Production equipment for A-grade fireproof insulation board

A technology for fire-proof insulation boards and production equipment, which is applied in the direction of supply devices, ceramic molding machines, mold separation devices, etc., can solve the problems of increasing the preparation process, increase production and economic benefits, improve production efficiency, and save production site occupancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

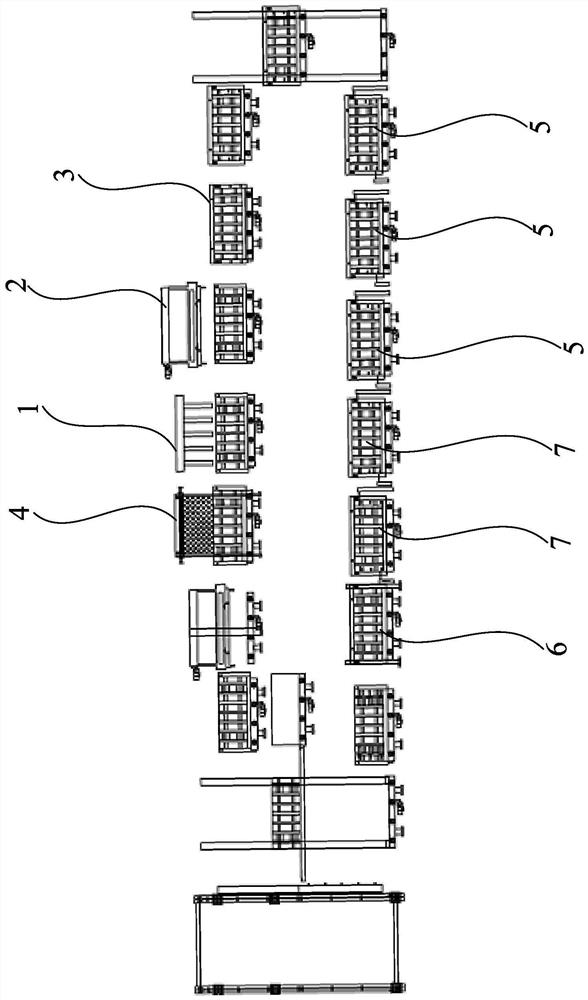

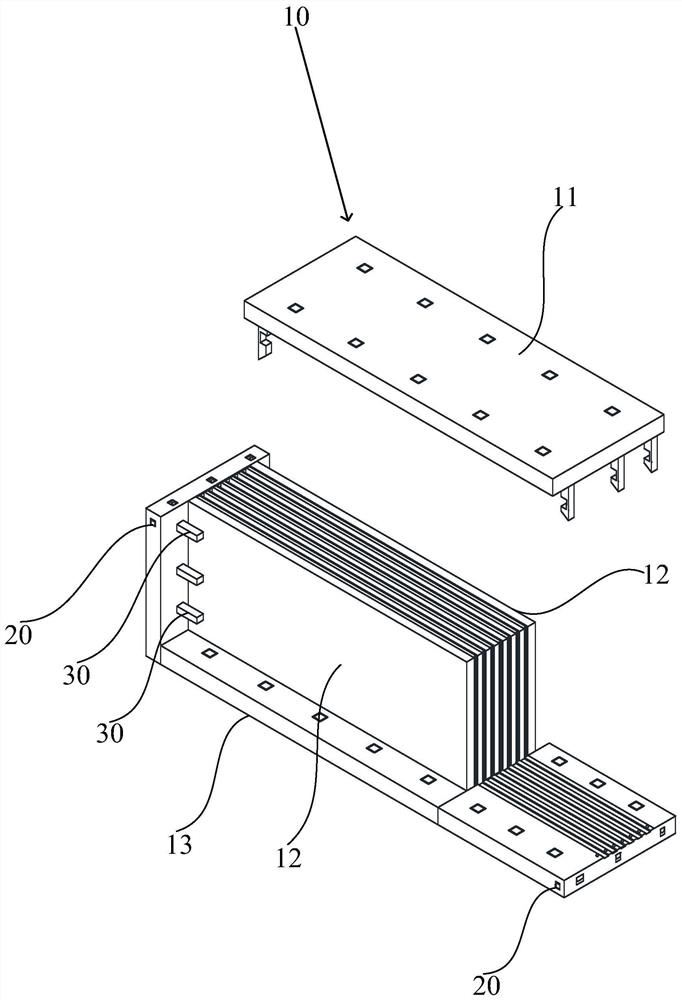

[0038] Such as figure 1 As shown, this embodiment discloses a production equipment for Class A fireproof insulation board, which is used for production equipment for Class A fireproof insulation board through such as figure 2 The mold 10 shown is also used for processing and making products. This mold 10 comprises loam cake 11, lower mold 13 and two side molds 12, loam cake 11 is connected to the top of lower mold 13, and two side molds 12 are respectively arranged on the both sides of lower mold 13, and two side molds 12 They can move along the direction of moving closer to each other, so as to reduce the thickness of the space in the mold 10 .

[0039] The production equipment used in this embodiment for Class A fireproof insulation boards includes a material injection unit 1, a hoisting upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com