A kind of preparation method of continuous fiber reinforced titanium matrix composite material

A titanium-based composite material and continuous fiber technology, which is applied in the field of metal-based composite material preparation, can solve the problems of reducing the performance of composite materials, uneven fiber arrangement, and affecting the performance of composite materials, so as to achieve fixation and positioning, and simple process operation , the effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

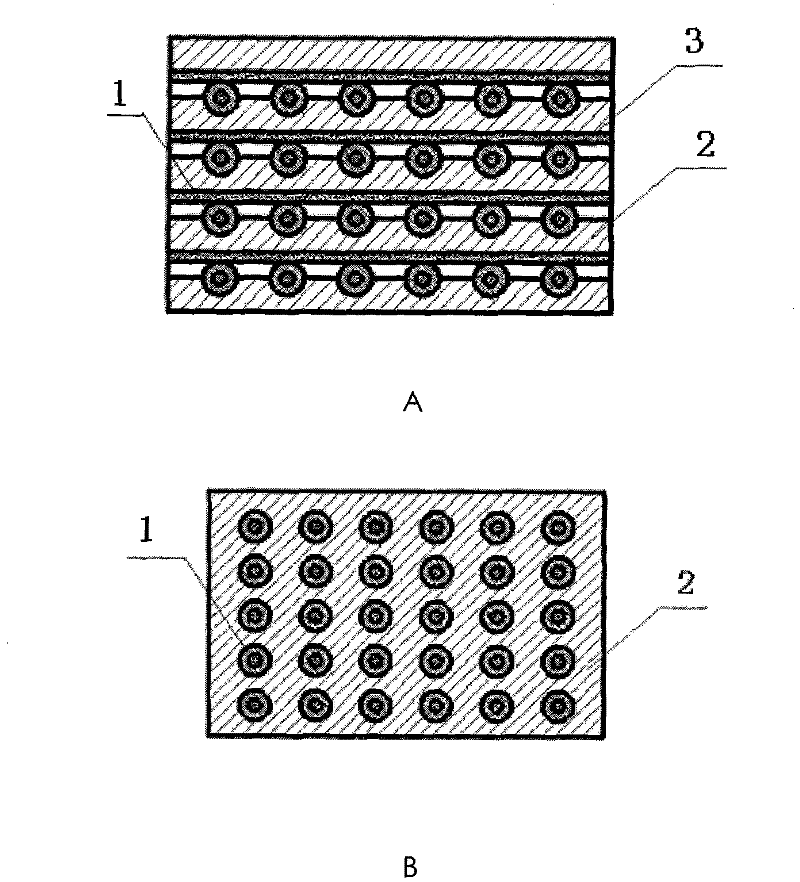

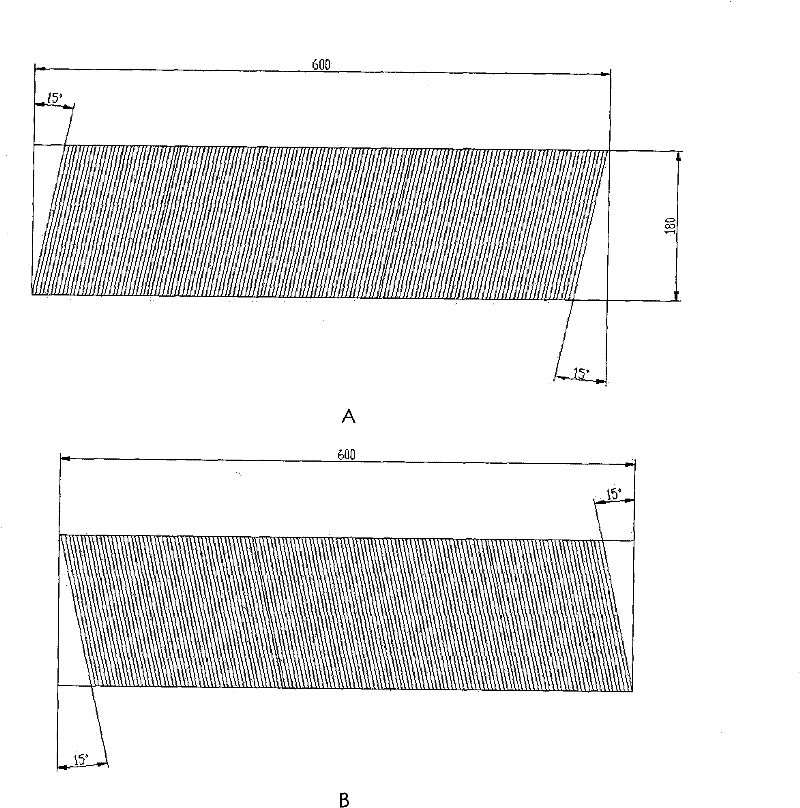

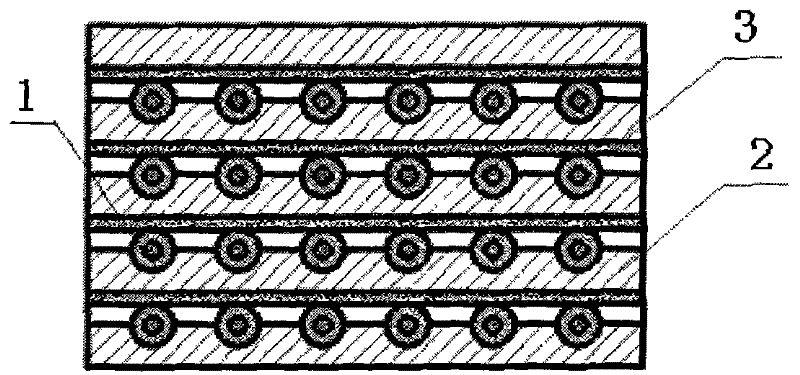

[0039] (1) On the surface of the foil that needs to be reinforced, take pictures according to the percentage of fibers, and cut grooves by chemical milling. The groove spacing is 0.2mm. The groove on the surface of the material is -15° to the short side;

[0040] (2) Chemical cleaning of the foil surface to remove photosensitive materials and other impurities on the surface;

[0041] (3) a fiber is arranged in each groove on the surface of the foil;

[0042] (4) Temporarily bond the 9458 adhesive tape of 3M Company on the surface of the fiber to fix the fiber in the groove of the foil;

[0043] (5) Machining the hollow inner sheath of A3 steel;

[0044] (6) Machining the outer sheath of A3 steel;

[0045] (7) Laminating two layers of foils with fibers arranged therein, the laminated foils and fibers are arranged in a staggered manner;

[0046] (8) Tightly wind the laminated foil and fiber cloth onto the hollow inner sheath of A3 steel;

[0047] (9) Put an A3 steel outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com