Environment-friendly road surface and construction method thereof

A construction method and an environmentally friendly technology, which is applied to the environment-friendly road surface and its construction field, can solve the problems of serious volatilization of asphalt, high cost of heat insulation layer, loss of heat insulation protection, etc., and achieve the effect of comfortable driving, small vibration and prevention of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

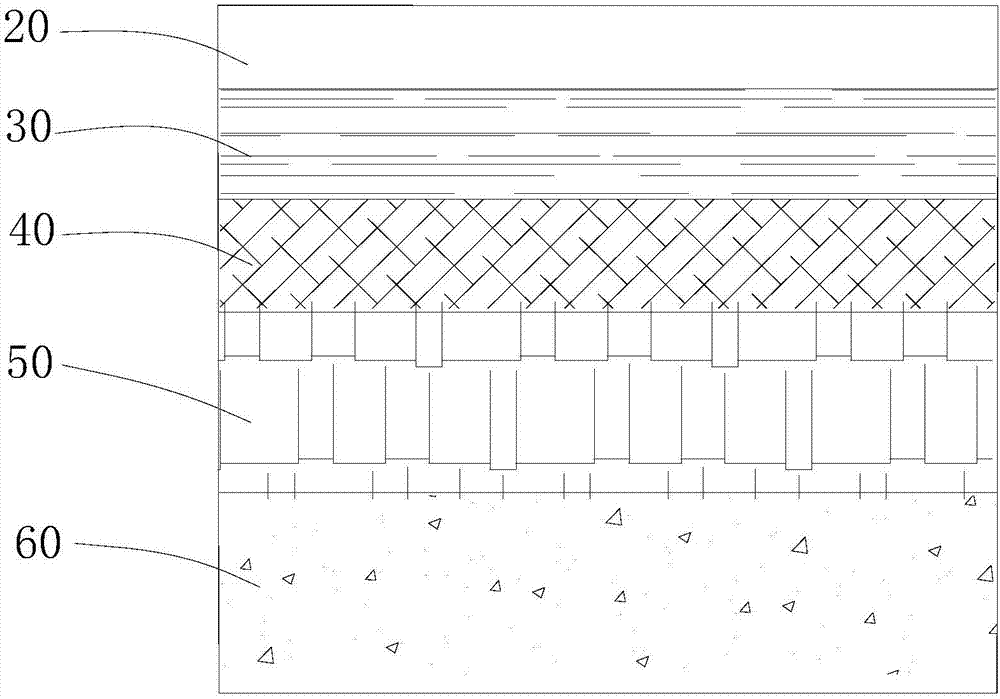

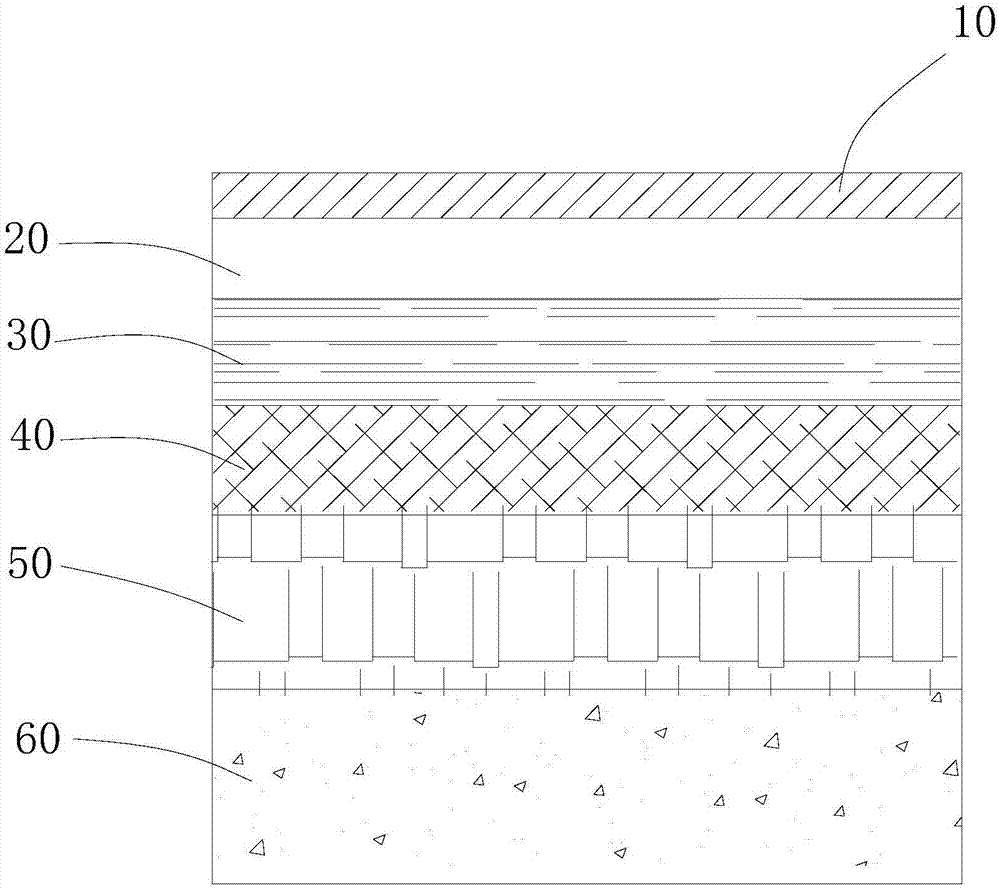

[0027] Such as figure 2 Shown, a kind of environmental protection pavement, is similar to the asphalt pavement in the prior art, comprises from bottom to top: subbase layer 60, base layer 50, asphalt lower layer 40, asphalt middle surface layer 30, asphalt upper layer 20, described asphalt upper layer The thicknesses of layer 20, asphalt middle surface layer 30, and asphalt lower layer 40 are respectively 4, 6, 8cm (also can be commonly used in the prior art) or 4, 5, 7cm or 4, 5, 6cm, difference is: all The asphalt upper layer 20 is also covered with a concrete seal 10 with a thickness less than or equal to 3 cm.

[0028] The concrete seal 10 completely covers the asphalt upper layer 20, and the harmful gas volatilized by the asphalt upper layer 20 under the condition of higher temperature is all wrapped under the concrete seal 10 to avoid gas leakage.

[0029] The subbase layer 60, base layer 50, asphalt lower layer 40, asphalt middle surface layer 30, and asphalt upper la...

Embodiment 2

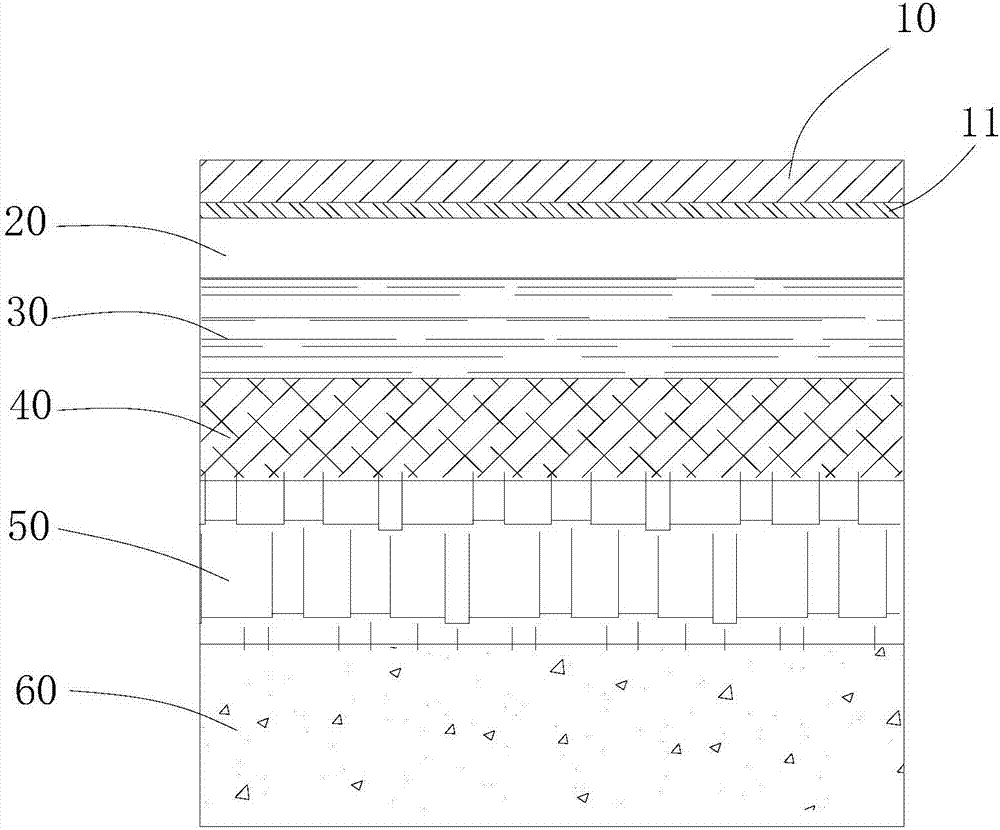

[0037] Such as image 3 As shown, the embodiment 2 is basically the same as the embodiment 1, the difference is that: a reinforcement mesh 11 is also provided between the asphalt top layer 20 and the concrete seal layer 10, preferably, the reinforcement mesh 11 adopts concrete with a spacing of 200x200mm. Accompanied by the fiber net, the firmness of the concrete sealing layer 10 is increased and the service life is prolonged. The rib net 11 can also be metal net, and the spacing can also be between 150-300mm.

[0038] In embodiment 2, the step of laying the concrete seal 10 on the asphalt upper layer 20 is similar to that of embodiment 1, the difference is: after step 2, the described reinforcement mesh 11 is paved on the cleaned asphalt upper layer 20, and then Carry out the pouring of the concrete sealing layer 10 of step 3. The concrete is connected to the asphalt upper layer 20 through the reinforcement mesh 11, further increasing the firmness between the two.

Embodiment 3

[0040] Figure 4 Shown is a schematic diagram of the environment-friendly pavement after the asphalt upper layer 20 as the thermal resistance layer is damaged. Fill in the asphalt repair layer 80 at the damaged part of the asphalt road, the upper surface of the asphalt repair layer 80 is flush with the surface of the original asphalt road, and then lay a concrete seal 10 on the repaired asphalt road to avoid more harmful gases overflow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com