Laser repairing remanufacturing method of ultra-large cutting equipment cutter

A laser repair and super-large technology, applied in the coating process and coating of metal materials, can solve the problems affecting the service life of the tool, cracks in the cladding layer, bubble initiation, etc., to prolong the service life, corrosion resistance and fatigue Effects of increasing strength and suppressing germination

Inactive Publication Date: 2014-04-02

JIANGSU WANLI MACHINERY +1

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

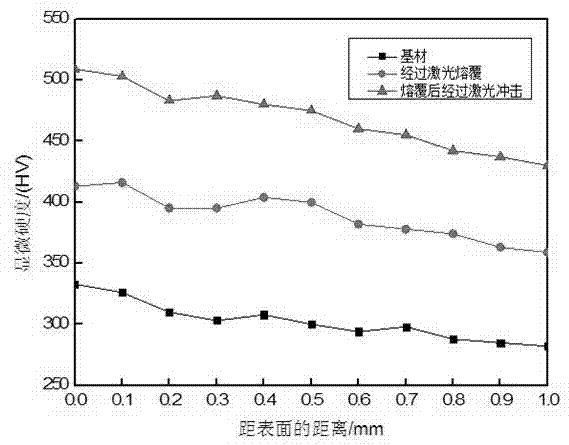

However, in the pure laser cladding process, the rapid heating of the high-energy-density laser beam produces a large temperature gradient between the repair layer and the substrate, and also generates high thermal stress, which will lead to the initiation of cracks and bubbles in the cladding layer, affecting tool life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0027] Example 1: Repair the super large shearing equipment tool made of Cr12MoV tool steel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a laser repairing remanufacturing method of an ultra-large cutting equipment cutter, and relates to the technical field of machine manufacturing and material processing application. Firstly, the laser cladding processing is implemented for a damaged area of the cutter; the supply mode of the cladding is preset laser cladding; then, an adsorption layer is coated on the surface of the damaged area of the cutter; the laser impact processing is implemented for the damaged area of the cutter under the protection of a restraint layer. The laser repairing remanufacturing method of the ultra-large cutting equipment cutter improves the wear resistance, corrosion resistance and oxidization resistance of metal surfaces, prominently enhances the fatigue strength of materials, prolongs the service life of the materials, effectively improves the micro-motion fatigue resistance of the cutter surface, restrains the production of fatigue cracks, and reduces the propagation rate of the fatigue cracks. Therefore, the processing method largely improves the wear resistance, corrosion resistance and fatigue strength of the materials so as to prolong the service life of the ultra-large cutting equipment cutter.

Description

technical field [0001] The invention relates to the technical field of mechanical manufacturing and material processing and processing applications, in particular to a laser repair and remanufacturing method for super-large shearing equipment knives, and is especially suitable for repairing damage to the blades of super-large shearing equipment knives. Background technique [0002] Laser cladding is a surface hardening processing technology, which uses a high-energy laser beam to melt the coating material, and forms a thin, low-dilution 50μm~2mm thick non-porous, crack-free, and base material. Materials combined with a good cladding layer. This process technology can be applied to large-area modification with individual tracks overlapping each other. Its unique features are its ability to clad a wide variety of alloy materials and its suitability for treating small areas. Laser cladding can significantly improve the surface properties of materials, expand its scope of appl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F17/00C23C24/10C21D1/09

Inventor 任旭东戴文杰殷文元任乃飞谢善忠崔卫东张西良王匀王存堂刘小梅

Owner JIANGSU WANLI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com