Electromagnetic coil spool and terminal assembling structure of clutch for washing machine

An electromagnetic coil and assembly structure technology, applied in the field of clutches, can solve the problems of loose terminals, falling off terminals, and swimming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

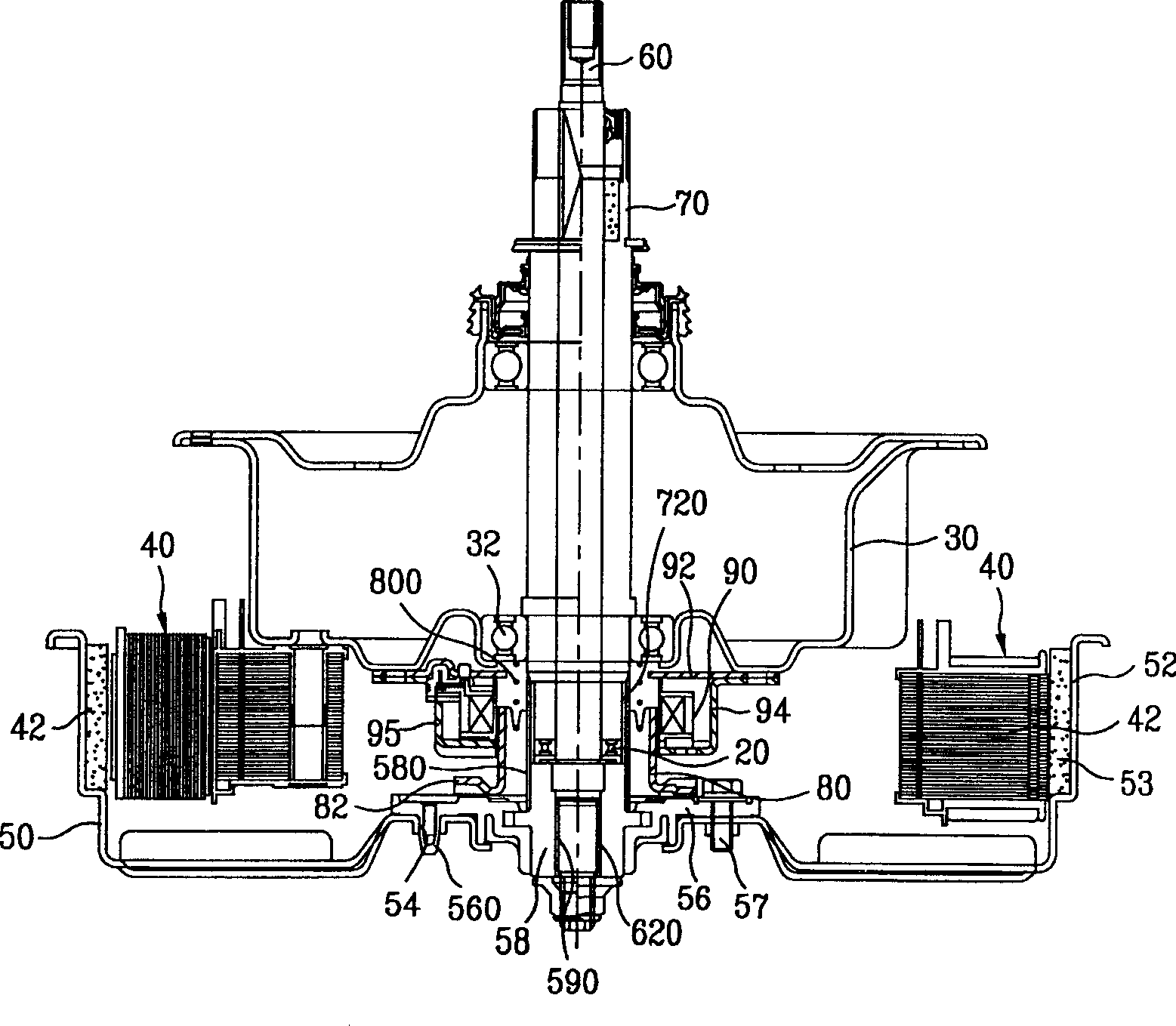

[0058] Refer below Figure 4 to Figure 9 , an embodiment of the bobbin and terminal assembly structure of the electromagnetic coil of the washing machine clutch of the present invention will be described in detail.

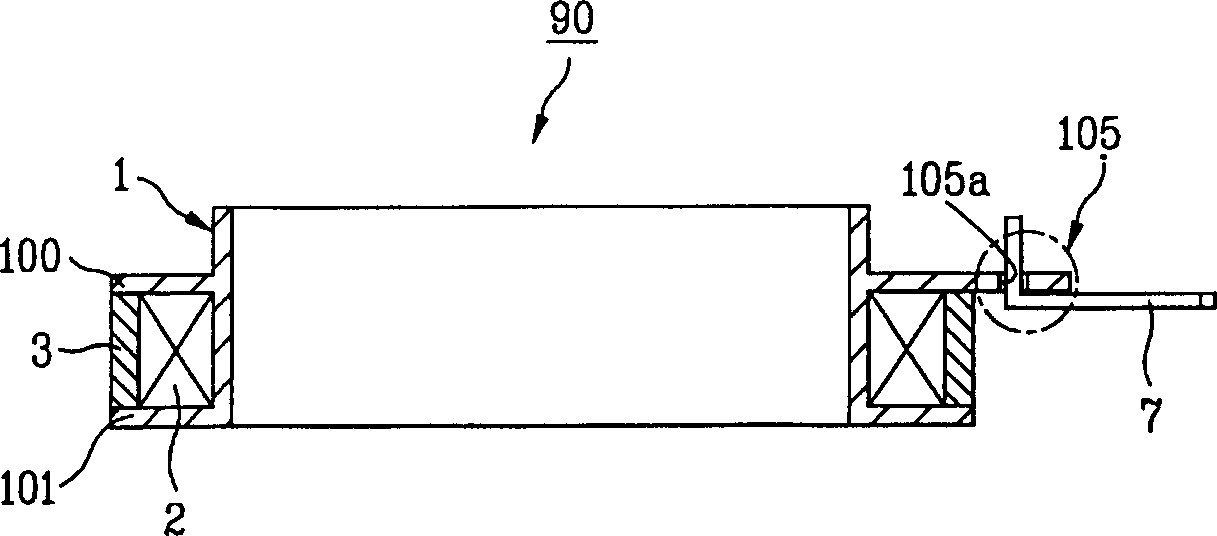

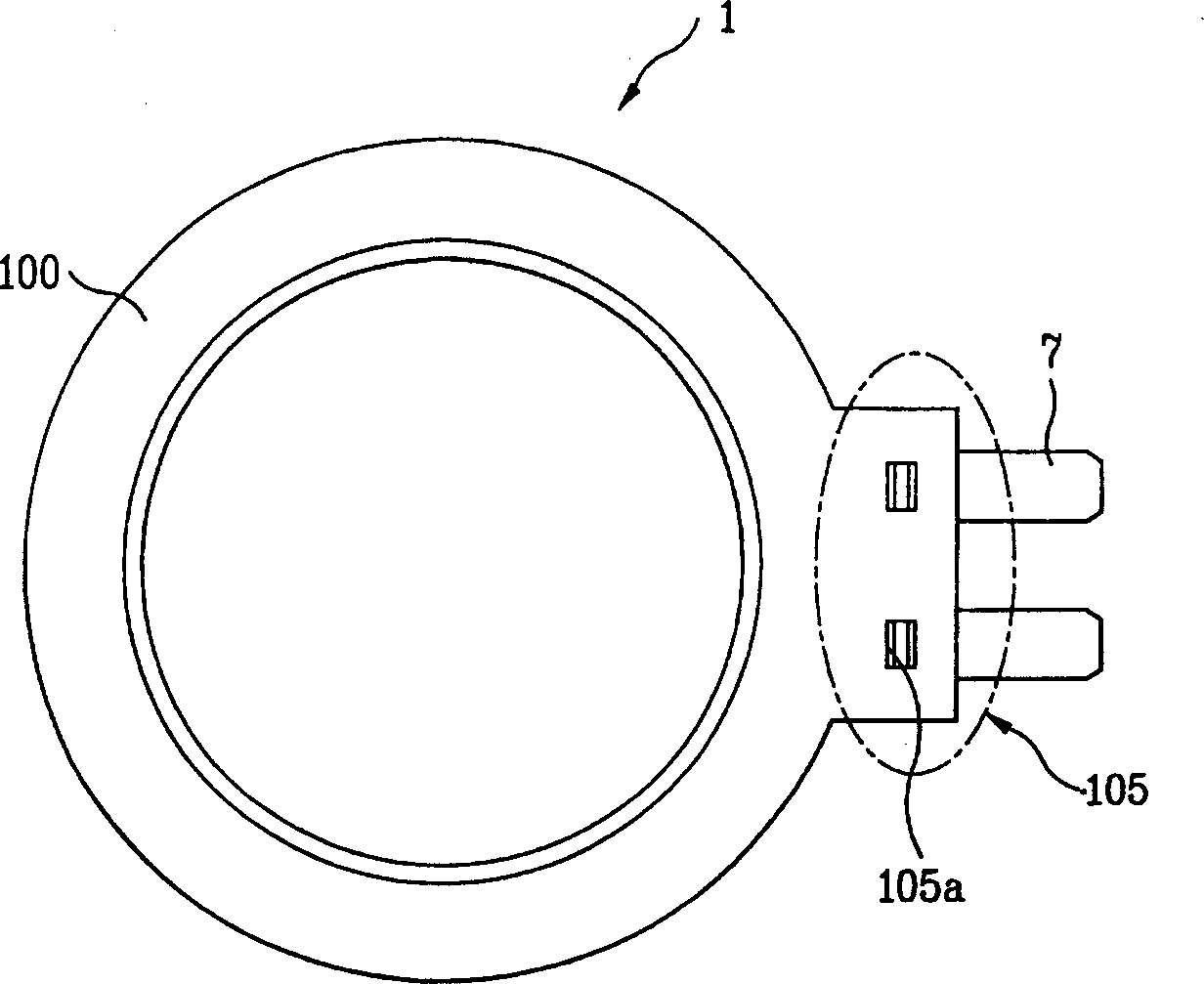

[0059] Such as figure 2 As shown, the electromagnetic coil (90) includes the following structures: a bobbin (1), a coil (2) and a package (3). The spool (1) roughly has a cylindrical shape, and an upper flange (100) and a lower flange (101) are respectively provided at positions separated from each other along the axial direction, and one side of the upper flange (100) is equipped with a The terminal portion (105) of the fixed terminal (7); the coil (2) is wound on the outside of the bobbin (1) between the upper flange (100) and the lower flange (101); in order to make the coil ( 2) not exposed, the package (3) formed by incombustible materials surrounds the outside of the coil (2); for the electromagnetic coil, the terminal portion (105) of the bobbin (1) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com