Vehicle alternating current transmission system

A transmission system, alternating current technology, applied in vehicle components, railway vehicles, motor vehicles, etc., can solve the problem of inability to meet variable frequency loads, and achieve the effects of maintenance-free reduction, improved system efficiency, and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

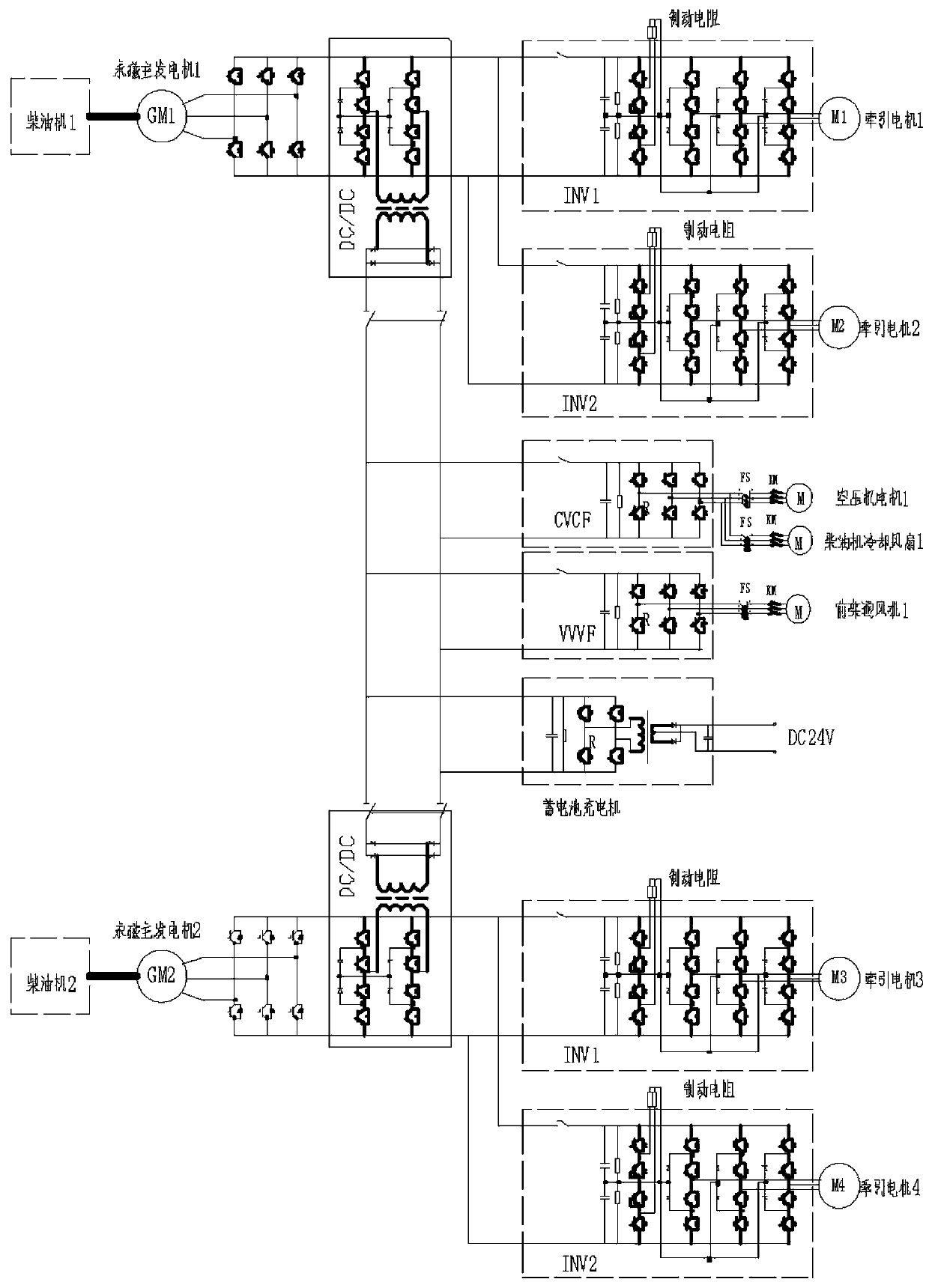

[0024] Vehicle AC drive system, 2×500KW diesel permanent magnet generator sets replace the original 1×1000KW electric excitation diesel generator set.

[0025] Dual diesel engine working mode:

[0026] Two 500KW diesel engines drive two 500KW permanent magnet synchronous generators respectively, and the four-quadrant finisher controls the output voltage and power of the permanent magnet synchronous generators so that they output 484-1072V three-phase AC voltage according to the diesel engine speed, and then supply four sets respectively Three-level traction inverter.

[0027] Single diesel engine working mode:

[0028] A 500KW diesel engine drives a 500KW permanent magnet main generator, and the four-quadrant finisher controls the output voltage and power of the permanent magnet generator so that it outputs 484-1072V three-phase AC voltage according to the diesel engine speed, and then supplies two sets of three electric generators respectively Flat traction inverter. Reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com