Vacuum furnace suitable for preparing large-diameter high-purity polysilicon ingot

A high-purity, polysilicon technology, applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problems that affect the quality of crystallization, structural form, unsuitable for large-scale casting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

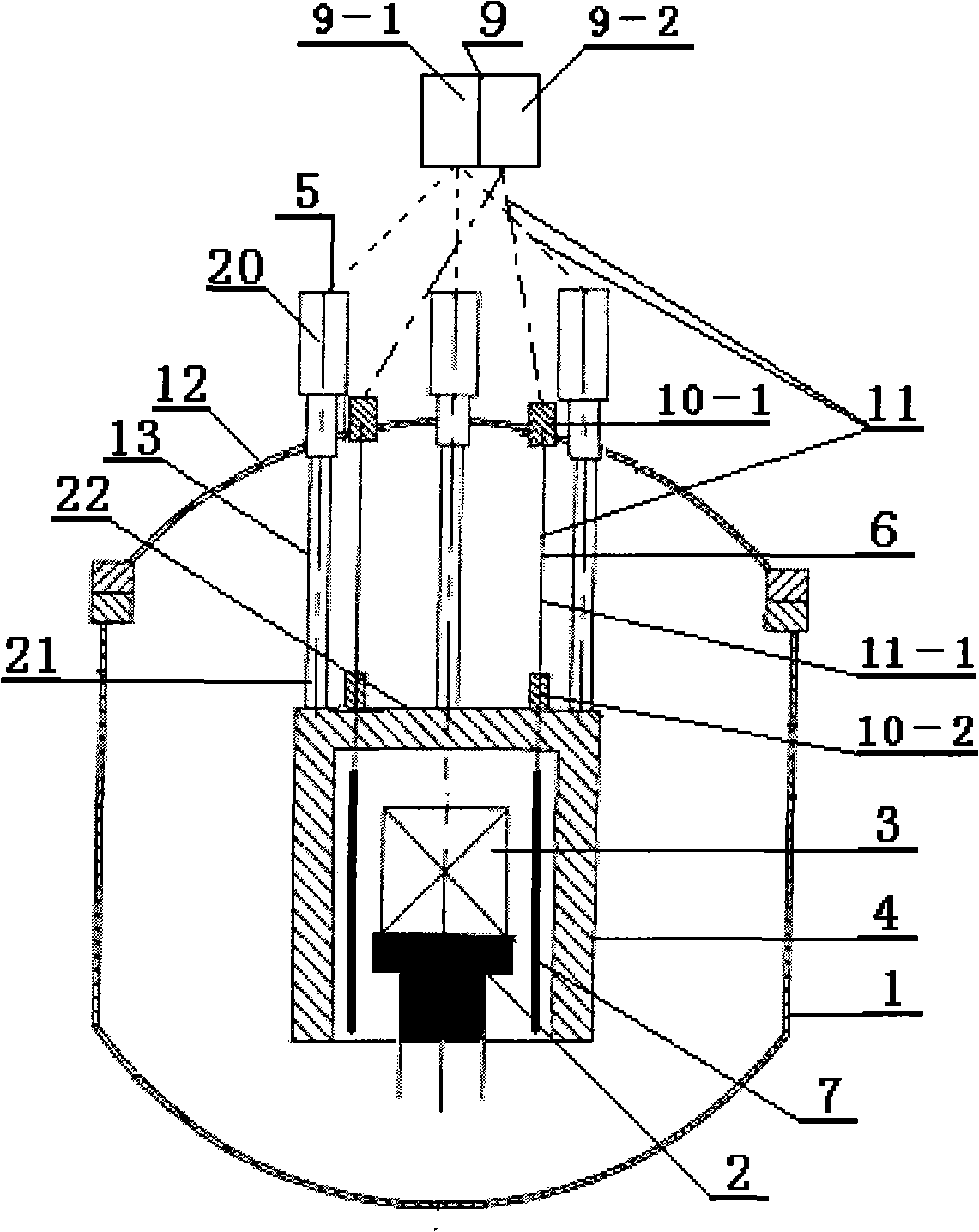

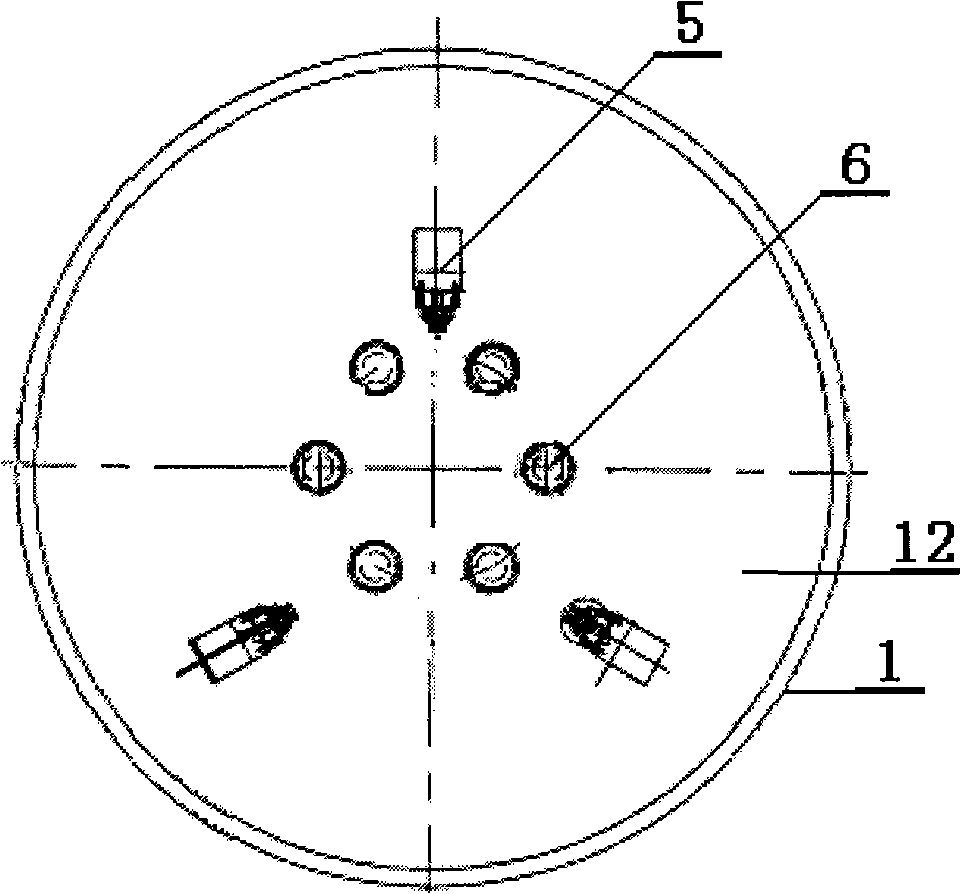

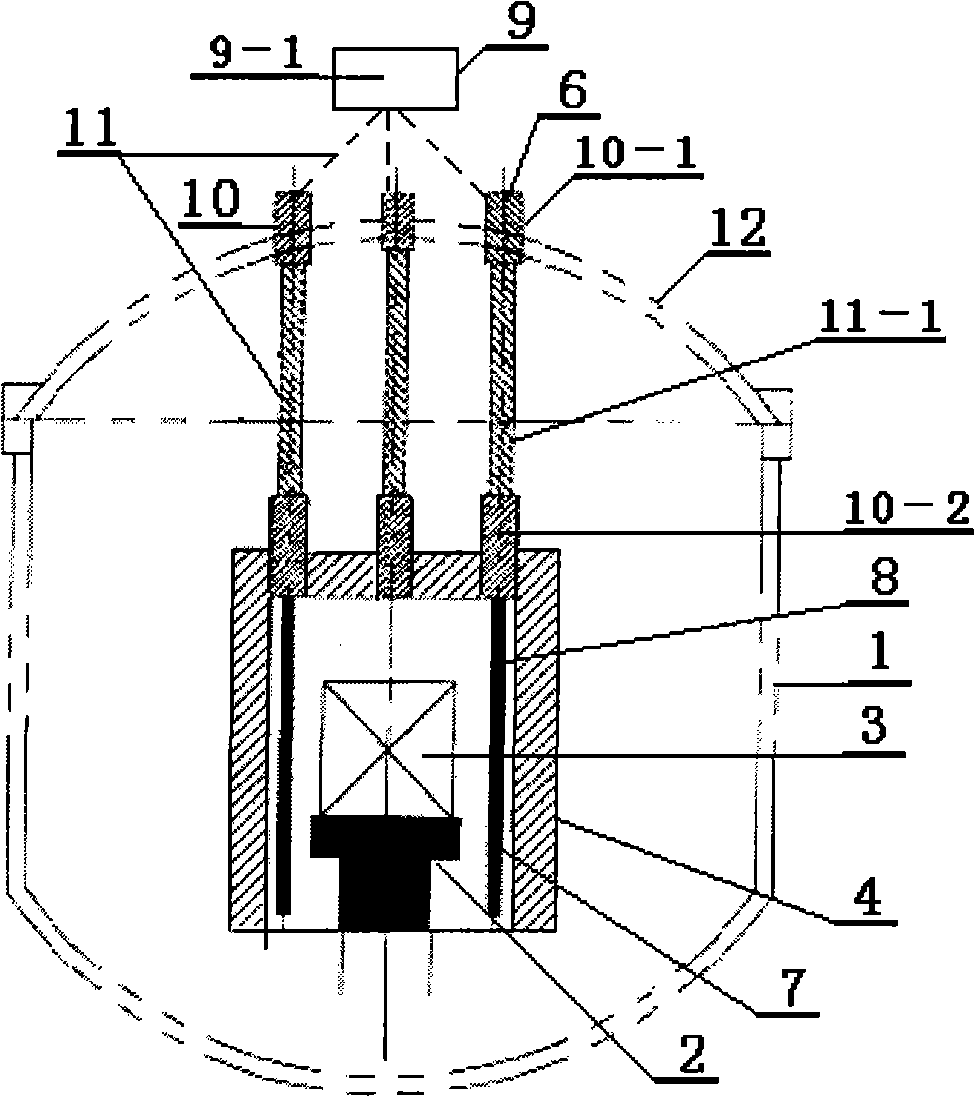

[0022] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the main body of the vacuum furnace suitable for manufacturing large-scale high-purity polycrystalline silicon ingots of the present invention includes a furnace body 1, a material table 2, a crucible 3, a heat preservation cover 4, a lifting mechanism 5, a power supply component 6 and an electric heating device 7, and the crucible 3 is set on the material platform 2, the heat preservation cover 4 covers the periphery of the crucible 3 arranged above the material platform 2, the electric heating device 7 is fixedly installed on the top of the heat preservation cover 4, and its main body is extended on the inner wall of the heat preservation cover 4 and the periphery of the crucible 3 In the gap 8 between them, the power supply component 6 includes an electrical contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com