Construction method of cast-in-situ stiff piles for foundation pit supporting

A foundation pit support and construction method technology, which is applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of inconsistent force characteristics of support piles, difficulty in meeting construction requirements, low steel utilization rate, etc., and achieve construction Simple and fast, self-compacting, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

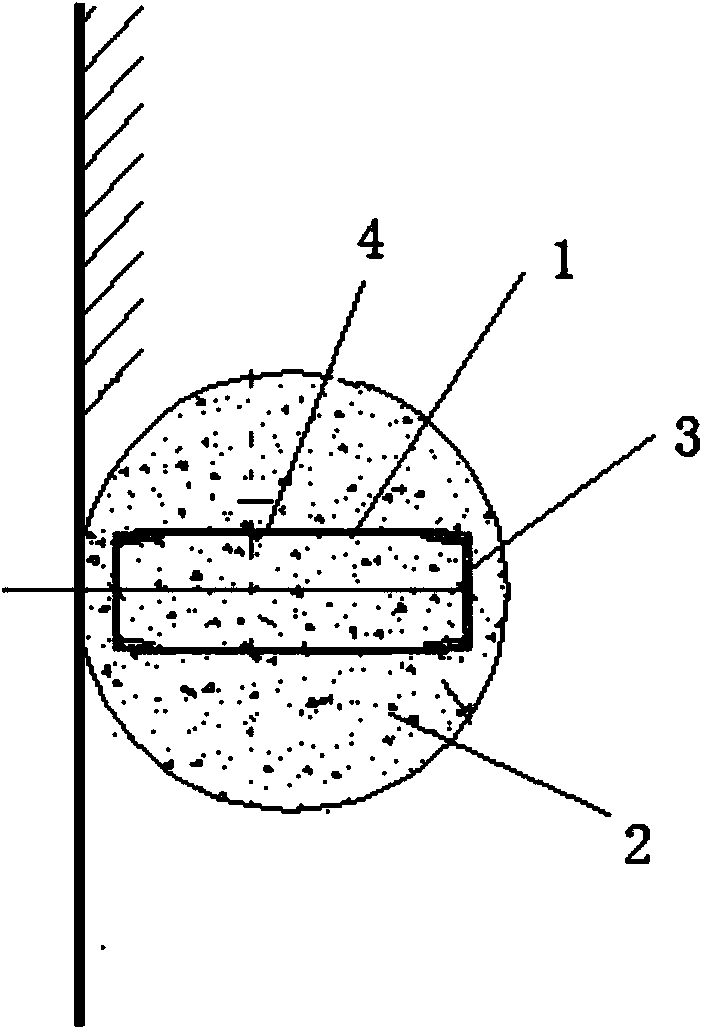

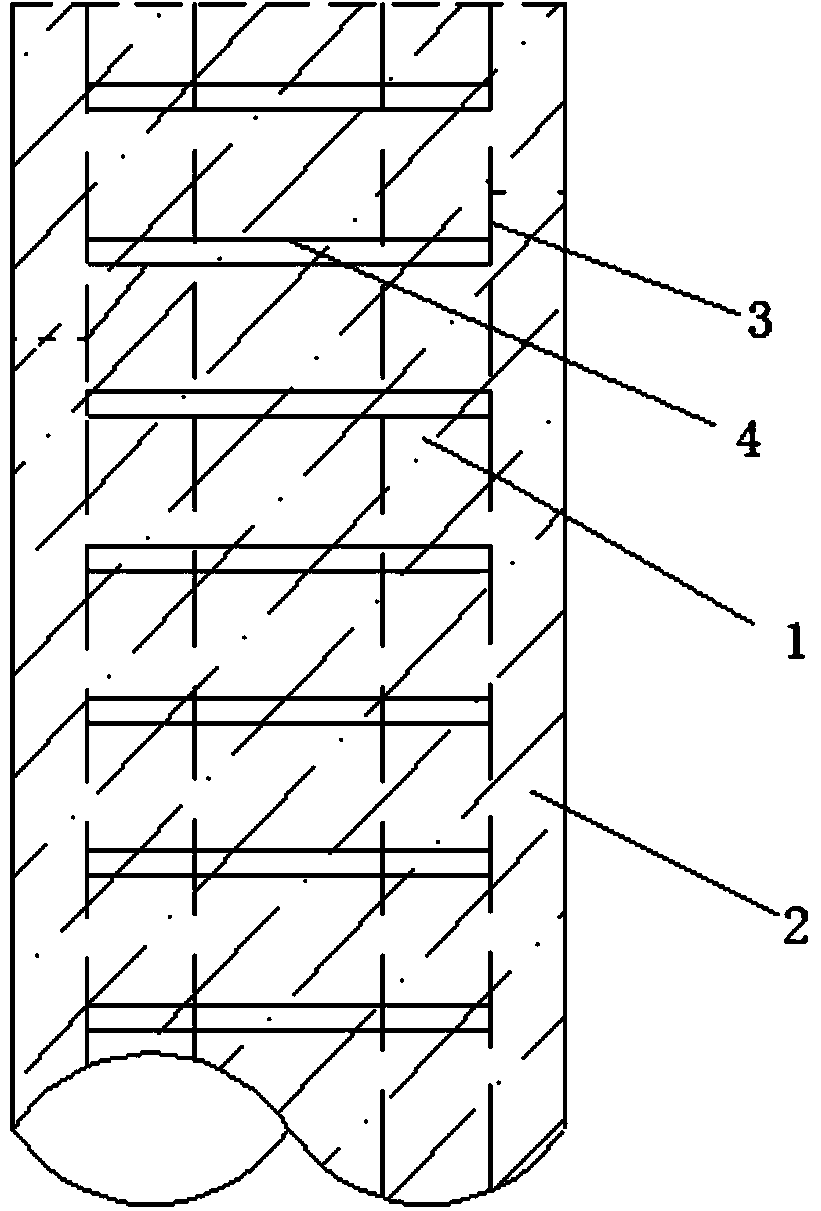

[0016] Referring to the accompanying drawings, the construction method of cast-in-place stiff piles for foundation pit support includes the following construction steps:

[0017] a. After setting out the line and laying the construction platform, use the auger drilling machine to drill the pile hole. The diameter of the pile hole is 350mm. Verticality deviation is not more than 0.5%;

[0018] b. Making and hoisting steel brackets

[0019] Making the shaped steel bracket is to adopt a plurality of connecting rods 4 to weld two parallel channel steels 3 to fix the formed steel bracket 1, hang the finished shaped steel bracket 1 to the center of the drilling hole, and then fill the crushed stones 2 into the Inside the drilled hole and cover the shaped steel support 1, the particle size of the crushed stone is 10-25mm;

[0020] c. Grouting

[0021] Secondary grouting is adopted, the first grouting is normal pressure grouting, and the grout is injected until it overflows the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com