Acrylic fabric cationic dyeing pad dyeing process

A cationic dye, cationic technology, applied in the field of acrylic fabric dyeing, can solve the problems of low production efficiency, poor cylinder cloth, low reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

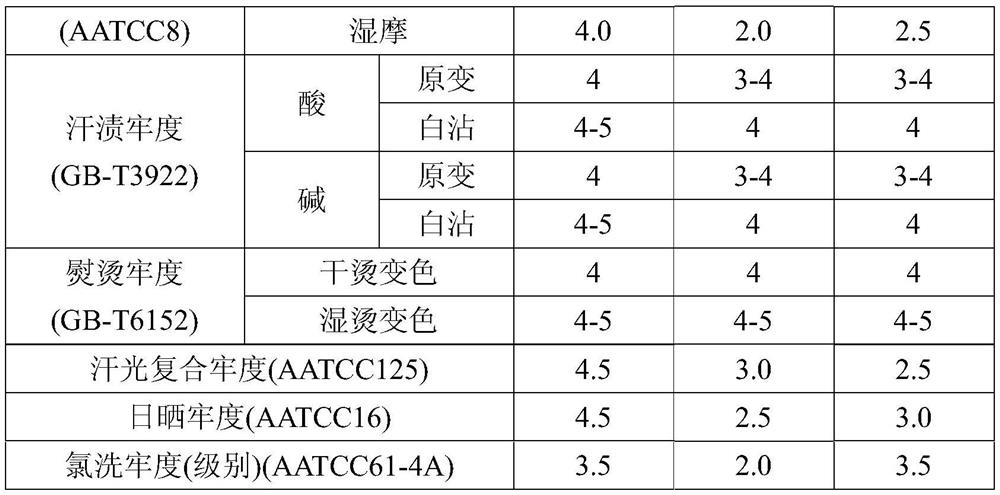

Examples

Embodiment 1

[0028] Fabric: acrylic pure fabric, acrylic 30*acrylic 30 86*66 plain weave;

[0029] Dye solution formula: cationic blue 5g / L, pH value of acetic acid dyeing solution to 4-5, cationic blue purchased from Zhejiang Runtu;

[0030] Soaping agent formula: DM-1501 soaping agent 2g / L;

[0031] Acrylic fabric cationic pad dyeing process: Padding cationic dye (85-95°C, 60% liquid content)→steaming (102°C, 90s)→washing→soaping→washing→drying (100°C, containing moisture rate 5%).

Embodiment 2

[0033] Fabric: acrylic / cotton blended fabric, acrylic fiber 70 cotton 30 40s*acrylic fiber 70 cotton 30 40s 140*100 five pieces of three-flying satin;

[0034] Dye solution formula: Cationic dyes: X-FDL black 20g / L, X-GRL red 1.8g / L, X-BL blue 2.0g / L, pH value of acetic acid dye solution to 4-5, X-FDL black, X - GRL red and X-BL blue were purchased from Zhejiang Runtu;

[0035] Reactive dyes: black G15g / L, red SE1.2g / L, yellow SE1.0g / L, black G, red SE and yellow SE were all purchased from Huntsman;

[0036] Fixing solution formula: caustic soda 6g / L, soda ash 20g / L, sodium chloride 200g / L;

[0037] Soaping agent formula: DM-1501 soaping agent 2g / L;

[0038] Pad dyeing process of acrylic / cotton blended fabrics: padding cationic dyes (85-95°C, 42% liquid content)→steaming (102°C, 120s)→washing→soaping→washing→drying (105°C, Moisture content 5%)→Padding reactive dyes (at room temperature, liquid volume 60%)→Drying (105°C, moisture content 5%)→Steaming (102°C, 90s)→Washing→Soa...

Embodiment 3

[0040] Fabric: Acrylic / Cotton / Nylon Blend Fabric, Acrylic 60 / Cotton 35 / Nylon 5 24s / 2x24s / 2 169x47 Twill

[0041] Formula of dyeing solution: cationic dyes: X-FDL black 87.1g / L, X-GRL red 18.2g / L, X-BL blue 23.4g / L, acetic acid dyeing solution pH value to 4-5, X-FDL black , X-GRL red and X-BL blue were purchased from Zhejiang Runtu;

[0042] Reactive dyes: Yanlan R150% 46.4g / L, black SE8.7g / L, yellow SE2.9g / L, Yanlan R was purchased from Shanghai Yayun, black SE and yellow SE were purchased from Huntsman;

[0043] Fixing solution formula: caustic soda 6g / L, soda ash 20g / L, sodium chloride 200g / L;

[0044] Disperse dyes: Chari Su Black 10g / L, Chari Su Lan 10g / L, Chari Su Black and Chari Su Lan purchased from Yorkshire;

[0045] Pad dyeing process of acrylic / cotton / nylon blended fabrics: padding cationic dyes (85-95°C, liquid volume 66%)→steaming (102°C, 120s)→washing→soaping→washing→drying (90°C) ℃, moisture content 6%) → padding dispersion + active first bath (room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com