Spring tensioning device comprising a universal tension table

A technology of spring clamping and clamping table, applied in the field of spring clamping devices, which can solve the problems of high purchase cost, maintenance cost, and space occupied by spring clamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

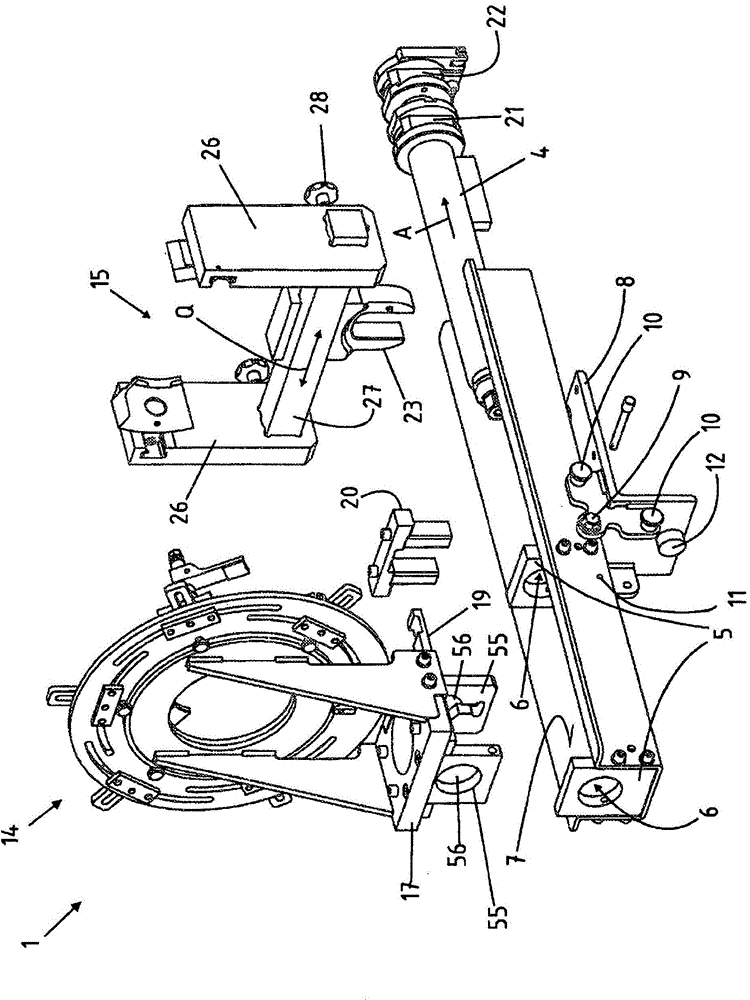

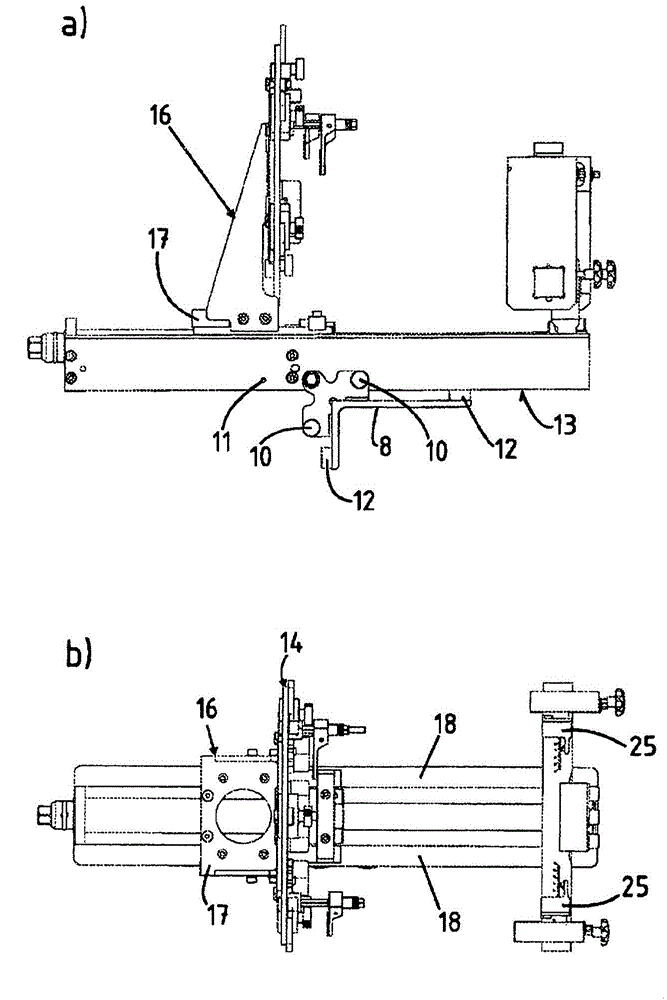

[0057] In the figures, the same reference symbols are used for identical or similar components, even if a repeated description is omitted for reasons of simplification.

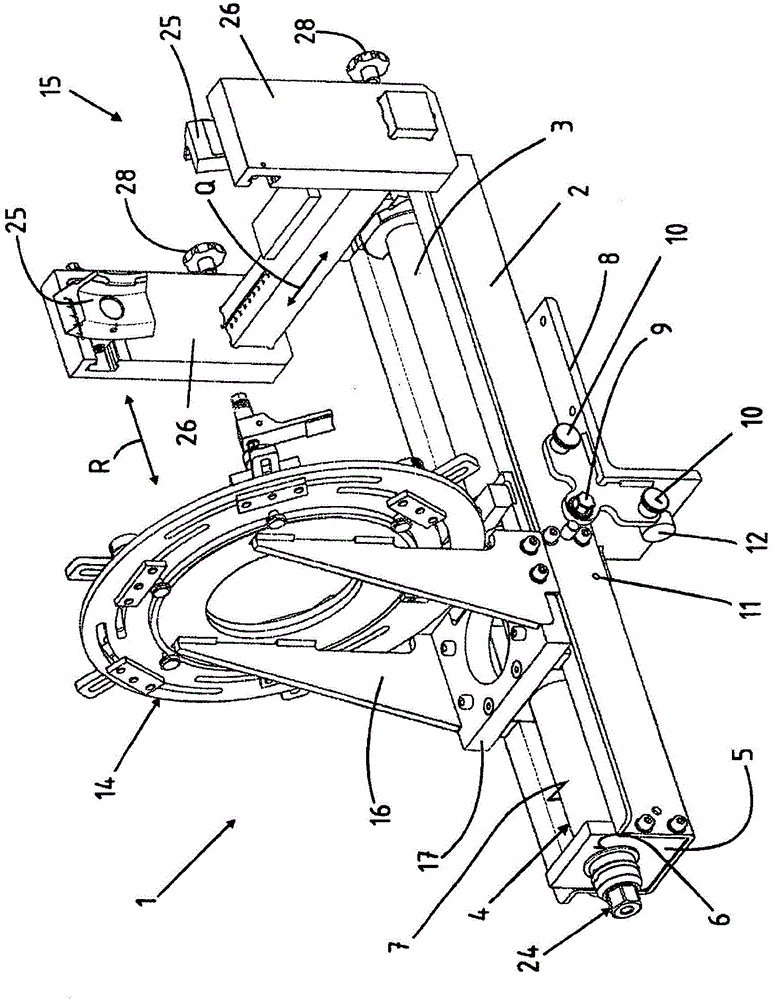

[0058] figure 1The spring clamping device 1 according to the invention is shown in a perspective side view from below in a horizontal operating position. The spring clamping device 1 has a profile rail 2 on which the components of the spring clamping device 1 are fixed decisively. Arranged inside the profiled rail 2 is a drive device 3 , which in the embodiment is formed by a movably inserted spring clamp 4 which is positively fastened inside the profiled rail 2 . For this purpose, transverse plates 5 are formed on the profiled rail 2 , the spring clamps 4 pass through recesses 6 in the transverse plates 5 in a form-fitting manner, and these transverse plates 5 are likewise received in a form-fitting manner on the inner peripheral surface 7 of the profiled rail 2 superior.

[0059] Thus profile 2 itself ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com