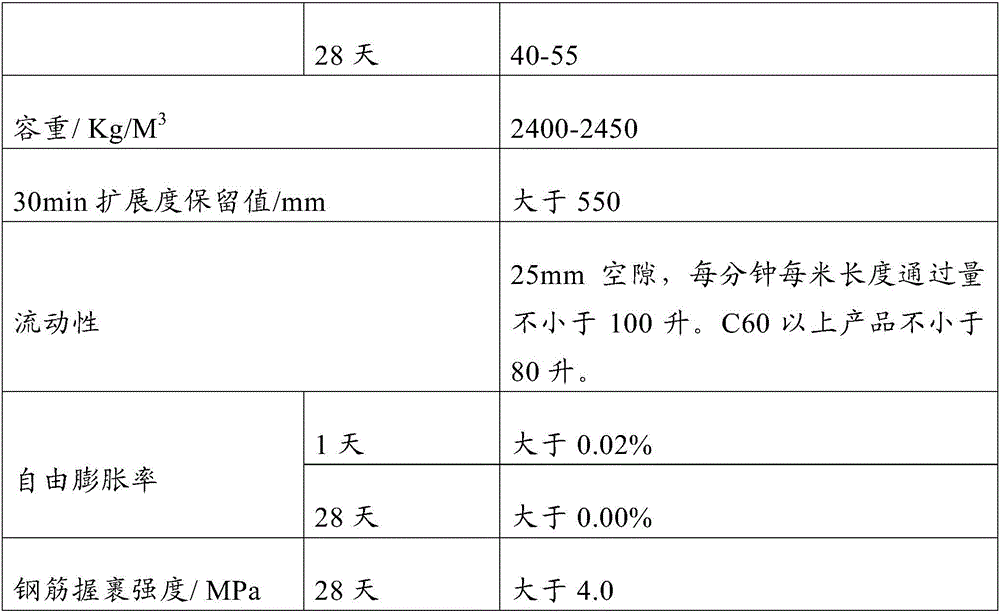

[0028] A concrete material for high-performance structural engineering reinforcement with a strength grade of C30, the specific preparation method of which is as follows:

[0029] First select raw materials according to Table 2: (Unit: Kg / M 3 )

[0030] cement

UEA

fine aggregate

Coarse aggregate

water

437

44

976

728

2.88

0.8

211

[0031] Table 2

[0032] Among them, the cement is 42.5 grade ordinary Portland cement, the UEA is the UEA of Shanghai White Cement Factory, the fine aggregate modulus is 2.5mm, the coarse aggregate particle size is 5-16mm, and the sodium naphthalene sulfonate is Zhejiang Wulong naphthalene series high-efficiency reducer. Aqueous, the fibers are Grace 6mm polypropylene chopped fibers.

[0033] Then use mechanical stirring for more than 3 minutes, and use waterproof and moisture-proof packaging. When in use, add water and mechanically stir for more than ...

Embodiment 2

[0035] A concrete material for high-performance structural engineering reinforcement with a strength grade of C60, the specific preparation method of which is as follows:

[0036] First select raw materials according to Table 3: (Unit: Kg / M 3 )

[0037] cement

UEA

fine aggregate

Coarse aggregate

polycarboxylate

water

latex powder

610

61

778

763

2.018

0.6

206

1.4

[0038] table 3

[0039] Among them, the cement is 42.5 grade ordinary Portland cement, the UEA is the UEA of Shanghai White Cement Factory, the fine aggregate modulus is 2.5mm, the coarse aggregate particle size is 5-16mm, and the polycarboxylate is Suzhou Fuke Polycarboxylate High Efficiency Water reducing agent, fiber is Grace 6mm polypropylene chopped fiber.

[0040] Then use mechanical stirring for more than 3 minutes, and use waterproof and moisture-proof packaging. When in use, add water and mechanically stir for more than 5 minutes....

Embodiment 3

[0042] A concrete material for high-performance structural engineering reinforcement with a strength grade of C80, the specific preparation method of which is as follows:

[0043] First select raw materials according to Table 4: (Unit: Kg / M 3 )

[0044] cement

fine aggregate

Coarse aggregate

polycarboxylate

fiber

water

latex powder

624

61

685

913

3.283

0.6

167

2.8

[0045] Table 4

[0046] Among them, the cement is 52.5 grade ordinary Portland cement, the silica fume is Erken silica fume from Sweden, the fine aggregate modulus is 2.8mm, the coarse aggregate particle size is 5-10mm, and the polycarboxylate is Suzhou Fuke polycarboxylate. Acid high-efficiency water reducer, the fiber is Grace 3mm polypropylene chopped fiber.

[0047] Then use mechanical stirring for more than 3 minutes, and use waterproof and moisture-proof packaging. When in use, add water and mechanically stir for more than 5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com