Hydraulic side pressing die

A blank holder and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high replacement cost, high scrap rate, high blank holder force, avoid flat wrinkle deformation, stable product quality, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

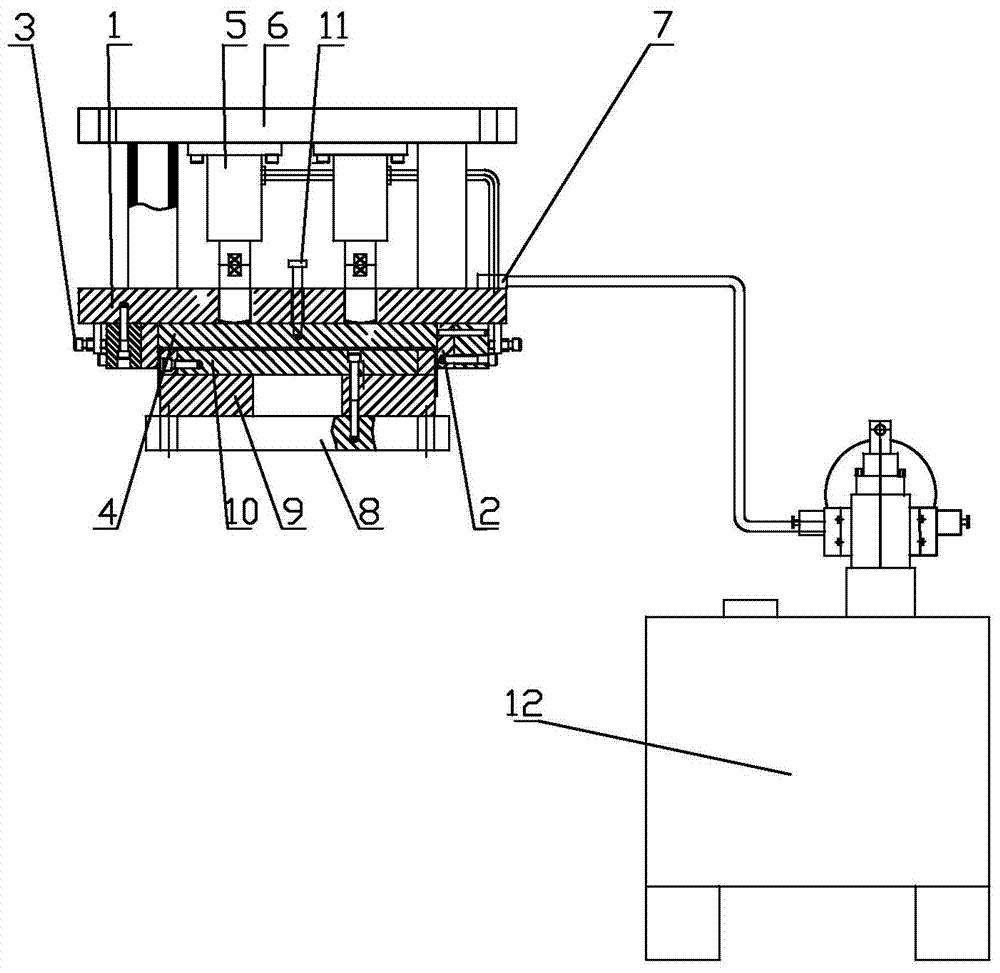

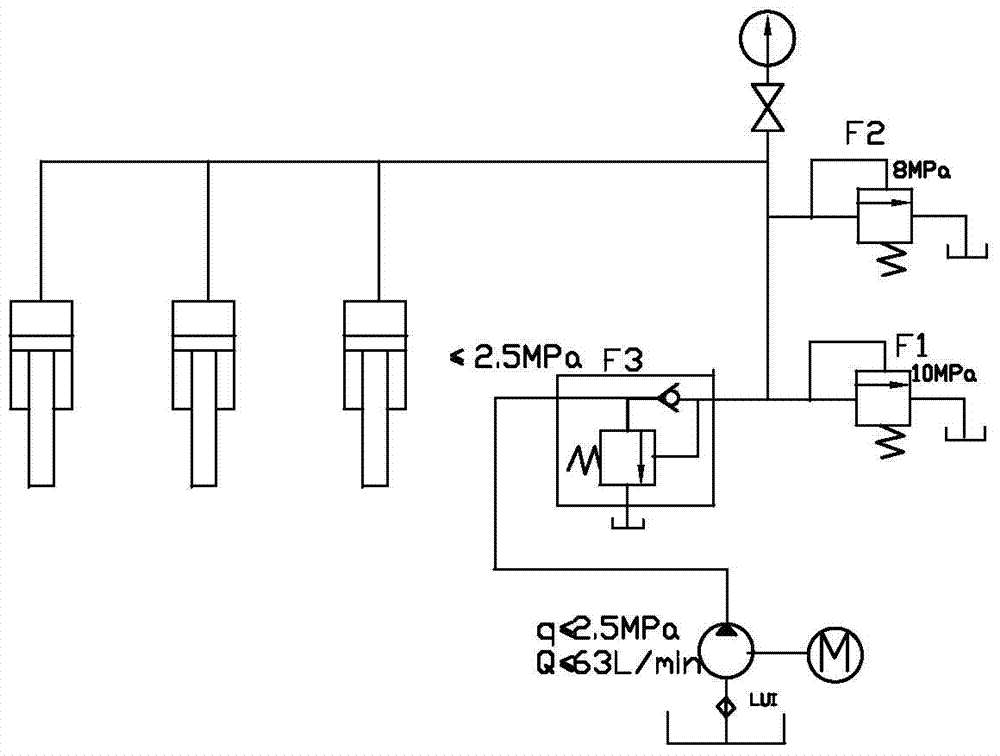

[0014] Such as figure 1 The shown hydraulic edge blanking mold includes a mold base 1, a concave formwork assembly 2 is installed under the mold base 1, and adjusting screws 3 are arranged on both sides of the concave formwork assembly 2. The concave formwork assembly 2 is generally formed by splicing a plurality of mold pieces to form a die , Adjust the gap between the female template assembly 2 and the punch by adjusting the screw 3. A blank holder stripper 4 is installed in the concave template assembly 2, and the blank blank blank 4 moves up and down in the concave template assembly, and can pass through slide rails or other sliding structures. The blank-holding stripper plate 4 is connected with the hydraulic cylinder 5, and the hydraulic cylinders 5 are fixed on the upper plate 6 of the formwork. The hydraulic cylinders 5 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com