Patents

Literature

41results about How to "Easy and quick fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

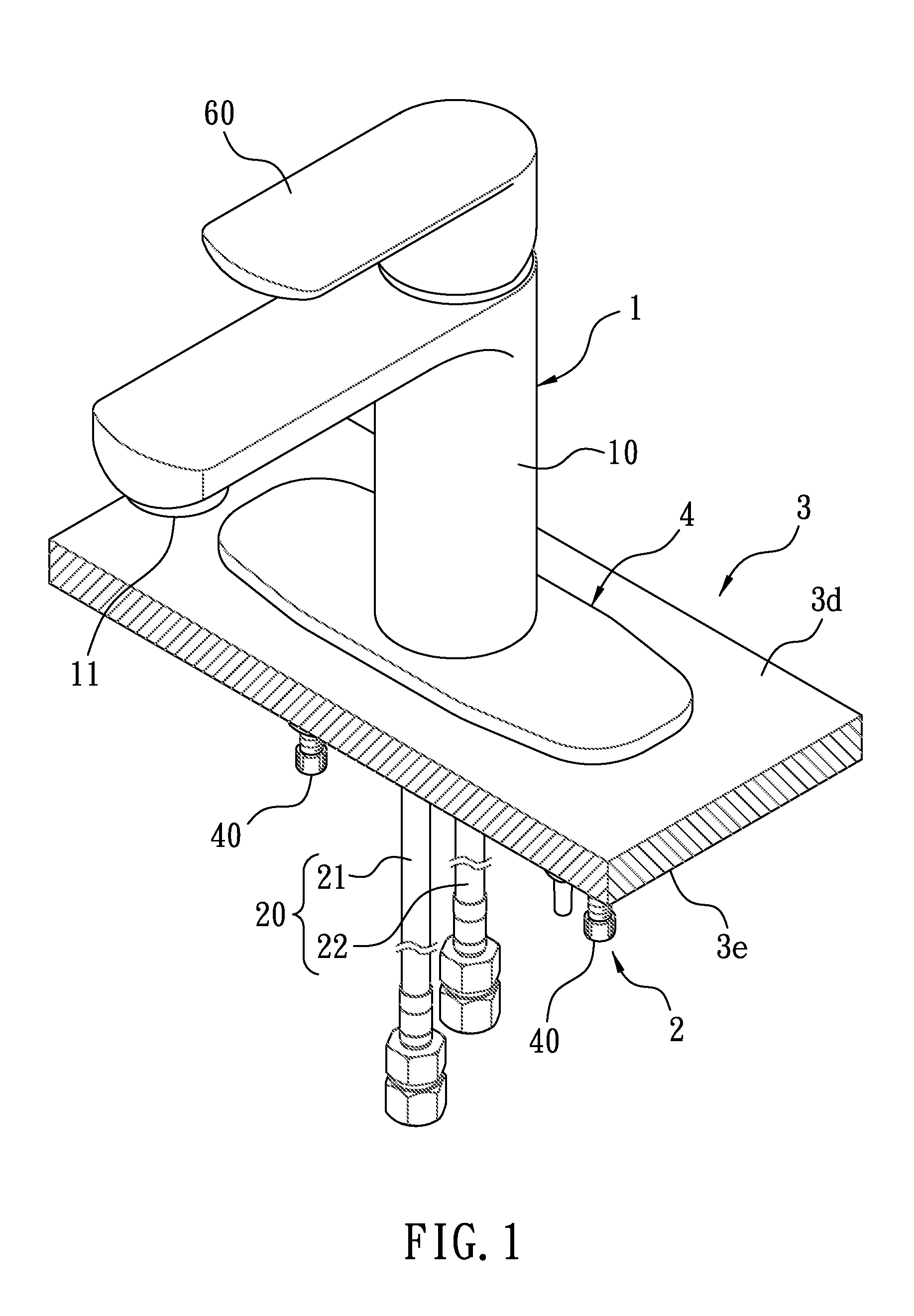

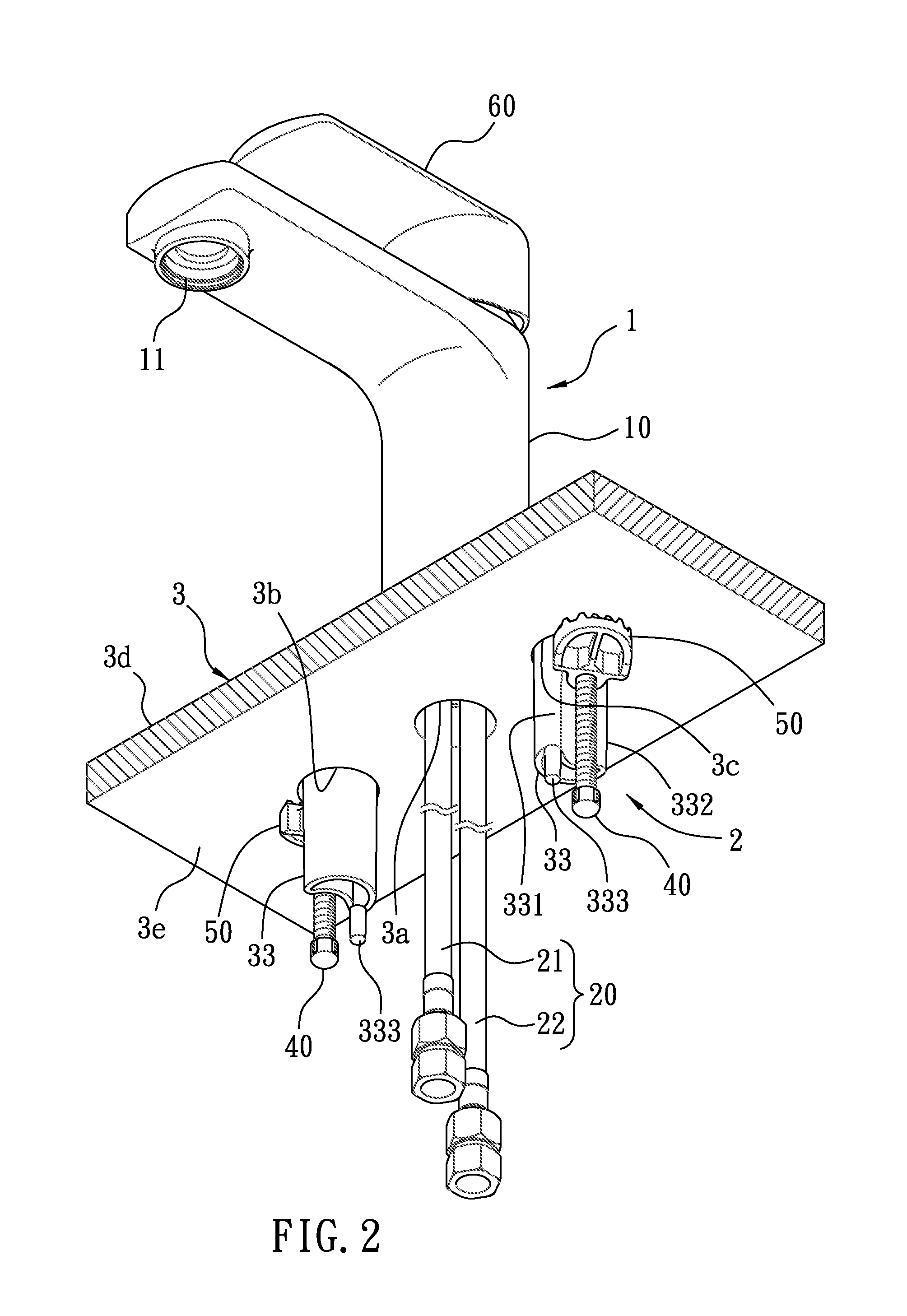

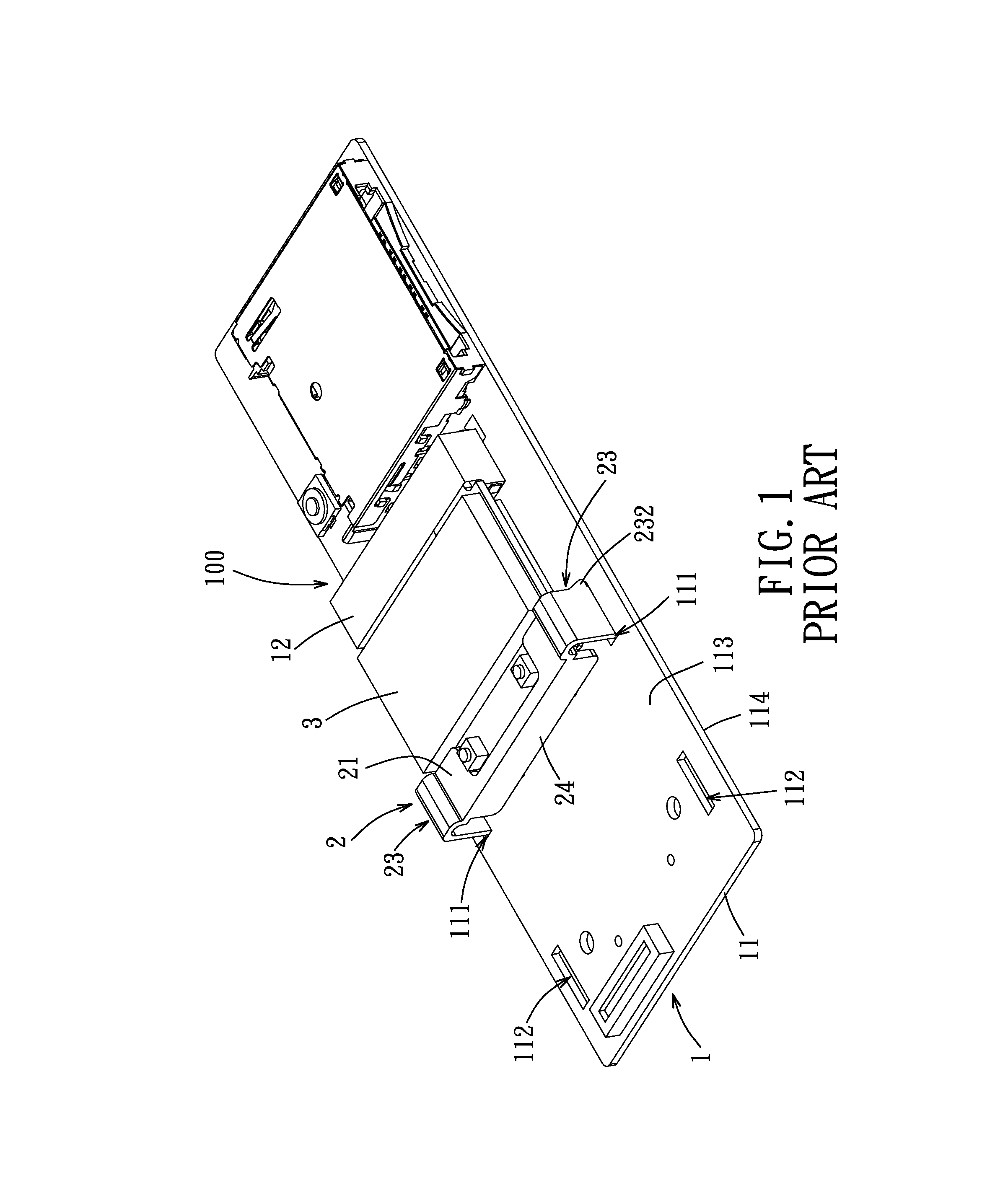

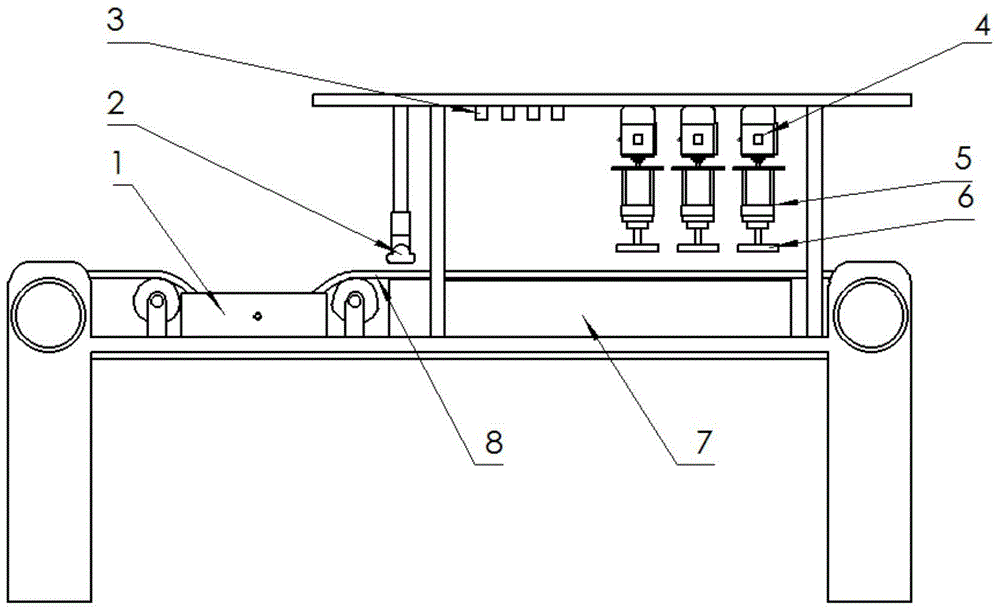

Fixing structure of faucet

Owner:GLOBE UNION INDAL

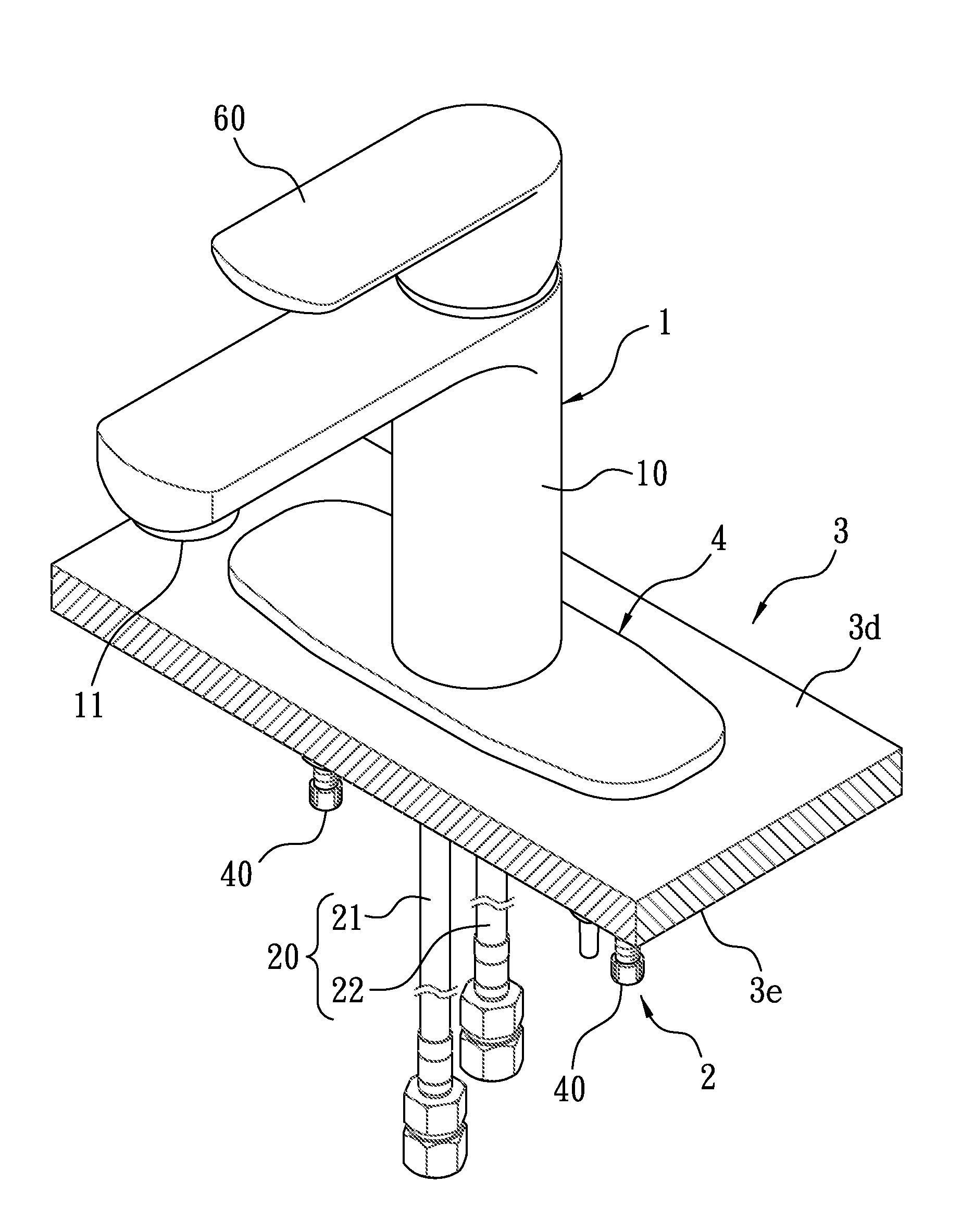

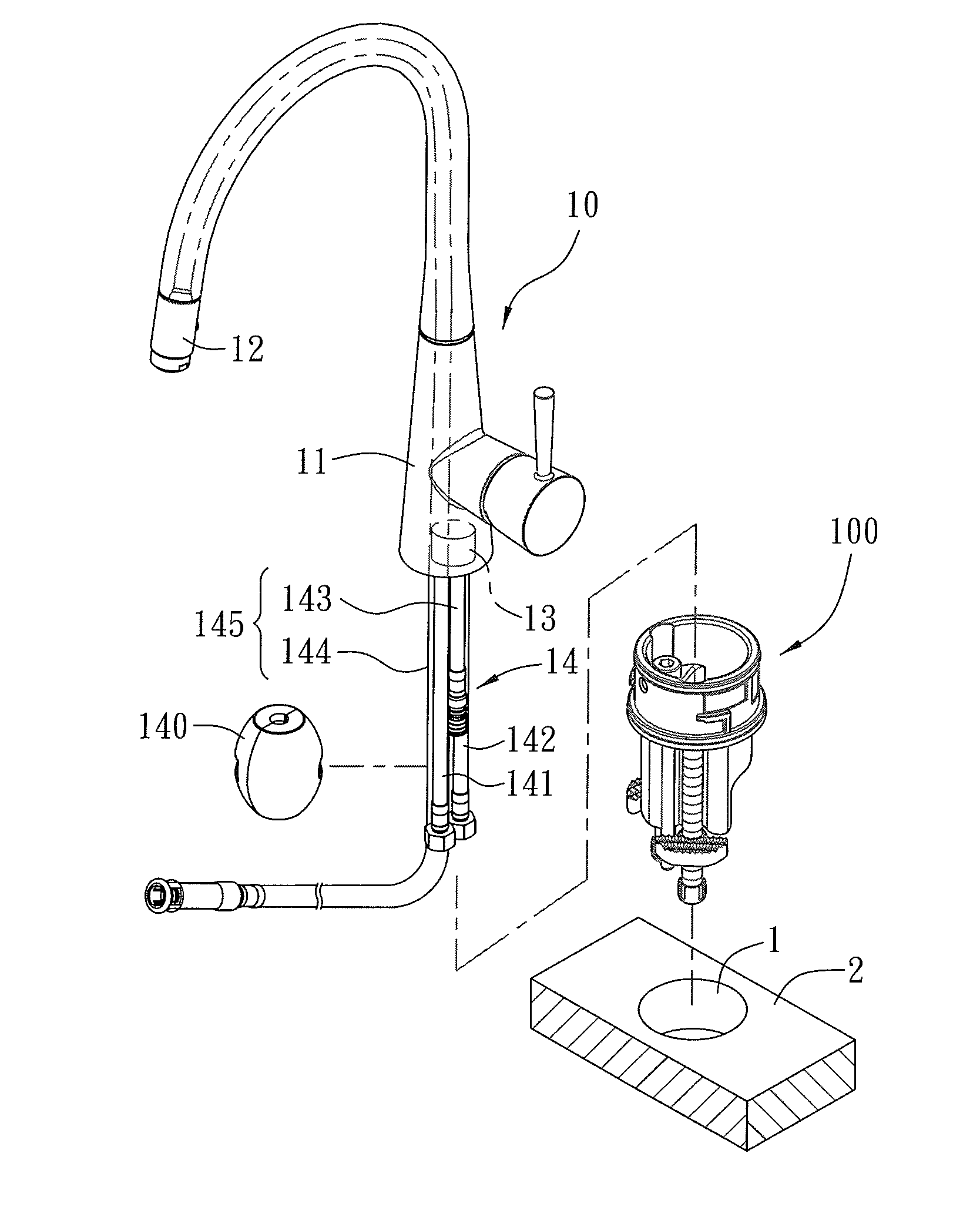

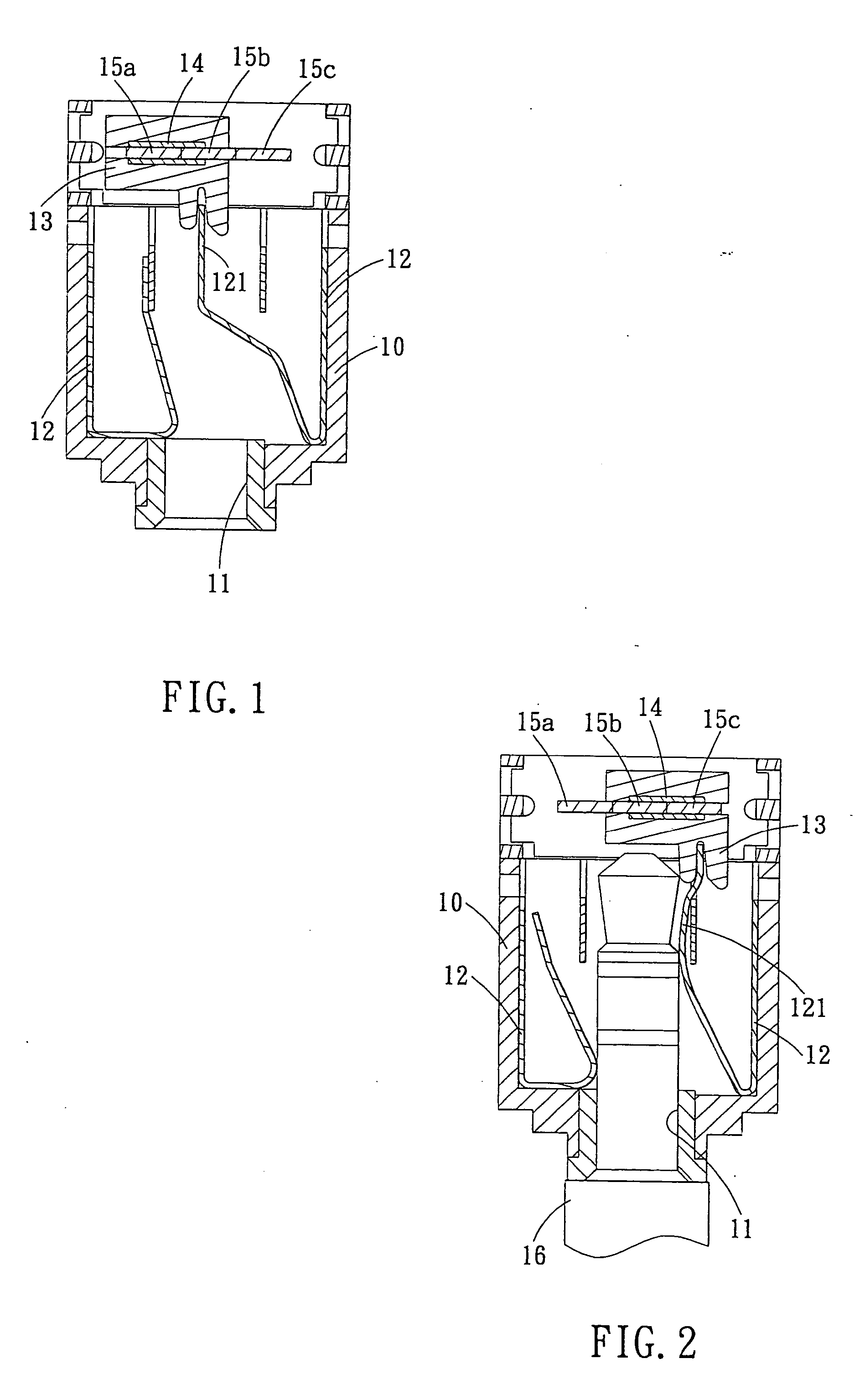

Lavatory faucet

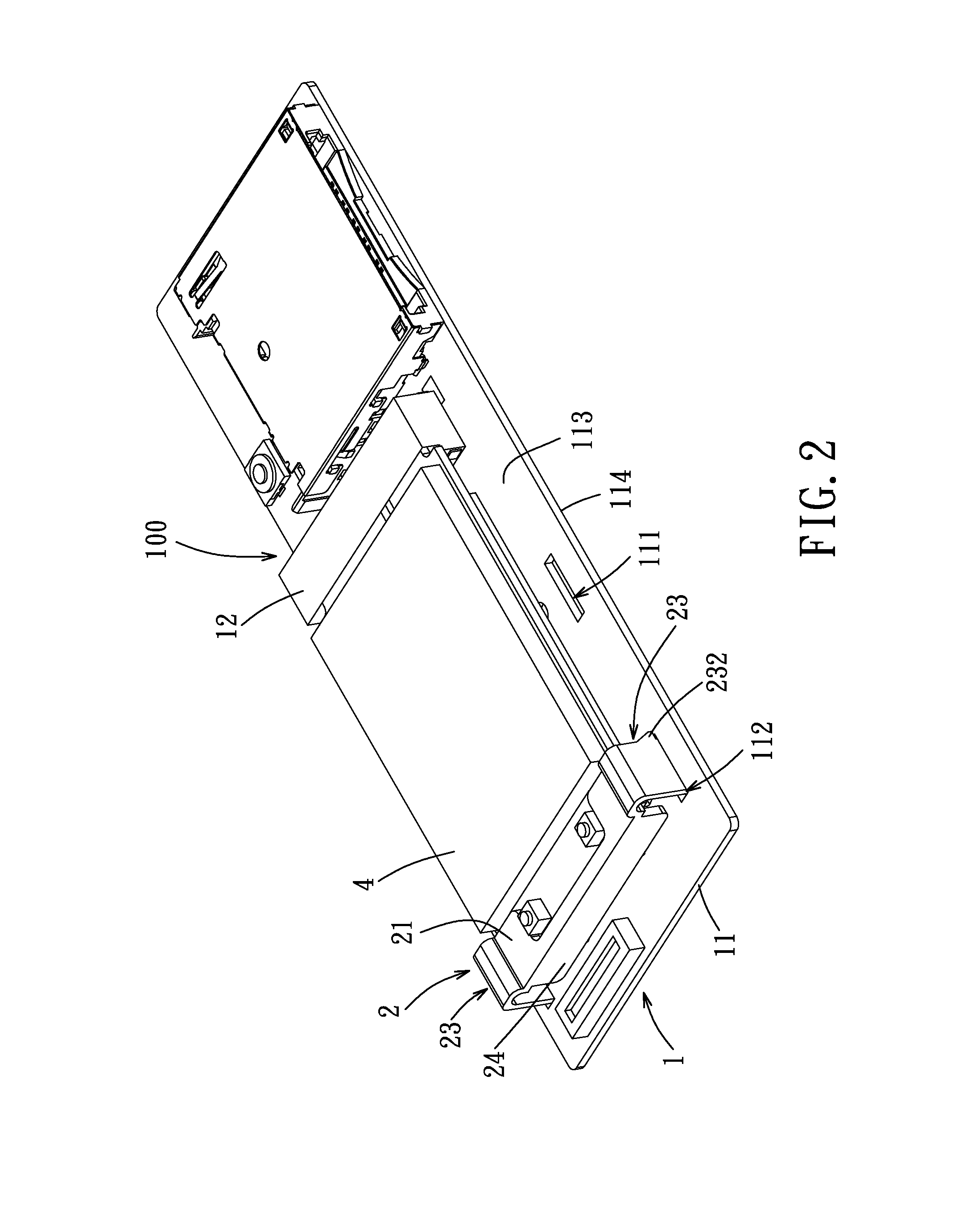

InactiveUS20160024762A1Large caliberThe process is convenient and fastWash-standsDomestic plumbingEngineeringMechanical engineering

A lavatory faucet is fixed on a basin and contains: a body and a fixing device. The body includes a housing and a supply pipe assembly; the fixing device includes a mounting seat, two screw rods, and two clamping blocks; the basin includes a central orifice, a left orifice, and a right orifice. The mounting seat includes an upper fitting sleeve, two extending wings for abutting against a top face of the basin, and two support feet. The upper fitting sleeve has a channel defined therein relative to the central orifice, each extending wing has a through hole to insert each support foot, and each support foot has a first stopping fence. Each screw rod extends out of the through hole and is rotated above the mounting seat, each clamping block is screwed with each screw rod and is limited by the first stopping fence as rotating each screw rod.

Owner:GLOBE UNION INDAL

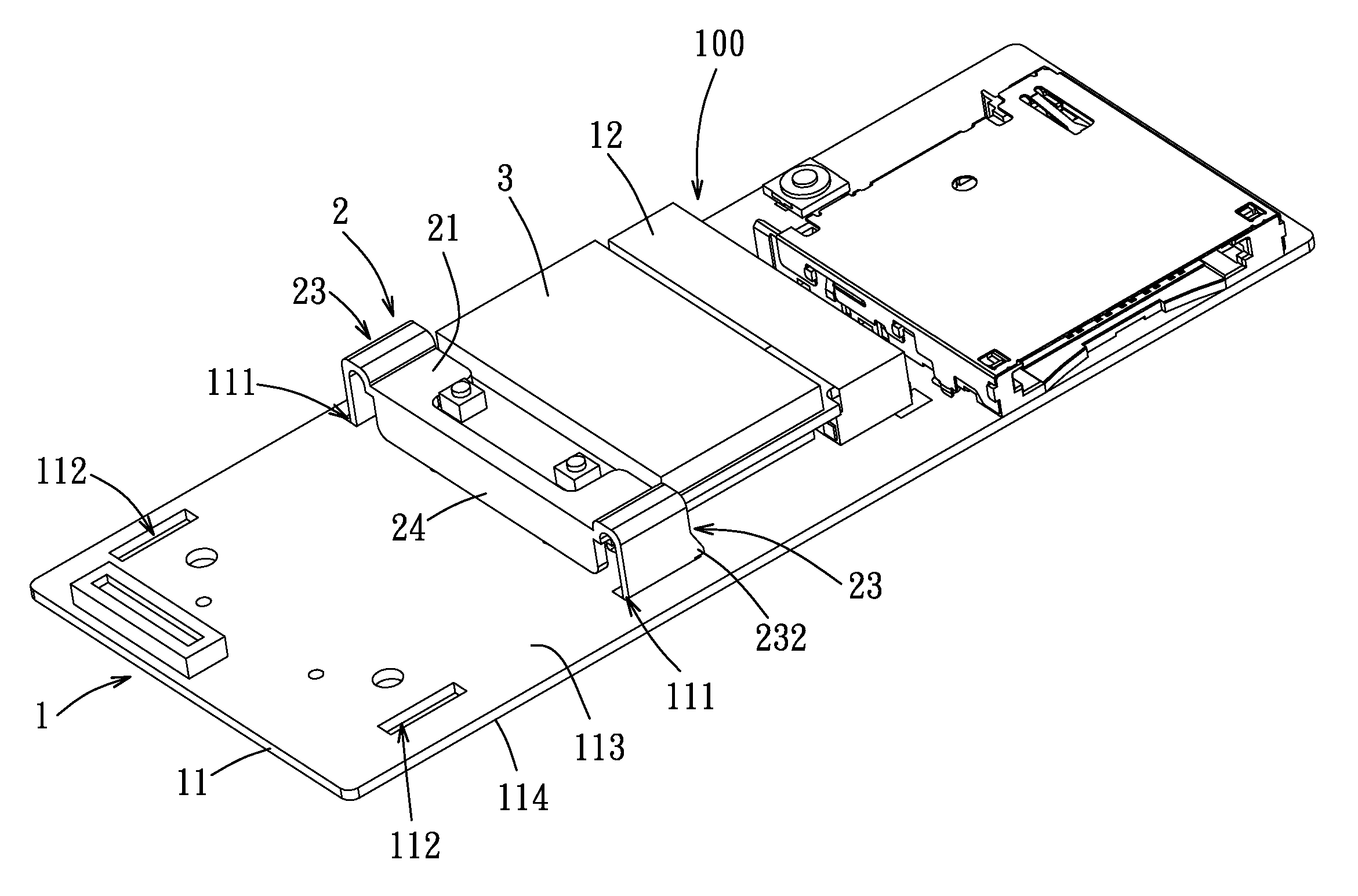

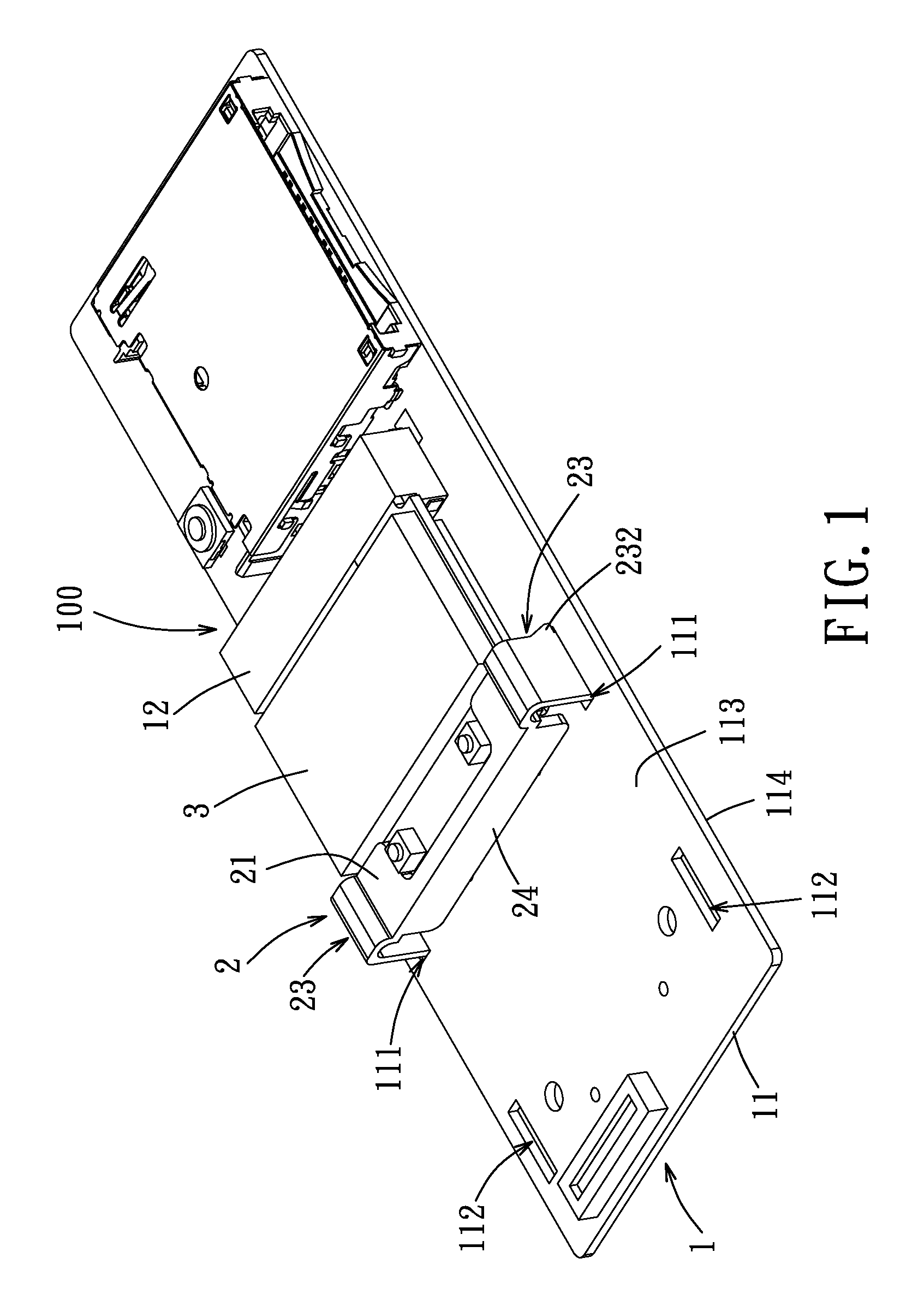

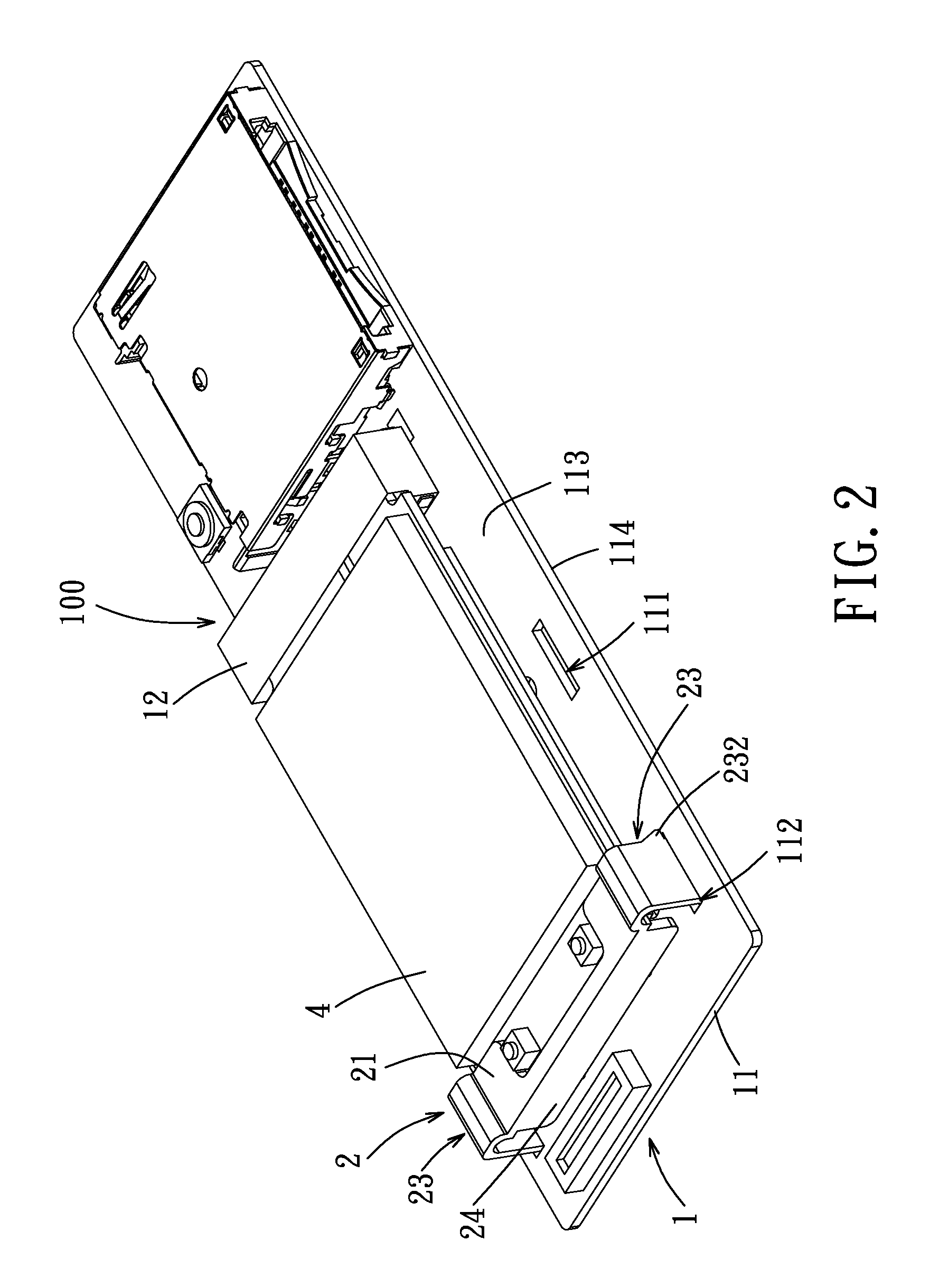

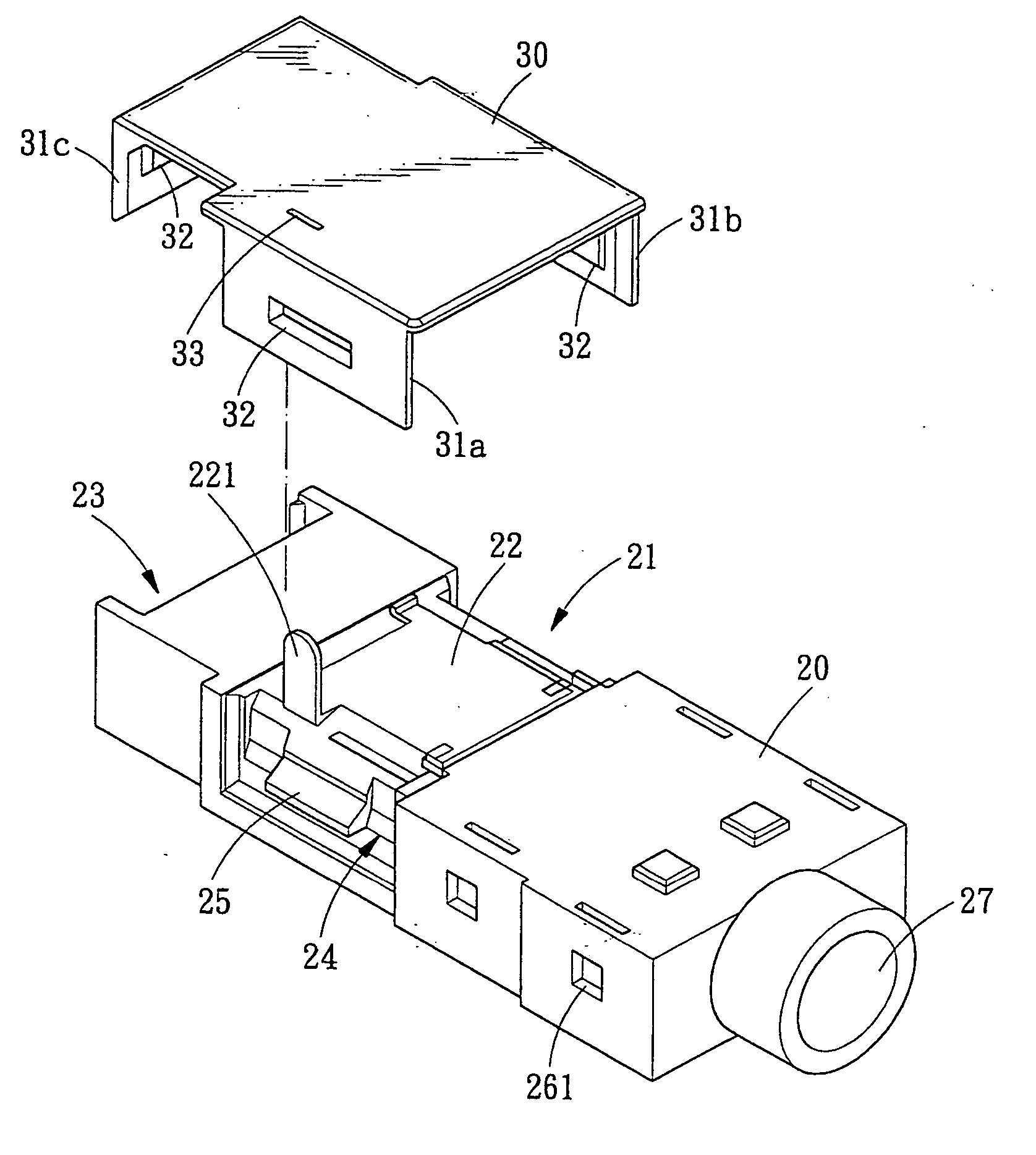

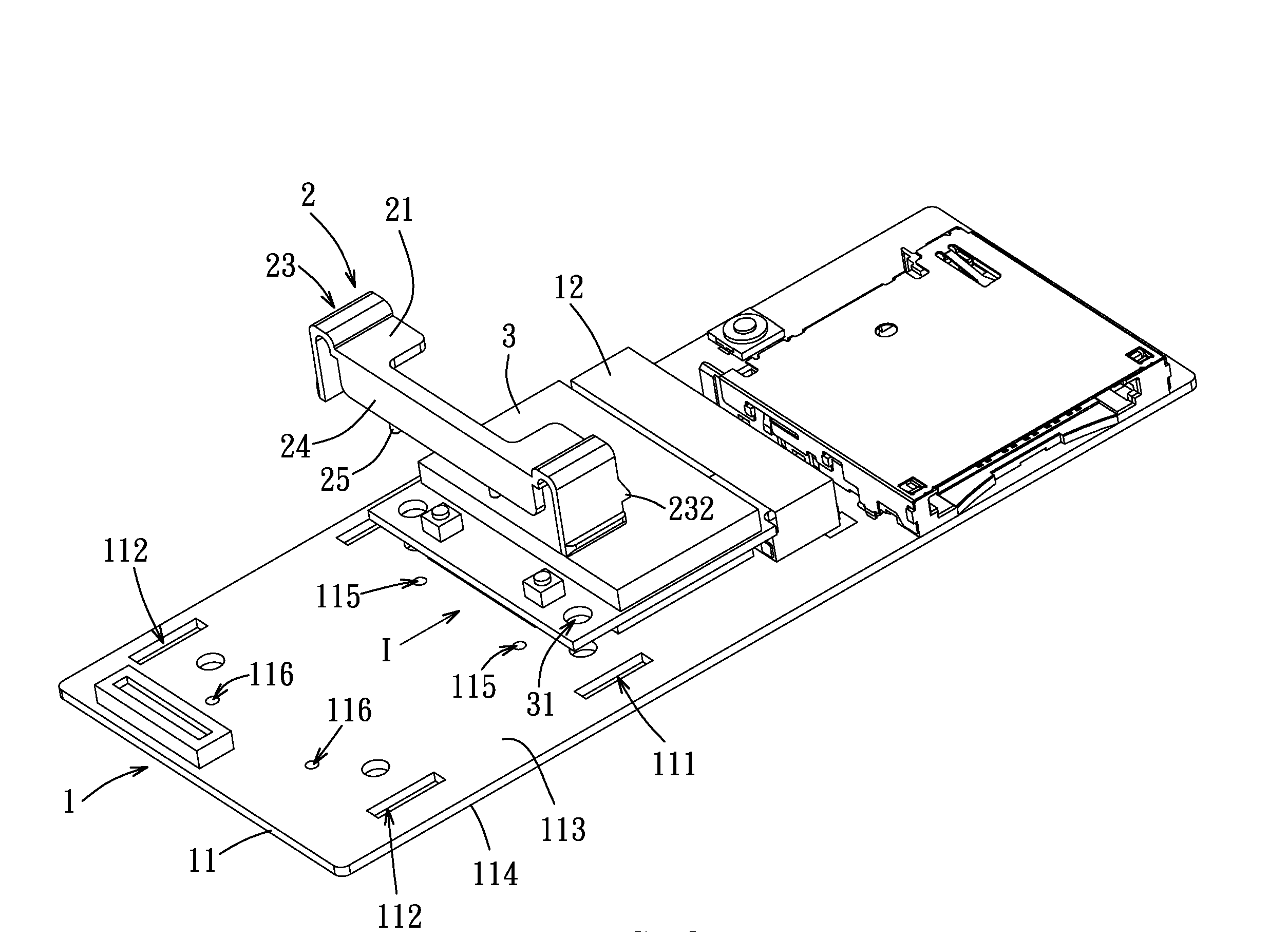

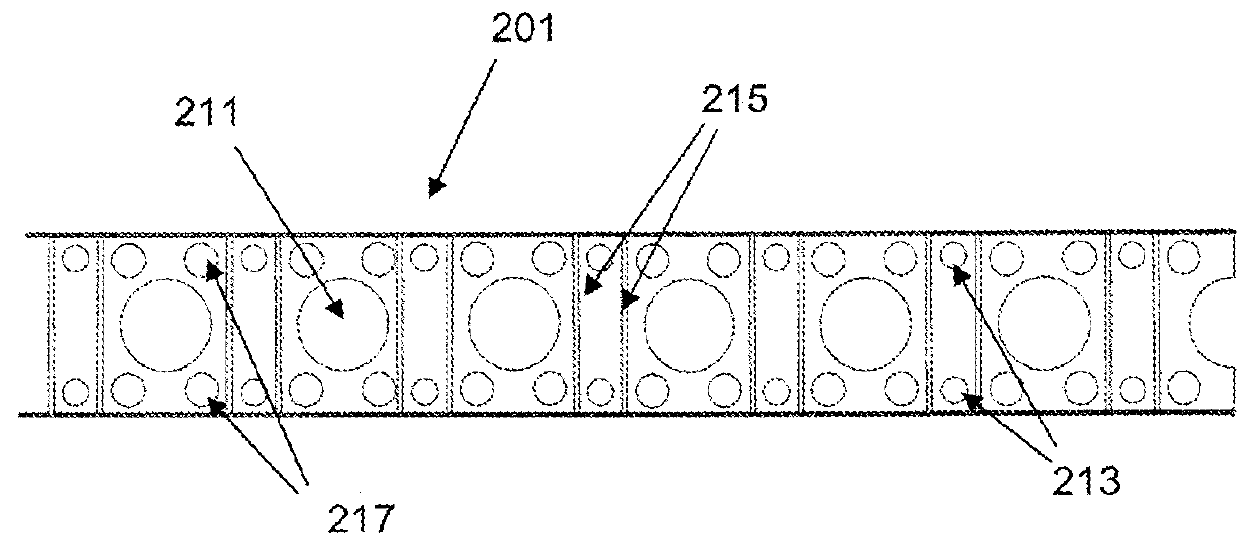

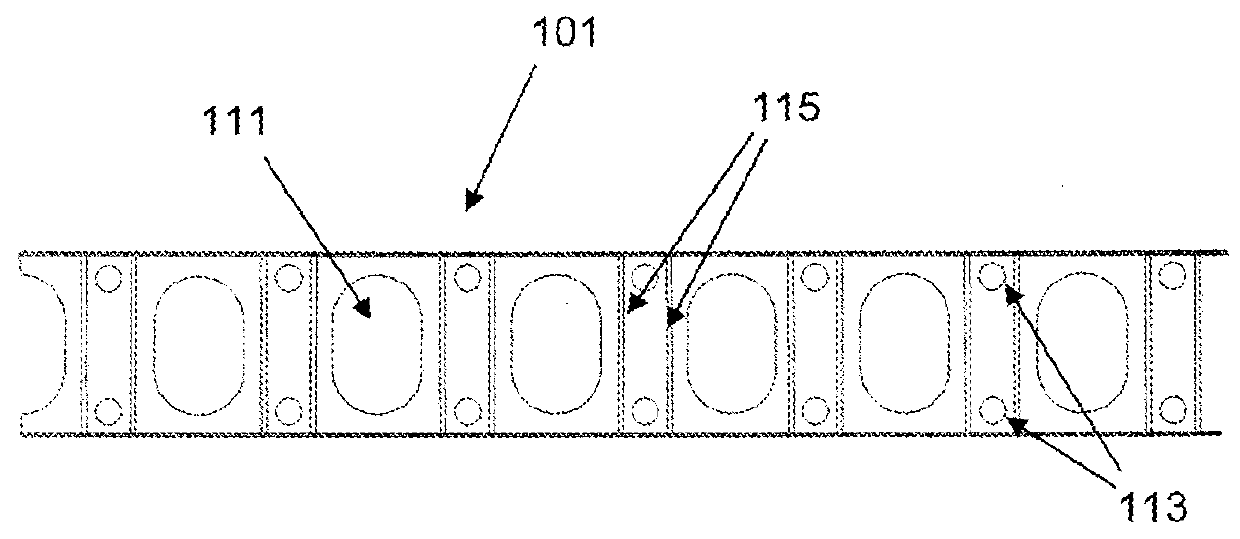

Circuit board device and a combined circuit board and electronic card assembly

ActiveUS8764457B2Easy and quick fixShorten the timeCircuit arrangements on conductive chasisPrinted circuitsElectrical and Electronics engineering

A circuit board device for fixing an electronic card, which is formed with at least one aperture, includes a circuit board and a securing member. The circuit board includes a board body formed with two through holes, and a socket connector provided on the board body for mating with the electronic card. The securing member includes a pressing plate for pressing against the electronic card, at least one engaging stud projecting from a bottom end of the pressing plate for engaging the aperture, and two resilient engaging arms provided respectively on left and right sides of the pressing plate. The engaging arms extend respectively through the through holes and engage releasably the board body.

Owner:WISTRON CORP

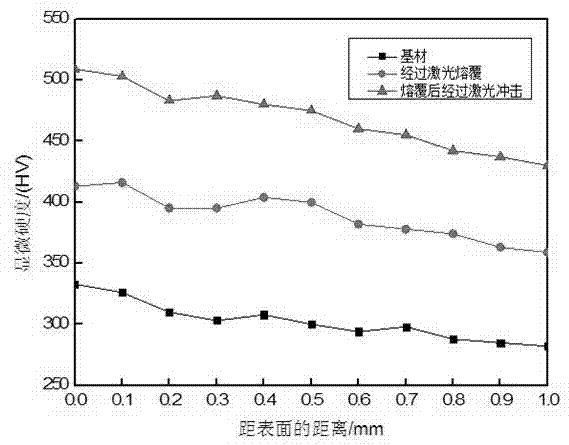

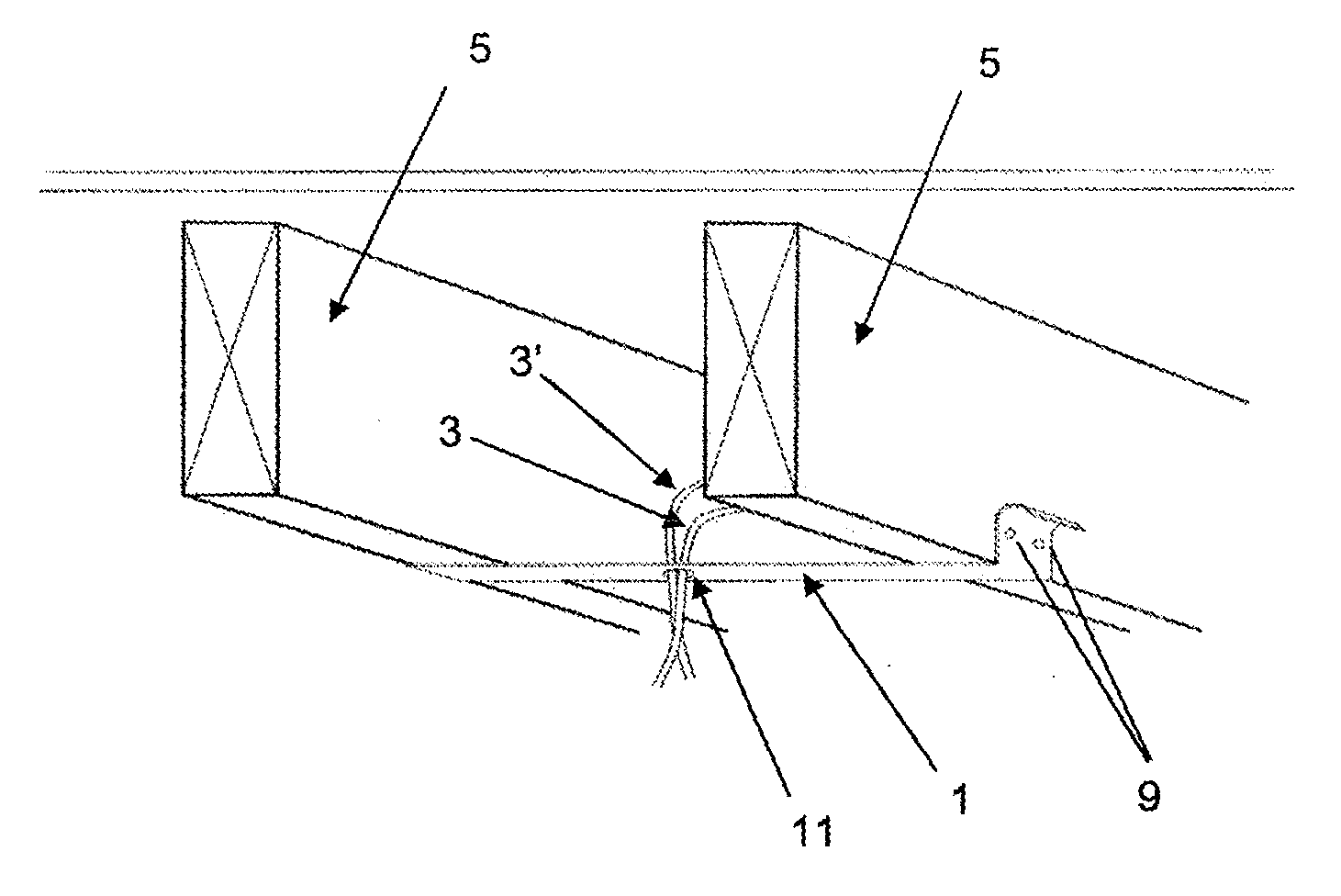

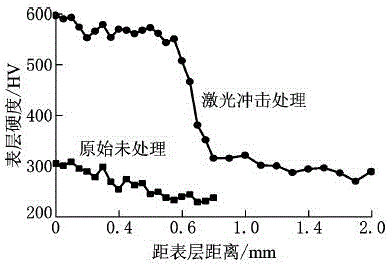

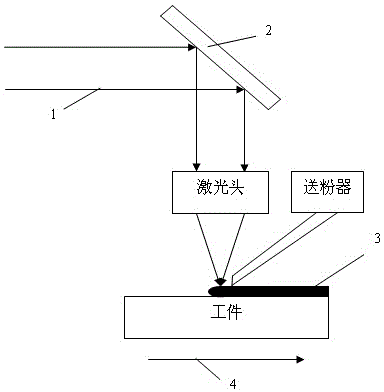

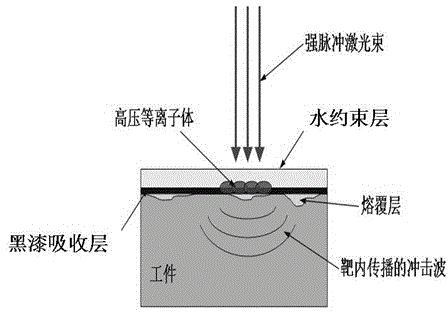

Laser repairing remanufacturing method of ultra-large cutting equipment cutter

InactiveCN103695939AImprove wear resistanceImprove fatigue strength and service lifeMetallic material coating processesRemanufacturingCorrosion

The invention discloses a laser repairing remanufacturing method of an ultra-large cutting equipment cutter, and relates to the technical field of machine manufacturing and material processing application. Firstly, the laser cladding processing is implemented for a damaged area of the cutter; the supply mode of the cladding is preset laser cladding; then, an adsorption layer is coated on the surface of the damaged area of the cutter; the laser impact processing is implemented for the damaged area of the cutter under the protection of a restraint layer. The laser repairing remanufacturing method of the ultra-large cutting equipment cutter improves the wear resistance, corrosion resistance and oxidization resistance of metal surfaces, prominently enhances the fatigue strength of materials, prolongs the service life of the materials, effectively improves the micro-motion fatigue resistance of the cutter surface, restrains the production of fatigue cracks, and reduces the propagation rate of the fatigue cracks. Therefore, the processing method largely improves the wear resistance, corrosion resistance and fatigue strength of the materials so as to prolong the service life of the ultra-large cutting equipment cutter.

Owner:JIANGSU WANLI MACHINERY +1

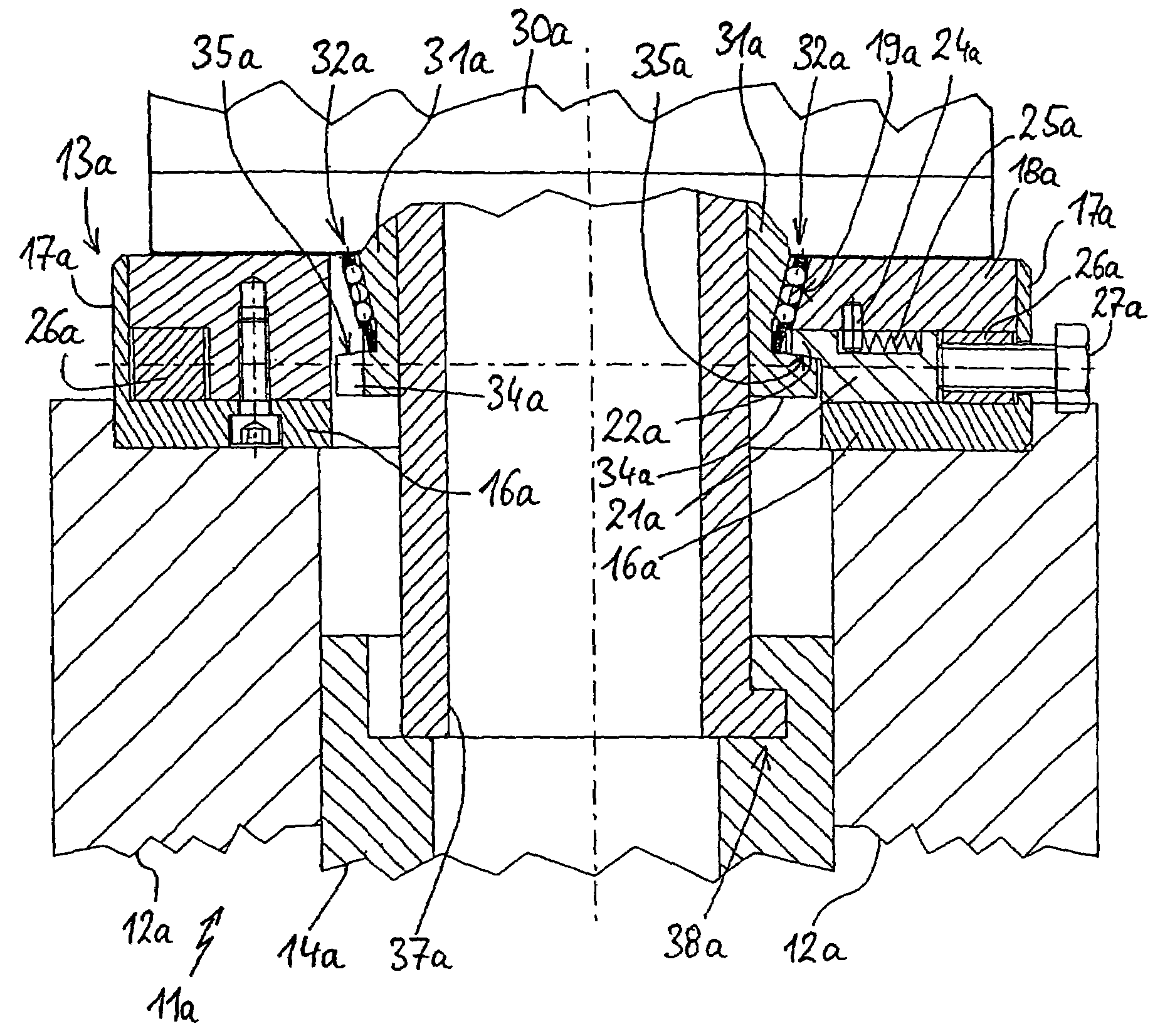

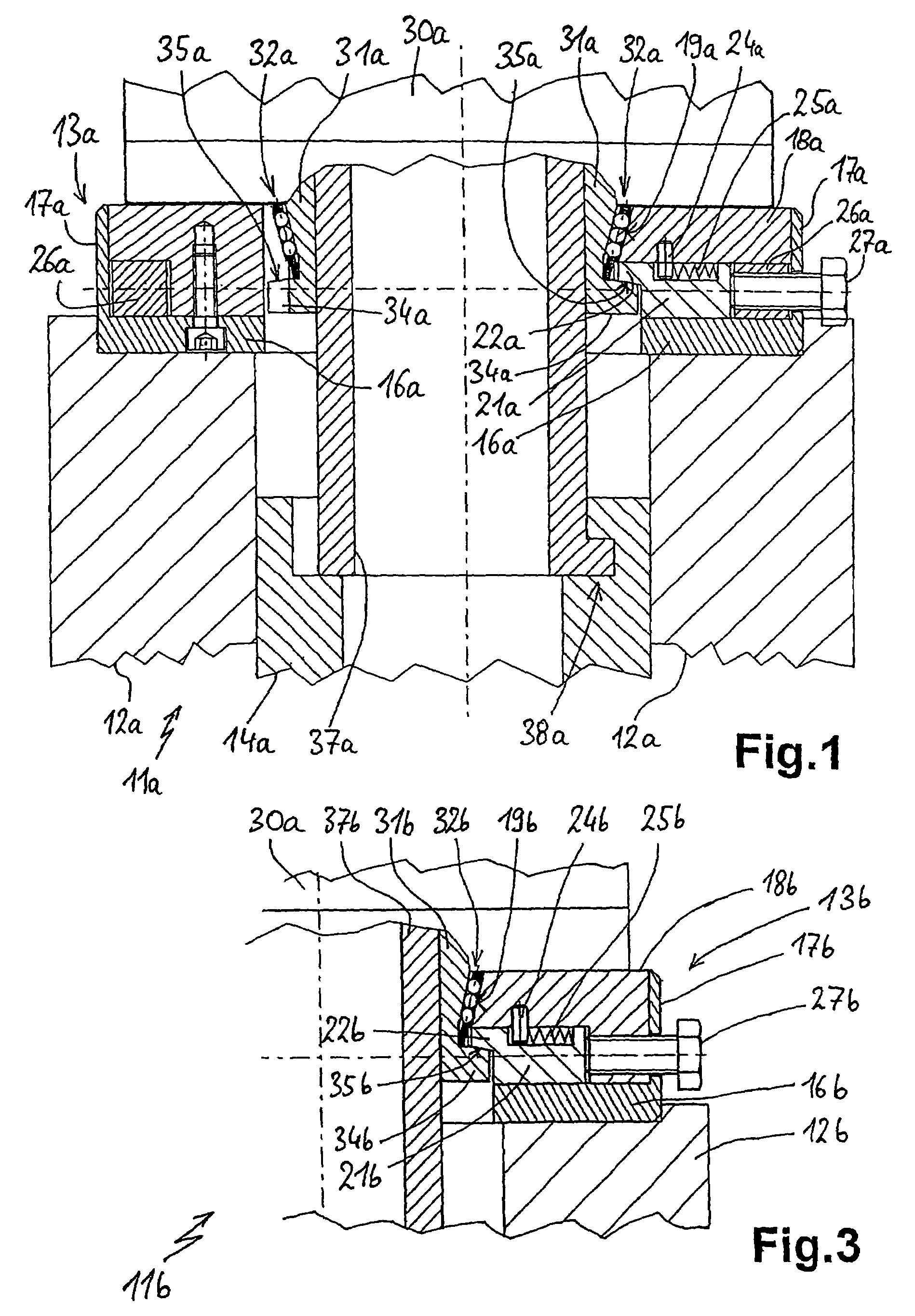

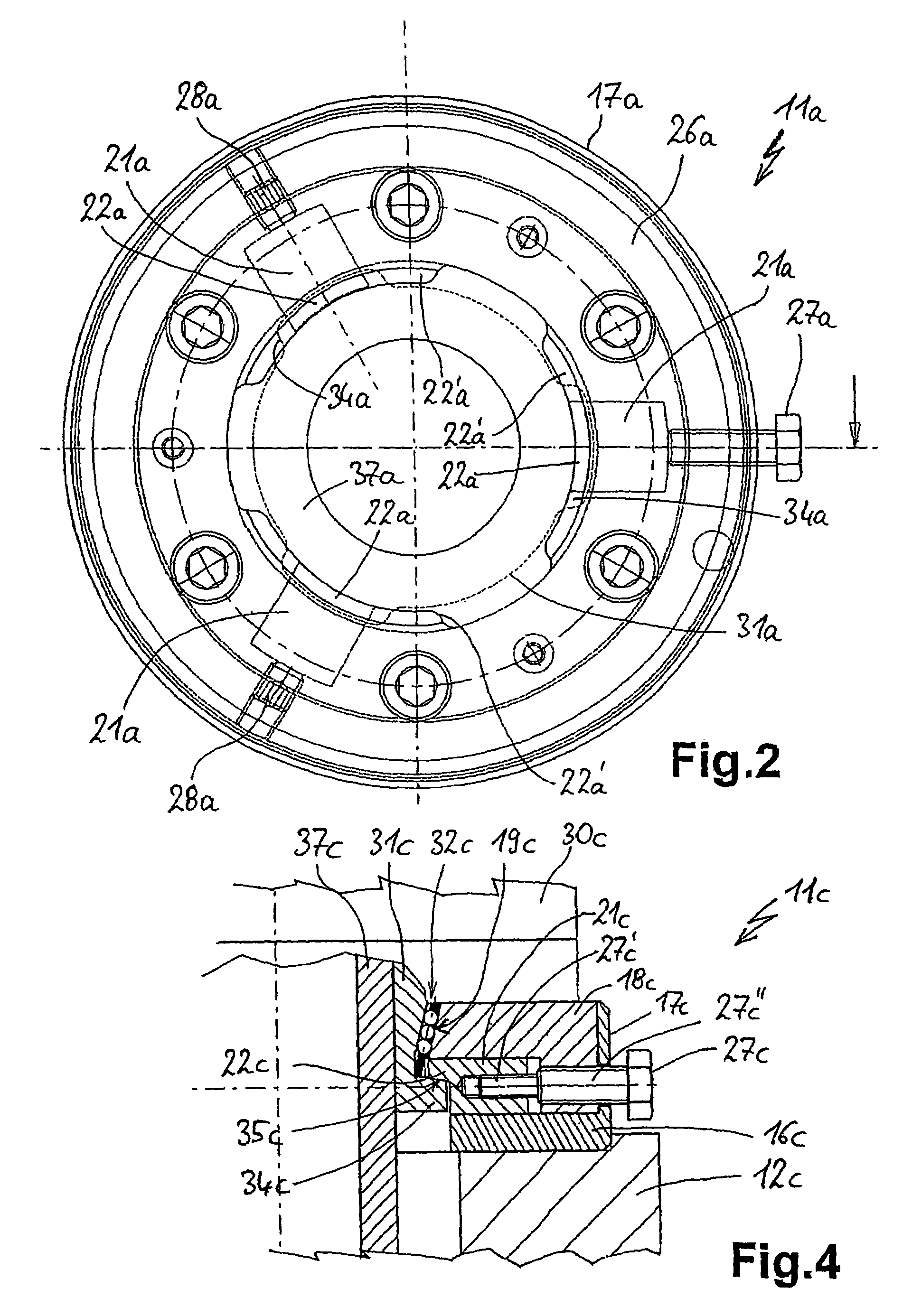

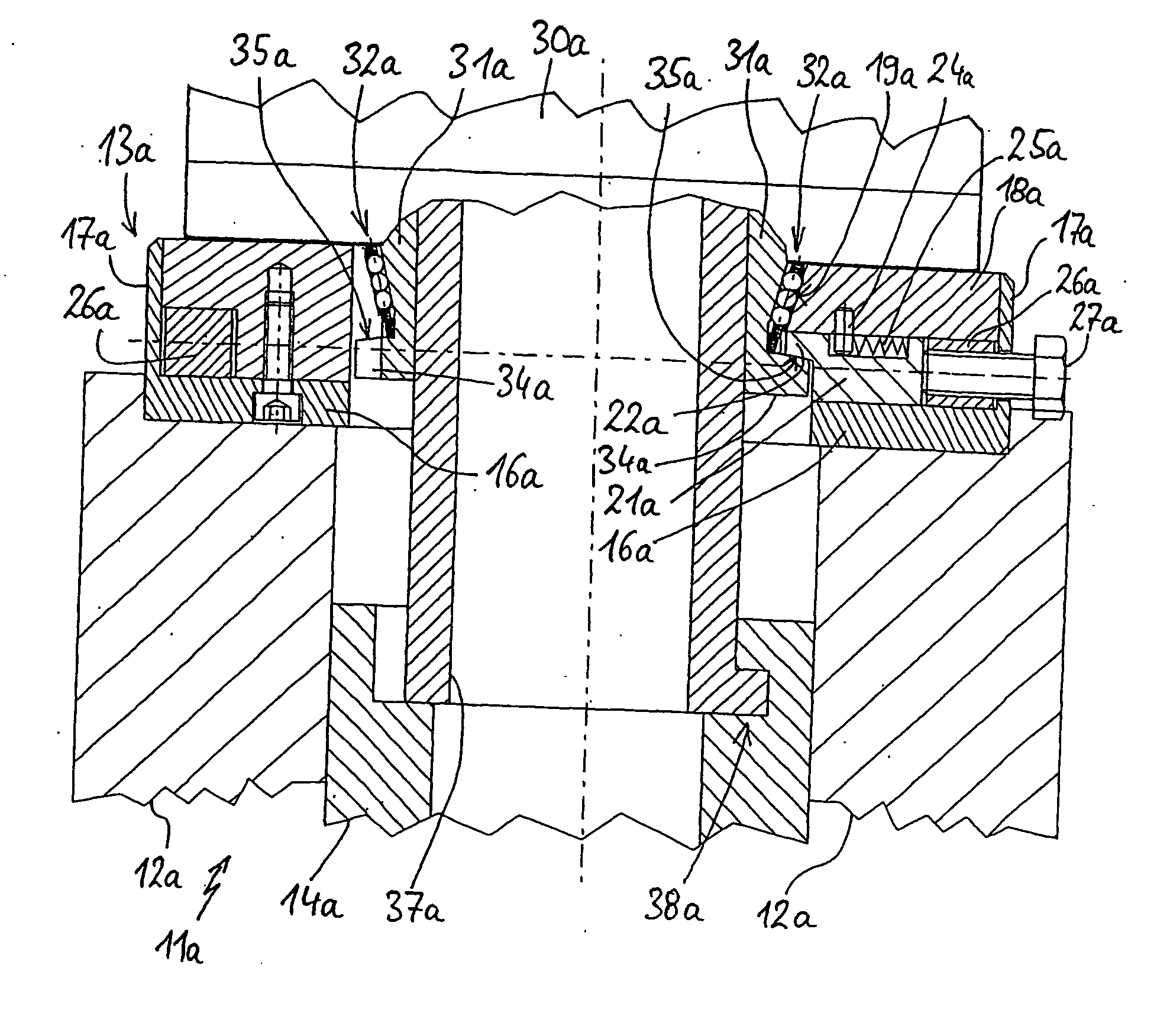

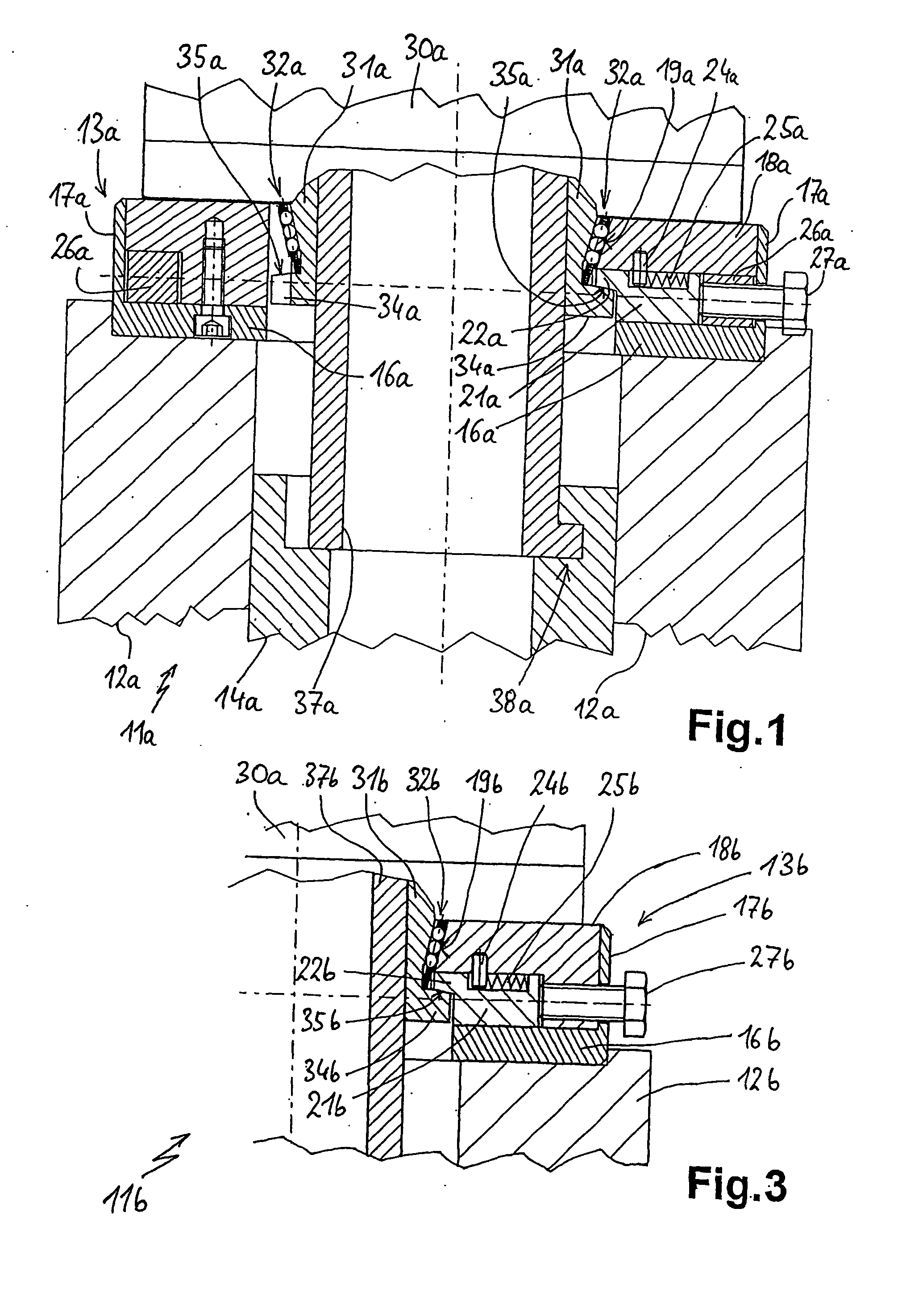

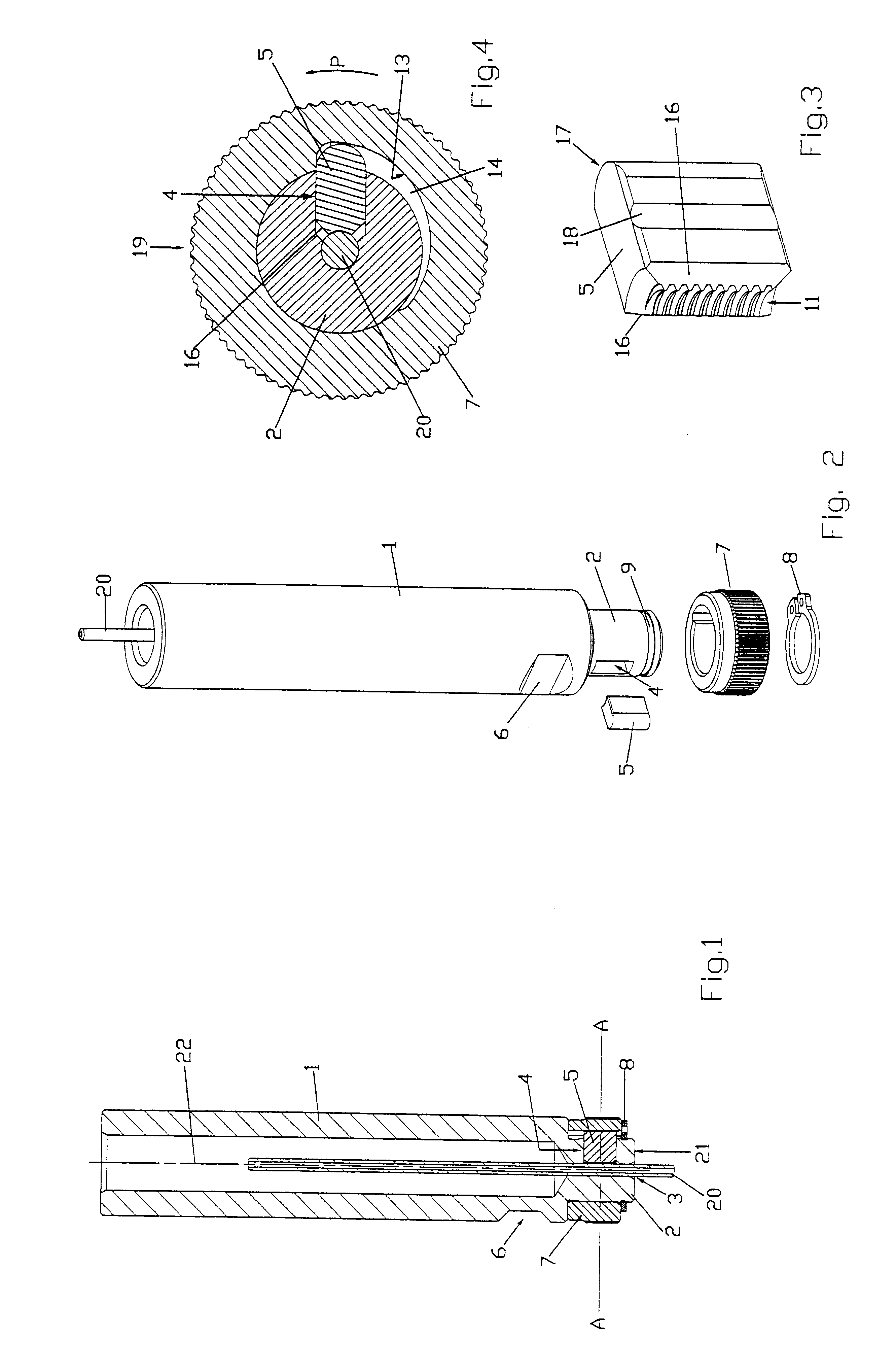

Workpiece clamping system

A workpiece clamping system with a machine spindle and a clamping chuck has a bayonet lock with projections. The bayonet lock is closed by insertion and turning. The bayonet lock can be clamped or locked, whereby parts of the projections are movable and exert a locking force on the other projections. A bayonet lock can be placed internally or externally on the workpiece clamping system.

Owner:HAINBUUFU GMBH SHUPANENDE TEHINIKU

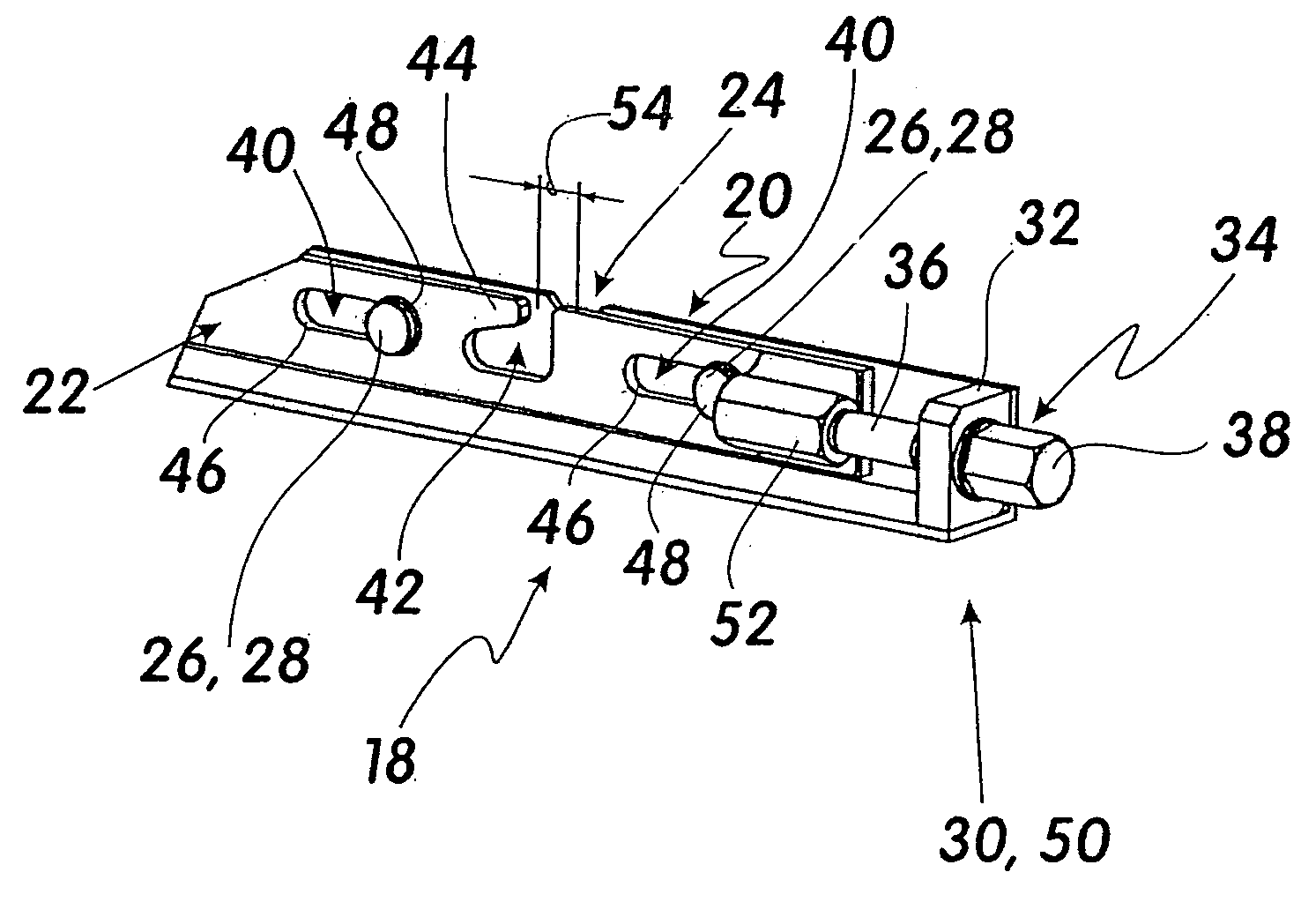

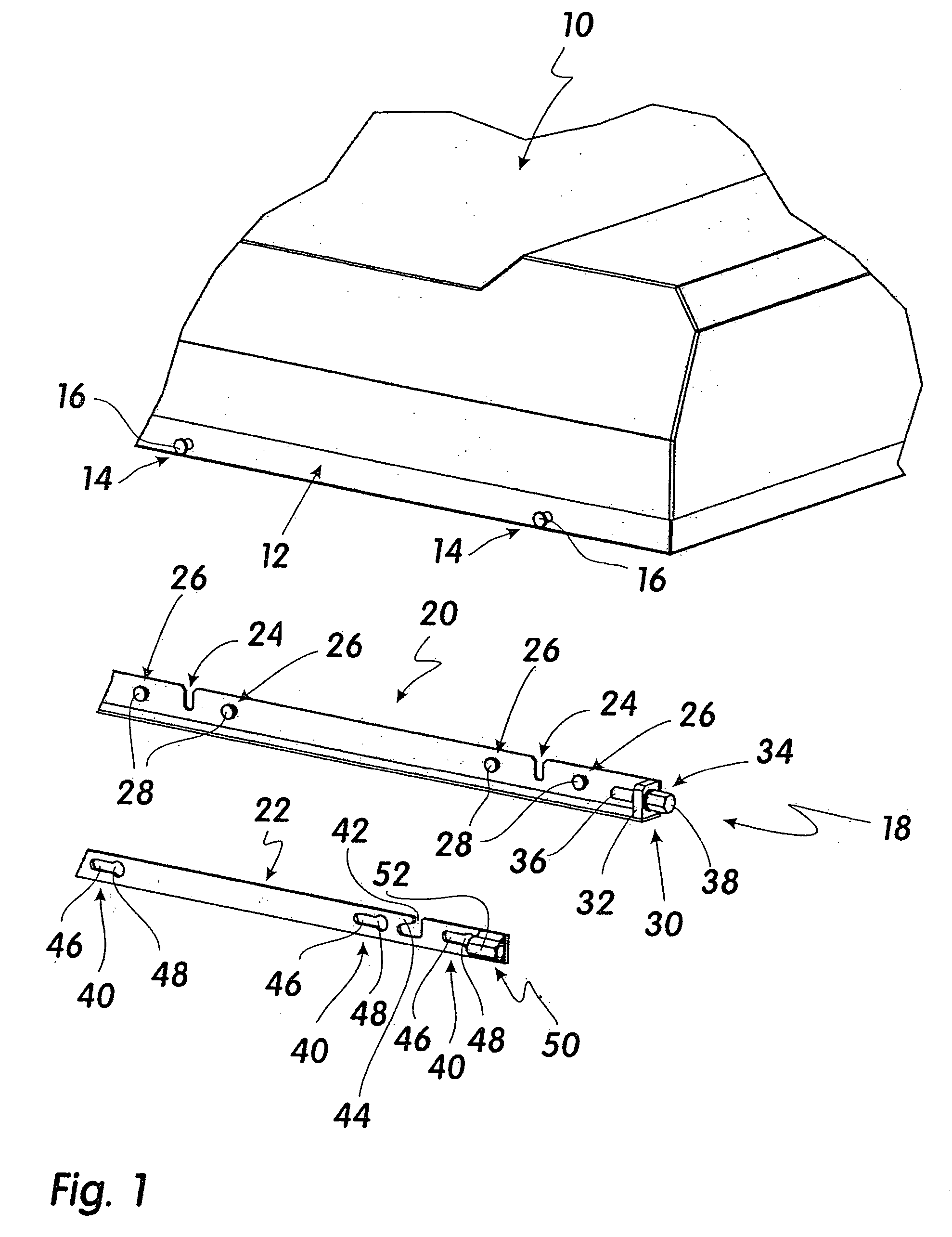

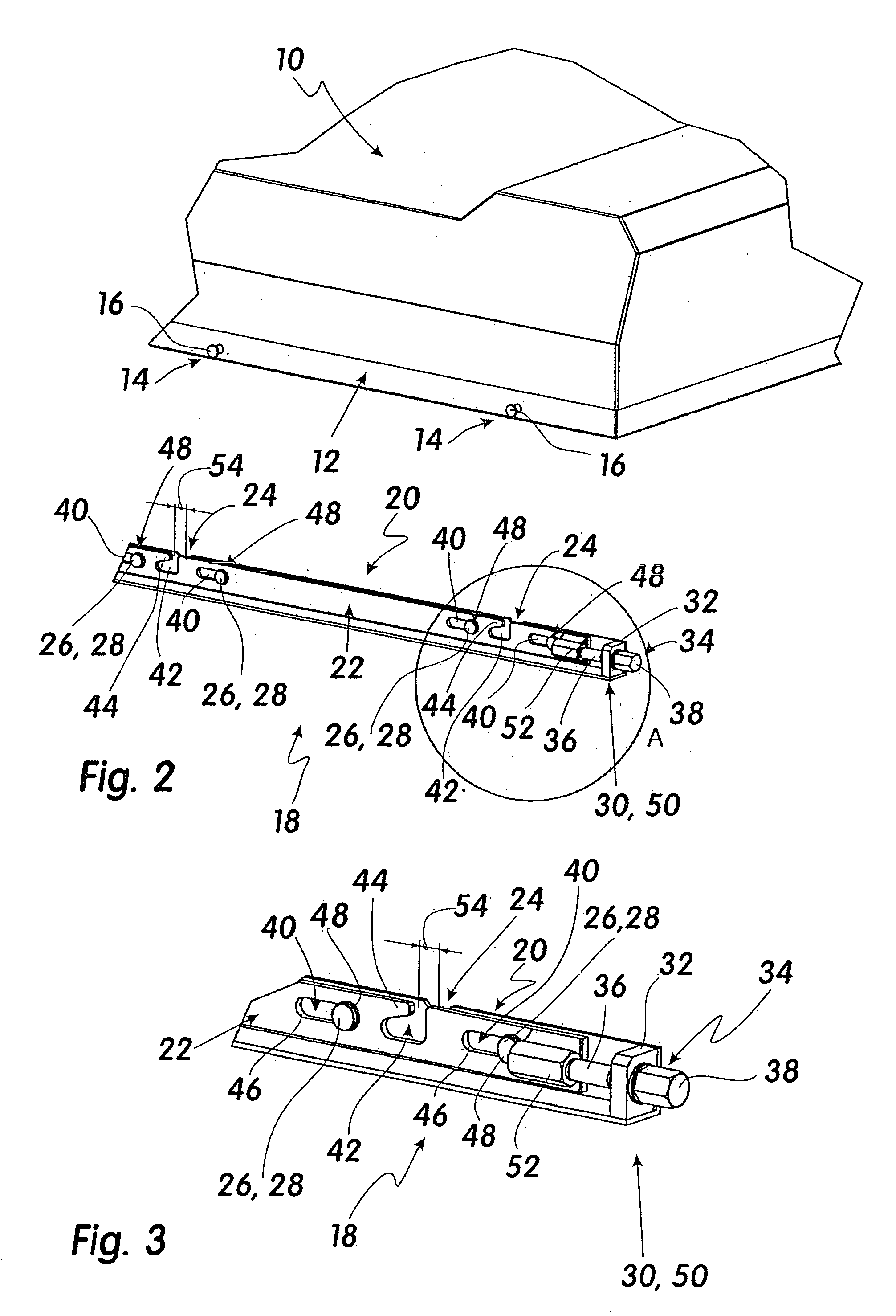

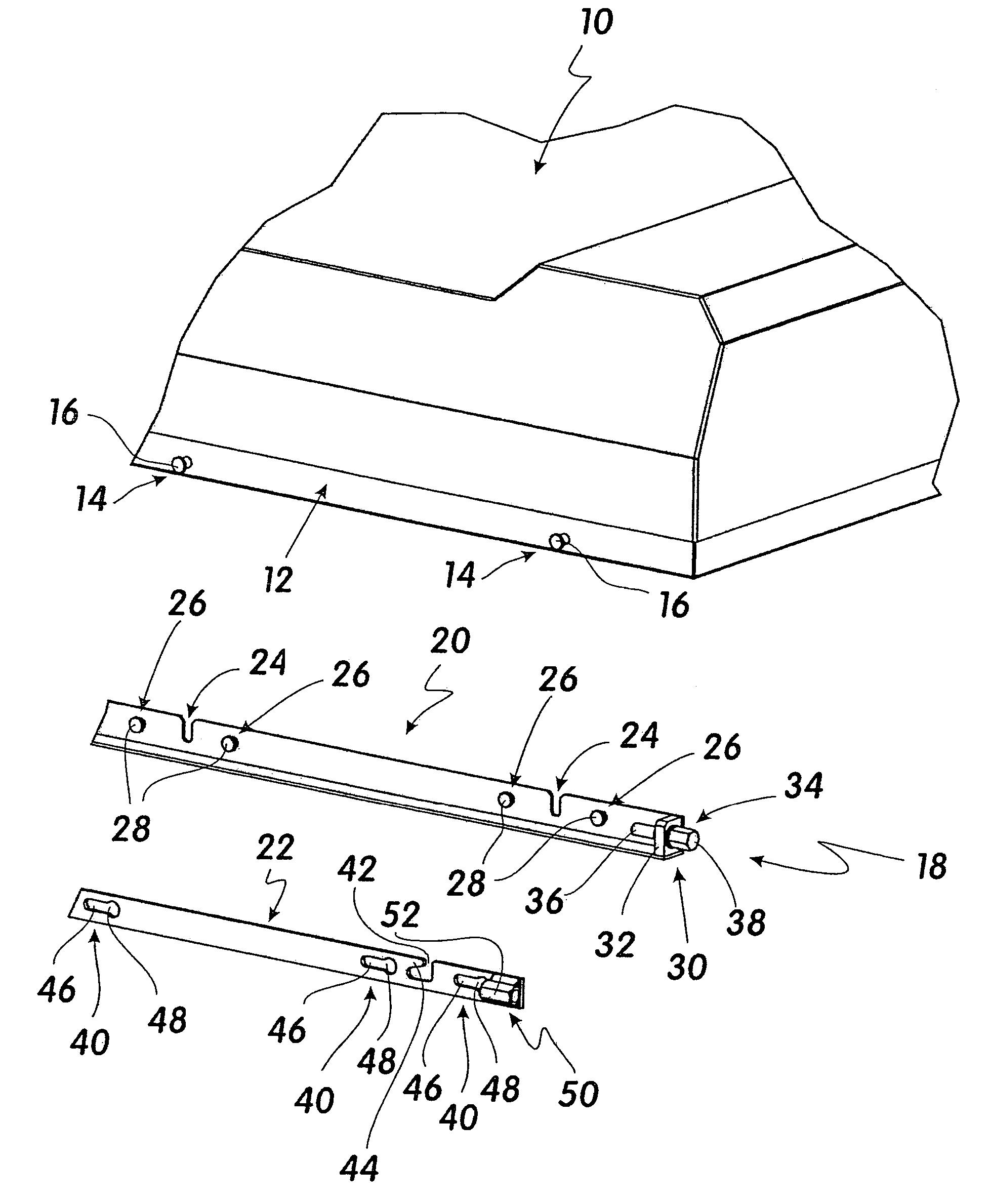

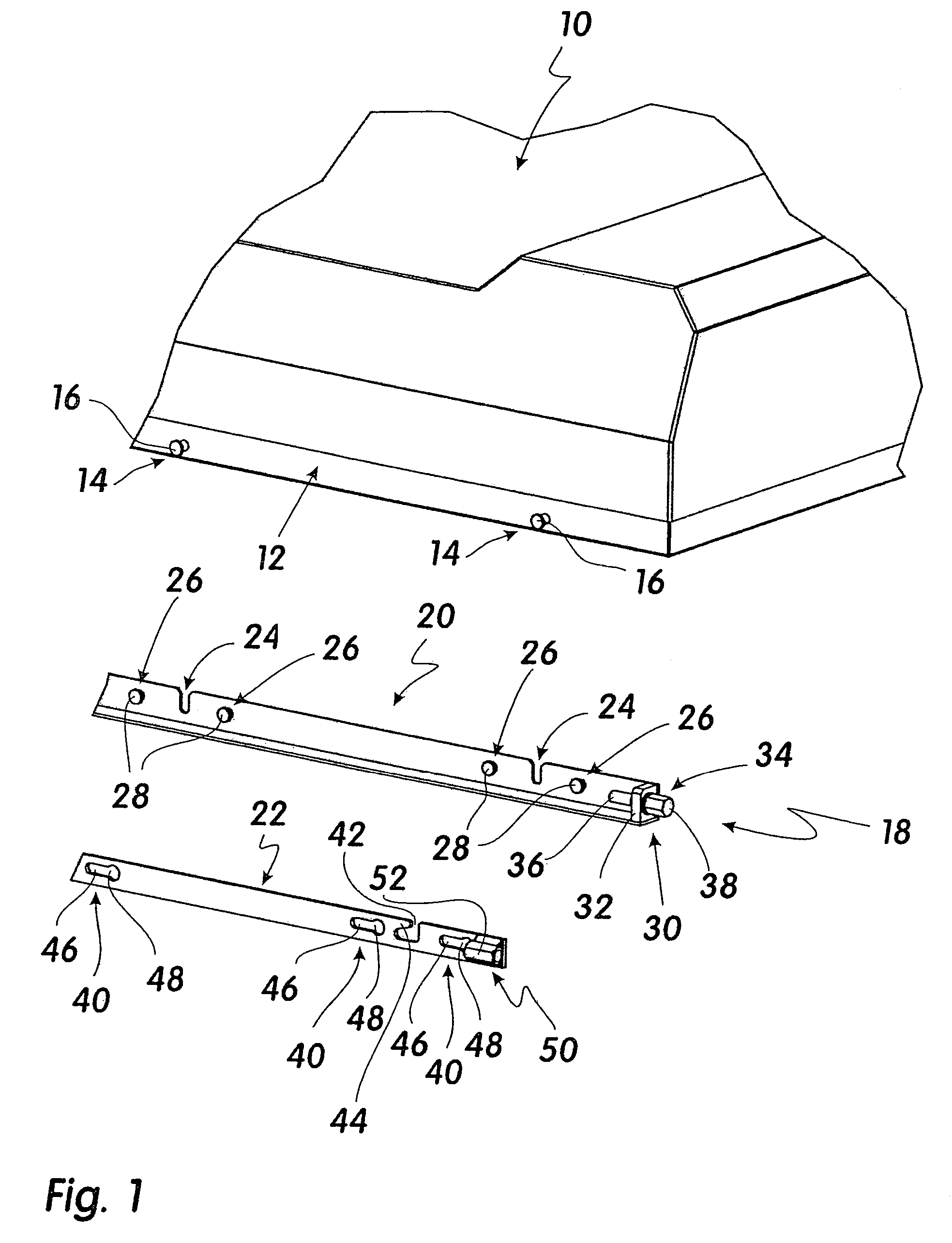

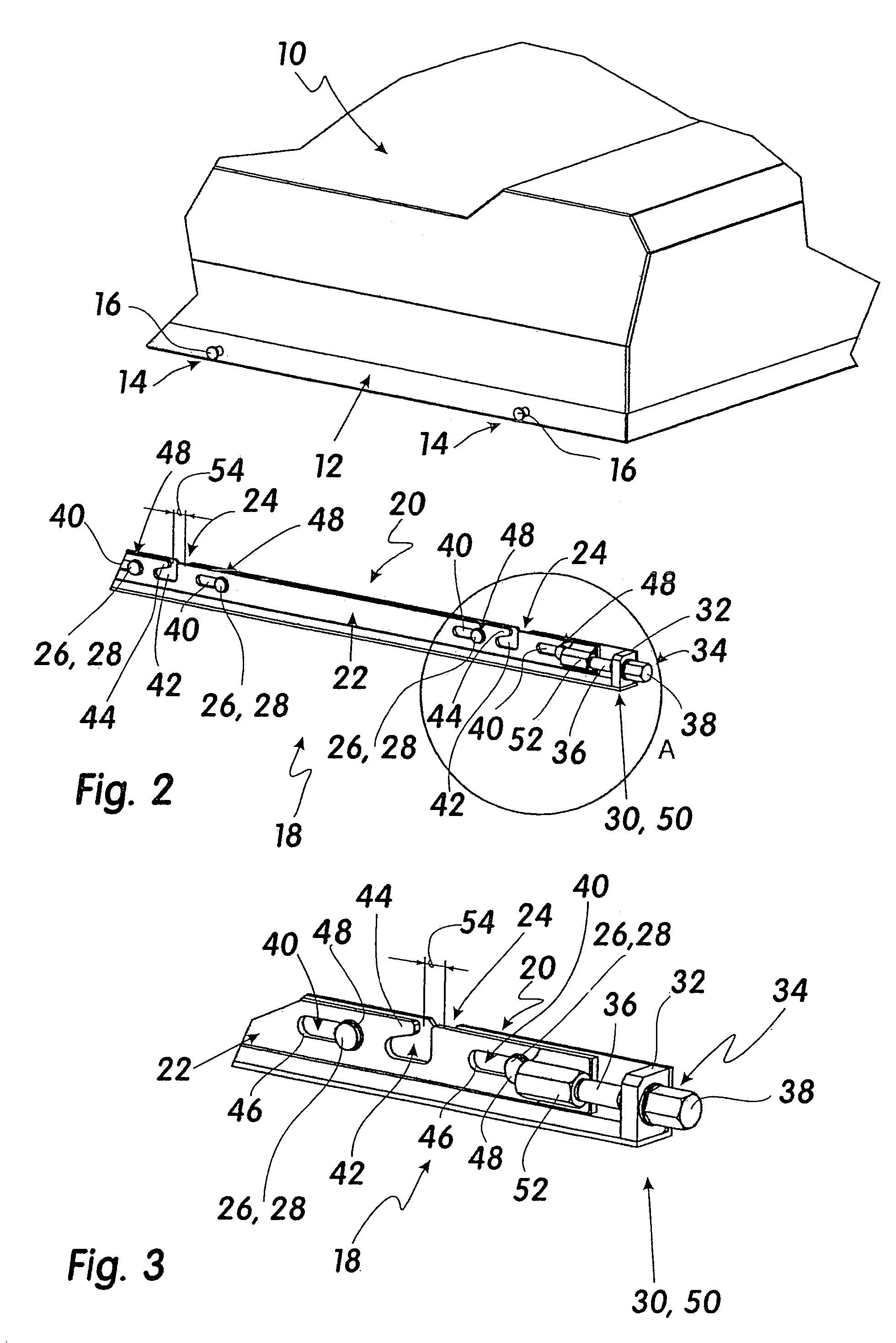

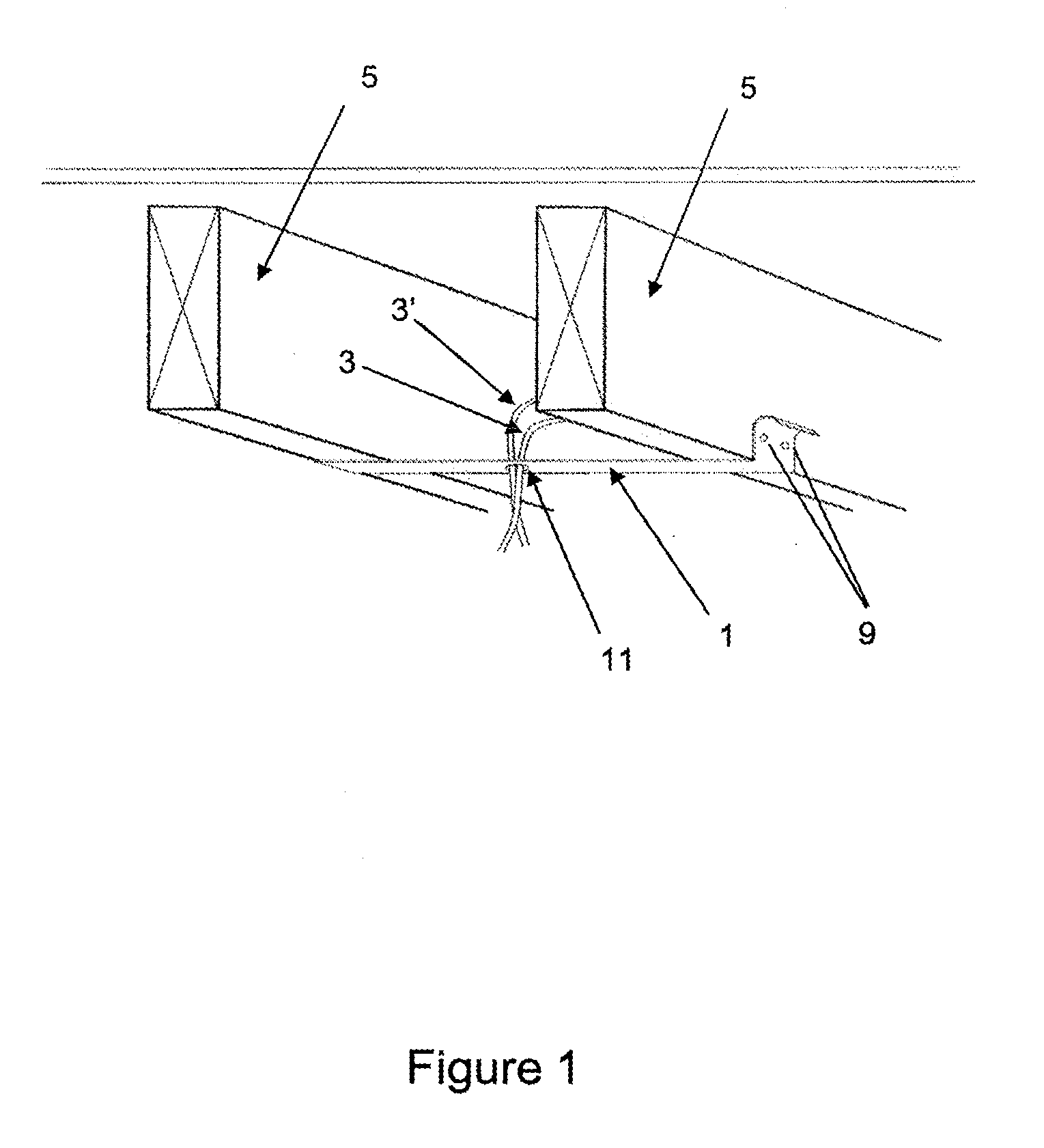

Fixing arrangement for vehicle roof mounting of an air conditioning module

InactiveUS20050204764A1Without taking a great deal of timeSimple structurePortable framesCandle holdersEngineeringAir conditioning

Described is a fixing arrangement for releasably fixing an air conditioning module to the roof of a vehicle such as a rail vehicle. The module has opposite side surfaces from which first fixing projections project. The vehicle roof supports positioning rail members in mutually parallel relationship at a spacing from each other corresponding to the spacing between the side surfaces of the module. The positioning rail members have upwardly open first openings. Second fixing projections project from the positioning rail members at the outside thereof laterally beside the first openings. Locking rail members are adapted to co-operate with the positioning rail members, for which purpose the locking rail members have slots operatively associated with the second fixing projections and second upwardly open openings which are associated with the first openings and which have a portion extending in the longitudinal direction of the respective locking rail member for lockingly receiving the first projections on the positioning rail members.

Owner:KONVEKTA

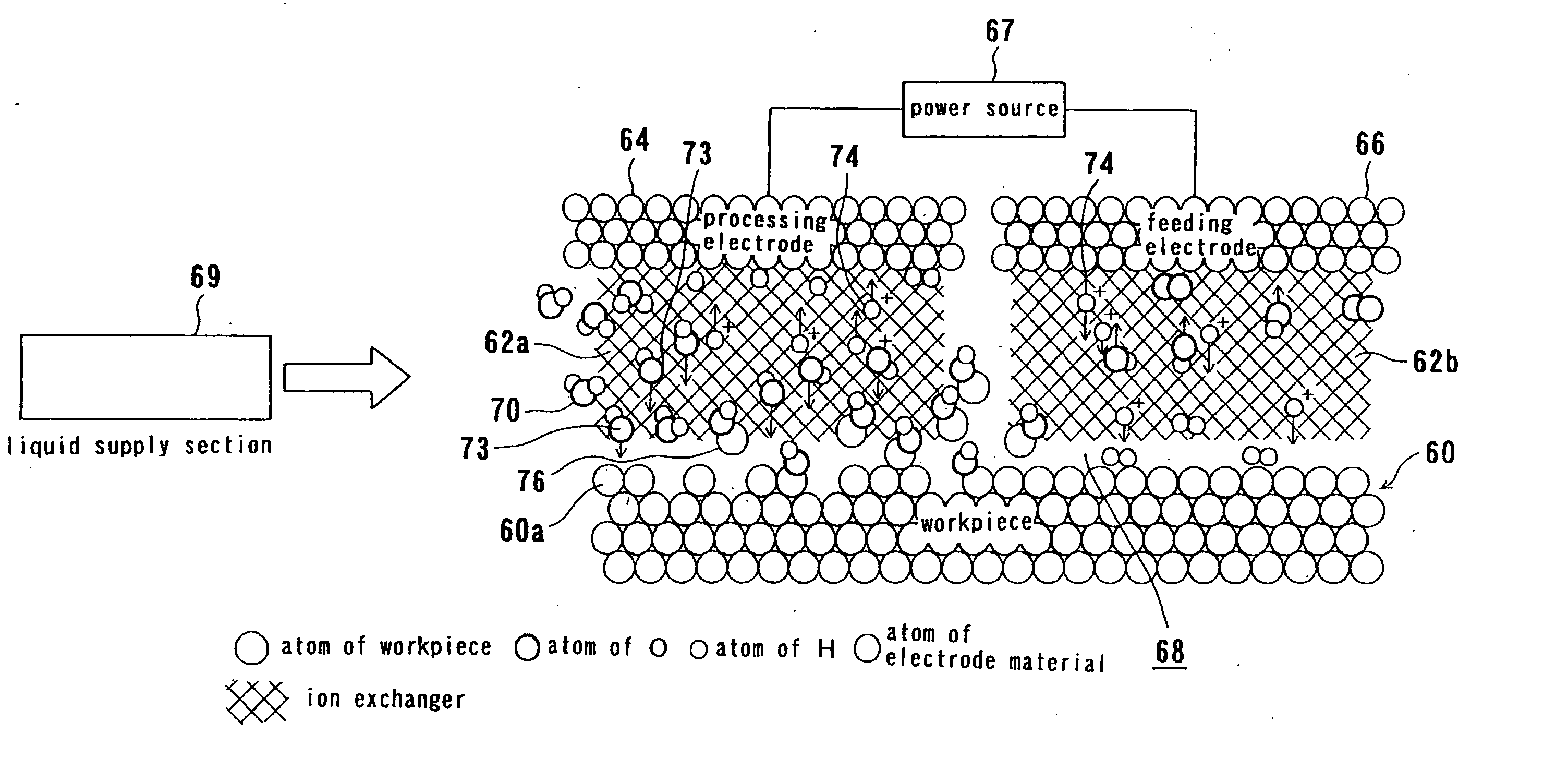

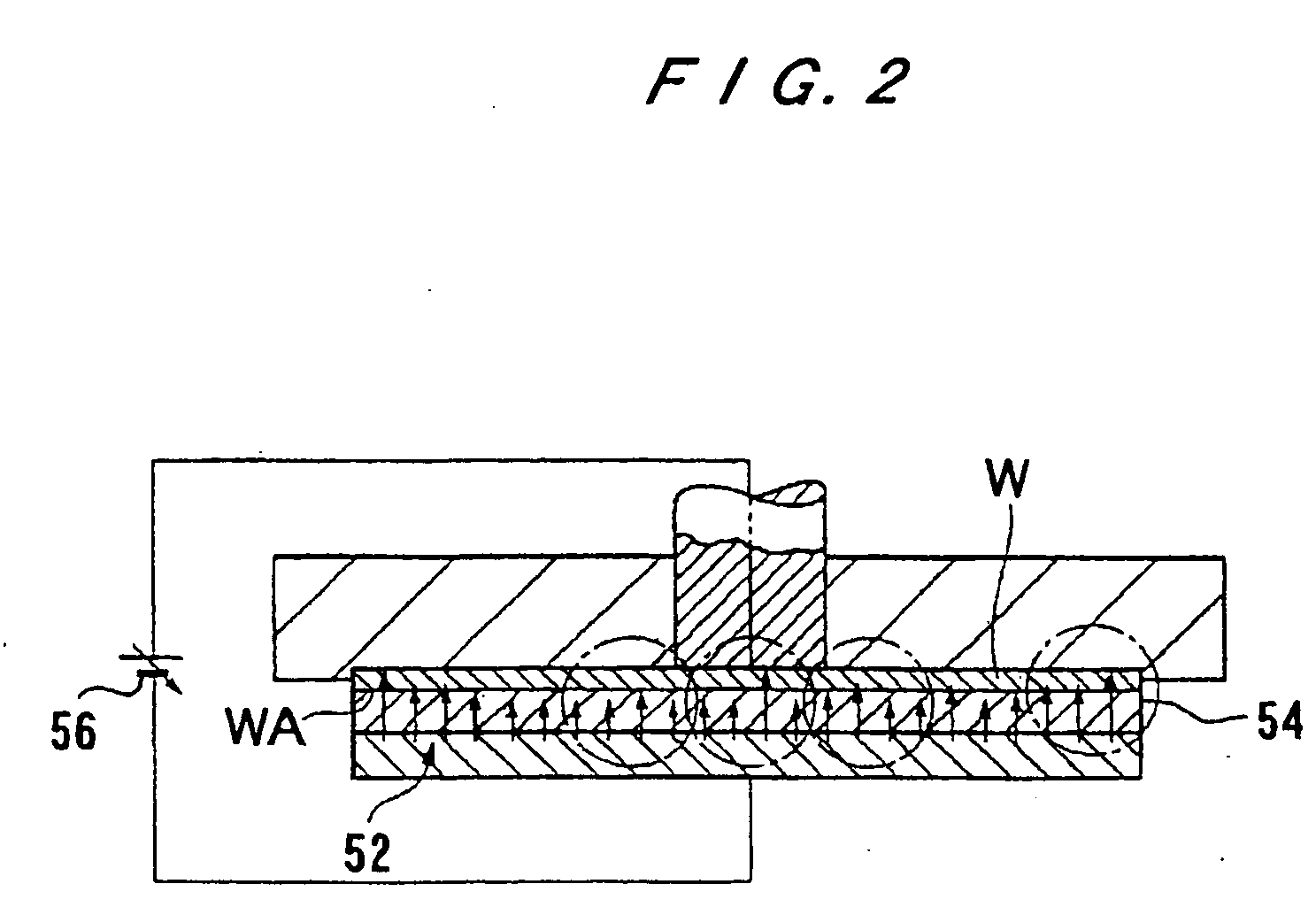

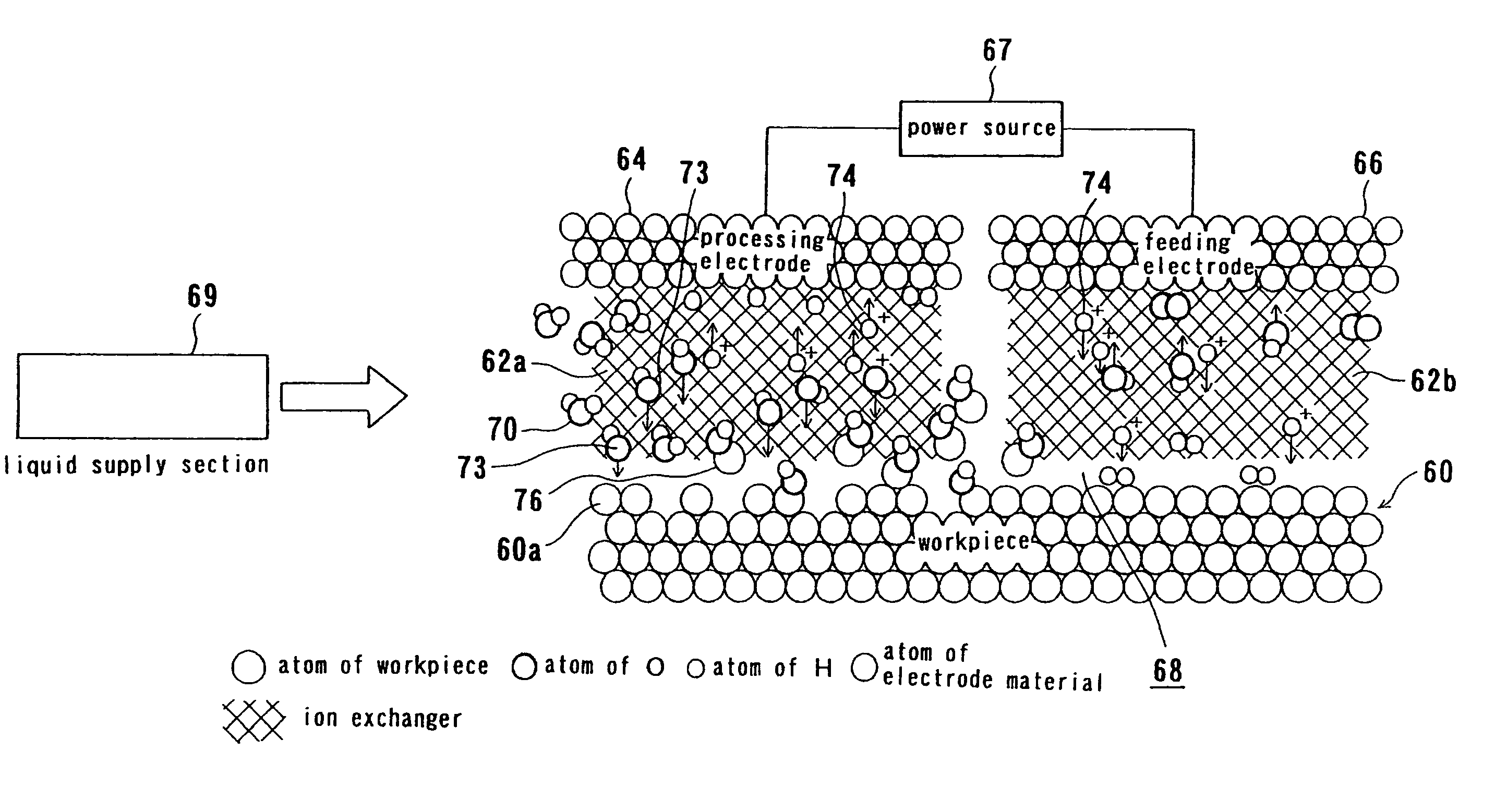

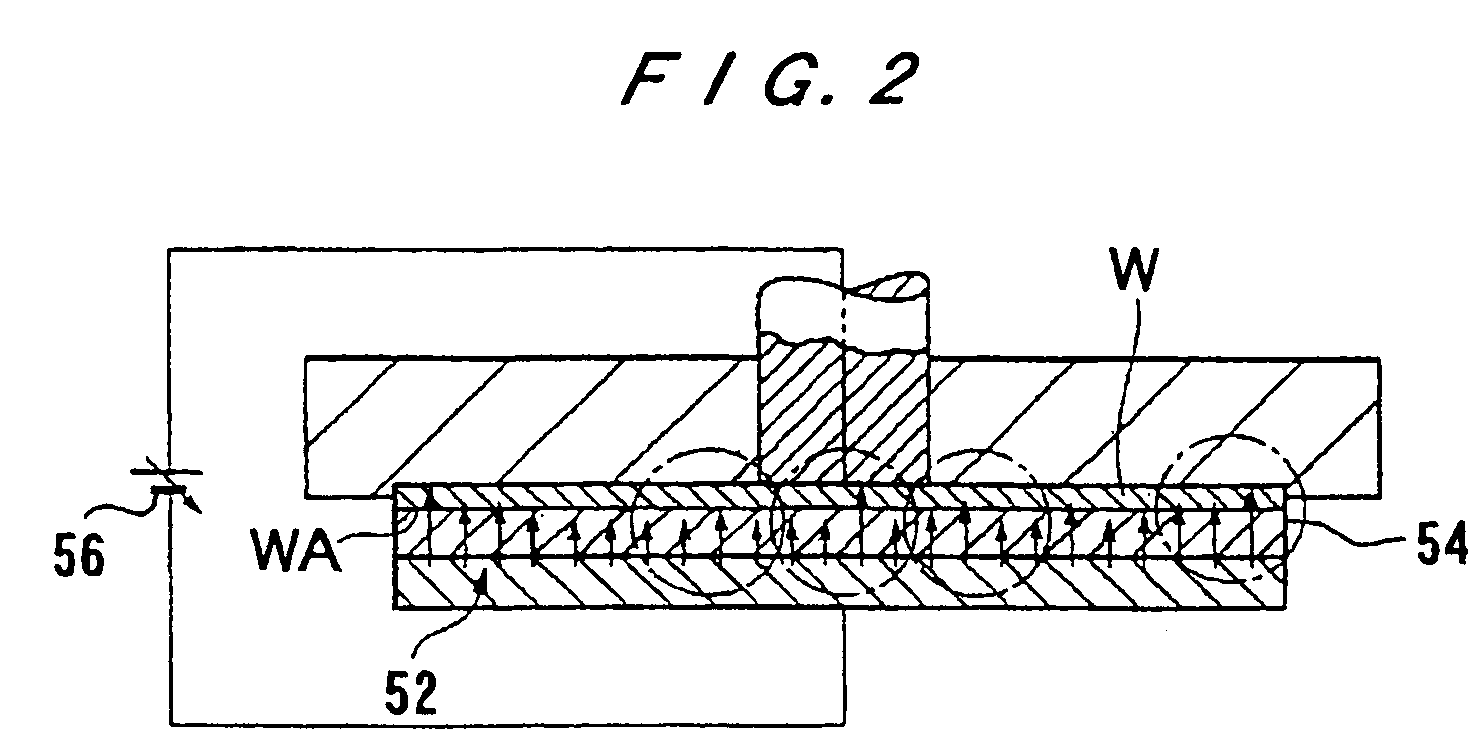

Electrolytic processing apparatus and method

InactiveUS20050121328A1Uniform processing rateImprove uniformityCellsMachining electric circuitsElectricityElectrolysis

This invention relates to an electrolytic processing apparatus and method useful for processing a conductive material formed in the surface of a substrate, or for removing impurities adhering to the surface of a substrate. An electrolytic processing apparatus, including, a processing electrode that can come close to a workpiece, a feeding electrode for feeding electricity to the workpiece, an ion exchanger disposed in the space between the workpiece and the processing and the feeding electrodes, a fluid supply section for supplying a fluid between the workpiece and the ion exchanger, and a power source, wherein the processing electrode and / or the feeding electrode is electrically divided into a plurality of parts, and the power source applies a voltage to each of the divided electrode parts and can control voltage and / or electric current independently for each of the divided electrode parts.

Owner:EBARA CORP

Fixing arrangement for vehicle roof mounting of an air conditioning module

InactiveUS7401757B2Without taking a great deal of timeSimple structurePortable framesCandle holdersComputer moduleEngineering

Described is a fixing arrangement for releasably fixing an air conditioning module to the roof of a vehicle such as a rail vehicle. The module has opposite side surfaces from which first fixing projections project. The vehicle roof supports positioning rail members in mutually parallel relationship at a spacing from each other corresponding to the spacing between the side surfaces of the module. The positioning rail members have upwardly open first openings. Second fixing projections project from the positioning rail members at the outside thereof laterally beside the first openings. Locking rail members are adapted to co-operate with the positioning rail members, for which purpose the locking rail members have slots operatively associated with the second fixing projections and second upwardly open openings which are associated with the first openings and which have a portion extending in the longitudinal direction of the respective locking rail member for lockingly receiving the first projections on the positioning rail members.

Owner:KONVEKTA

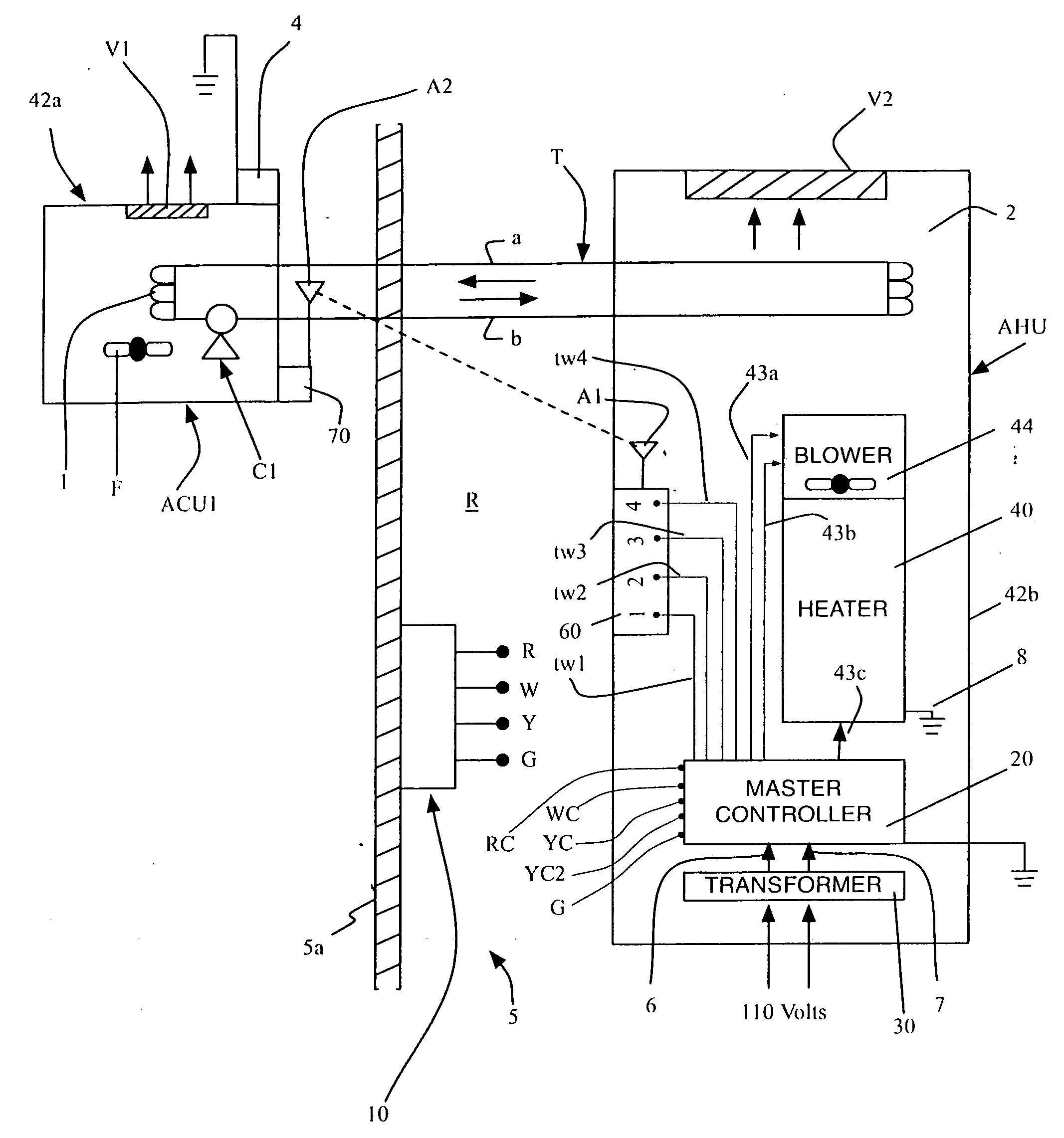

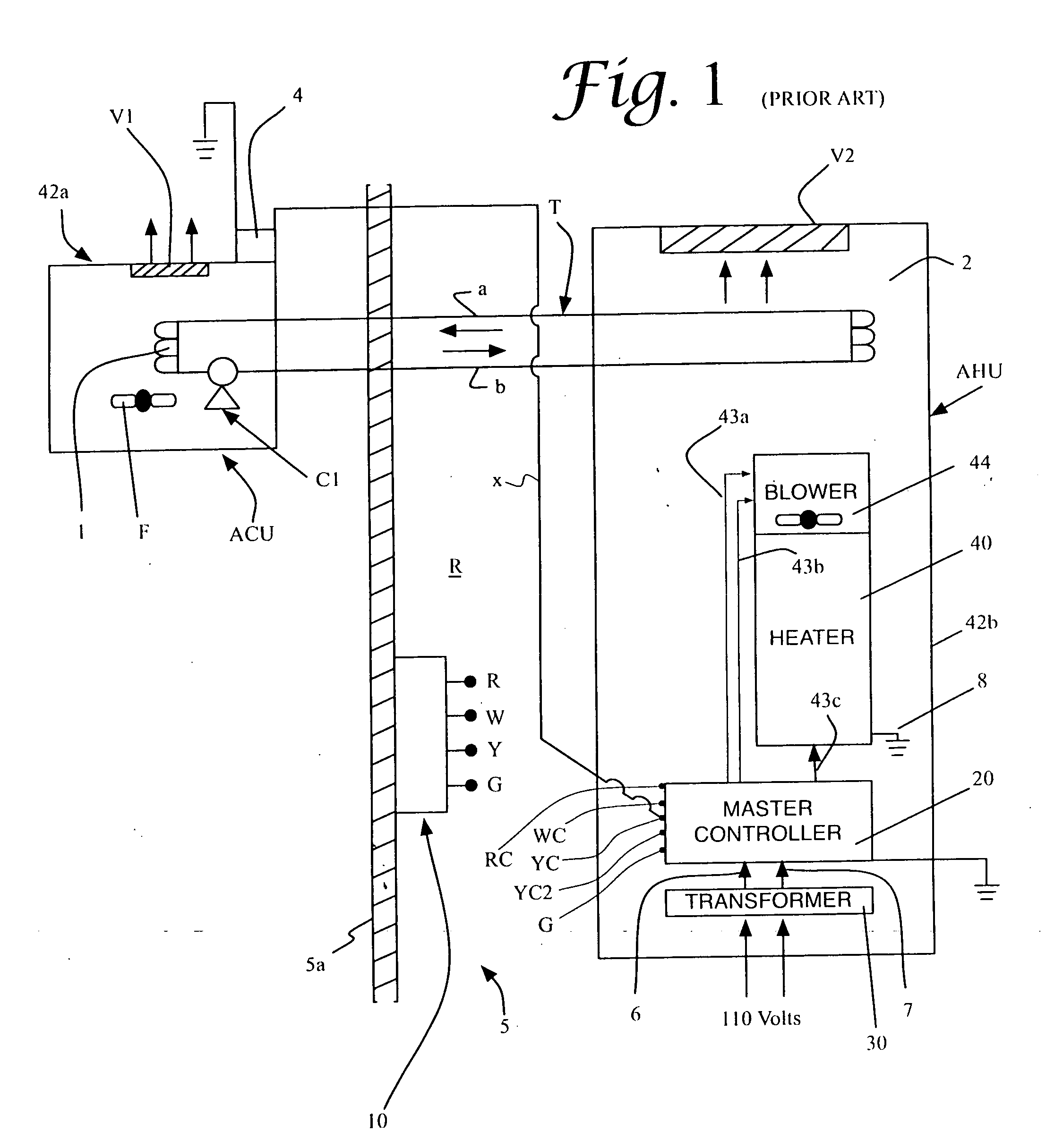

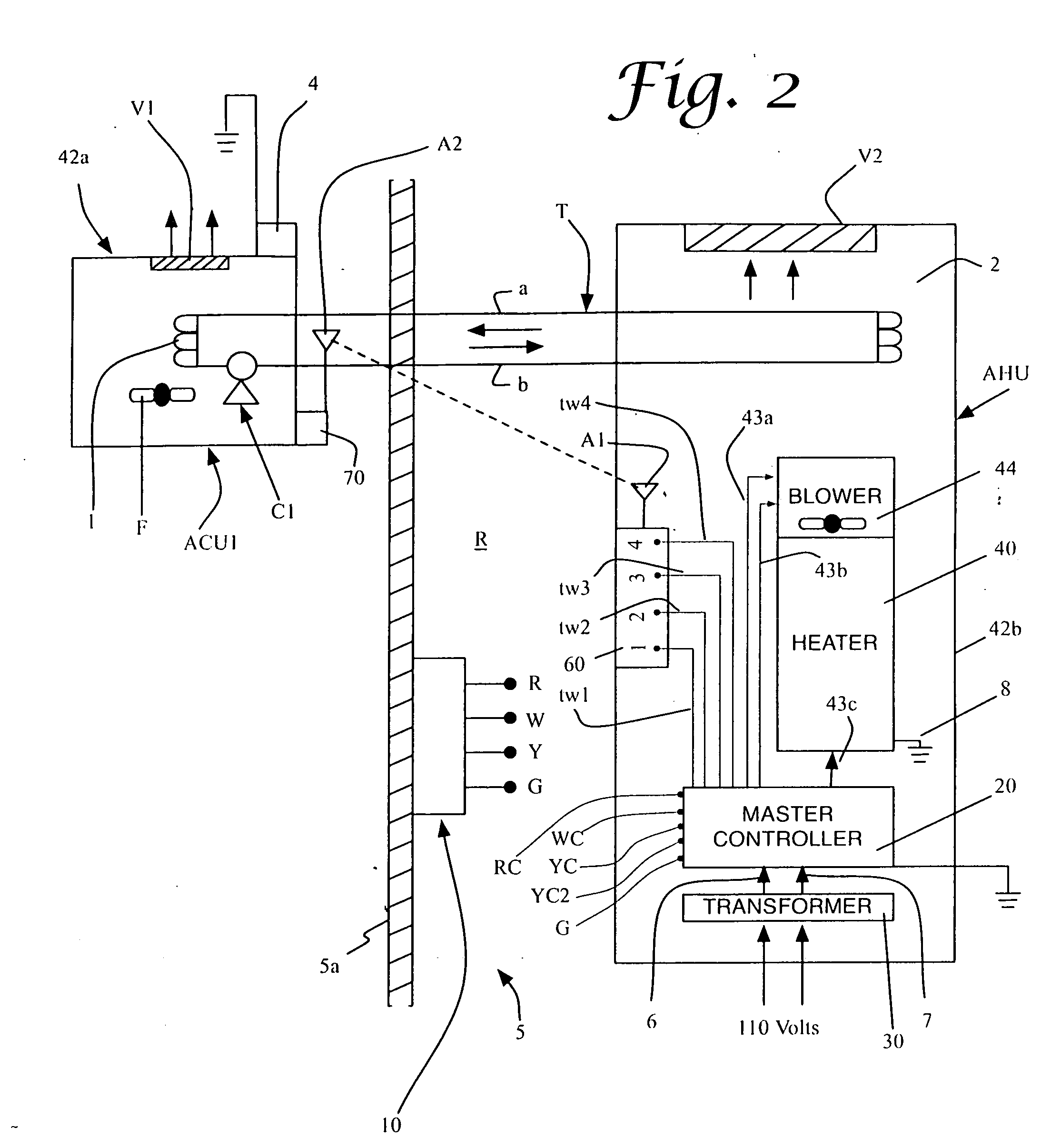

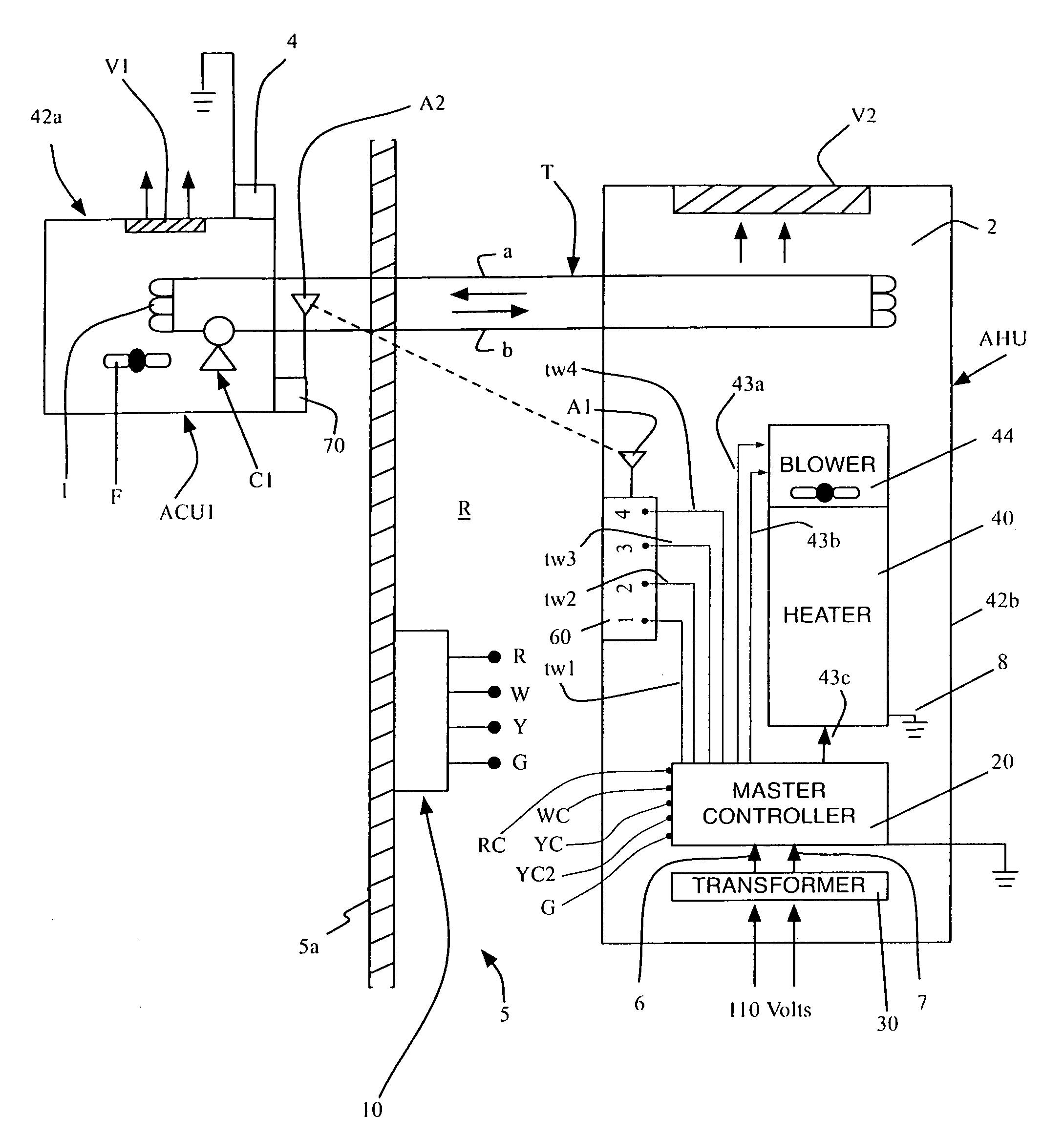

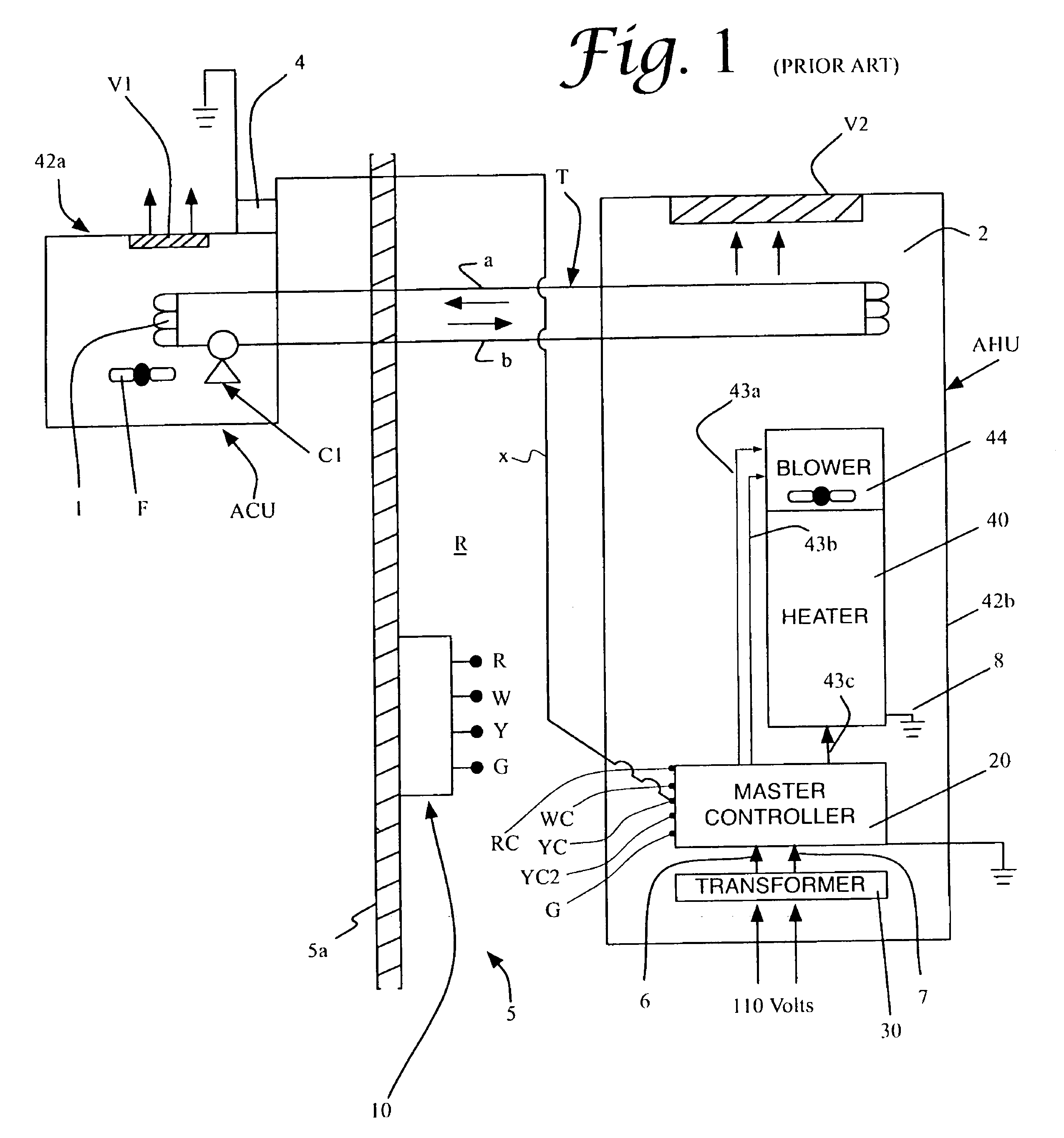

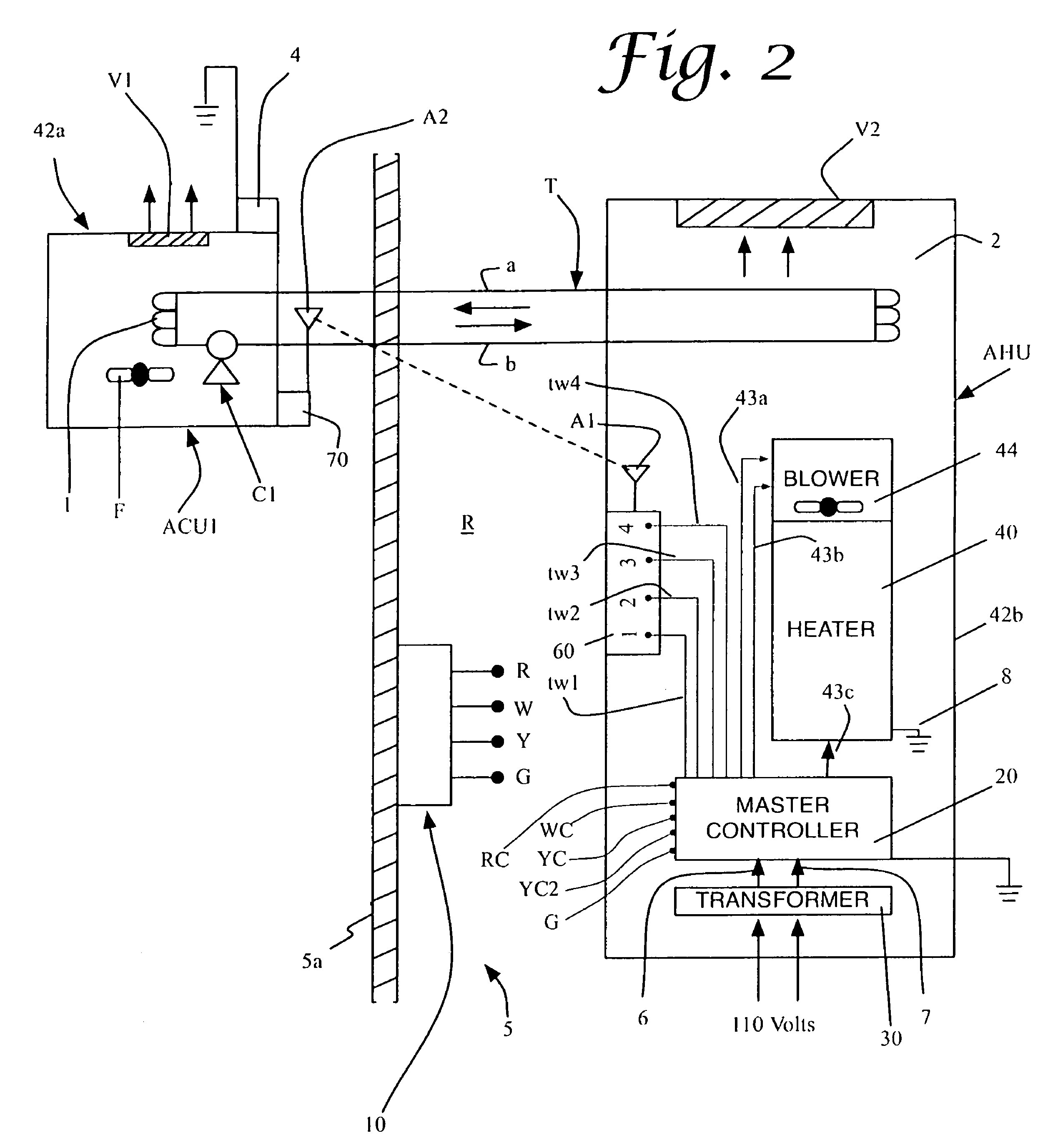

Air conditioning system, control unit and other components used therewith

ActiveUS20090101726A1Easy to installEasy and quick fixMechanical apparatusDomestic cooling apparatusElectricityTemperature control

An air-conditioning system operable at different states employs a control unit including a receiver and a transmitter. The receiver is connected electrically to a switching device for a compressor of the air-conditioning system. The compressor is installed at a remote location exterior to a building. The receiver is responsive to an encoded radio signal to provide an electronic control signal for actuating the switching device. The transmitter is installed within the building and is electrically connected to a thermostat within the building that responds to temperature changes to provide a temperature control signal. The transmitter upon receipt of the temperature control signal transmits to the remote location the encoded radio signal for operating the air-conditioning system at one of the different states.

Owner:RANKICH STEPHEN

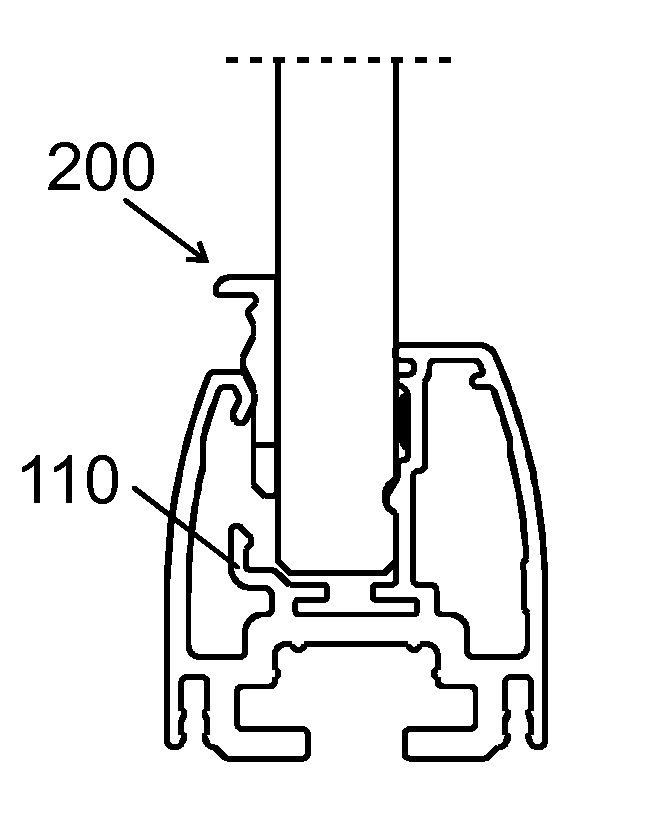

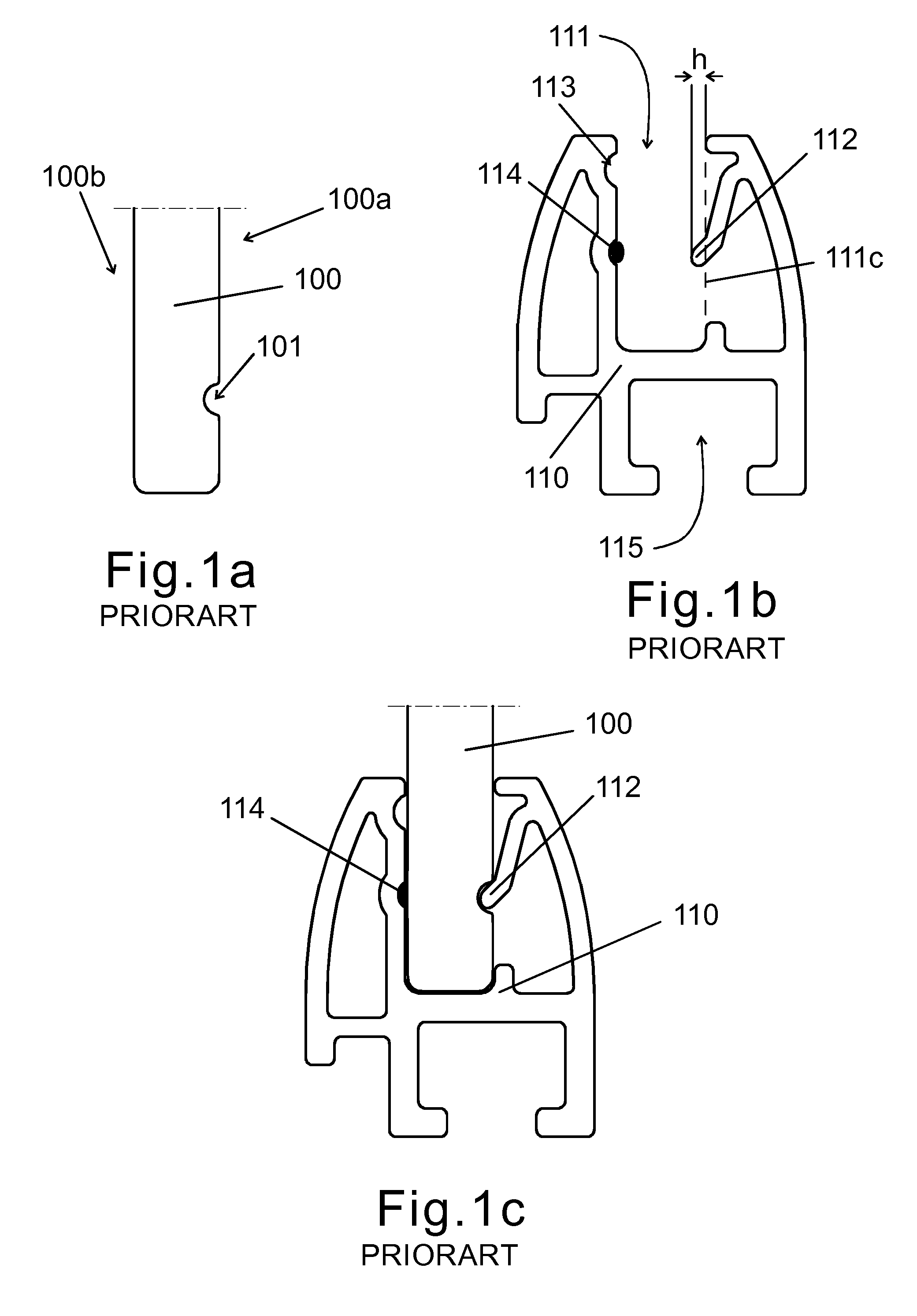

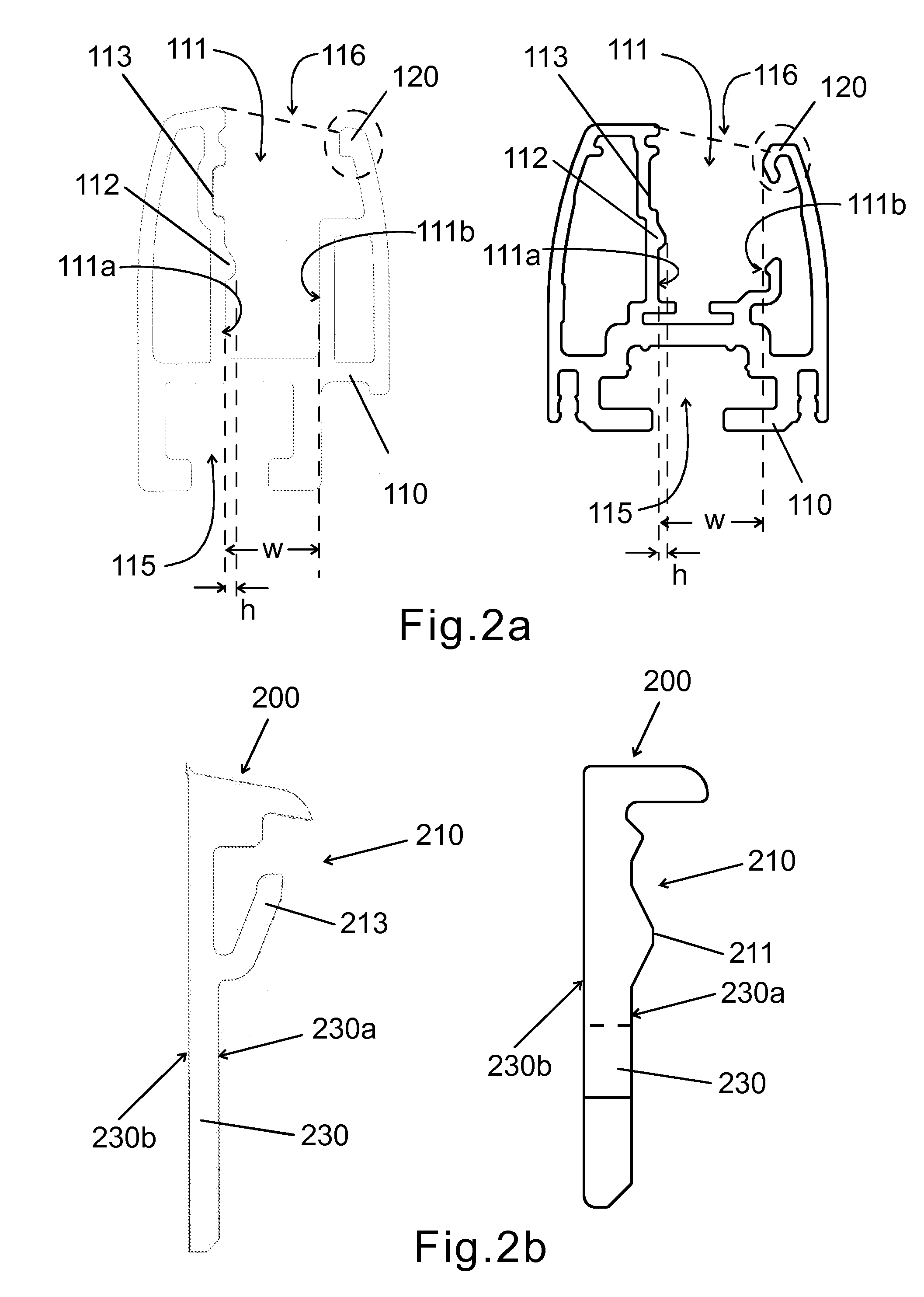

Profile bar to be locked to a panel, and a panel system

InactiveUS20120189378A1Easy to installEasy to disassembleWashersWing arrangementsEngineeringMechanical engineering

A profile bar to be locked to a panel. A frame has a shape that is a continuous profile. The frame includes a slot in which the panel can be installed. A first side and a second side of the slot delimit the slot and support the panel. A protrusion is provided on the first side of the slot and fitted to be placed in a groove in the panel. A locking piece includes a locking part which can be inserted between the panel in the slot. The locking part makes the slot narrower, to push the panel against the protrusion and to support the panel such that the protrusion remains in the groove of the panel. The detachment of the panel from the frame is prevented. A panel system includes a planar panel equipped with at least one locking groove and profile bar to be locked to the panel.

Owner:LUMON INVEST

Workpiece clamping system

ActiveUS20070063454A1Accurate fitEasy constructionSleeve/socket jointsChucksEngineeringMechanical engineering

A workpiece clamping system with a machine spindle and a clamping chuck has a bayonet lock with projections. The bayonet lock is closed by insertion and turning. The bayonet lock can be clamped or locked, whereby parts of the projections are movable and exert a locking force on the other projections. A bayonet lock can be placed internally or externally on the workpiece clamping system.

Owner:HAINBUUFU GMBH SHUPANENDE TEHINIKU

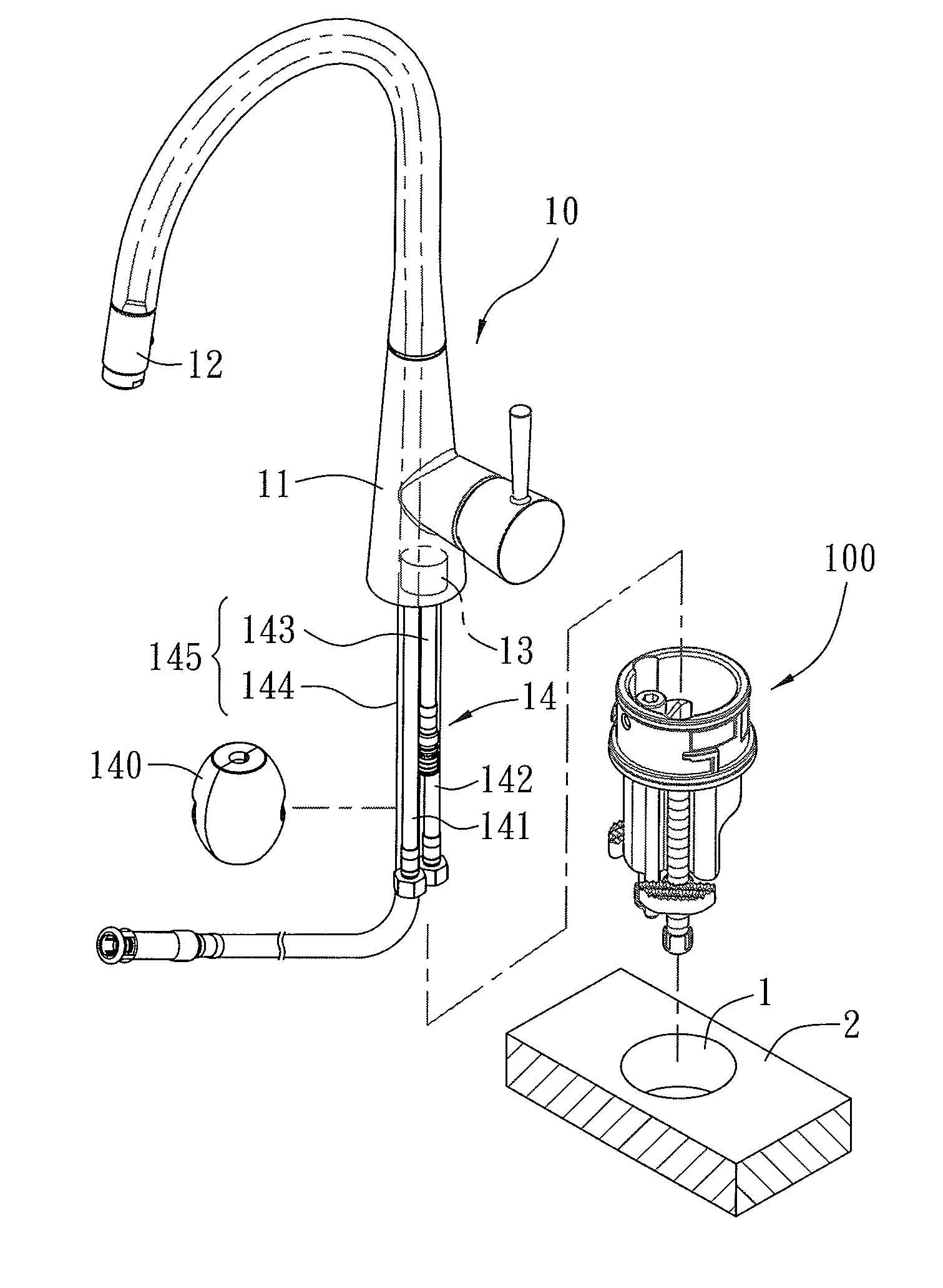

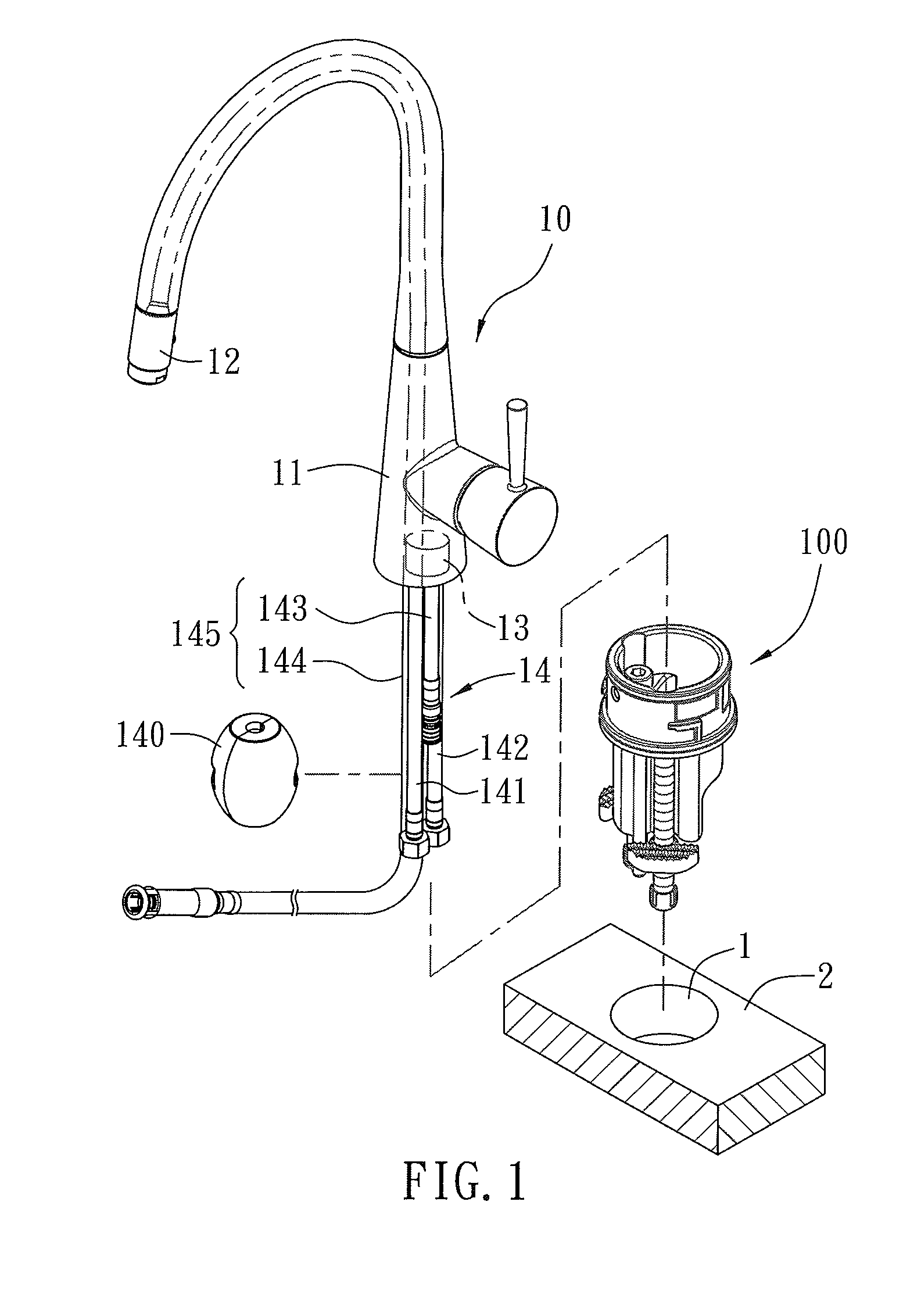

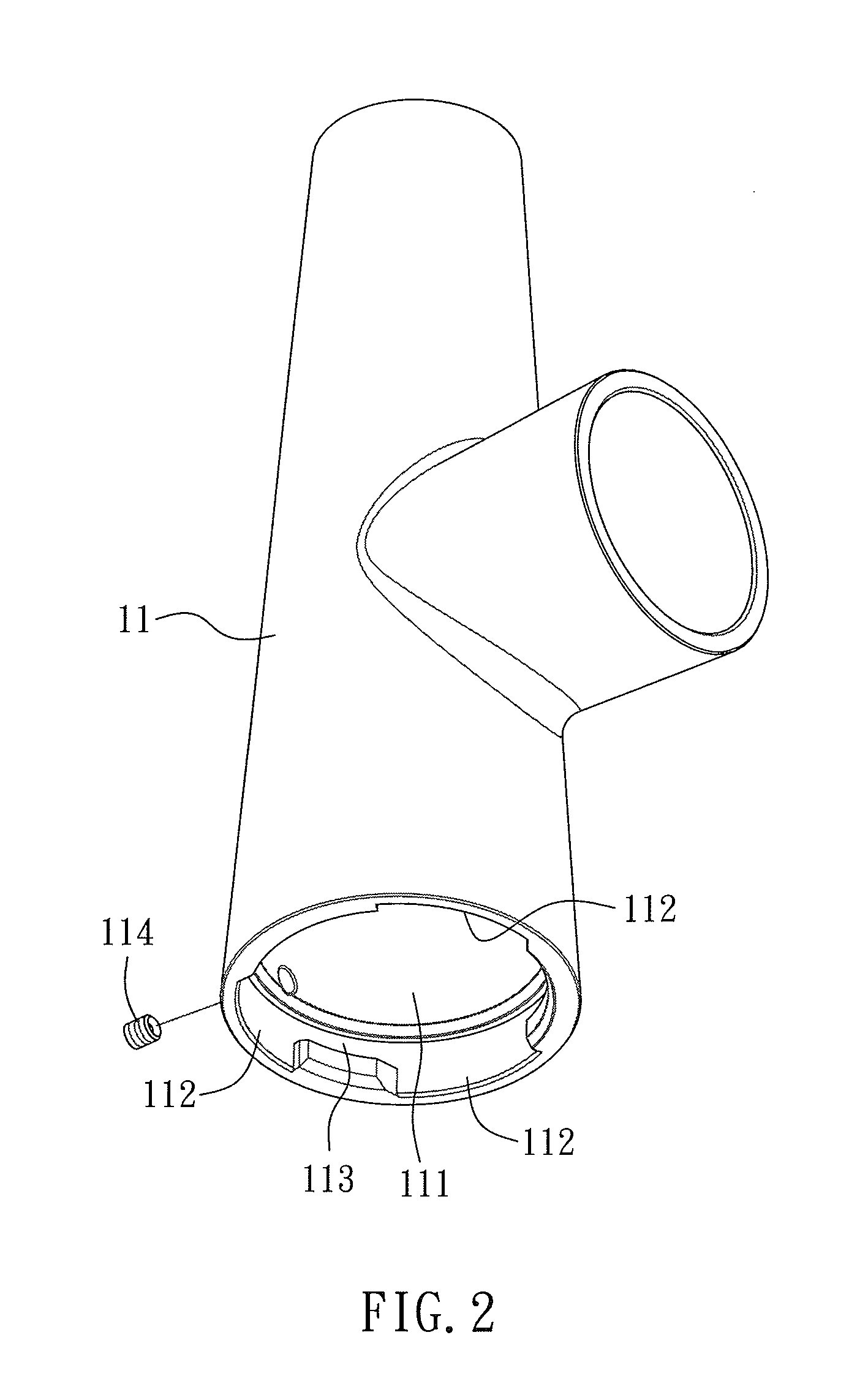

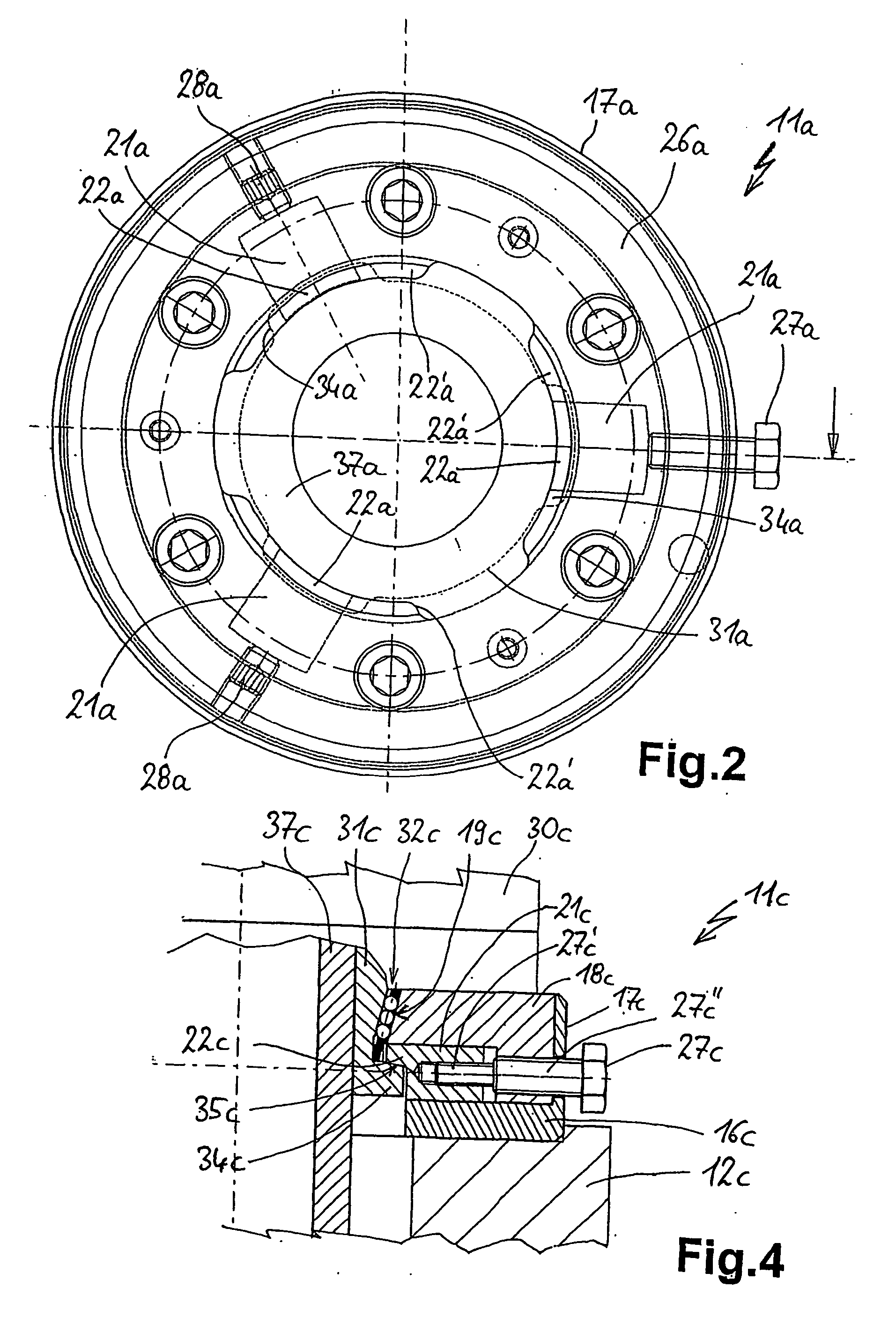

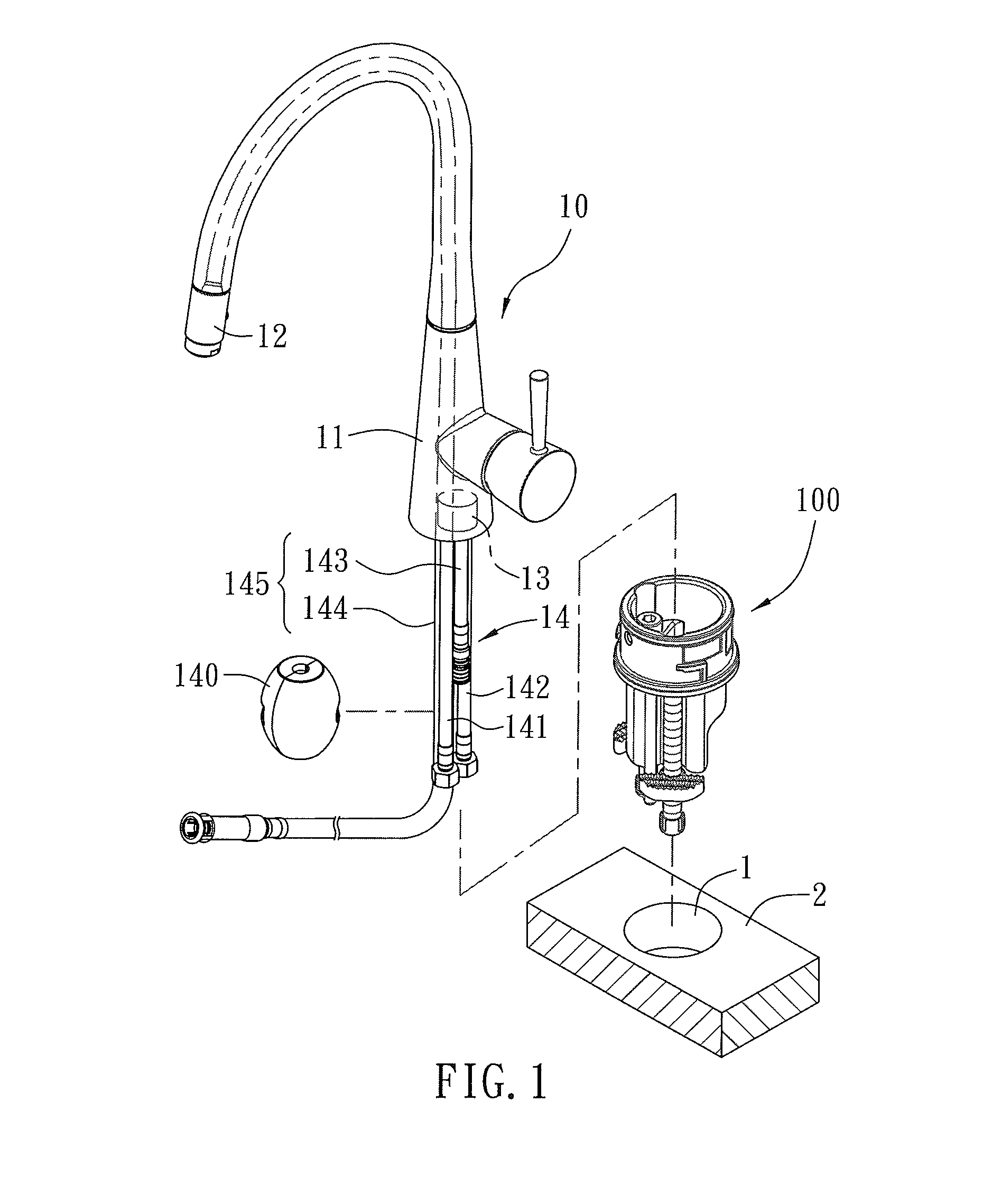

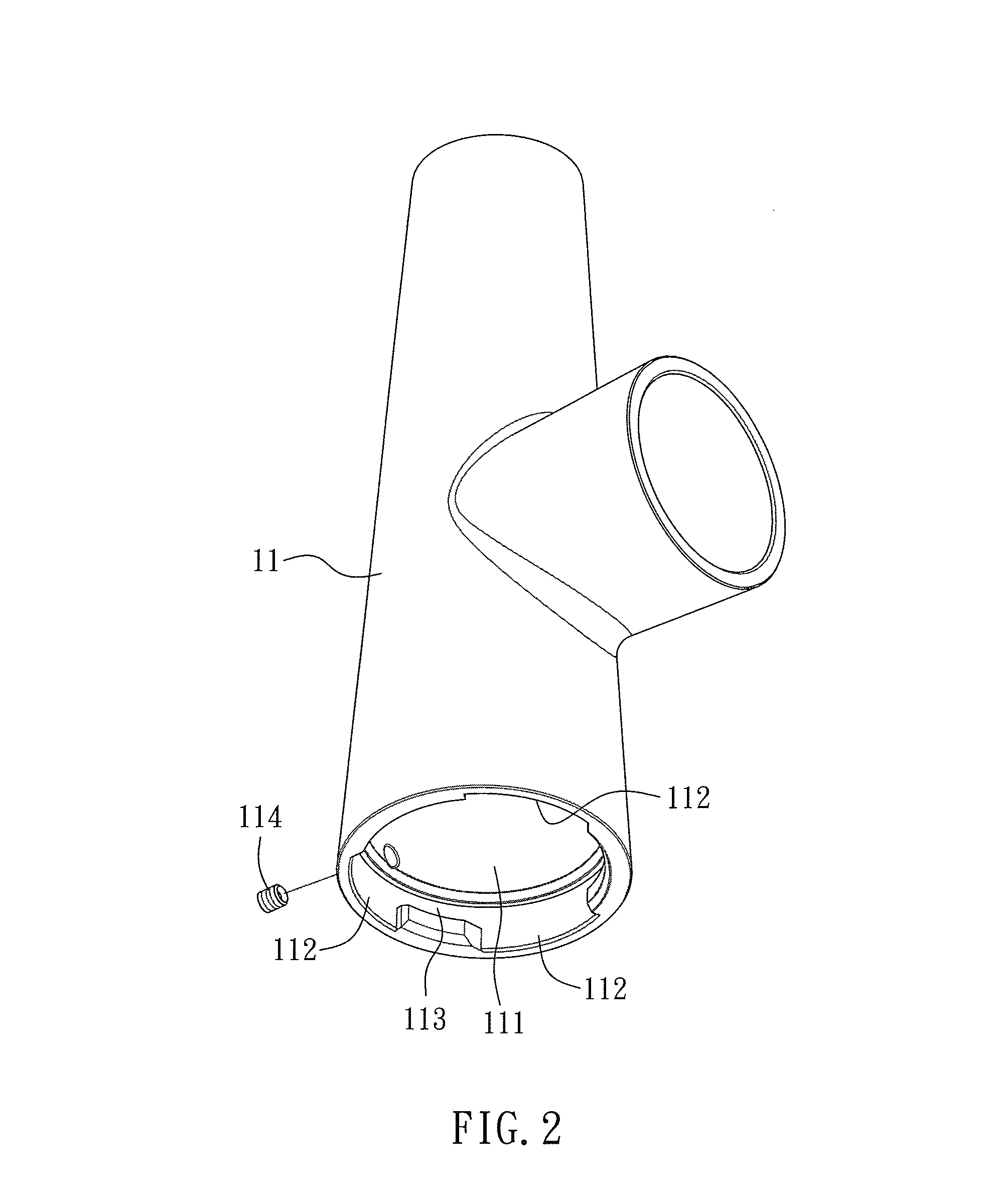

Fixing Structure of Faucet

ActiveUS20140075667A1Easy and quick fixDomestic plumbingThin material handlingEngineeringThermal water

A fixing structure of a faucet is fixed on a sink countertop with a hole and contains a faucet having a housing, a pull-out spray head, a mixing valve, and a water supply set. The water supply set includes a cold-water inlet pipe, a hot-water inlet pipe, and a mixing outlet pipe. A positioning device includes a base having a peripheral fence, a bottom fence, and a mouth. The bottom fence has a limiting face and at least one orifice, the limiting face has a channel, two stop posts, and an abutting face. Two screw rods extend out of the hole and are rotated above the base. Two clamping blocks are screwed with the two screw rods and are limited by the two stop posts to rotate when the two screw rods are rotated, and the two clamping blocks move upwardly to retain a bottom end of the sink countertop.

Owner:GLOBE UNION INDAL

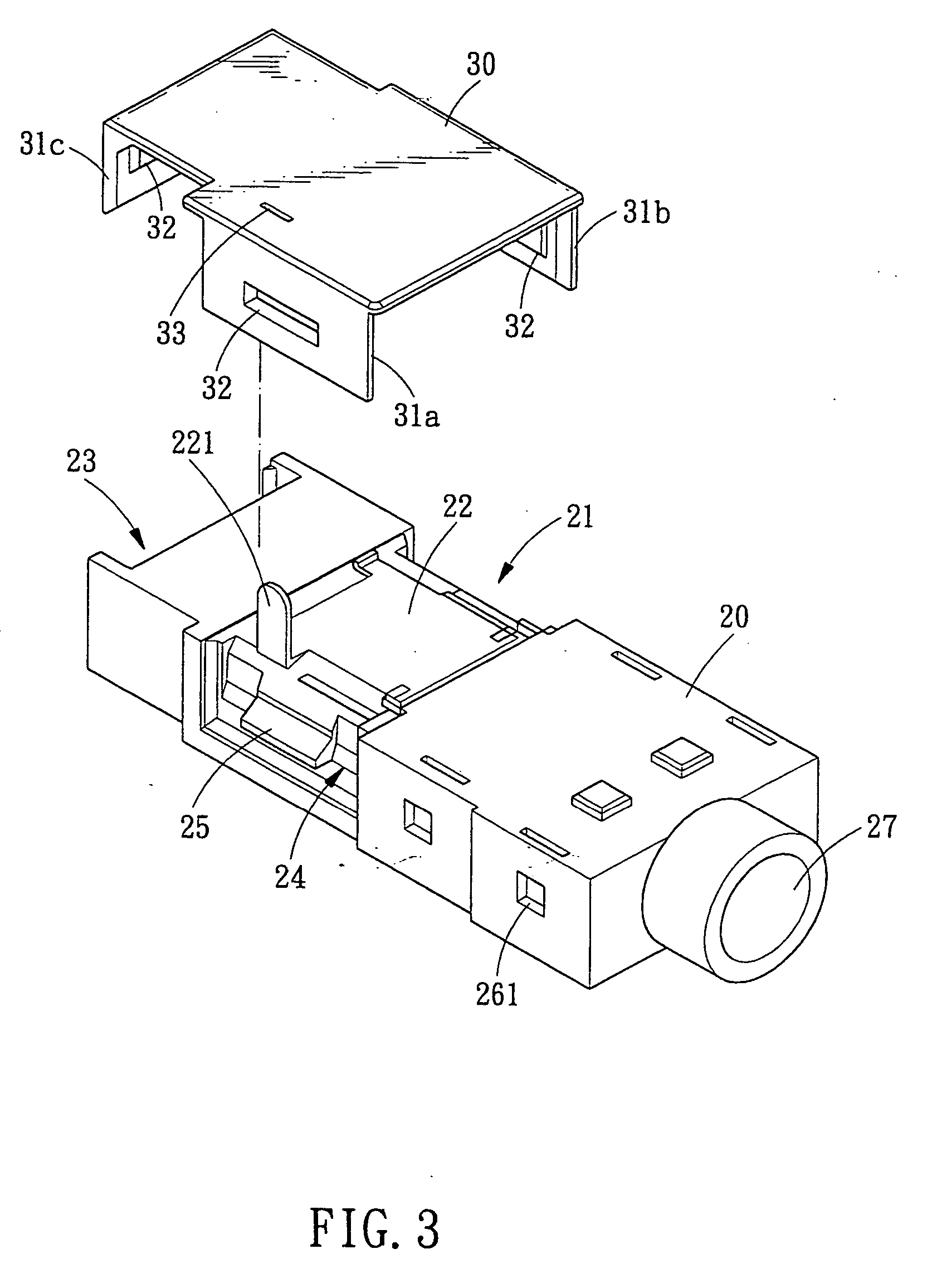

Earphone connector assembly

InactiveUS20060083399A1Easily assembleDecrease costTwo pole connectionsCoupling device detailsHeadphonesEngineering

The present invention relates to an earphone connector assembly which comprises: a connector, a cover and a plurality of independent terminals. The connector is provided with a plurality of sockets, in the sockets are formed retaining holes, and the independent terminals are provided with non-return flap in response to the sockets. With the help of the non-return flap and the retaining hole, the independent terminal can be quickly and easily fixed in the sockets of the connector. Thereby, the earphone connector of the present invention can be easily assembled and the cost is accordingly decreased.

Owner:YANG JOHNSON

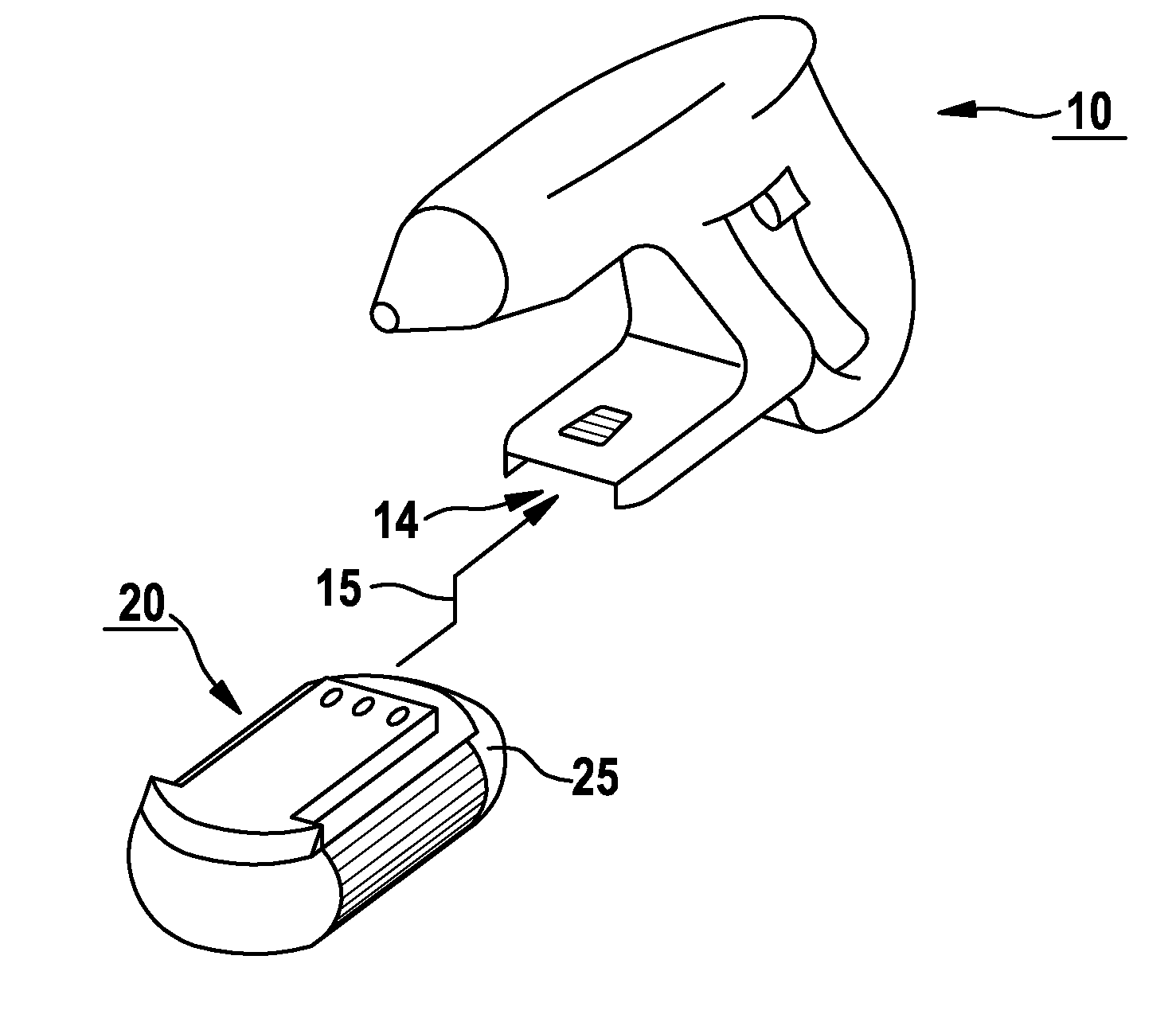

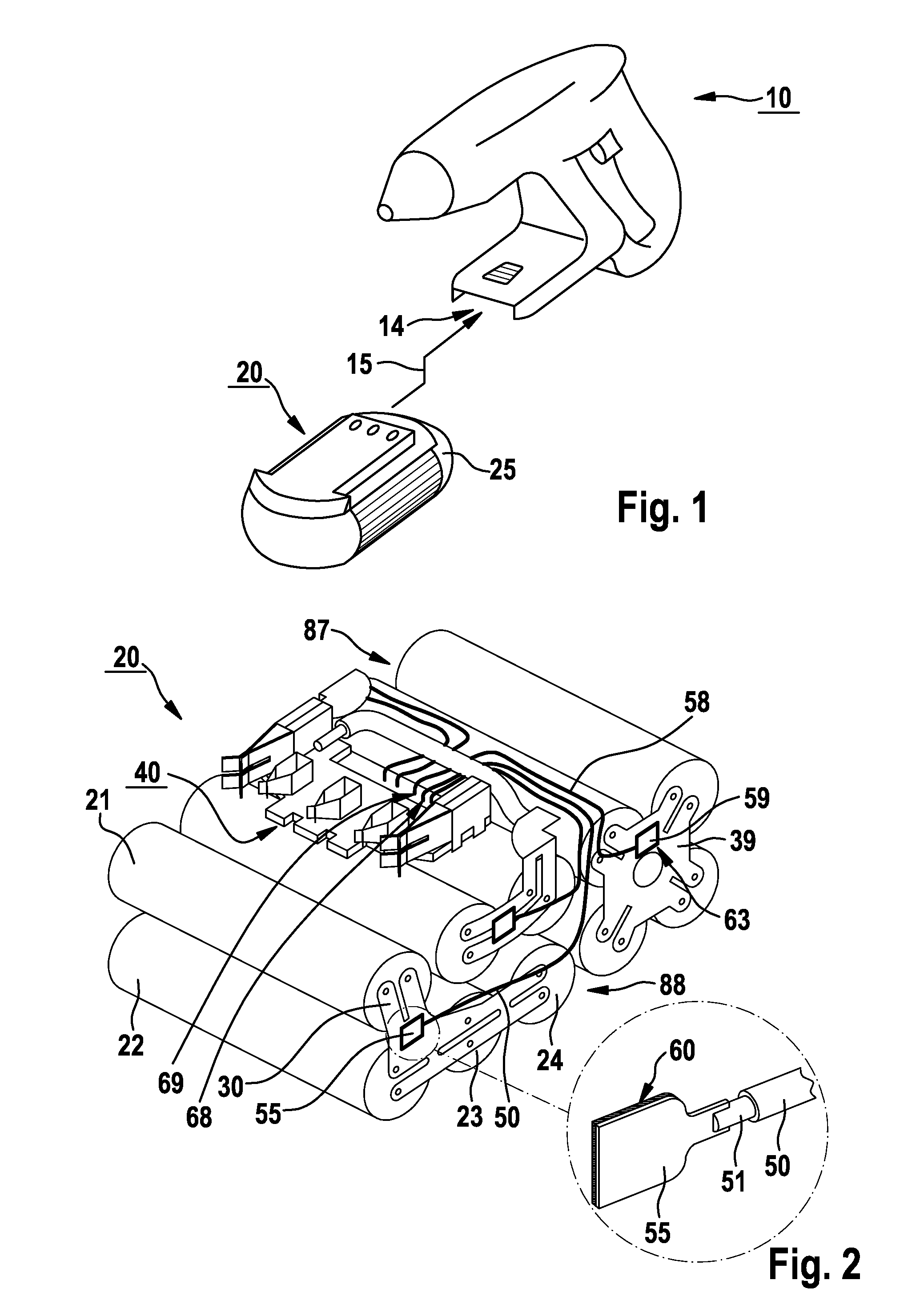

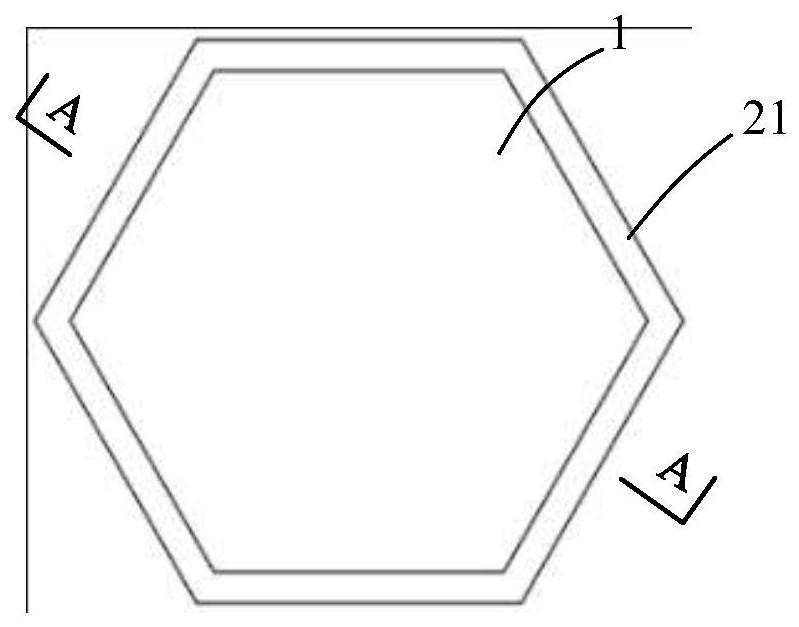

Making electrical contact with a rechargeable battery having a plurality of rechargeable battery cells

ActiveUS20110180291A1Avoid contactContact errorDrilling rodsConstructionsElectricityElectrically conductive adhesive

In a rechargeable battery (20) having a plurality of rechargeable battery cells (21, 22, 23,24), wherein at least one rechargeable battery cell (21) is connected to an electronic component (40), which is associated with the rechargeable battery (20), via an electrical line (50), the electrical line (50) has at least one contact element (55) which is electrically conductively connected to the at least one rechargeable battery cell (21) by means of an electrically conductive adhesive (60).

Owner:ROBERT BOSCH GMBH

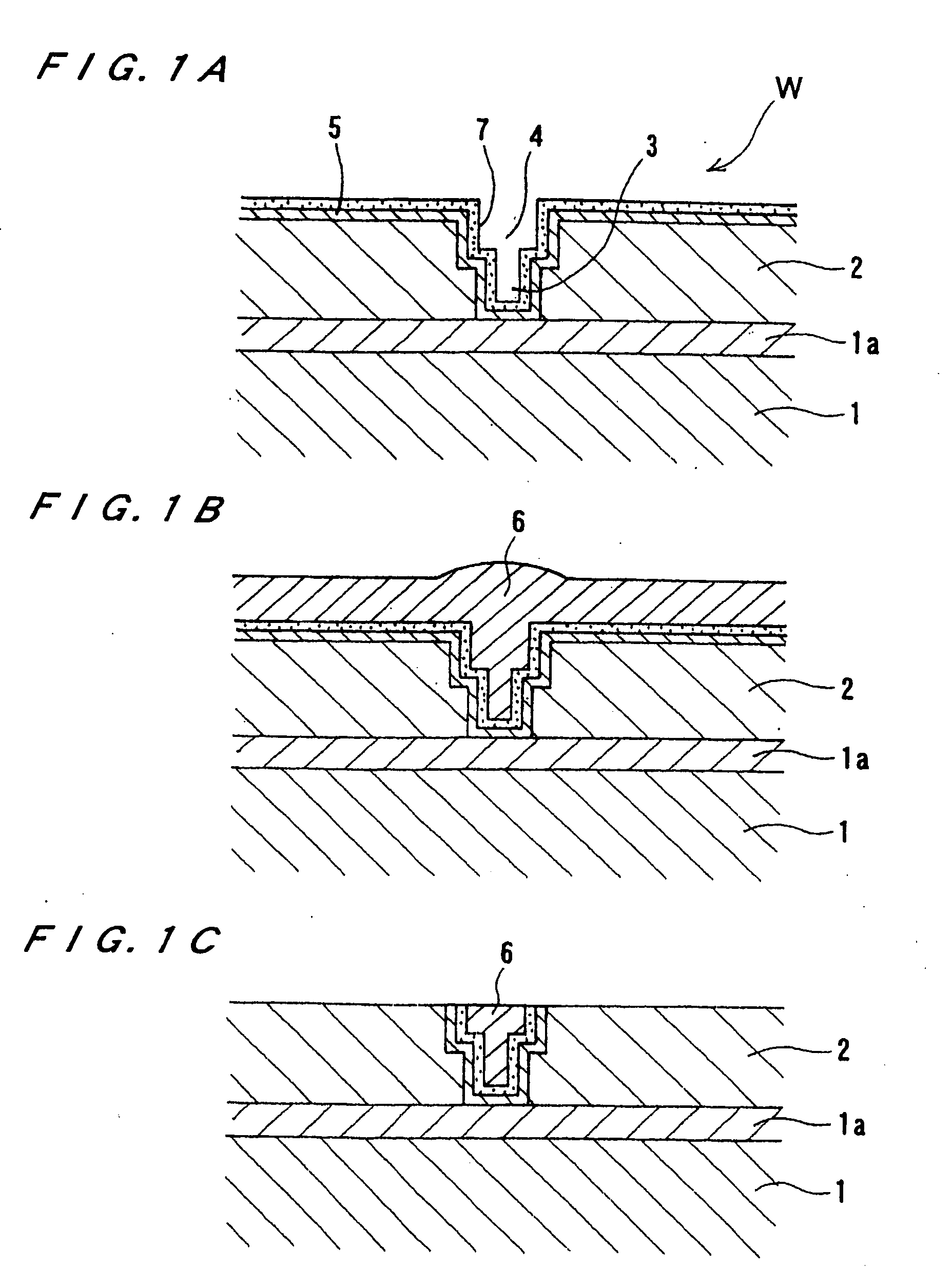

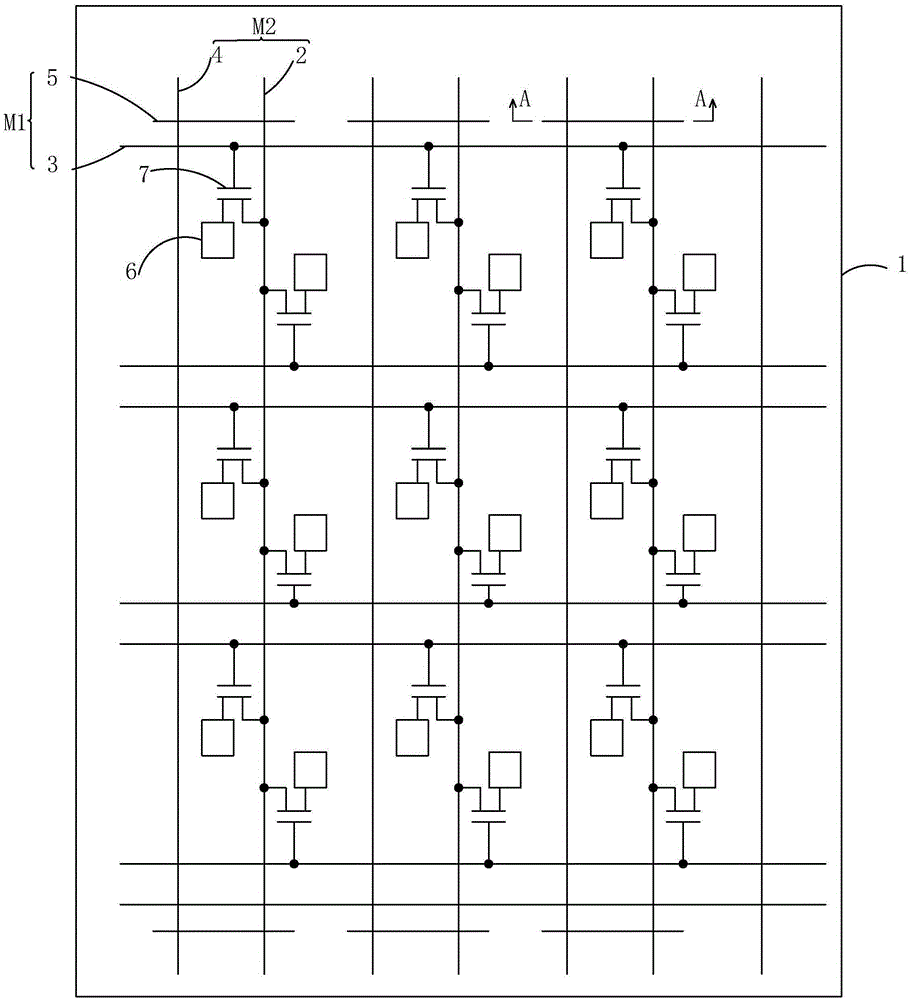

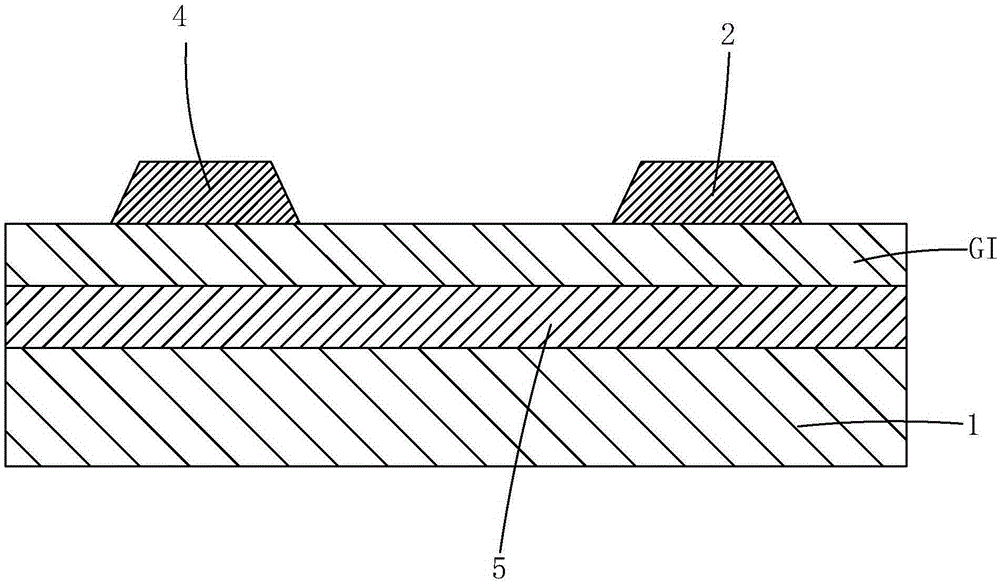

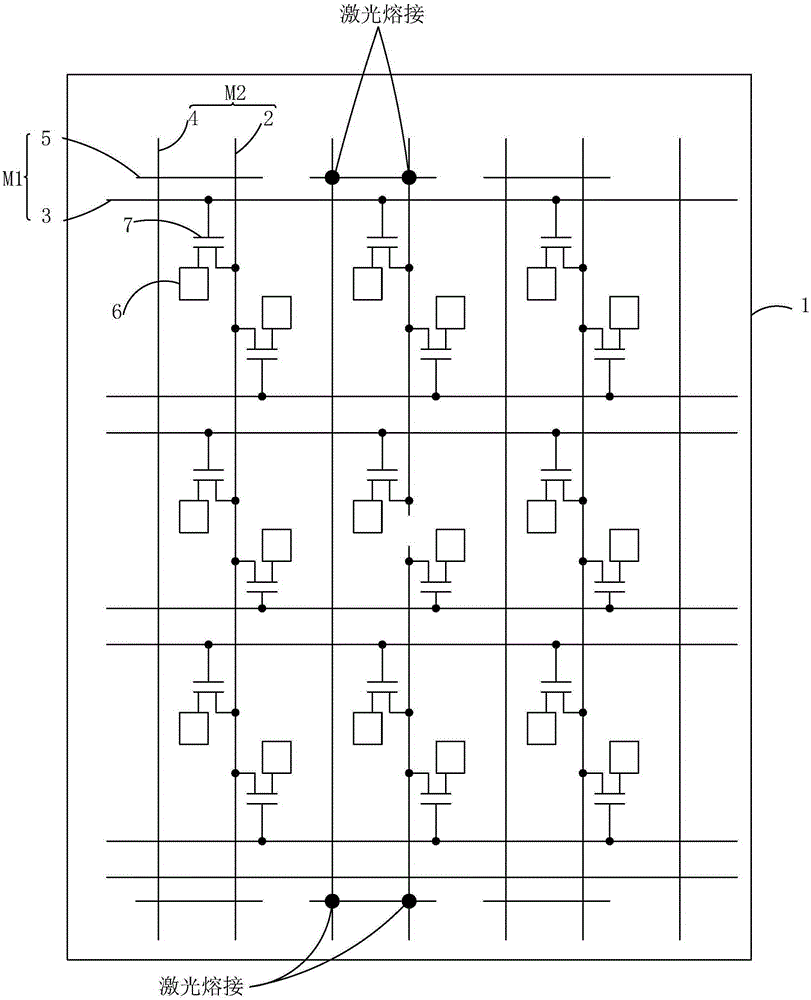

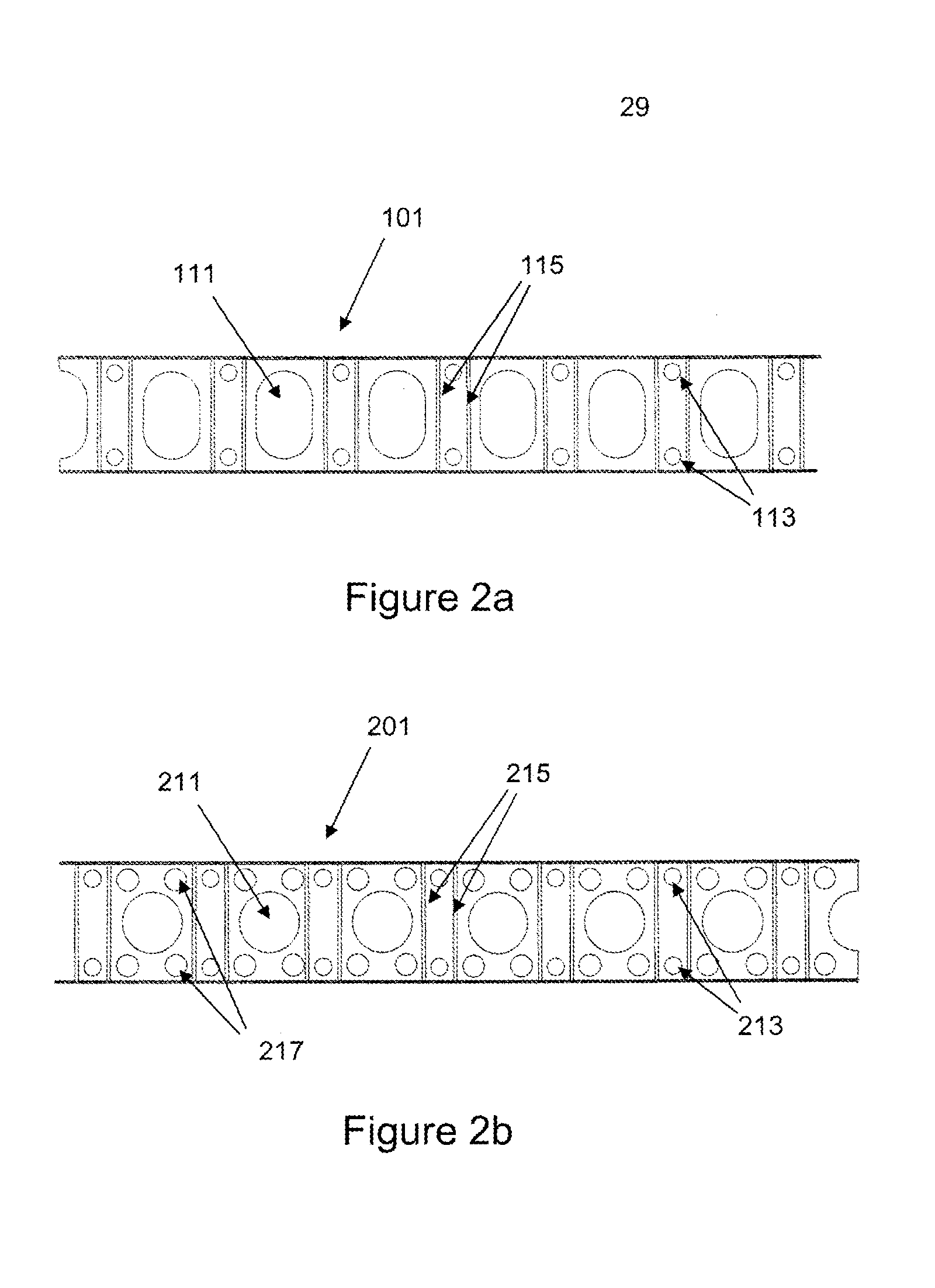

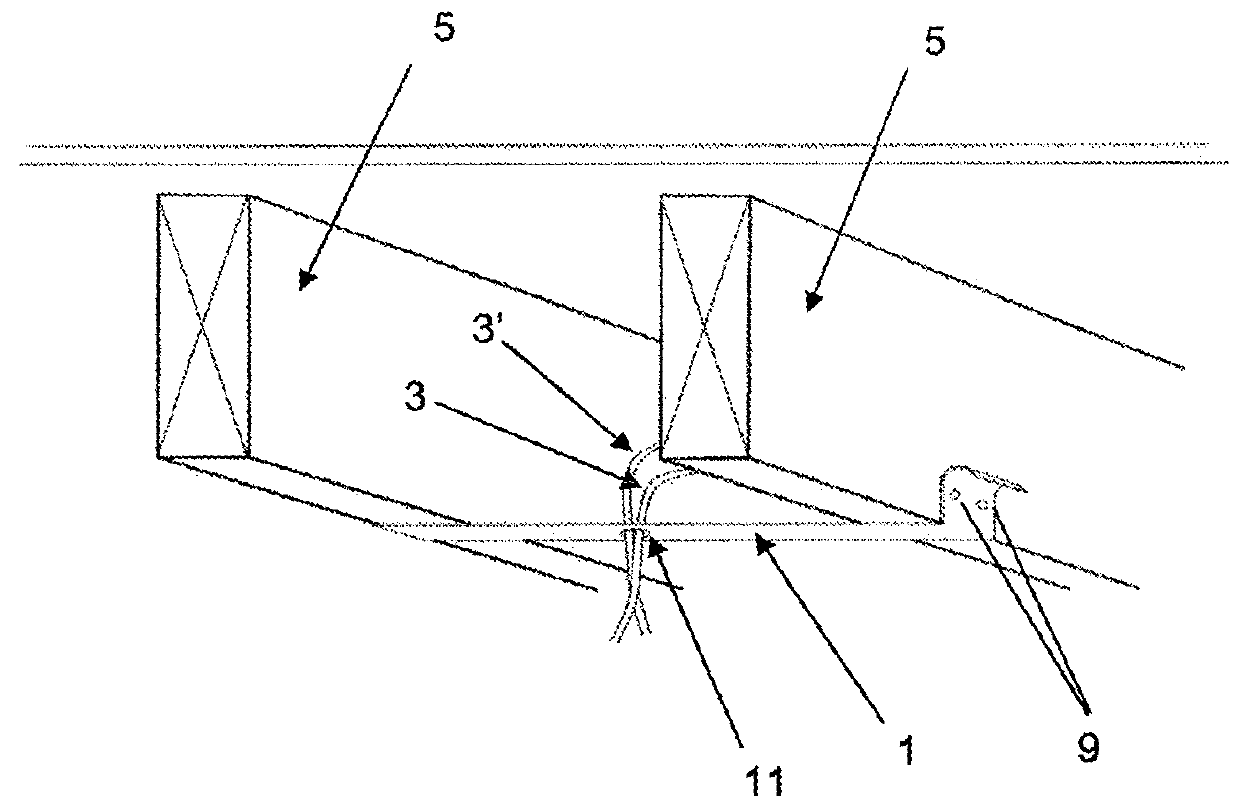

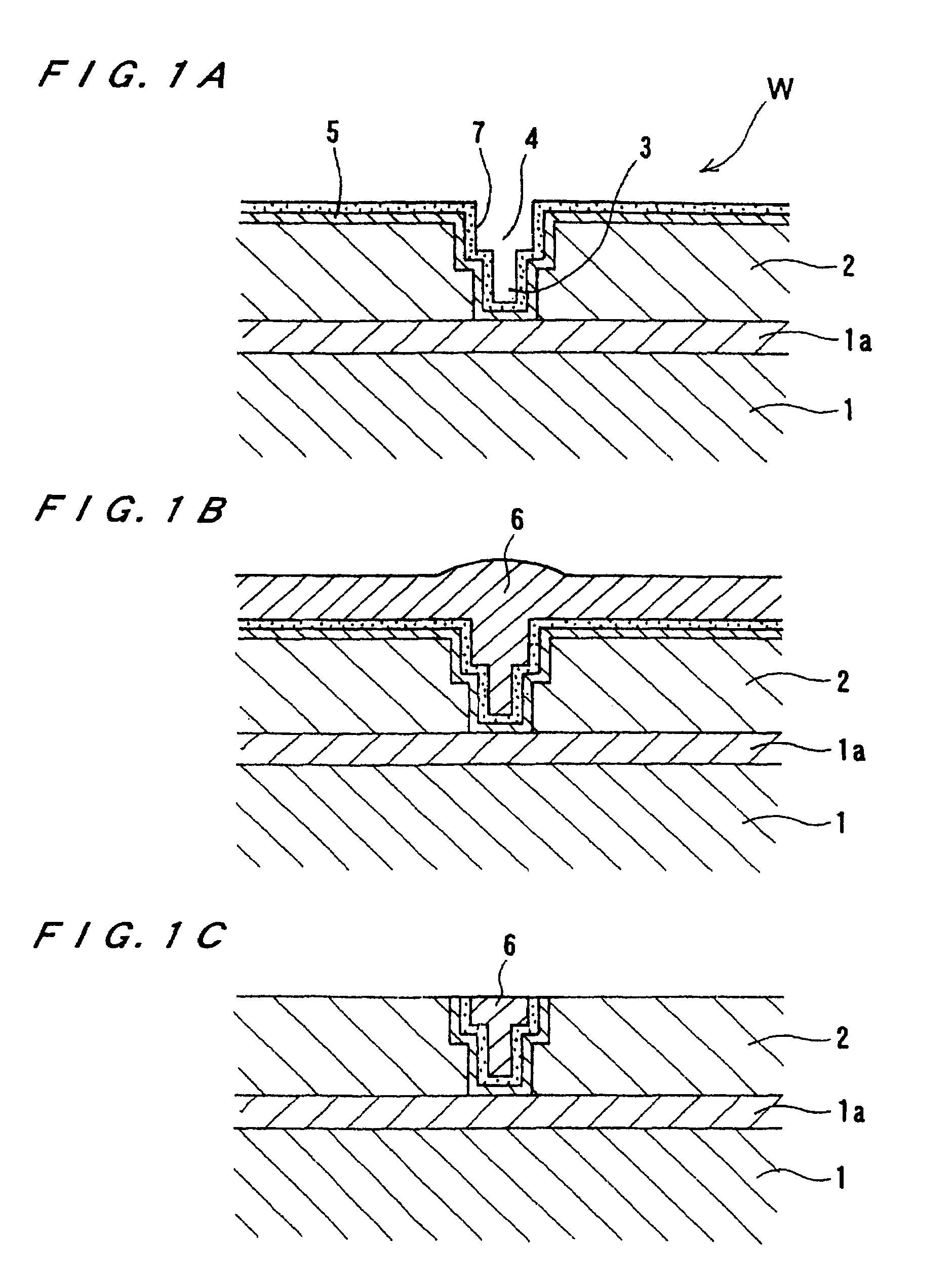

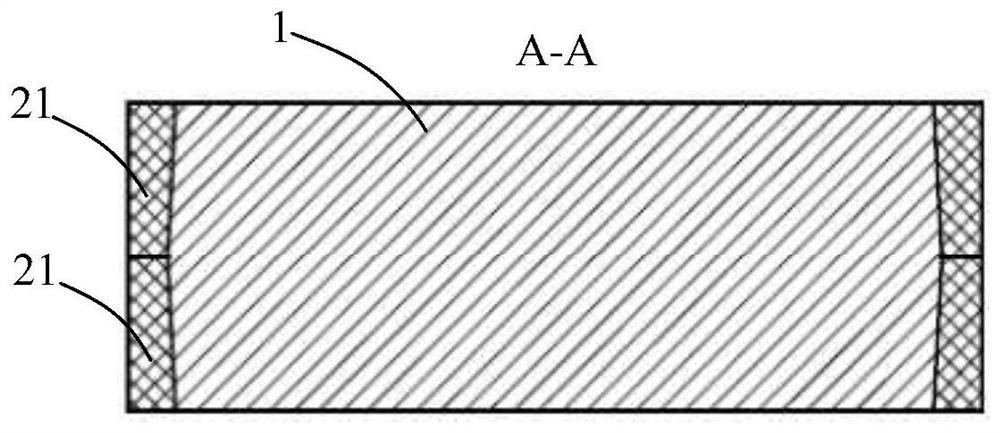

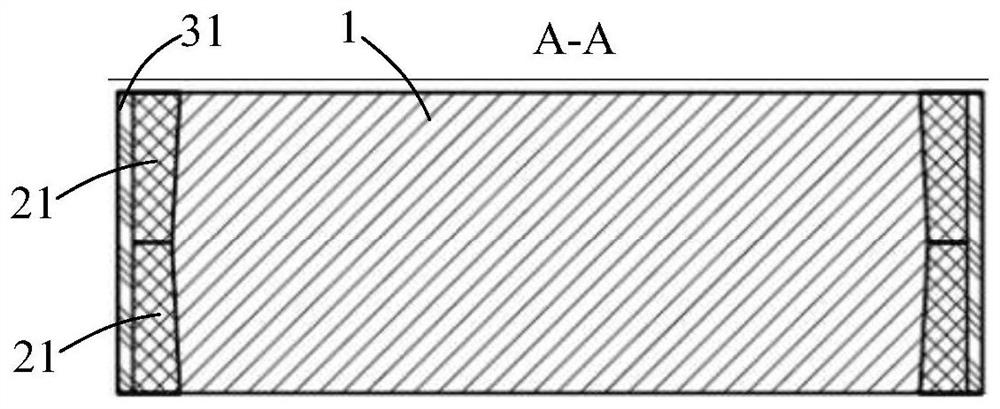

Array substrate structure and data line breakage repairing method for array substrate

InactiveCN105301809ABroken RepairEasy and fast disconnectionNon-linear opticsArray data structureFusion welding

The invention provides an array substrate structure and a data line breakage repairing method for an array substrate. Standby data lines (4) corresponding to data lines (2) one by one are arranged, repairing lines (5) are arranged below the two ends of each data line (2) and the two ends of the corresponding standby data line (4) respectively, and when the data lines (2) are broken, the broken data lines (2), the corresponding repairing lines (5) and the corresponding standby data lines (4) can be connected together only by performing laser fusion welding on intersecting points of the broken data lines (2) and the corresponding repairing lines (5) and intersecting points of the corresponding standby data lines (4) and the corresponding repairing lines (5). The broken data lines of the array substrate can be easily and rapidly repaired, the repairing efficiency of the broken data lines of the array substrate can be improved, and the repairing success rate of the broken data lines of the array substrate can be increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Cable positioning arrangement

ActiveUS20120298596A1Convenient ArrangementEasy and quick fixPipe supportsMetal working apparatusEngineeringMechanical engineering

Owner:JONES WARREN NIGEL

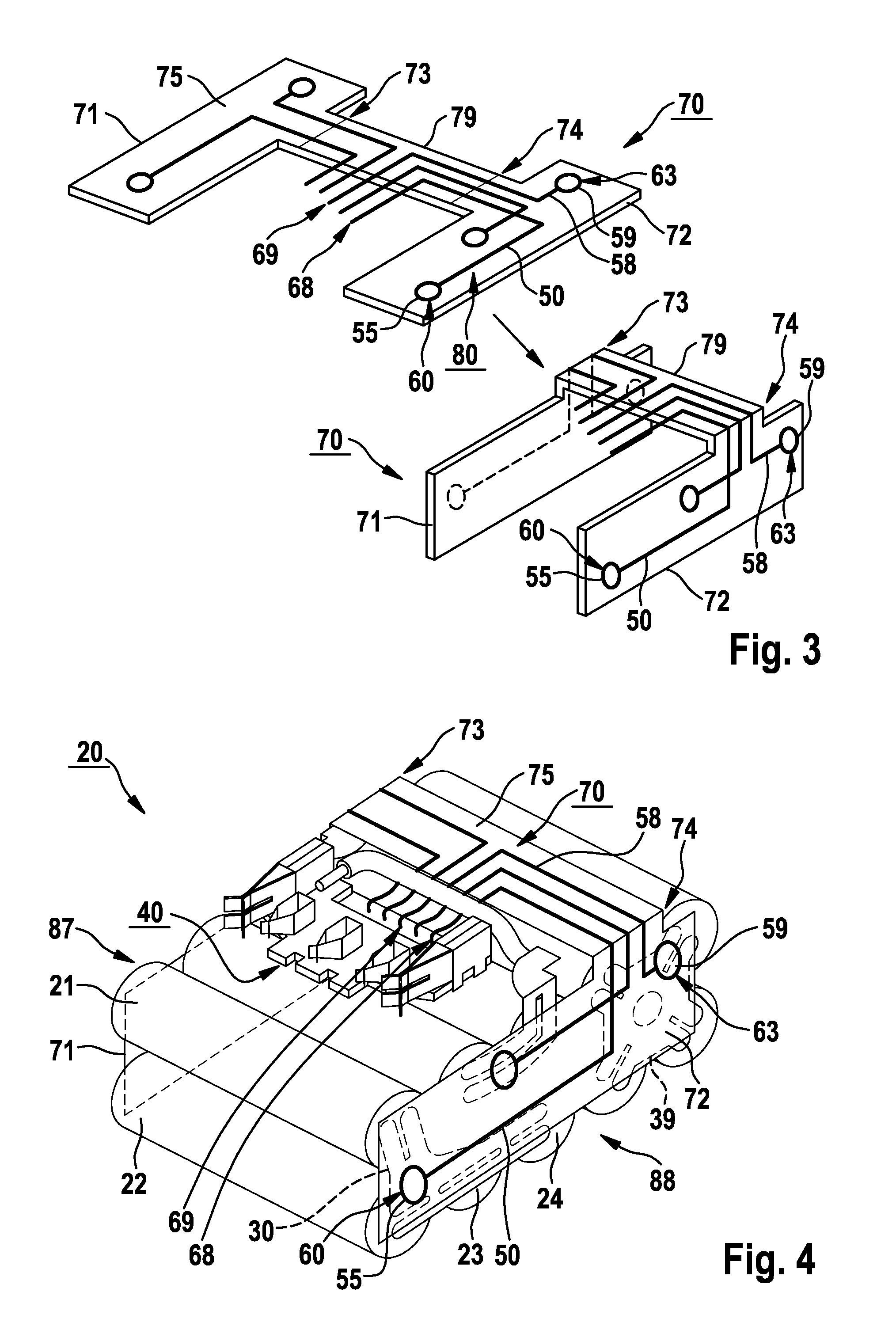

Circuit board device and a combined circuit board and electronic card assembly

ActiveUS20130072038A1Easily and quickly fix and permitShorten timeCoupling device connectionsElectrical apparatus contructional detailsEngineeringElectrical and Electronics engineering

A circuit board device for fixing an electronic card, which is formed with at least one aperture, includes a circuit board and a securing member. The circuit board includes a board body formed with two through holes, and a socket connector provided on the board body for mating with the electronic card. The securing member includes a pressing plate for pressing against the electronic card, at least one engaging stud projecting from a bottom end of the pressing plate for engaging the aperture, and two resilient engaging arms provided respectively on left and right sides of the pressing plate. The engaging arms extend respectively through the through holes and engage releasably the board body.

Owner:WISTRON CORP

Cable positioning arrangement

ActiveUS9385513B2Convenient ArrangementEasy and quick fixMetal working apparatusCable installation apparatusMechanical engineeringEngineering

Owner:JONES WARREN NIGEL

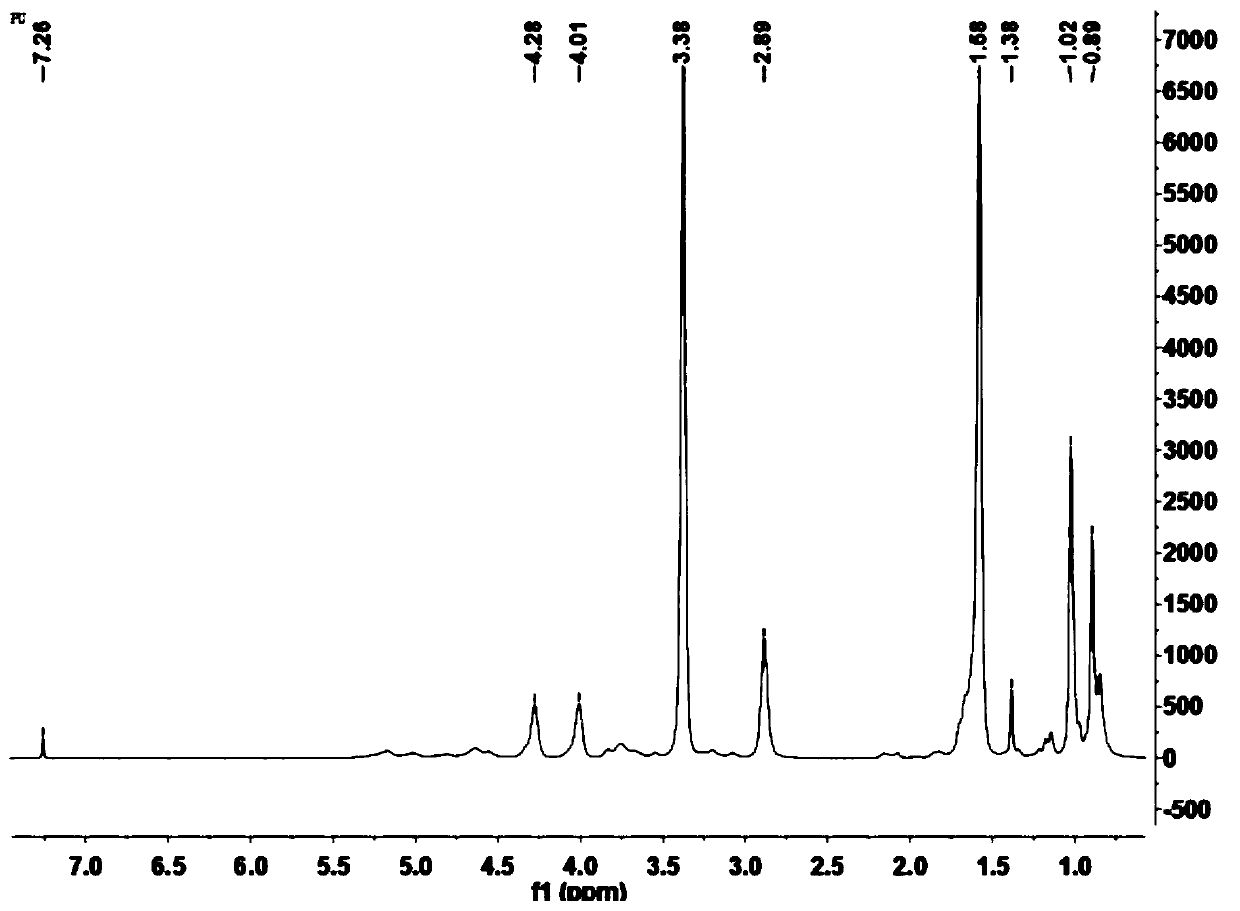

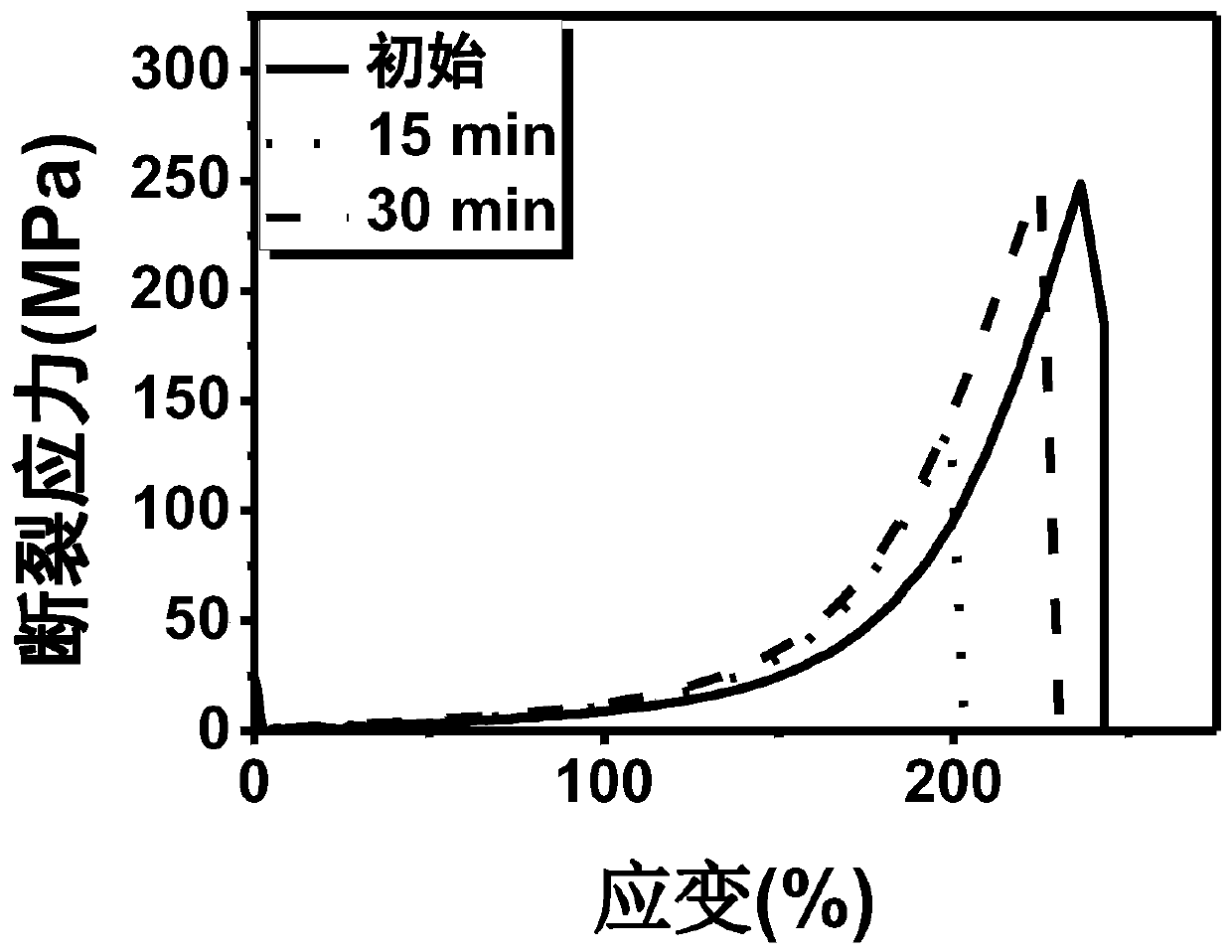

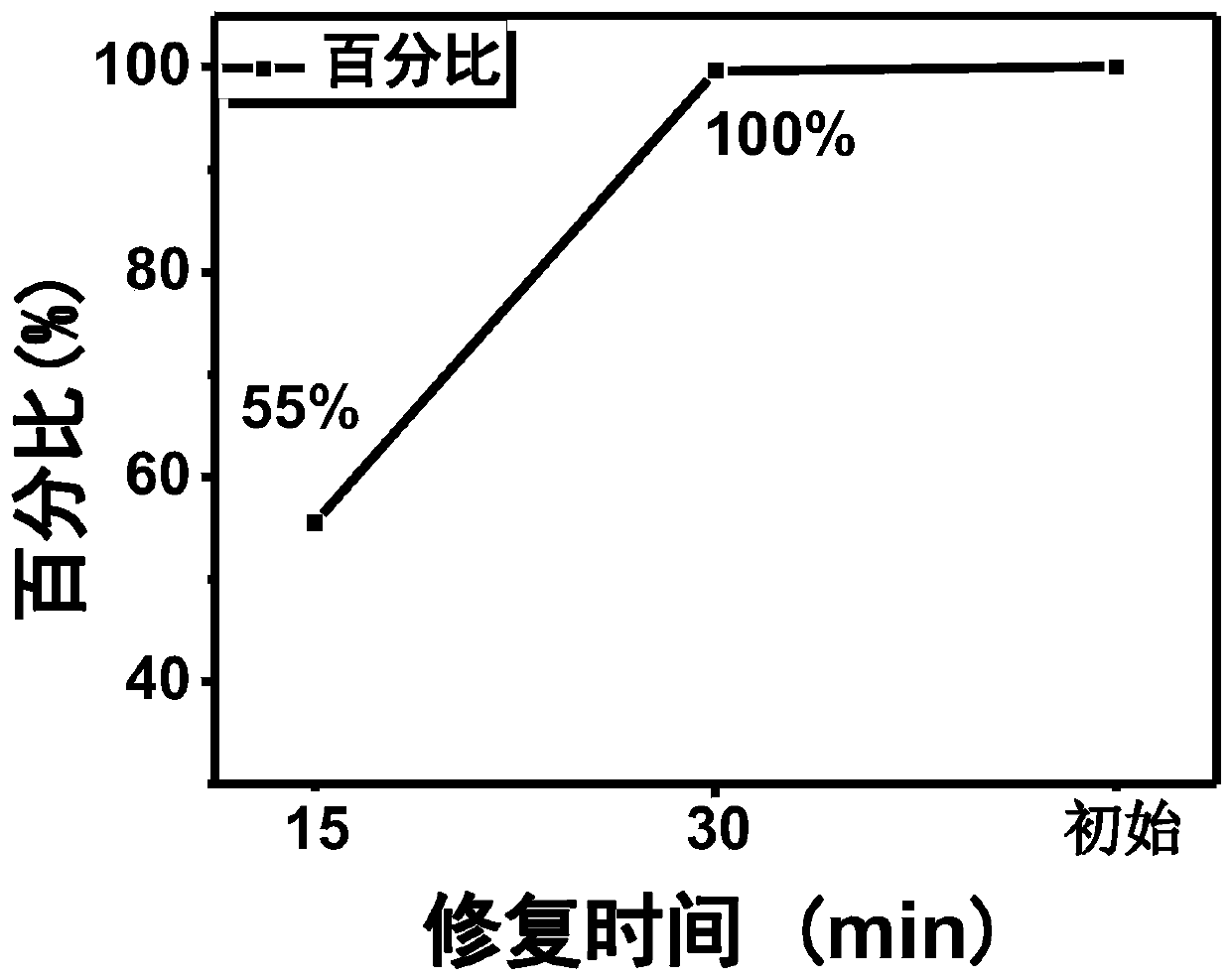

Polyurethane self-repairing film, preparation method and self-repairing degree detection method

ActiveCN111434721AQuick fixEasy and quick fixMaterial strength using tensile/compressive forcesLuminous intensityPhoto irradiation

The invention discloses a polyurethane self-repairing film, a preparation method and a self-repairing degree detection method. The detection method comprises the following steps of: cutting the polyurethane self-repairing film into two pieces; butting the tangent planes together; irradiating for 30 to 40min by using a mercury lamp with a 365nm optical filter at 40-50 DEG C to achieve repairing; stretching, collecting breaking stress-strain data in the stretching process through a rheometer, taking a light-emitting picture in the stretching process through a camera, comparing the breaking stress-strain data and the light-emitting picture, and detecting the self-repairing degree of the polyurethane self-repairing film. The polyurethane self-repairing film disclosed by the invention can realize rapid repairing under certain conditions, is simple and rapid in repairing process, and can be used as an outdoor film. The self-repairing degree can be detected through the luminous intensity in the stretching process, and compared with a traditional method for detecting the self-repairing degree through breaking stress, the method is more visual and can be observed through naked eyes.

Owner:TIANJIN UNIV

Laser repair remanufacture method of automobile engine crankshaft

InactiveCN105862028AImprove wear resistanceImprove fatigue strength and service lifeMetallic material coating processesWorking lifeCorrosion

A laser repair remanufacture method of an automobile engine crankshaft relates to the technical fields of machine manufacture and material treatment, processing and application. First, laser cladding treatment is carried out on the damage zone of the crankshaft, and cladding is supplied in a manner of preset laser cladding. Then, the surface of the damage zone of the crankshaft is coated with an absorbing layer, and laser shock treatment is carried out on the damage zone of the crankshaft under the protection of a constrained layer. In the invention, the wear resistance, corrosion resistance and oxidation resistance of a metal surface are improved, the fatigue strength of materials is greatly improved, the service life of the materials is greatly prolonged, the fretting fatigue resistance of the crankshaft surface is effectively improved, the occurrence of fatigue cracks is inhibited, and the expansion rate of the fatigue cracks is reduced. Therefore, the treatment method greatly improves the wear resistance, corrosion resistance and fatigue strength of the materials, thereby prolonging the working life of the automobile engine crankshaft.

Owner:JIANGSU UNIV

Continuous grinding mechanism based on grinding belt surface self-growth

ActiveCN104907918ASimple structureImprove efficiencyBelt grinding machinesLapping machinesWear particleEngineering

The invention discloses a continuous grinding mechanism based on grinding belt surface self-growth. The continuous grinding mechanism based on the grinding belt surface self-growth comprises a grinding belt, a water tank, an abrasive particle injector head, a UV light lamp tube, a workpiece installing head, a double-directional cylinder and a base station; the water tank is filled with UV light solidified coatings, an idler wheel is installed in the water tank, two idler wheels which are higher than the water tank are installed on two sides of the water tank, when the grinding belt moves, the grinding belt firstly enters the water tank, after the grinding belt moves out of the water tank and moves to be horizontal, the surface of the grinding belt is covered with the UV light solidified coatings, and grinding belt surface self-growth is conducted; the abrasive particle injector head is installed above the horizontal position of the grinding belt, the UV light lamp tube is installed on the back face of the abrasive particle injector head, and the height of the workpiece installing head can be adjusted through the double-directional cylinder, the height can be maintained until workpiece machining is completed. By means of the structure, restoration of the grinding belt is simple, fast and convenient, dismounting of the grinding belt is not needed, the restoration of the grinding belt and the workpiece machining can be conducted synchronously, and the surface of the restored grinding belt is flatter and neater.

Owner:浙江海宁经编产业园区开发有限公司

Life extension method of pump shell and blade micro-cracks strengthened by laser

InactiveCN103409758BExtended service lifeImprove fatigue strengthMetallic material coating processesLaser processingHeat-affected zone

The invention discloses a method for prolonging life of pump shells and blades by carrying out laser strengthening, which relates to the technical fields of machinery manufacturing and laser processing application. The method adequately combines the characteristics of laser cladding with laser shock strengthening, i.e., the method comprises the steps of performing laser cladding repair on micro-cracks at first, and then performing laser shock strengthening treatment on a cladding layer, thus effectively solving the problem that the pump shells and blades are easy to generate internal defects such as cracks and air holes in the laser cladding repair process, and avoiding the problems of welding deformation, large heat influence area, easy generation of heat cracks and the like in a conventional processing method; the method disclosed by the invention is capable of generating a high-amplitude residual compressive stress on the surface of a material, effectively improving the fretting fatigue resistance of the material, comprehensively improving the mechanical properties of the material, and greatly prolonging the fatigue life of the material, thus achieving the purposes of prolonging the life and improving the reliability and safety.

Owner:JIANGSU UNIV

Clamping apparatus

Owner:EROWA

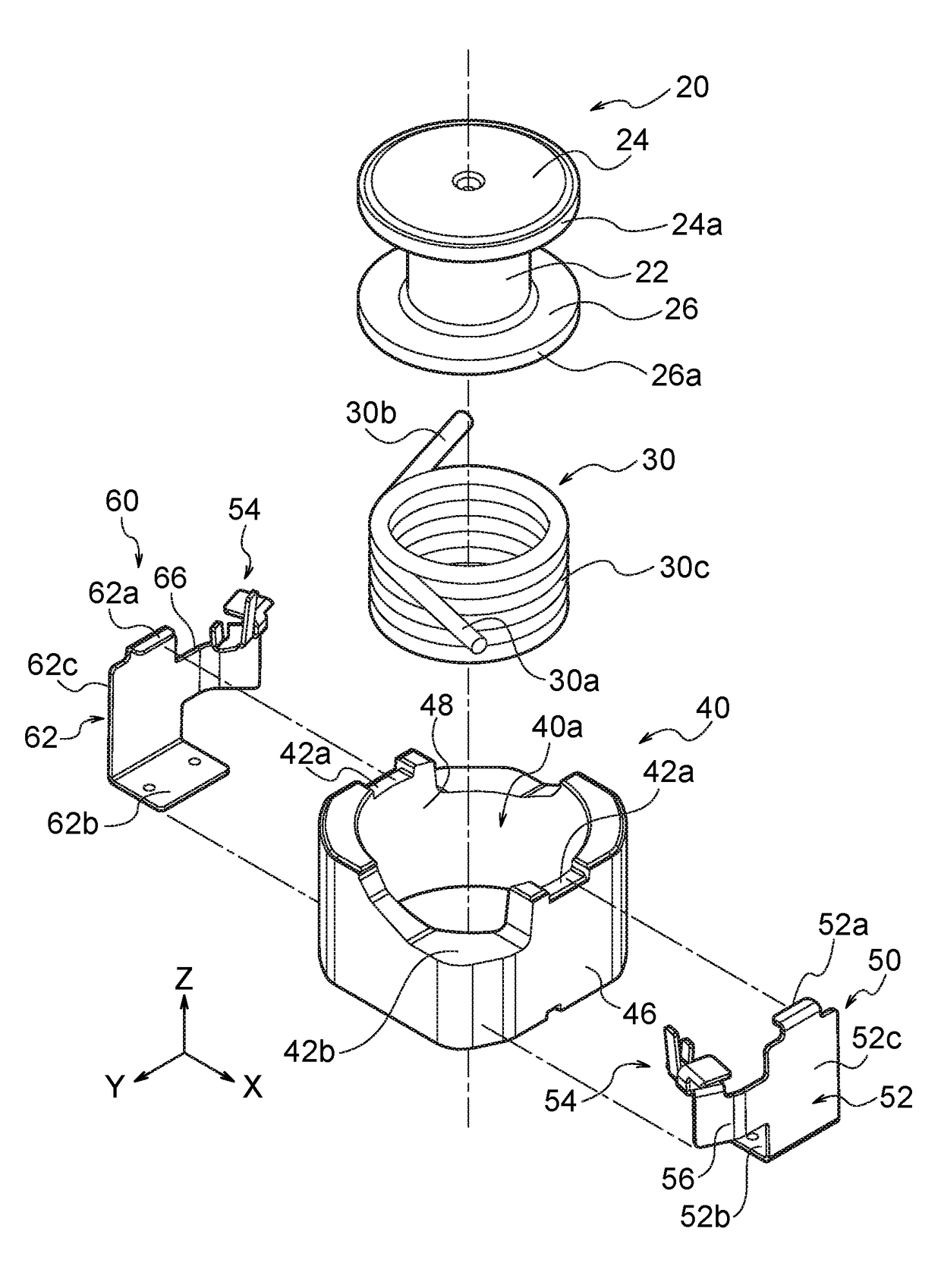

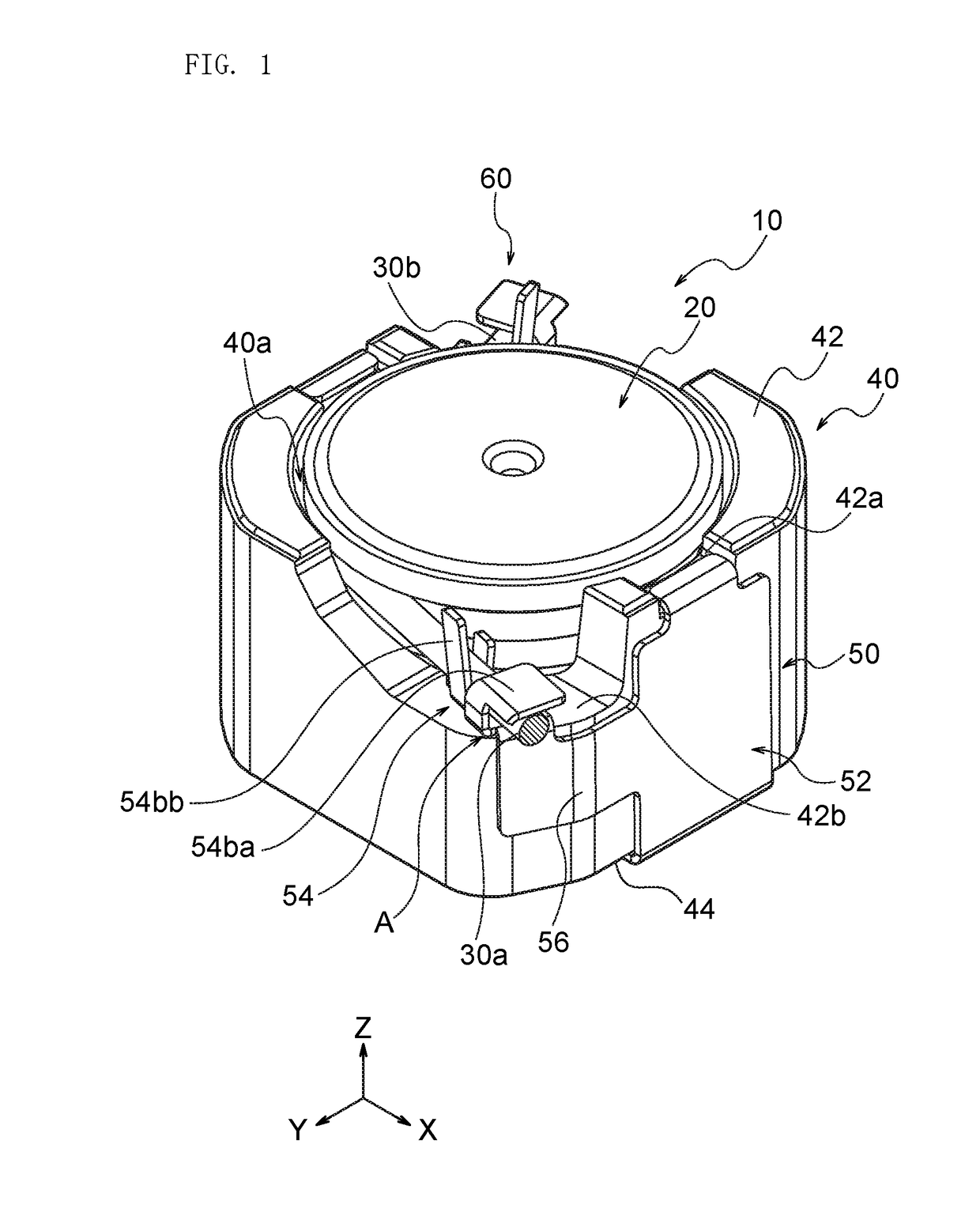

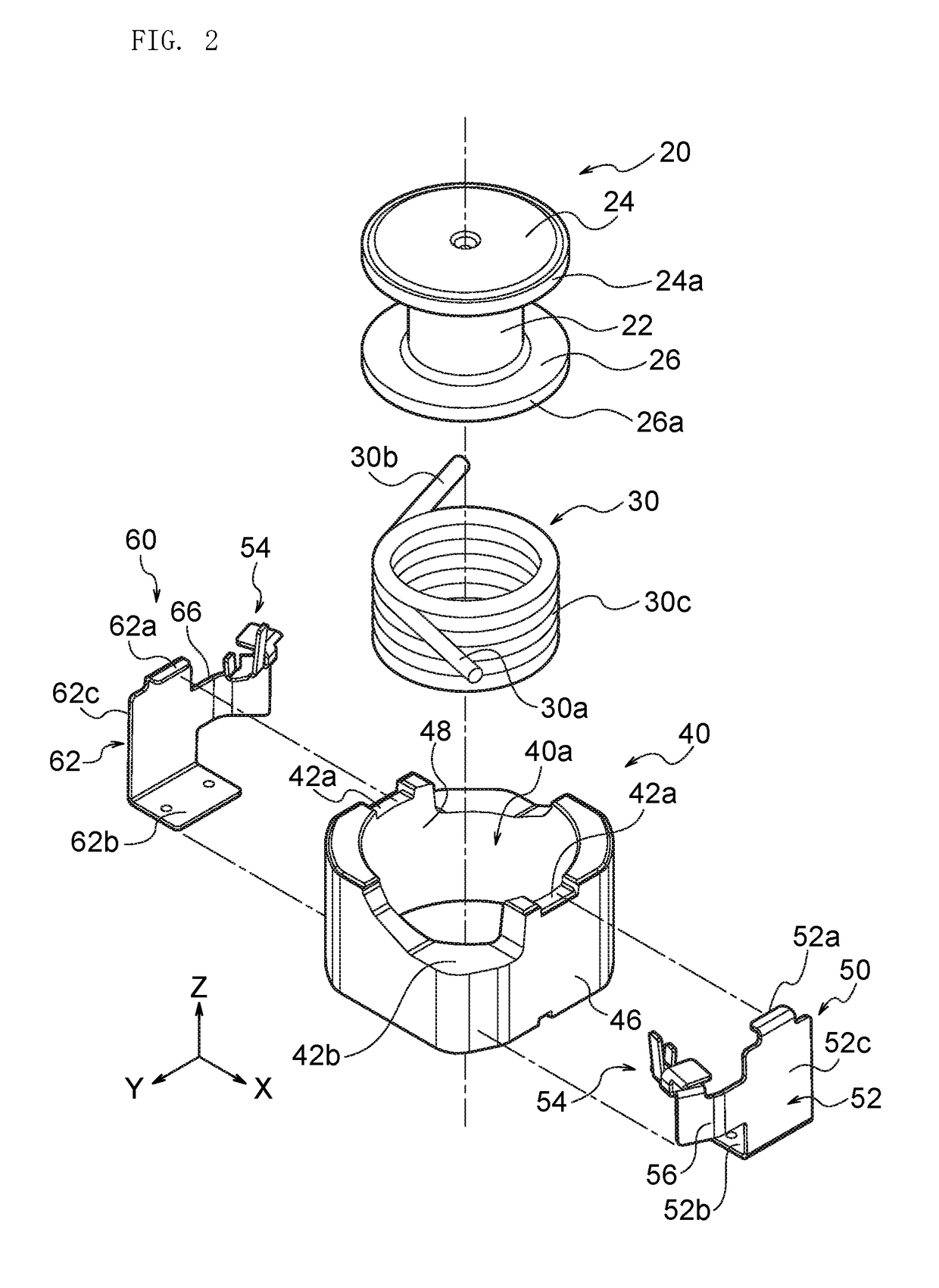

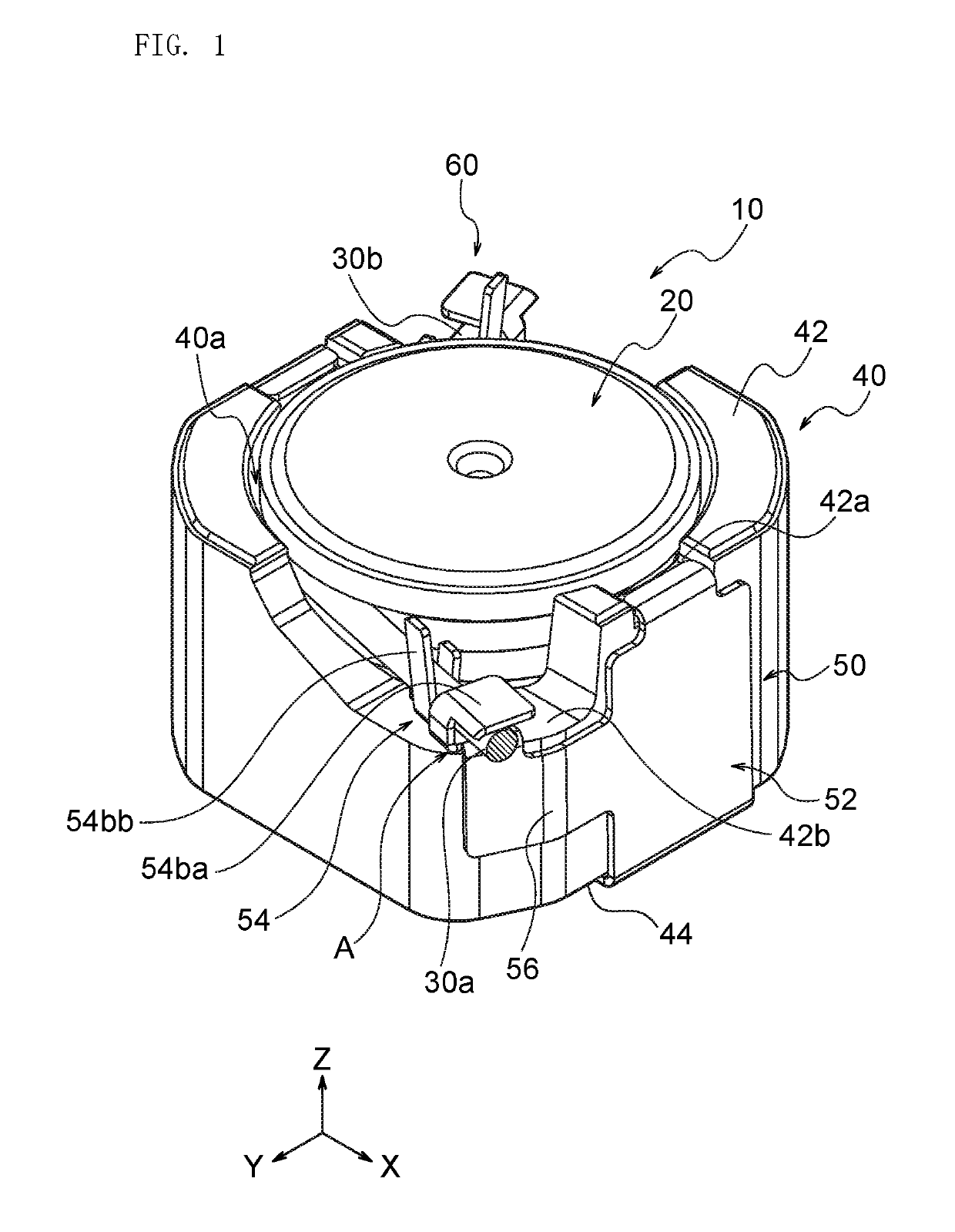

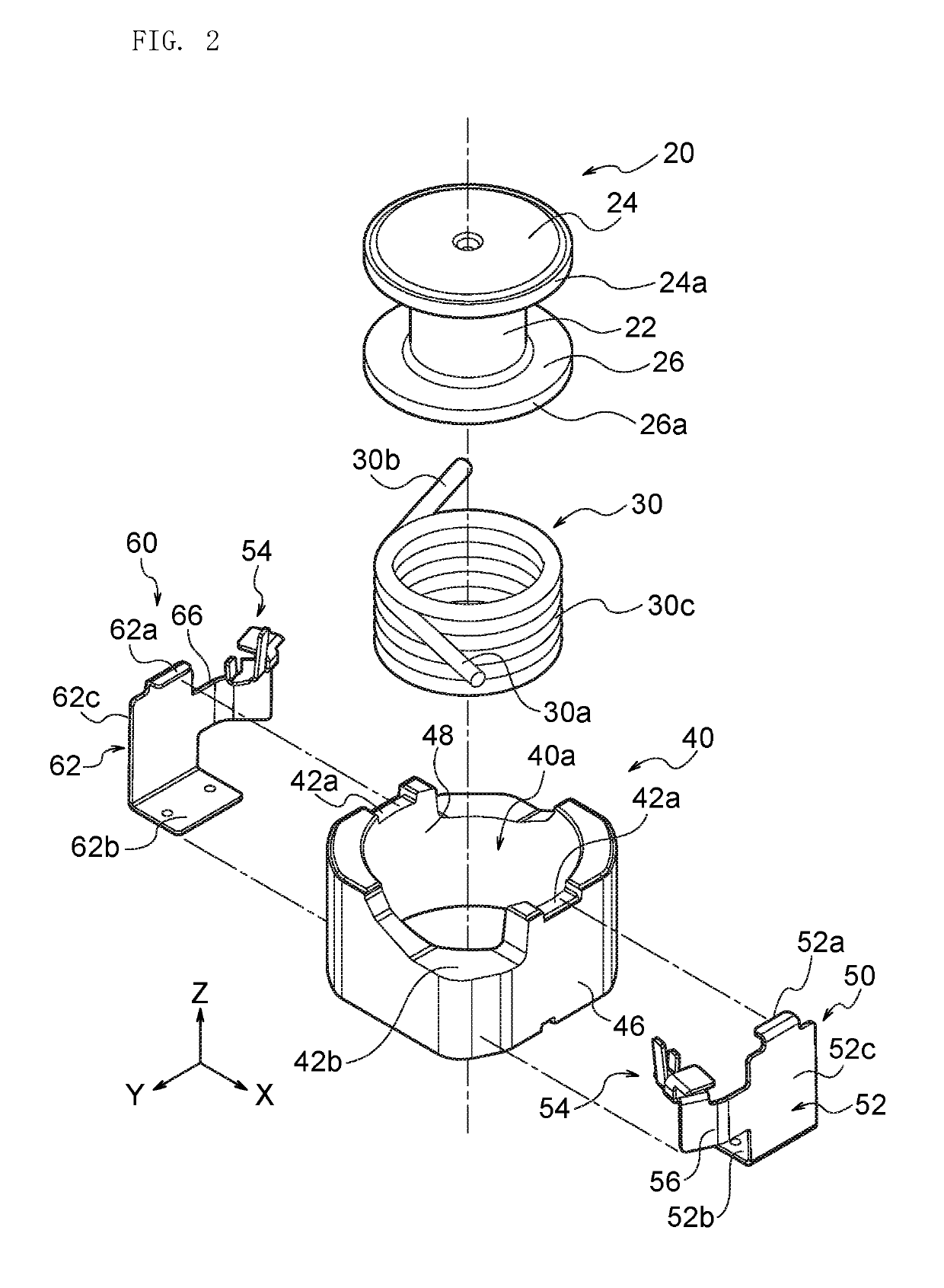

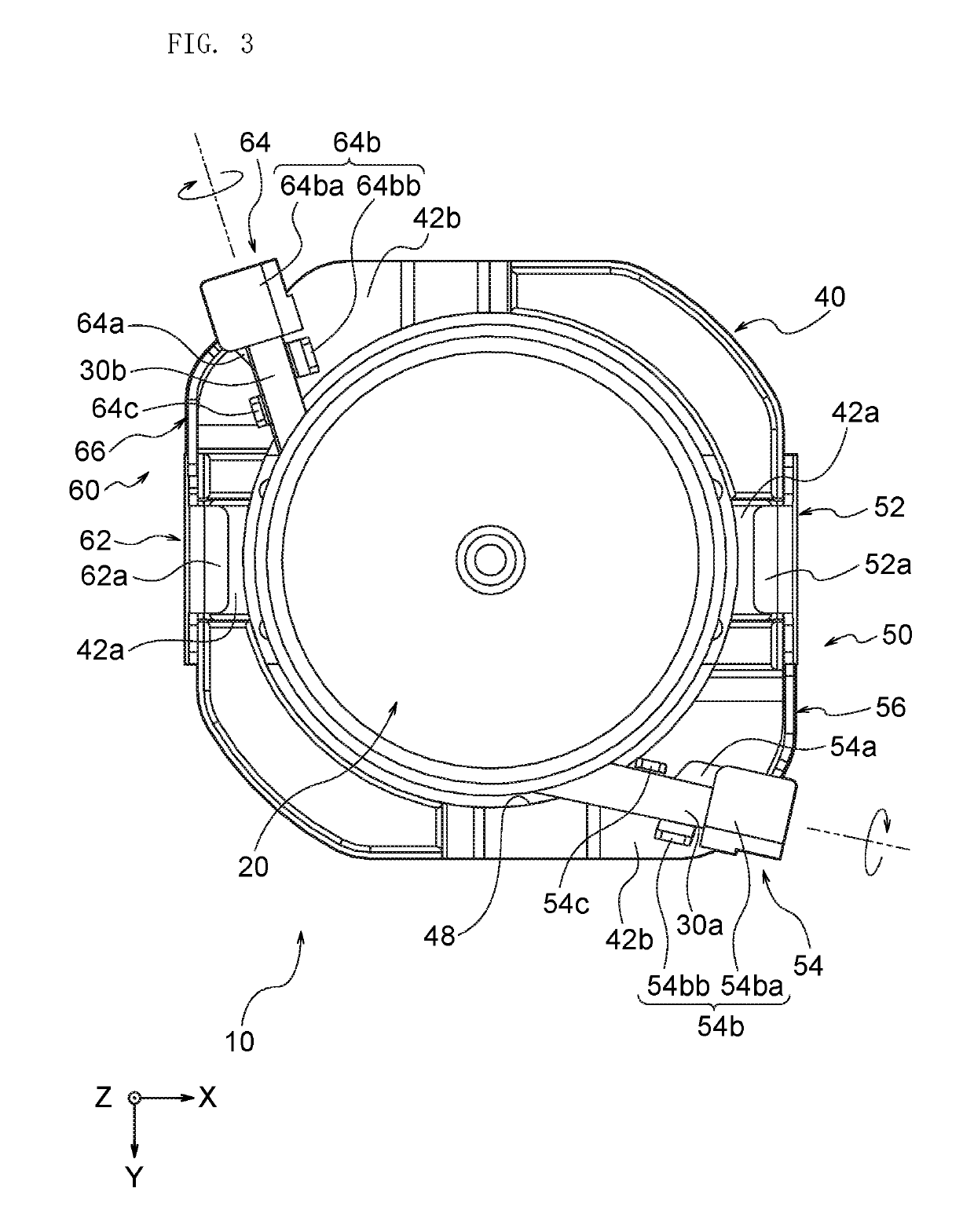

Coil device

ActiveUS20170309392A1Avoid problemsAvoid positioningTransformers/inductances coils/windings/connectionsCores/yokesOuter coreFlange

A coil device includes an inner core having a winding core and a pair of flanges, a wire, an outer core arranged outside the inner core, a first terminal with a first wirebound having a first wirebound bottom arranged axially on a core end surface of the outer core and connected to a first end of the wire, and a second terminal with a second wirebound having a second wirebound bottom arranged on the core end surface and connected to a second end of the wire. The first wirebound has a first wire fixing portion bending from the first wirebound bottom toward a first rotating direction and fixing the first end. The second wirebound has a second wire fixing portion bending from the second wirebound bottom toward the same rotating direction as the first rotating direction and fixing the second end.

Owner:TDK CORPARATION

Electrolytic processing apparatus and method

InactiveUS7655118B2Uniform processingImprove uniformityCellsMachining electric circuitsElectricityElectrolysis

This invention relates to an electrolytic processing apparatus and method useful for processing a conductive material formed in the surface of a substrate, or for removing impurities adhering to the surface of a substrate. An electrolytic processing apparatus, including, a processing electrode that can come close to a workpiece, a feeding electrode for feeding electricity to the workpiece, an ion exchanger disposed in the space between the workpiece and the processing and the feeding electrodes, a fluid supply section for supplying a fluid between the workpiece and the ion exchanger, and a power source. The processing electrode and / or the feeding electrode is electrically divided into a plurality of parts, and the power source applies a voltage to each of the divided electrode parts and can control voltage and / or electric current independently for each of the divided electrode parts.

Owner:EBARA CORP

Double-frustum embedding and extruding prestress constraint bullet shielding layer

PendingCN112814315APrevent prolapseReduce unevennessCovering/liningsShieldsStructural engineeringFrustum

The invention discloses a double-frustum embedding and extruding prestress constraint bullet shielding layer. The double-frustum embedding and extruding prestress constraint bullet shielding layer is mainly formed by assembling double-frustum filling blocks and hoops matched with the double-frustum filling blocks for constraint. Two oppositely-buckled hoops are adopted to be assembled on two frustum faces of the double-frustum filling blocks correspondingly, inner rings of the hoops and the outer conical faces of the corresponding frustums are matched and wedged through the conical faces, and the hoops of two frustums are fixedly connected. According to the double-frustum embedding and extruding prestress constraint bullet shielding layer, radial prestress or three-way prestress is simply and conveniently applied to fragile materials such as ceramic, concrete and glass under the room temperature condition, the constraint bullet shielding layer is suitable for applying prestress to protective components of various sizes, a fiber reinforced polymer which is lighter in weight and higher in strength can also be adopted as a constraint material, non-uniformity of the wall thickness of the hoops is reduced to a certain degree, materials are saved, the limiting function is achieved, and when any face of prestress constraint block is impacted, the two oppositely-buckled hoops can effectively prevent the frustums from being disengaged from the hoops.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Coil device

ActiveUS10453601B2Avoid positioningNot easy to relative displacementTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire rodEngineering

A coil device includes an inner core having a winding core and a pair of flanges, a wire, an outer core arranged outside the inner core, a first terminal with a first wirebound having a first wirebound bottom arranged axially on a core end surface of the outer core and connected to a first end of the wire, and a second terminal with a second wirebound having a second wirebound bottom arranged on the core end surface and connected to a second end of the wire. The first wirebound has a first wire fixing portion bending from the first wirebound bottom toward a first rotating direction and fixing the first end. The second wirebound has a second wire fixing portion bending from the second wirebound bottom toward the same rotating direction as the first rotating direction and fixing the second end.

Owner:TDK CORPARATION

Arrangement for fixing the compensating weight guide rails of an elevator, and guide rail bracket used in the arrangement

The object of the invention is an arrangement and a guide rail bracket for fixing the compensating weight guide rails of an elevator.

Owner:KONE CORP

Air conditioning system, control unit and other components used therewith

ActiveUS8052063B2Easy to installEasy and quick fixMechanical apparatusDomestic cooling apparatusElectricityTemperature control

Owner:RANKICH STEPHEN

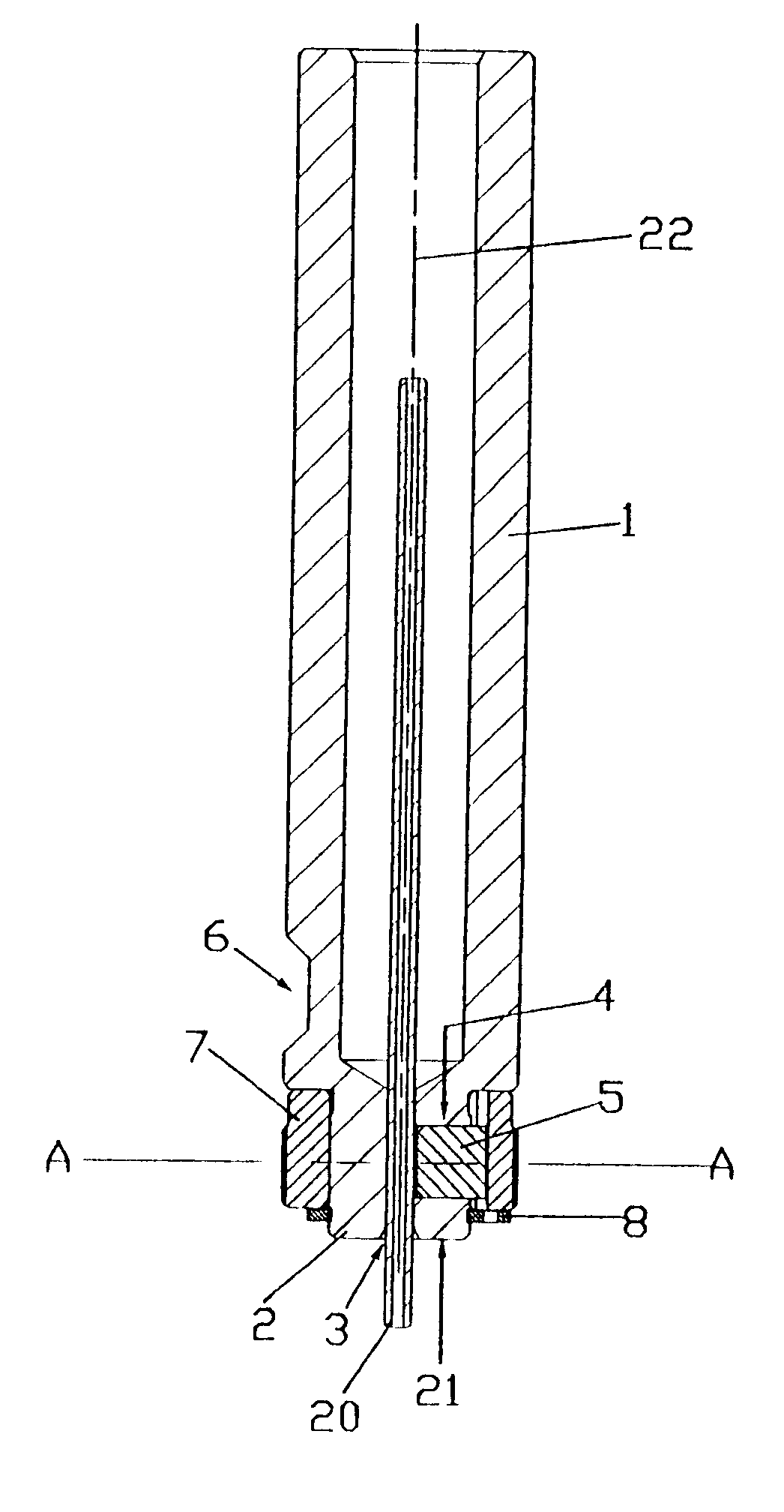

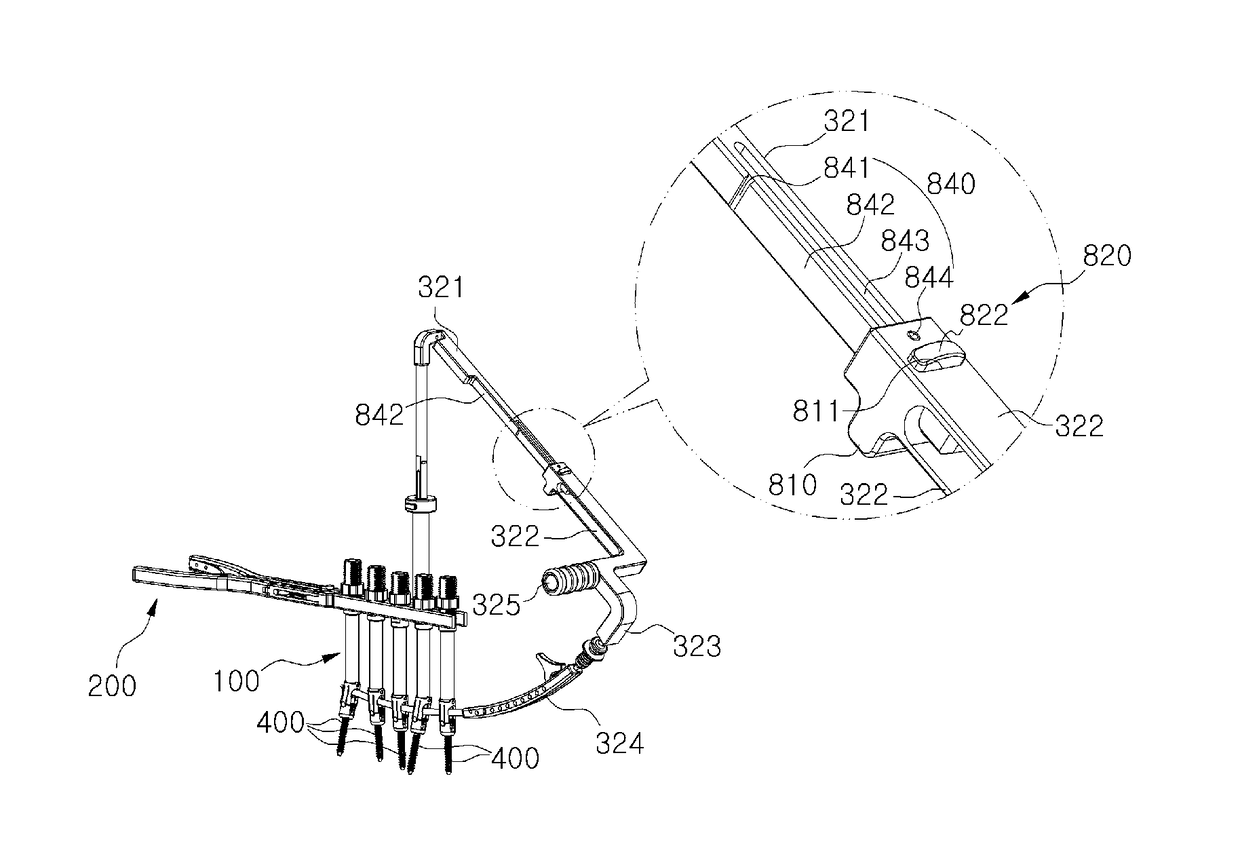

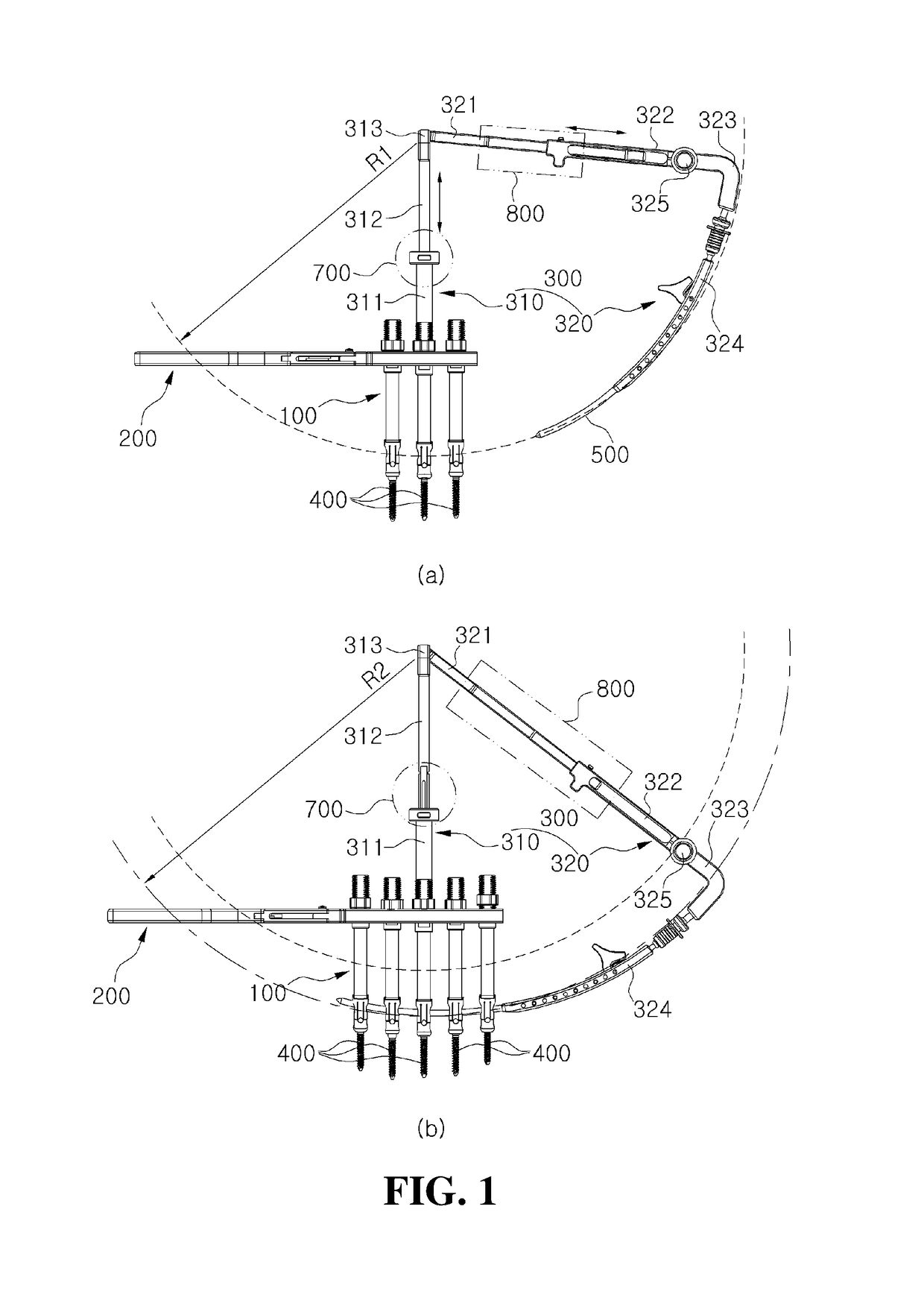

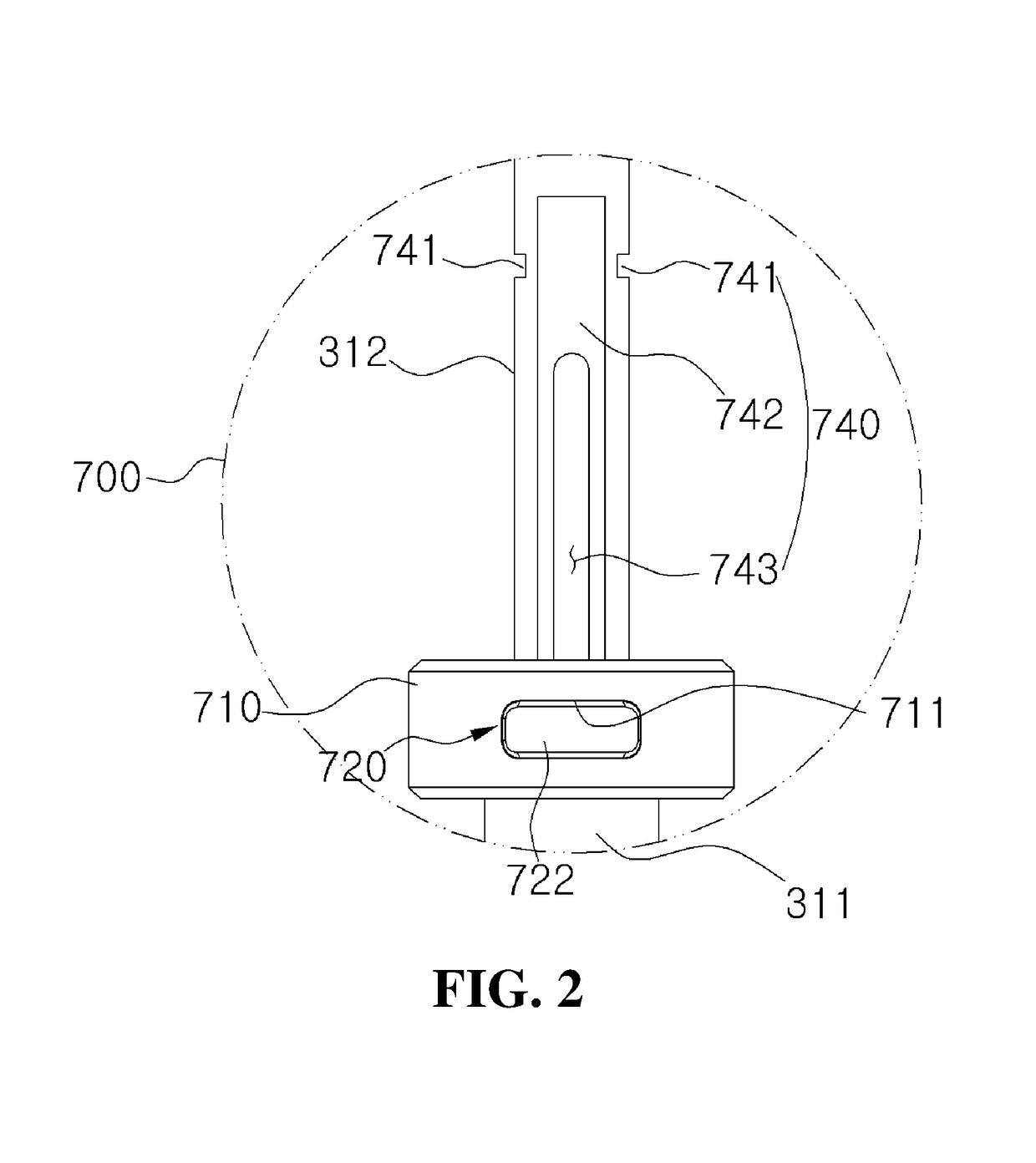

Rod inserter for fixing of pedicle screw, screw holder with joint for minimal invasive surgery, screw reducer for minimal invasive surgery and apparatus for minimal invasive surgery using these devices

InactiveUS9913670B2Easy to fixPromote generationInternal osteosythesisMinimal invasive surgeryReducer

Provided are a rod inserter for fixing a pedicle screw. The rod inserter for fixing a pedicle screw, the rod inserter including a rotational support unit having a length corresponding to a radius of lordosis formed by lumbar of vertebrae of a subject person and of which a lower end is fixed and a rotational insertion unit having a length corresponding to the radius and having one end rotatably coupled to an upper end of the rotational support unit and the other end to which an arc-shaped rod is detachably coupled. Thus, the arc-shaped rods having lengths shapes different from each other according to the number of screws respectively fixed to the vertebrae of the subject person is coupled as one device to perform the operation.

Owner:MANTIZ LOGITECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com