Preparation method of special pre-curing adhesive for SMC (Sheet Molding Compound)

A preparation method and adhesive technology, which are used in non-polymeric organic compound adhesives and adhesives, etc., can solve the problems of low overall reinforcement strength of the repair layer, large deviation of adhesive fluidity, and poor oil and gas pipeline effect. Efficient SMC repair, improve the overall reinforcement strength, reduce the effect of repair failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

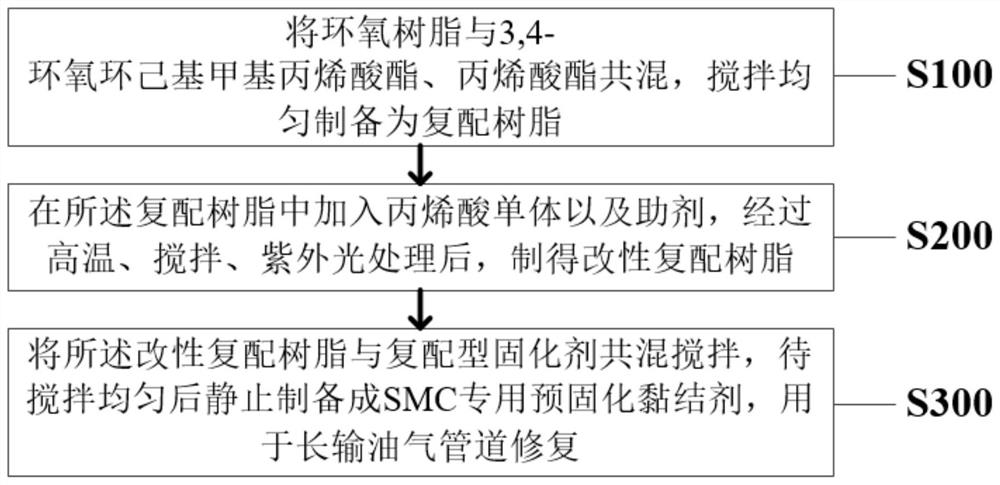

[0028] Such as figure 1As shown, the present invention discloses a method for preparing a special pre-cured adhesive for SMC. The method for preparing a special pre-cured adhesive for SMC is used to prepare a special pre-cured adhesive for bonding SMC to defective parts of oil and gas pipelines, wherein the The pre-cured adhesive preparation method comprises:

[0029] Step S100: blending epoxy resin with 3,4-epoxycyclohexyl methacrylate and acrylate, and stirring evenly to prepare a composite resin;

[0030] Specifically, when repairing defective parts of oil and gas pipelines, existing adhesives on the market are often used to paste the composite material sheet structure SMC on the corresponding defective parts. Among them, commonly used adhesives include thermosetting adhesives, thermoplastic adhesives and multi-component adhesives. Adhesives etc. Among them, thermosetting adhesives include epoxy resins, polyurethanes, silicones, polyimides, etc.; thermoplastic adhesives i...

Embodiment 2

[0054] In order to more clearly explain the technical scheme of a preparation method of a special pre-cured adhesive for SMC, the embodiment of the present application provides a detailed preparation process of a special pre-cured adhesive for SMC using the preparation method of a special pre-cured adhesive for SMC, specifically as follows:

[0055] Specifically, in order to solve the repair of oil and gas pipelines using adhesives in other fields such as automobiles and home decoration in the prior art, due to the problems of large fluidity deviation and poor weather resistance of the adhesives, the repair effect of oil and gas pipelines is poor, and the repair The technical problem of low overall reinforcement strength of the layer.

[0056] First, the epoxy resin, 3,4-epoxycyclohexyl methacrylate and acrylate are blended and stirred at a mass ratio of 100:40-55:35-55, the stirring rate is not greater than 200rad / min, and the mixture is completely stirred After being unifor...

Embodiment 3

[0061] In order to more clearly explain the technical scheme of a preparation method of a special pre-cured adhesive for SMC, the application provides a special pre-cured adhesive for SMC prepared by using the preparation method of a special pre-cured adhesive for SMC to carry out oil and gas pipelines. The construction method and detailed process of defect repair are as follows:

[0062] The on-site simulation experiment of SMC special pre-cured adhesive was carried out in a certain experimental site of a pipeline company. In this simulation, the target pipeline to be repaired is an OD1016mm×17.6mm, X70 pipeline, the design pressure is 10MPa, the design strength coefficient is 0.72, and there is a 30% wall thickness depth (5.3mm depth) of unfused pipe butt girth welds. defect. In this simulation experiment, the defect of the target pipeline was repaired using the SMC special pre-cured adhesive. The specific construction process includes:

[0063] Step 1: Mix 150g of epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com