Method for synthesizing N-methylpiperazine

A technology of methylpiperazine and a synthesis method, which is applied in the field of chemical synthesis of chemical products, can solve the problems that the production cost is difficult to reduce, can only reach 50%, and the replacement cost is high, and achieves obvious technological advancement, reduced energy consumption, and reduced production costs. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

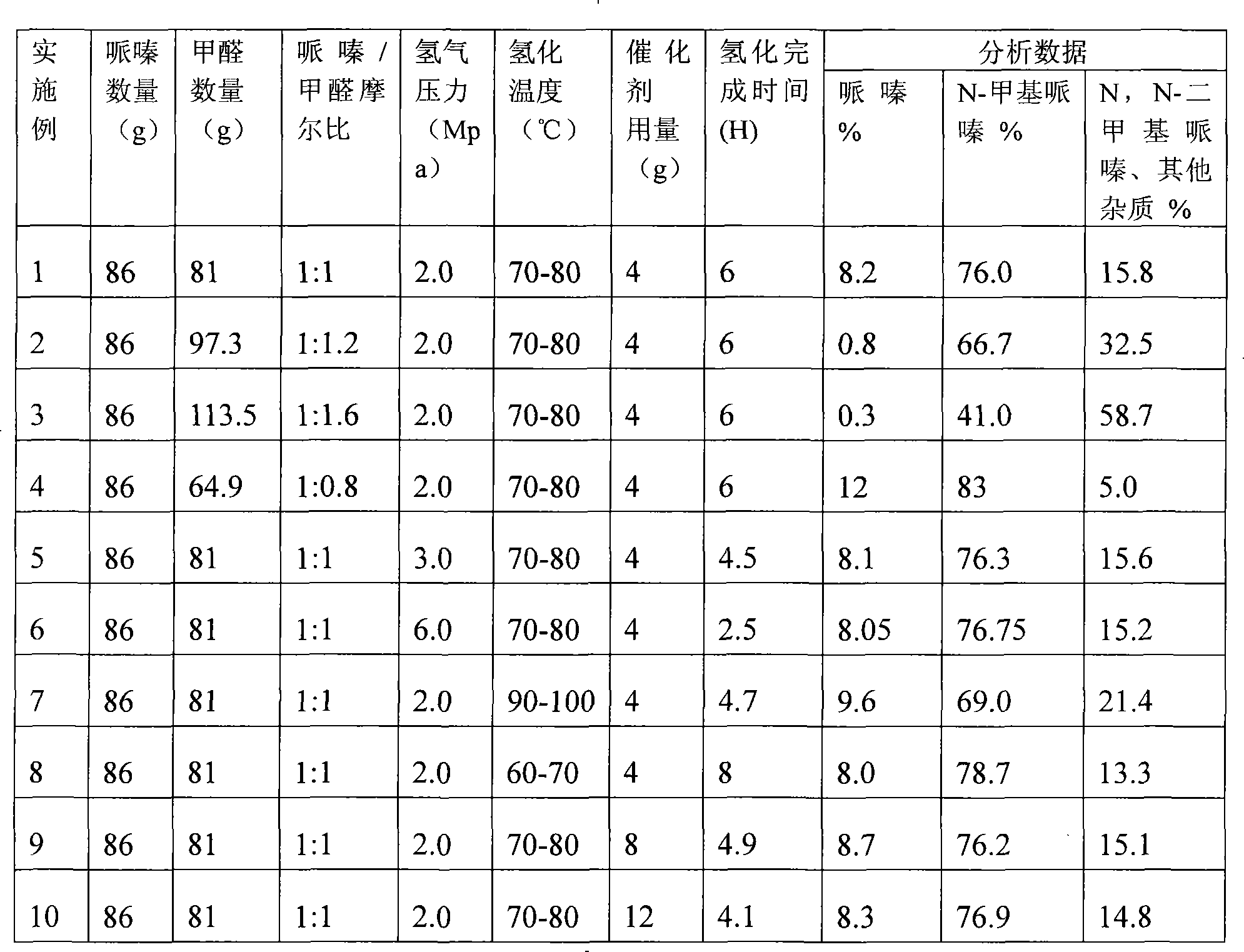

Examples

Embodiment 1

[0017] Add 86 grams of piperazine (1mol) and 800 grams of methanol to a capacity of 2 liters of autoclave, start the stirrer, add 81 grams of formaldehyde (1mol) with a concentration of 37% in batches from the feeding hole, and then add 4 grams of Raney Nickel catalyst, closed autoclave.

[0018] After replacement with nitrogen and hydrogen successively, then, raise the hydrogen pressure in the kettle to 2.0Mpa, close the hydrogenation valve, keep stirring, and slowly raise the temperature of the material to 70-80°C, maintain the temperature, and keep the kettle pressure at 2.0Mpa. Mpa, carry out the hydrogenation reaction until the hydrogenation reaction is completed (without absorbing hydrogen). Cool down the reaction kettle, release the pressure, and take out the reactants.

[0019] Filter and remove the catalyst Raney nickel for the next batch of reactions. Take the filtrate, distill and recover the solvent methanol and unreacted piperazine, collect the fraction at 137°C...

Embodiment 2

[0021] Add 97.3 grams of 37% formaldehyde (1.2mol) in batches, and all the other conditions are the same as in Example 1.

Embodiment 3

[0023] Add 113.5 grams of 37% formaldehyde (1.6mol) in batches, and all the other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com