Laser repair remanufacture method of automobile engine crankshaft

An automobile engine and laser repair technology, which is applied in the fields of mechanical manufacturing and material processing, can solve the problems of affecting the service life of the crankshaft, large deformation of the crankshaft, complex process, etc., to prolong the service life, improve the fatigue life, and have good repair effects Effect

Inactive Publication Date: 2016-08-17

JIANGSU UNIV

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This strengthening process can effectively improve the fatigue bending moment of the crankshaft and the wear resistance of the crankshaft journal, but the process is relatively complicated, and the deformation of the crankshaft after rolling is large, and the effect is not good, which affects the service life of the crankshaft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] Repair process: Repair the crankshaft made of QT700 ductile iron.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Login to View More

Abstract

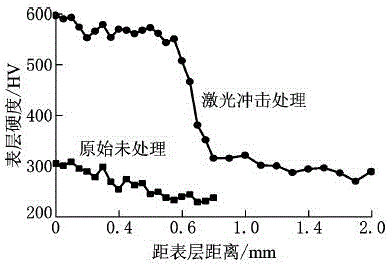

A laser repair remanufacture method of an automobile engine crankshaft relates to the technical fields of machine manufacture and material treatment, processing and application. First, laser cladding treatment is carried out on the damage zone of the crankshaft, and cladding is supplied in a manner of preset laser cladding. Then, the surface of the damage zone of the crankshaft is coated with an absorbing layer, and laser shock treatment is carried out on the damage zone of the crankshaft under the protection of a constrained layer. In the invention, the wear resistance, corrosion resistance and oxidation resistance of a metal surface are improved, the fatigue strength of materials is greatly improved, the service life of the materials is greatly prolonged, the fretting fatigue resistance of the crankshaft surface is effectively improved, the occurrence of fatigue cracks is inhibited, and the expansion rate of the fatigue cracks is reduced. Therefore, the treatment method greatly improves the wear resistance, corrosion resistance and fatigue strength of the materials, thereby prolonging the working life of the automobile engine crankshaft.

Description

technical field [0001] The invention relates to the technical field of mechanical manufacturing and material processing, in particular to a laser repair and remanufacturing method for an automobile engine crankshaft. Background technique [0002] Laser cladding is a surface hardening processing technology, which uses a high-energy laser beam to melt the coating material, and forms a thin, low-dilution 50μm~2mm thick non-porous, crack-free, and base material. Materials combined with a good cladding layer. This process technology can be applied to large-area modification with individual tracks overlapping each other. Its unique features are its ability to clad a wide variety of alloy materials and its suitability for treating small areas. Laser cladding can significantly improve the surface properties of materials, expand its scope of application and extend its service life at a lower cost. [0003] In advanced manufacturing technology, laser shock processing technology, as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C24/10C21D10/00

CPCC23C24/10C21D10/005

Inventor 任旭东杨进德李琳佟艳群吴教义任云鹏孙建荣戴峰泽

Owner JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com