Method for backfilling light foam concrete in urban abandoned underground space in soft soil area

A lightweight foam and concrete technology, applied in filling, soil protection, application, etc., can solve the problems of inaccessibility of large construction machinery, narrow opening of backfill space, and reduction of backfill body, so as to achieve light weight and save backfill The effect of moderate cost and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

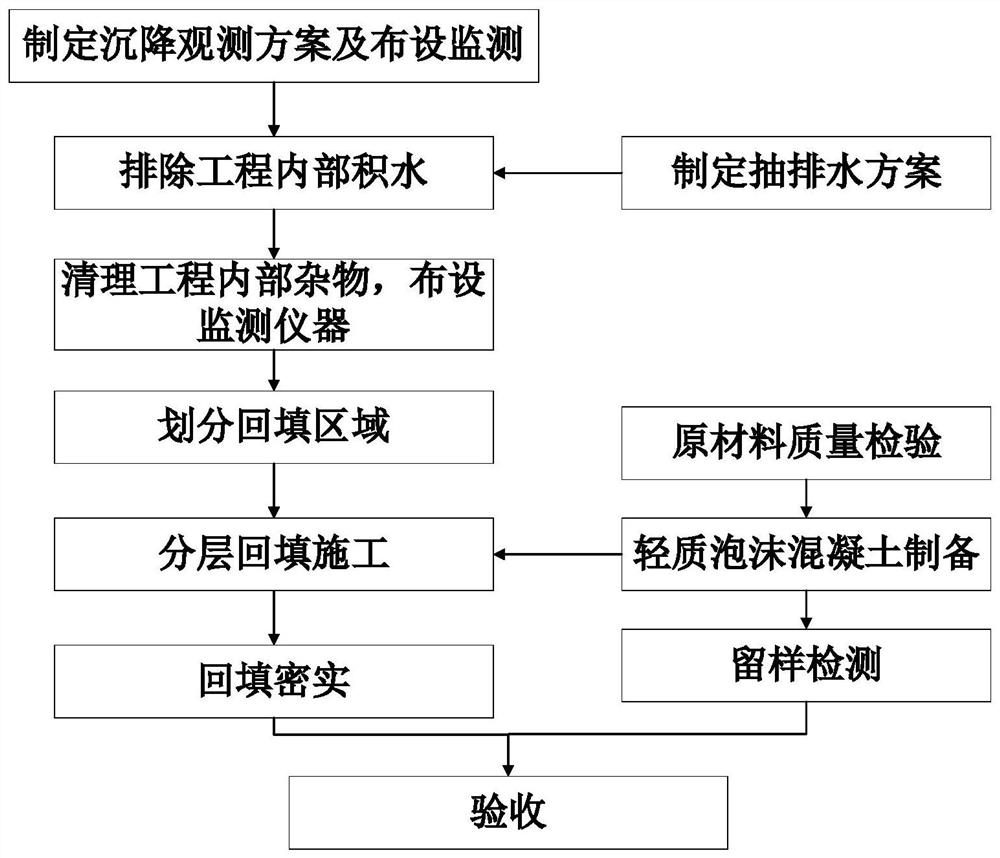

[0059] According to the internal structure and surrounding environment of the urban underground space in the soft soil area to be backfilled as follows Figure 4 As shown, the internal structure is mainly an arched underground space, and there is a lot of water inside. The southeast of the underground space is adjacent to roads and school teaching buildings, and the northwest is mainly a sports field. Therefore, a total of 25 deformation observation stations are arranged near the teaching buildings Point, set an observation reference point on the opposite side of the road.

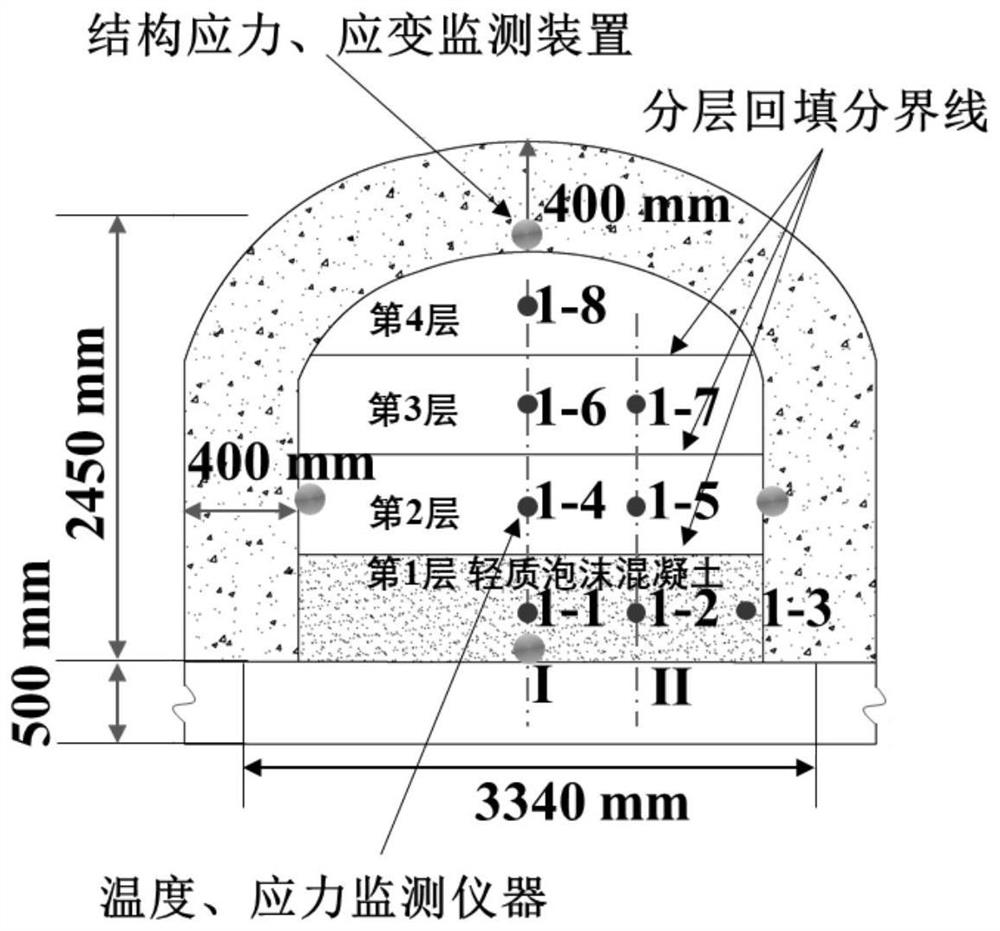

[0060] Set up two pumps at the entrance of the abandoned space to slowly pump the accumulated water inside the project, and record the deformation data of 25 observation points. Clean up internal debris. Lay out structural stress, strain monitoring devices and temperature stress monitoring instruments, such as figure 2 As shown, divide the backfill area.

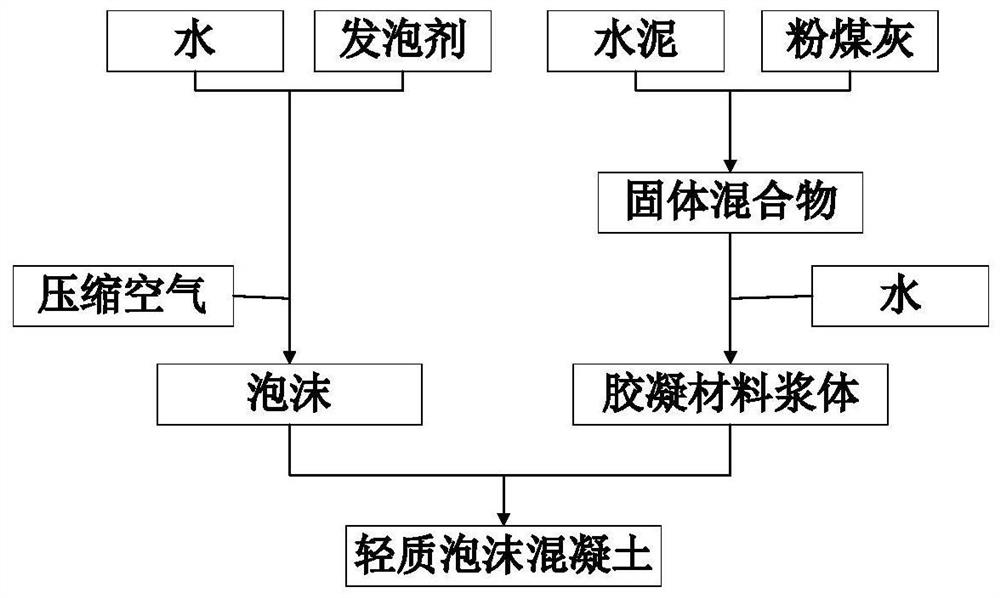

[0061] The density of lightweight foam concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com