Patents

Literature

42results about How to "Small pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

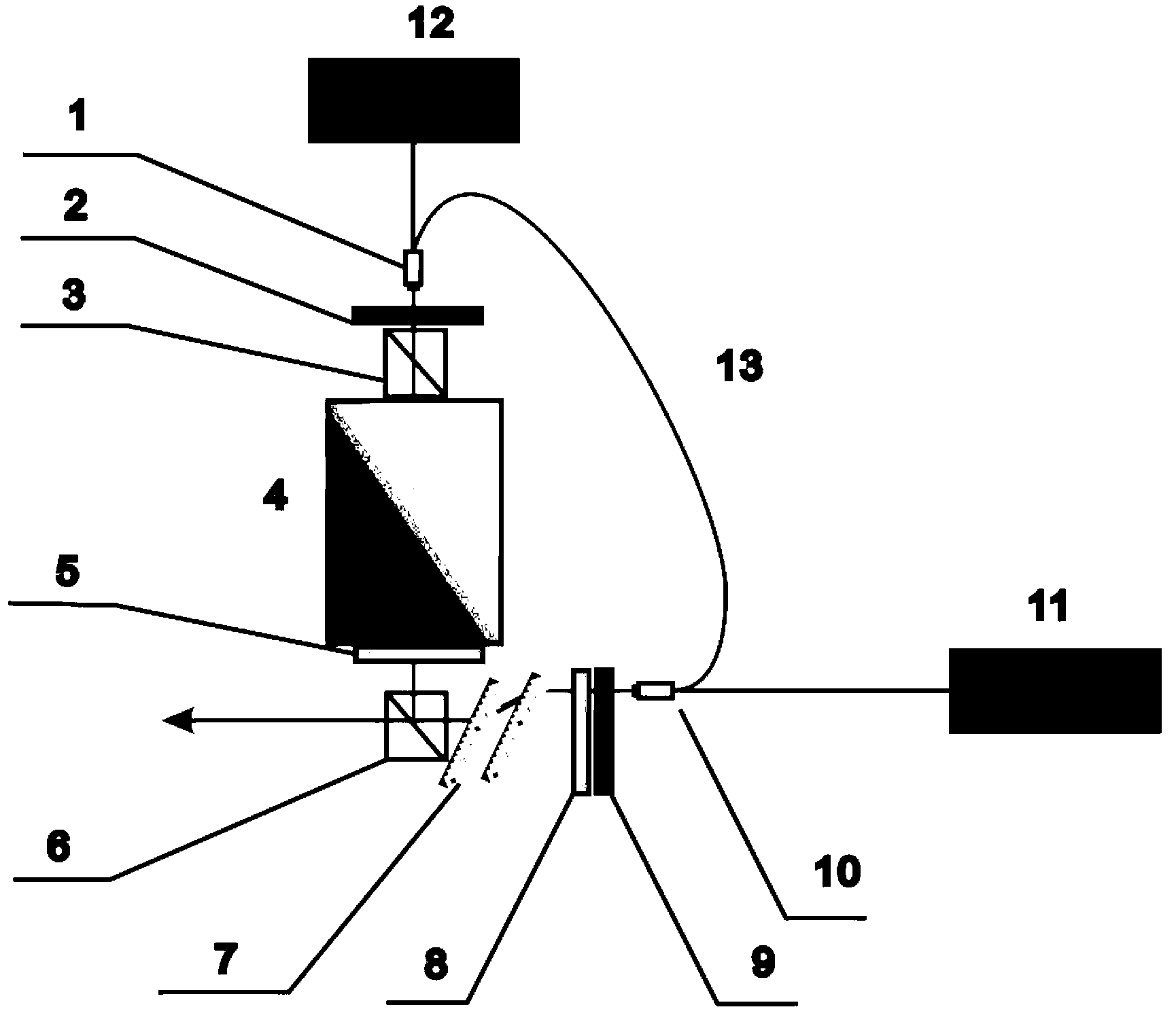

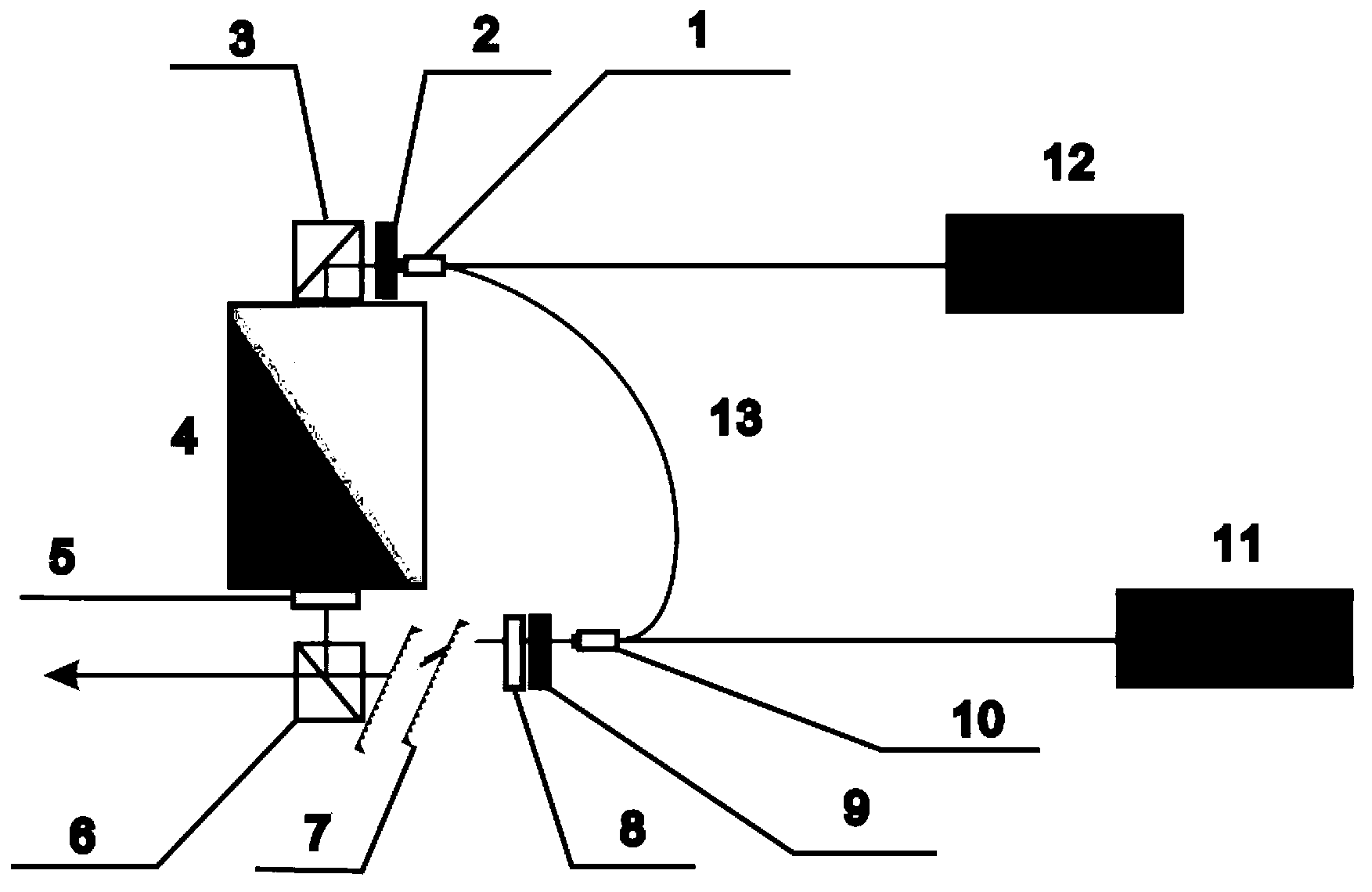

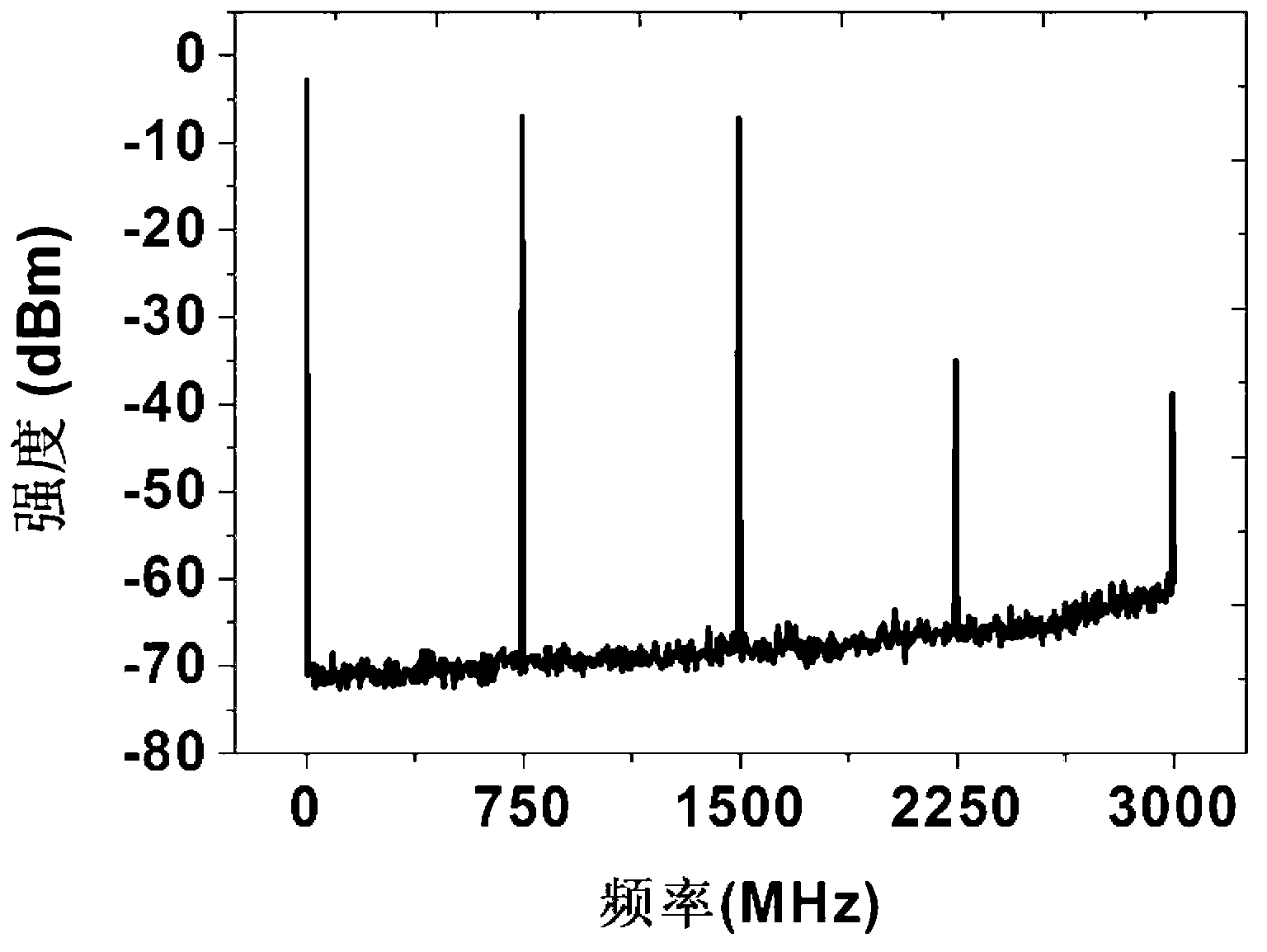

Ring cavity mode locking fiber laser

InactiveCN103022863AShorten the lengthReduce free spaceActive medium shape and constructionMode locked fiber laserGrating

The invention discloses a ring cavity mode locking fiber laser capable of generating high-repeating-frequency laser. The ring cavity mode locking fiber laser comprises an optoisolator, a polarization control component, a first wavelength division multiplexing collimator (1) and a second wavelength division multiplexing collimator (10). Simultaneously, a structure that the optoisolator made of a film magneto-optic material and light pass through a grating pair in unidirectional mode is adopted, the length of the optical fiber is greatly reduced, a laser system is simplified, coupling power and coupling efficiency are improved, repeating frequency, namely frequency interval, is improved, and resolution of the ring cavity mode locking fiber laser used as a frequency comb of a light source is improved.

Owner:PEKING UNIV

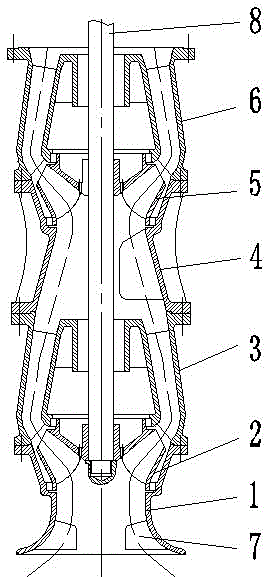

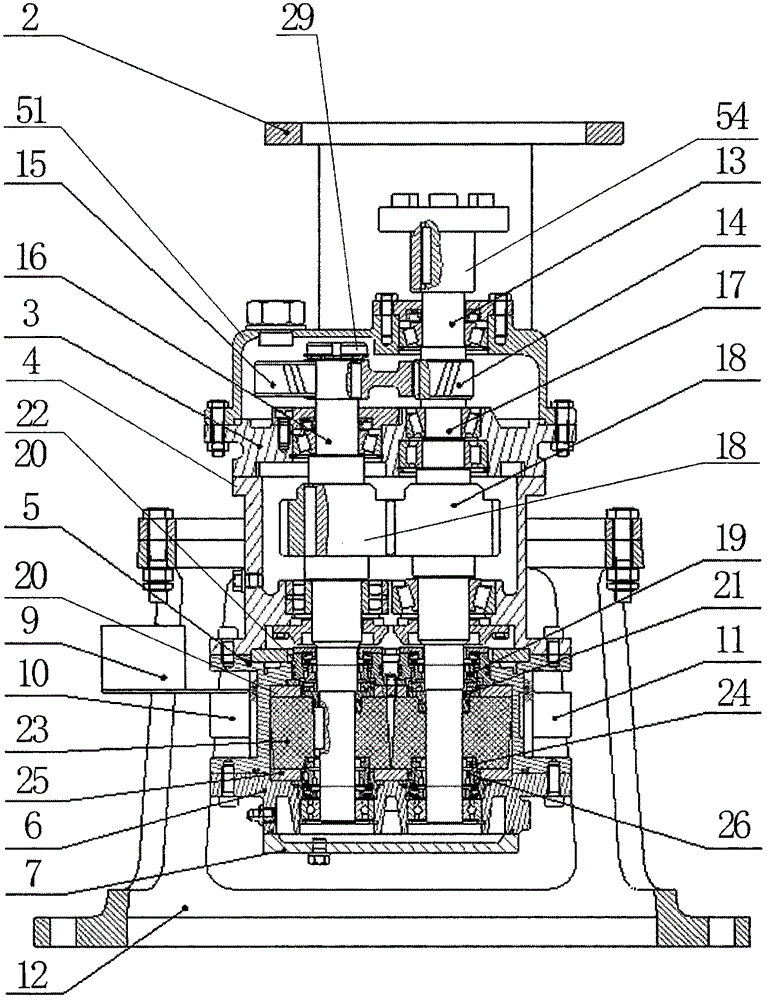

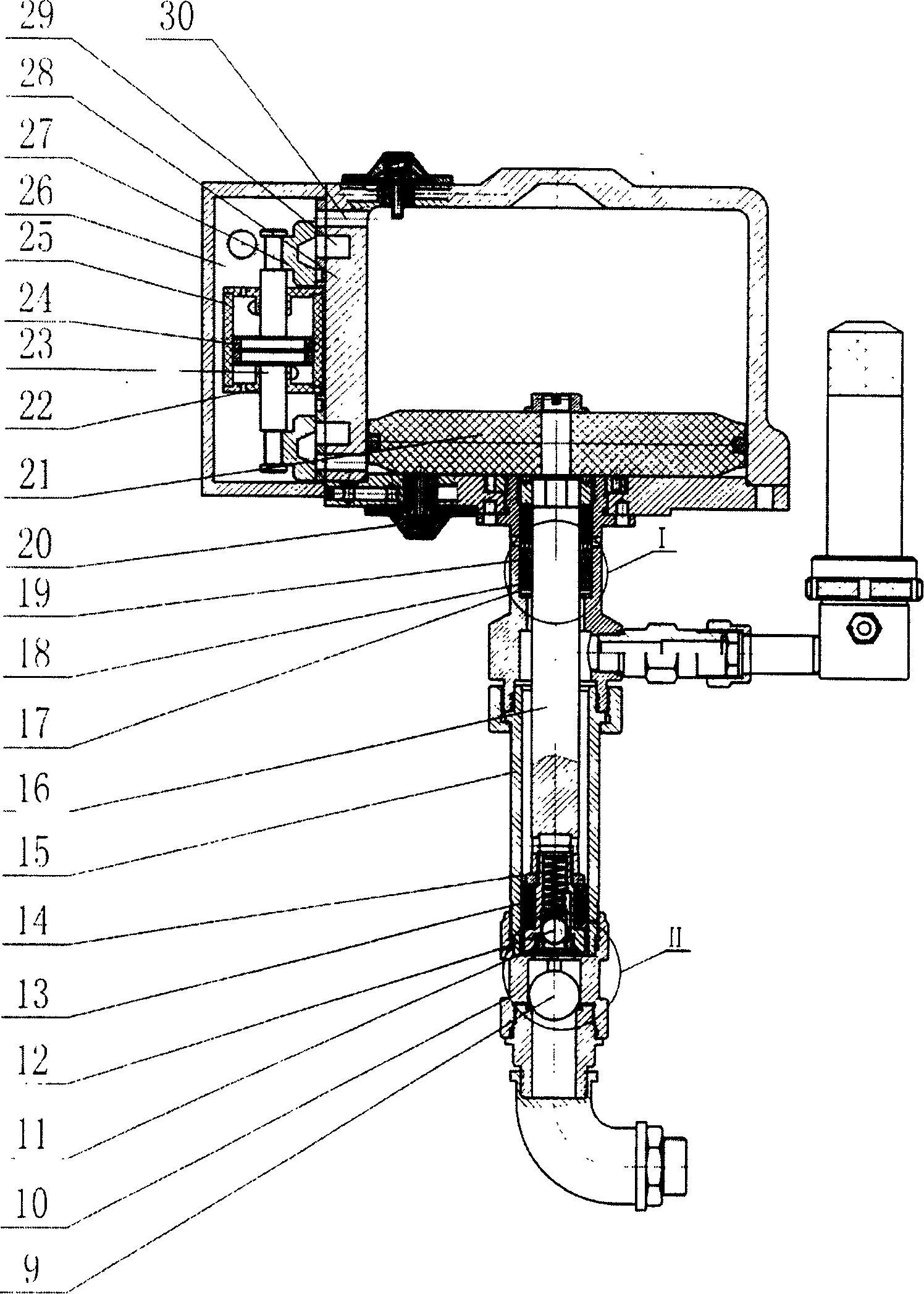

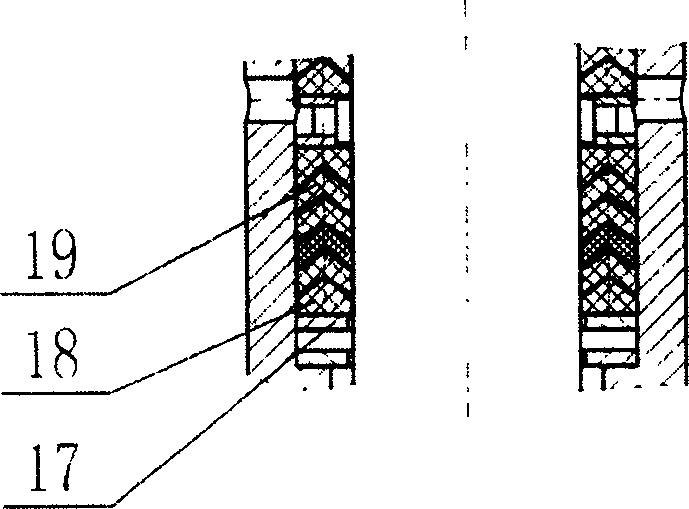

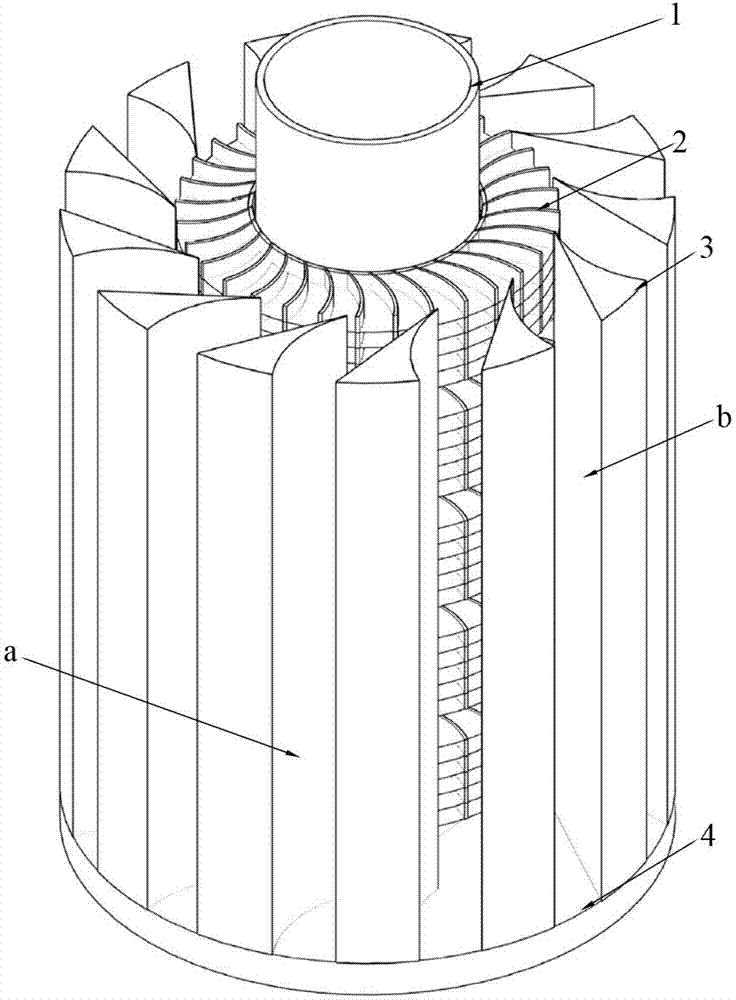

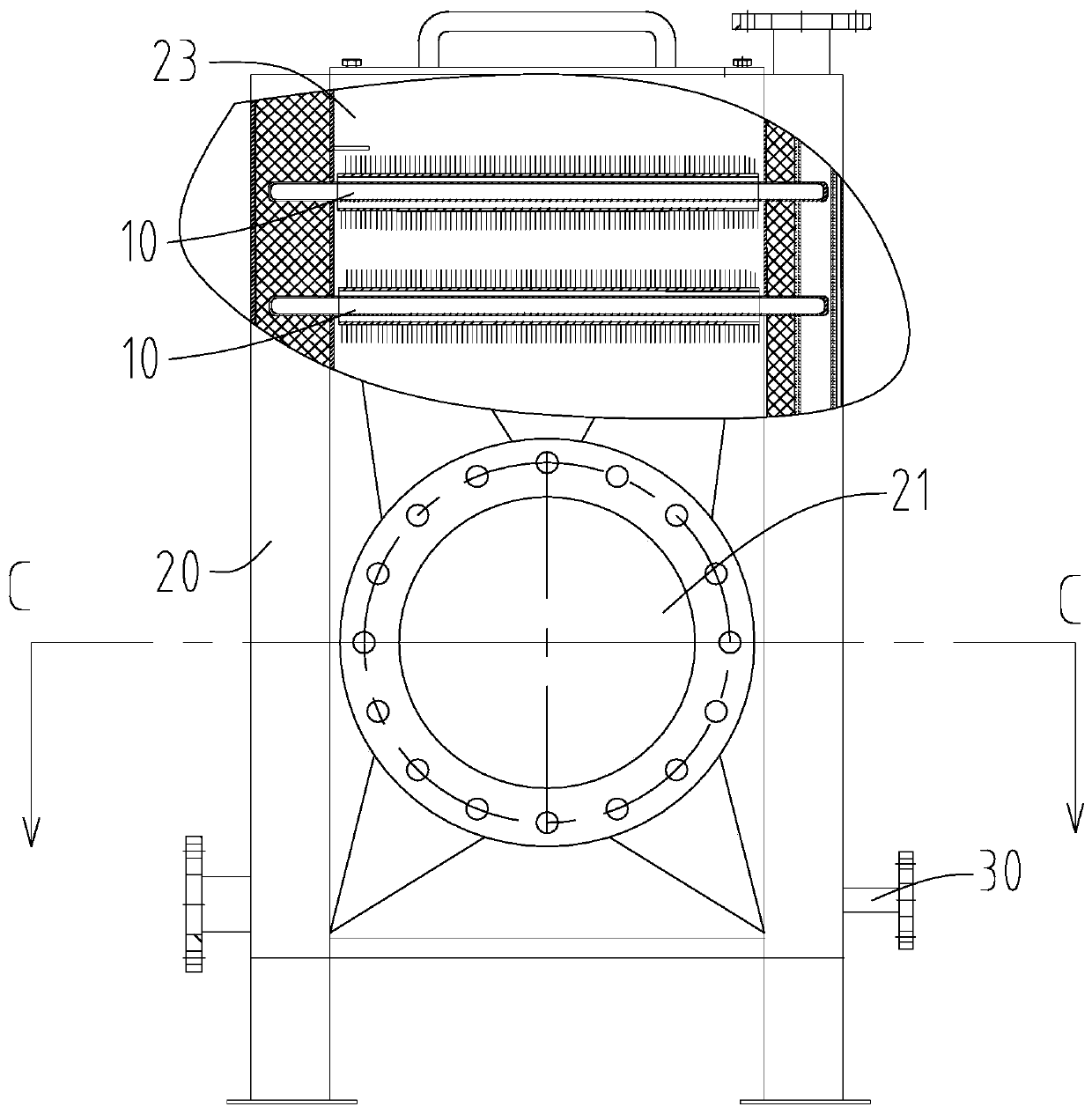

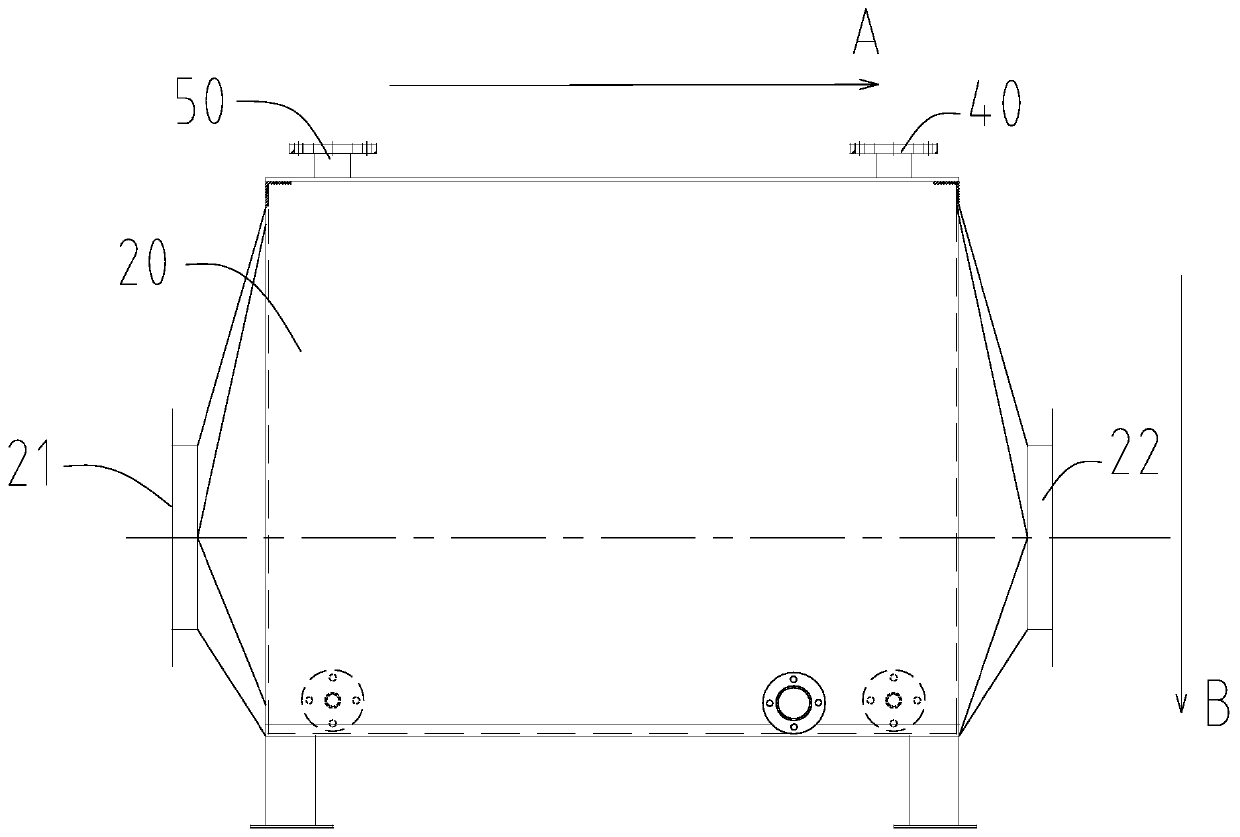

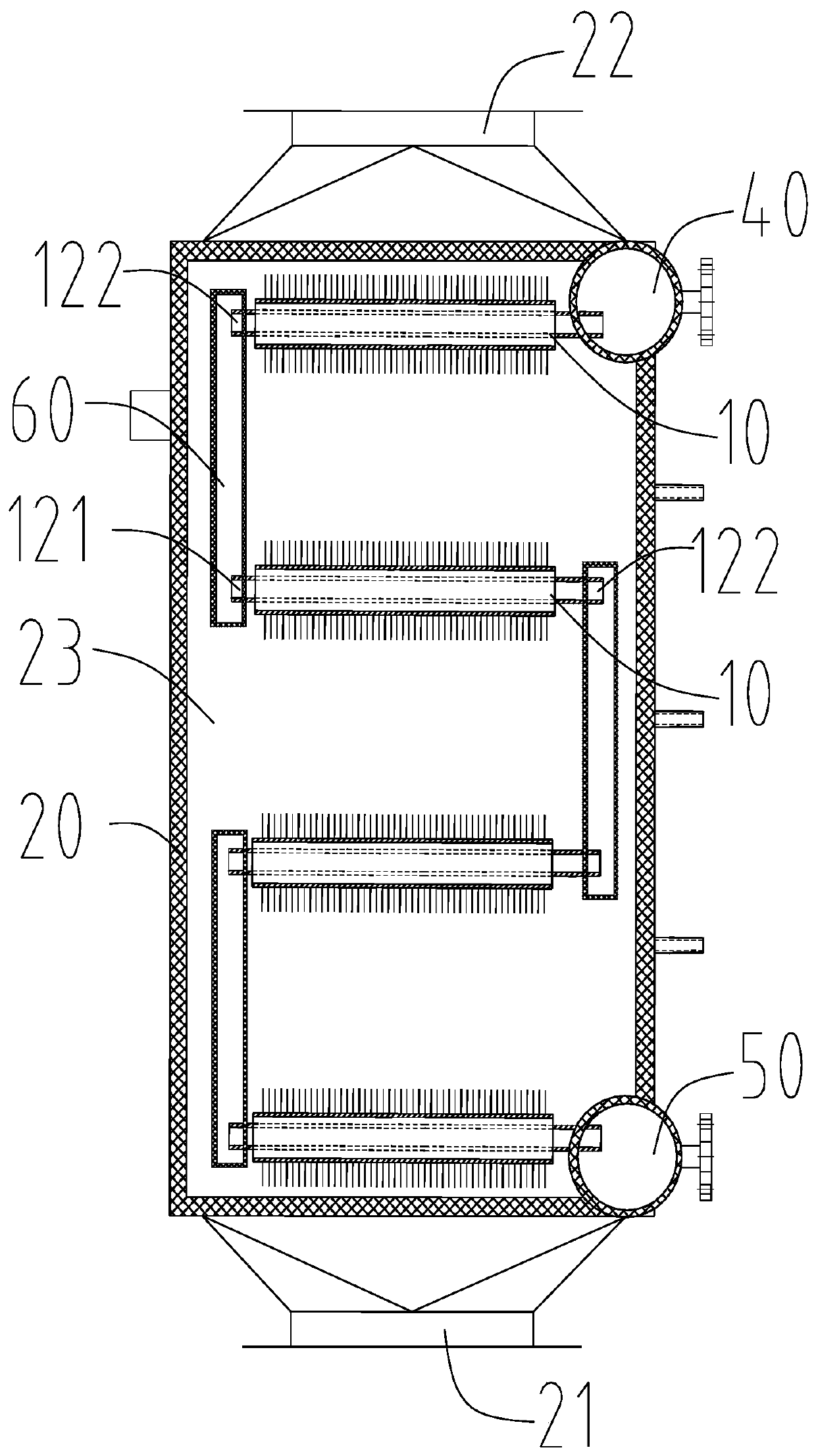

Multi-stage vertical high specific speed mixed-flow pump

InactiveCN104963874ASolve the problem that can only be a single-level structureBroaden the use range of headPump componentsPump installationsImpellerMixed flow

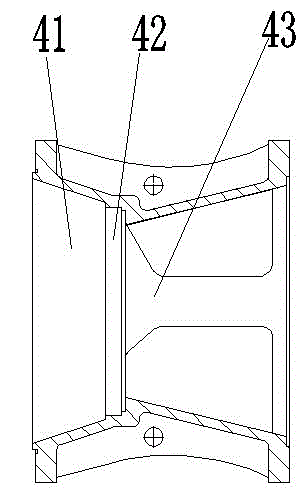

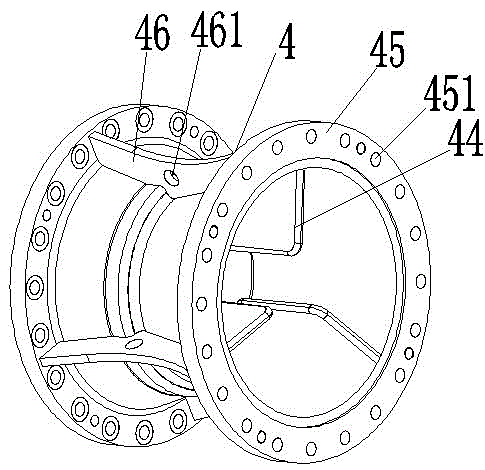

The invention discloses a multi-stage vertical high specific speed mixed-flow pump which comprises a suction cone and a drive shaft arranged in the center. The upper end of the suction cone is connected with primary guide vane bodies, the upper end of each primary guide vane body is connected with a secondary guide vane body, a primary vane wheel is arranged between the suction cone and the primary guide vane bodies, and a secondary van wheel is arranged between the primary guide vane bodies and the secondary guide vane bodies; the primary vane wheel and the secondary vane wheel are both arranged on the drive shaft, and middle transition joints are connected between the primary guide vane bodies and the secondary guide vane bodies; the secondary vane wheel is arranged between the middle transition joints and the secondary guide vane bodies; each middle transition joint is provided with a leading-in cavity which is connected with a leading-out cavity, a transition opening is formed between each leading-in cavity and the corresponding leading-out cavity, the inner walls of the leading-in cavities are all provided with transitional flow deflectors, and the two ends of each middle transition joint are provided with connecting flanges. According to the multi-stage vertical high specific speed mixed-flow pump, the lift is high, the flow is large, the efficiency is high, the size is small, the production cost is low, the installation is convenient, and the practical range of the vertical mixed-flow pump is greatly widened.

Owner:HUNAN NANFANG CHANGHE PUMP IND

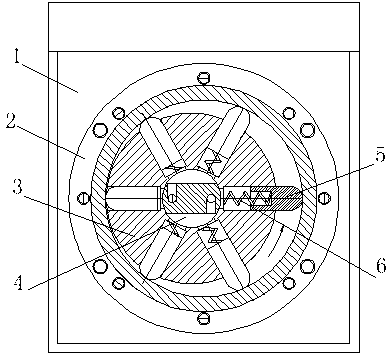

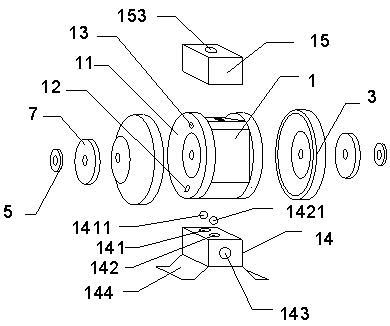

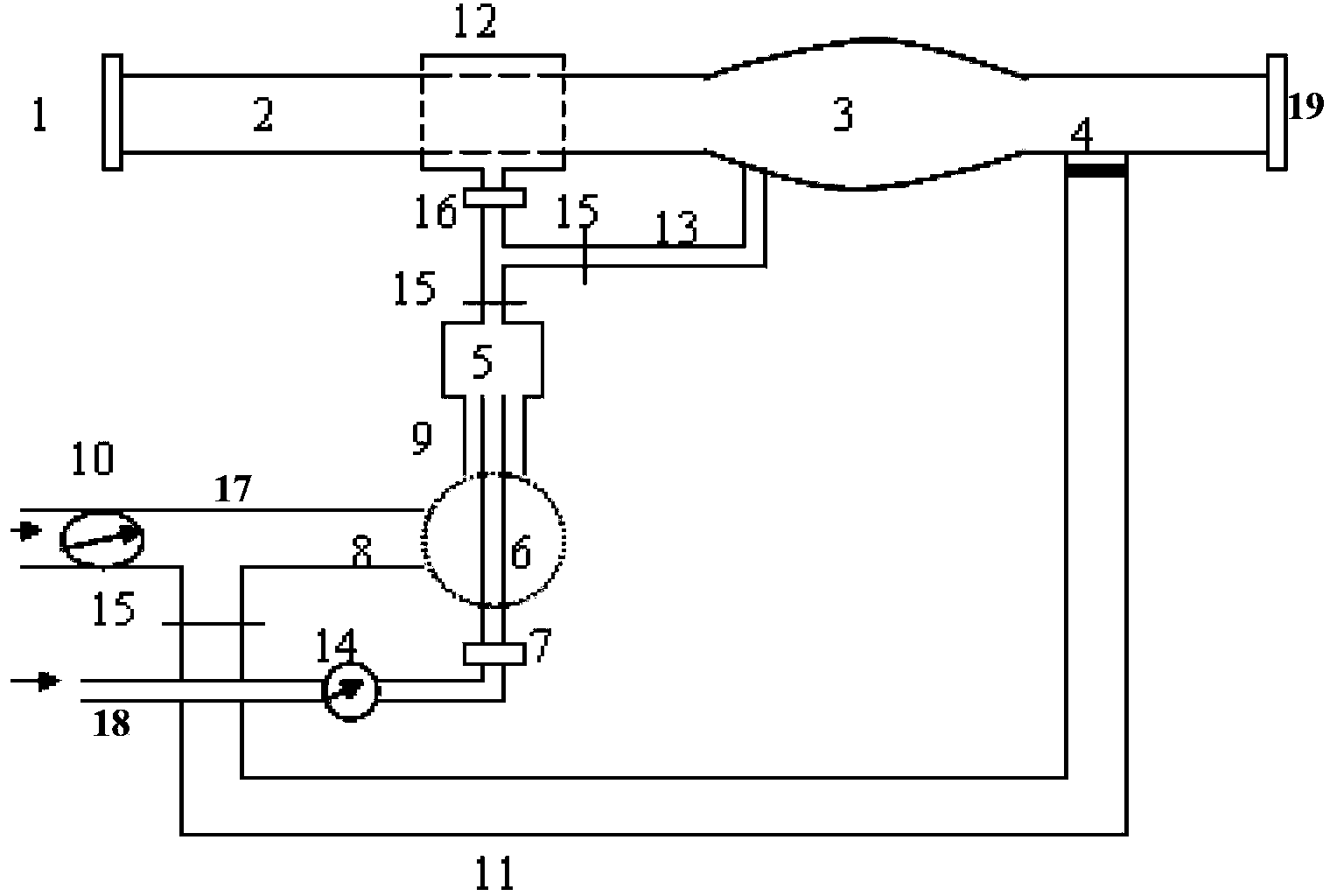

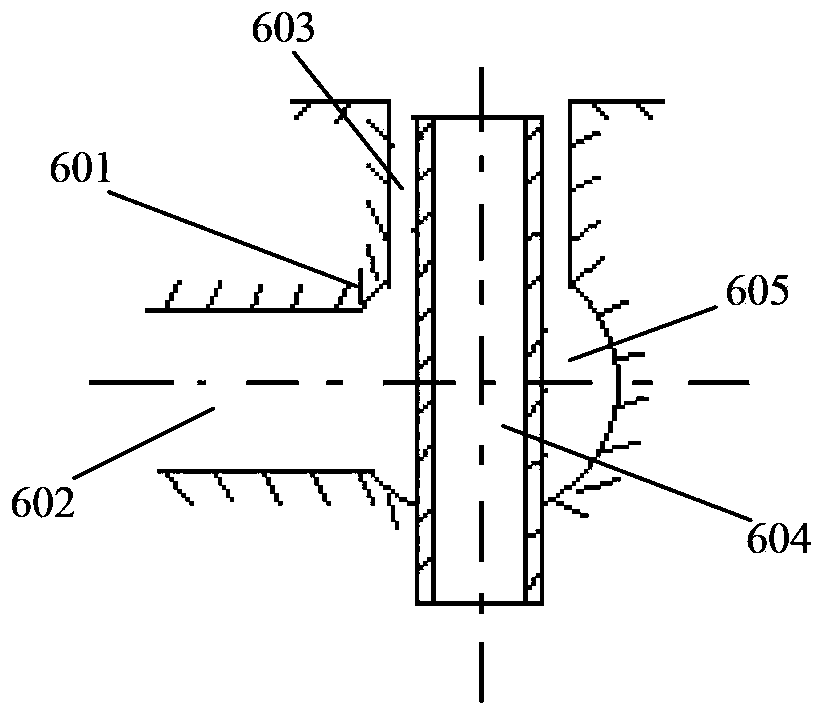

Pneumatic magnetic pump

InactiveCN103185010AAvoid shockAvoid corrosionPump installationsNon-positive displacement fluid enginesImpellerDiaphragm pump

The invention discloses a pneumatic magnetic pump and belongs to the technical field of magnetic driving and pneumatics. A conveying impeller shaft is positioned between a left pump body and a shielding sleeve; a conveying component is sleeved on the conveying impeller shaft; a driving impeller shaft is positioned between the shielding sleeve and a right pump body and is connected with a driving component through a deep groove ball bearing; the driving component is formed by sequentially connecting an outer magnetic ring, a driving impeller left baffle, a driving impeller framework, a driving vane and a driving impeller right baffle; the conveying component is formed by sequentially connecting a conveying impeller left baffle, a conveying vane, a conveying impeller framework, an inner magnetic ring and a conveying impeller right baffle; and the left pump body, the shielding sleeve and the right pump body are connected through bolts, and are sealed by O-shaped rubber sealing rings, with high tightness. The pneumatic magnetic pump has superior performance to a pneumatic diaphragm pump, has the significant advantages of no leakage, continuous and uniform liquid conveying, energy conservation, environment friendliness, safety, reliability, convenience for use and the like, and is wide in application.

Owner:BEIJING UNIV OF TECH

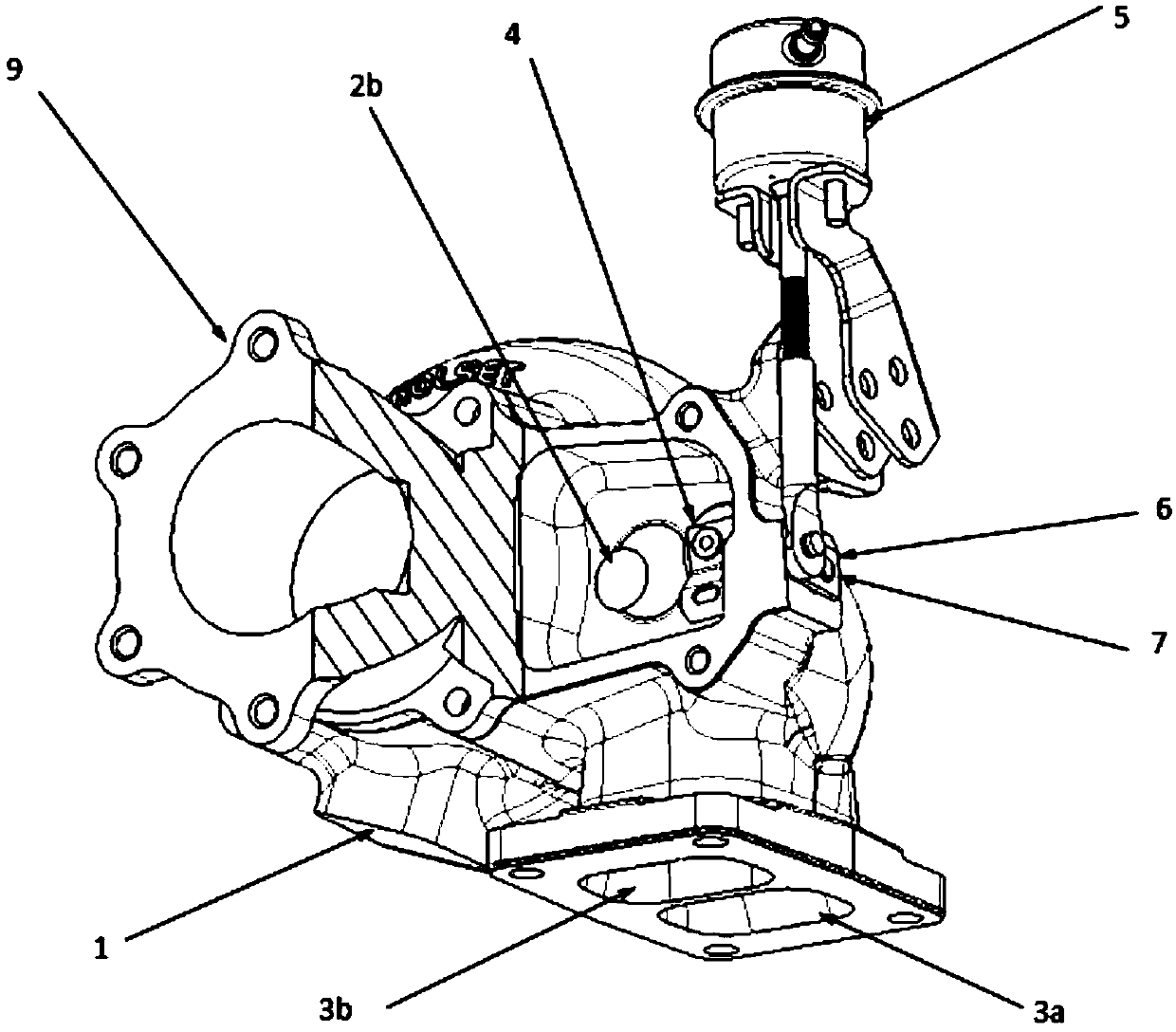

Shell structure of turbine shell

PendingCN107740710ASmall pulseReduce speedInternal combustion piston enginesEngine componentsCombustionTurbocharger

The invention belongs to the technical field of engine turbochargers, and relates to a shell structure of a turbine shell. The shell structure comprises the turbine shell; an outlet of the turbine shell is in sealed connection with a transition joint, and a transition joint cavity is formed between the transition joint and the turbine shell; a first turbine shell flue-gas bypass channel is formedin the upper part in the turbine shell, the gas inlet end of the first turbine shell flue-gas bypass channel communicates with a first turbine shell gas-inlet flowing channel formed in the bottom of the turbine shell, and the gas outlet end of the first turbine shell flue-gas bypass channel communicates with the transition joint cavity; and the turbine shell is internally provided with a flue-gasbypass valve for controlling opening and closing of the first turbine shell flue-gas bypass channel, and the bottom of the turbine shell is further provided with a second turbine shell gas-inlet flowing channel. According to the shell structure of the turbine shell, by adjusting the structures of the transition joint and the turbine shell, selecting and switching of the two structures are achieved, so that the overall combustion efficiency of an engine is improved, fuel economy is improved accordingly, and meanwhile, the risks of an excessive high supercharging pressure and an excessive high rotating speed of a supercharger are reduced.

Owner:WUXI CUMMINS TURBO TECH

High-pressure gas-controlled bacteria valve

InactiveCN109990099AAvoid interferenceEnable Attitude StabilizationOperating means/releasing devices for valvesLift valveInlet channelReciprocating motion

The invention relates to the technical field of valves, in particular to a high-pressure gas-controlled bacteria valve. The high-pressure gas-controlled bacteria valve comprises a first shell, a valveelement, a second shell and a pneumatic part; a medium cavity is formed inside the first shell, an inlet channel communicating with the medium cavity and the outside is formed in the first shell, andan outflow channel communicating with the medium cavity and the outside is further arranged on the first shell; the valve element is arranged in the valve cavity and is located between the inlet channel and the outflow channel; a pneumatic cavity is formed in the second shell, and the outer wall of the second shell is provided with an air channel interface communicating with the pneumatic cavityand the outside; the pneumatic part can perform reciprocating motion in the pneumatic cavity under the driving of an external air source and simultaneously drive the valve element to do reciprocatingmotion; and the valve element is suitable for cutting off or opening a passage formed by the inlet channel and the outflow channel when the valve element performs reciprocating motion in the medium cavity, and the movement direction of the valve element is perpendicular to the inlet channel. According to the high-pressure gas-controlled bacteria valve, the flow rate of the medium can be more stable, meanwhile, the valve has the advantages of being high in reliability, high in adaptability and the like.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

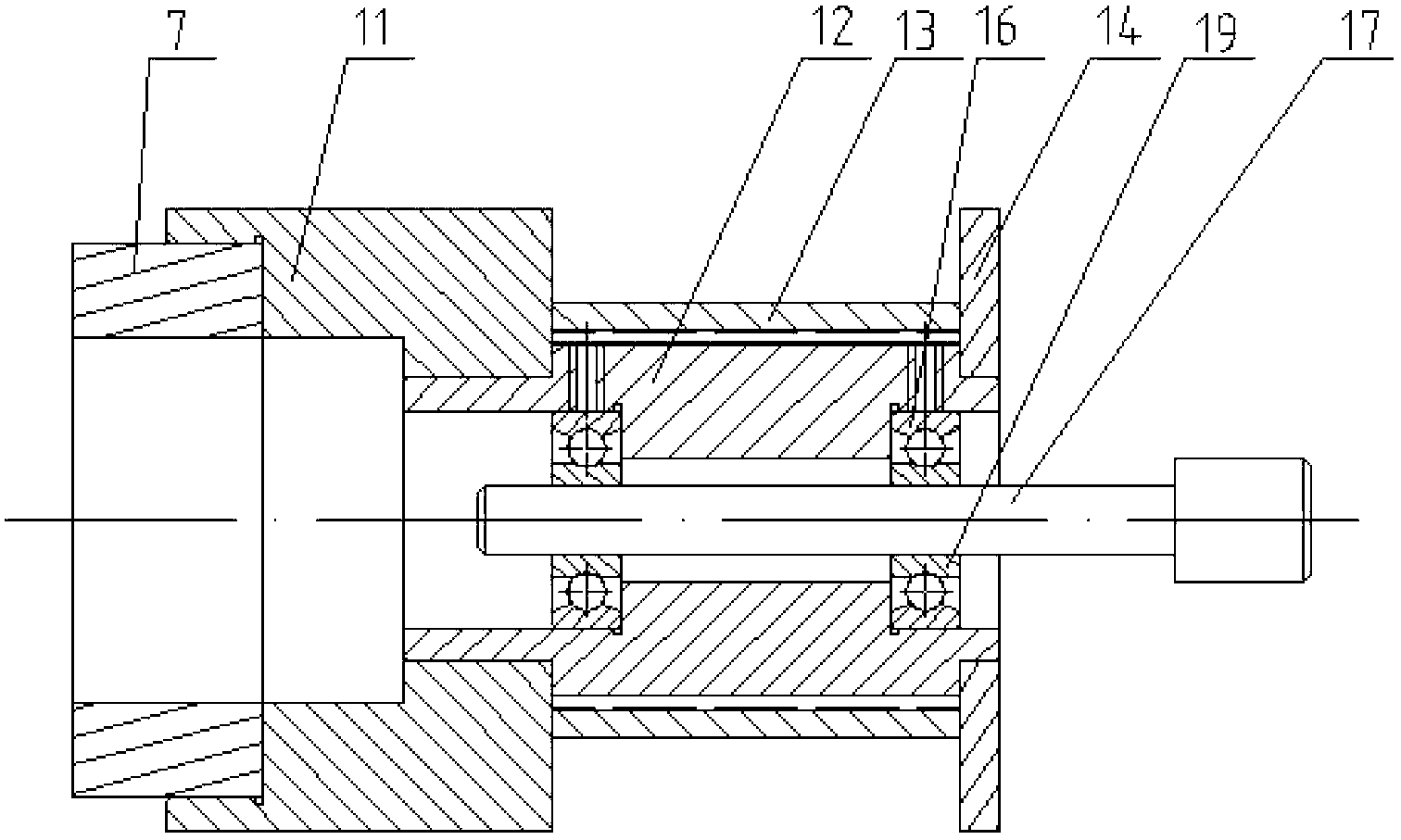

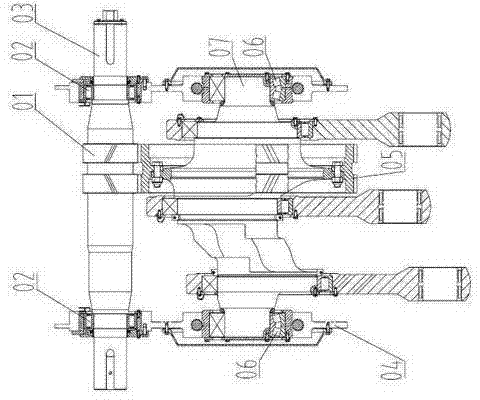

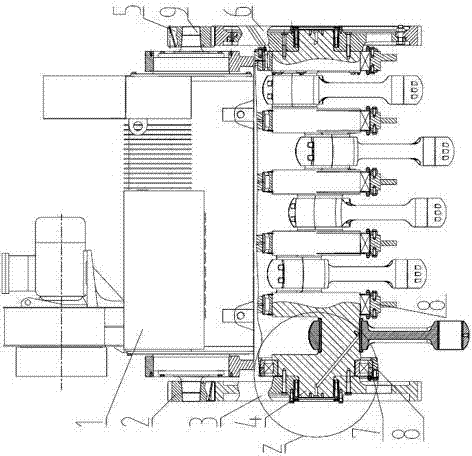

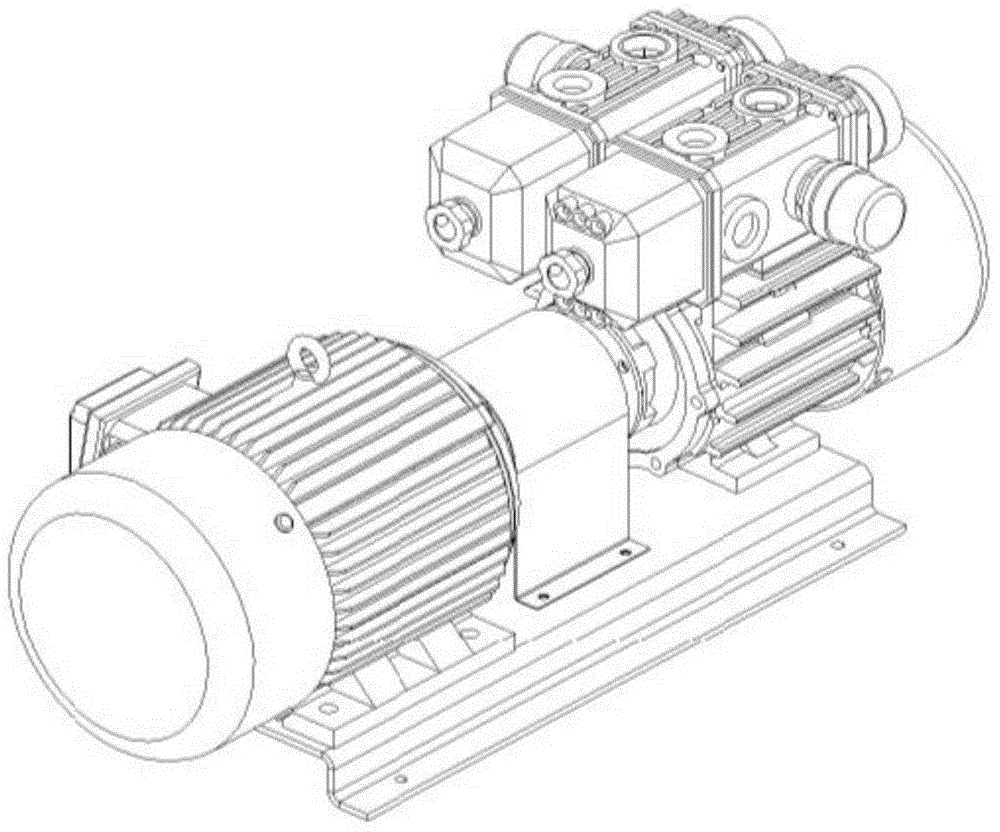

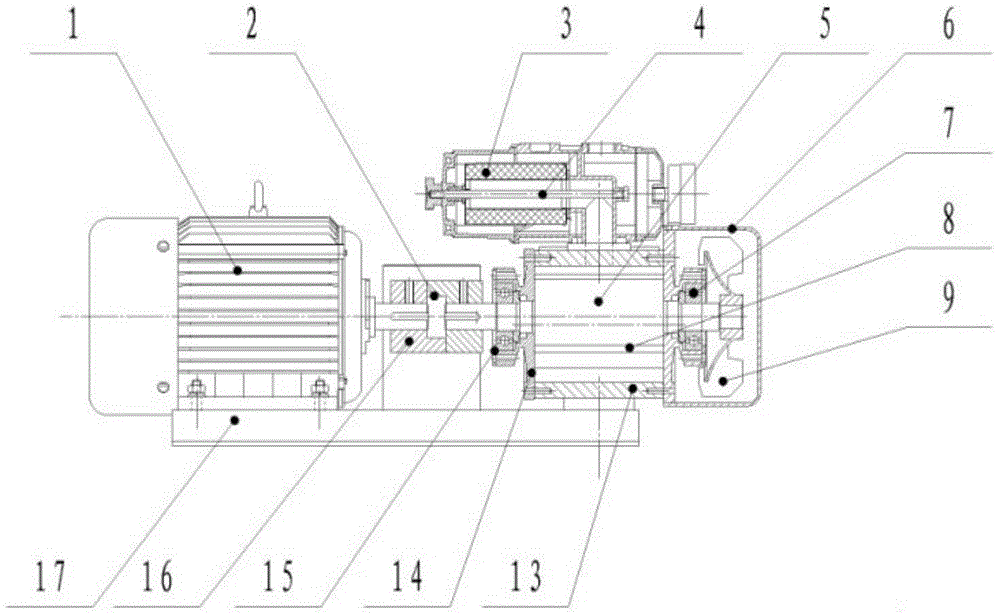

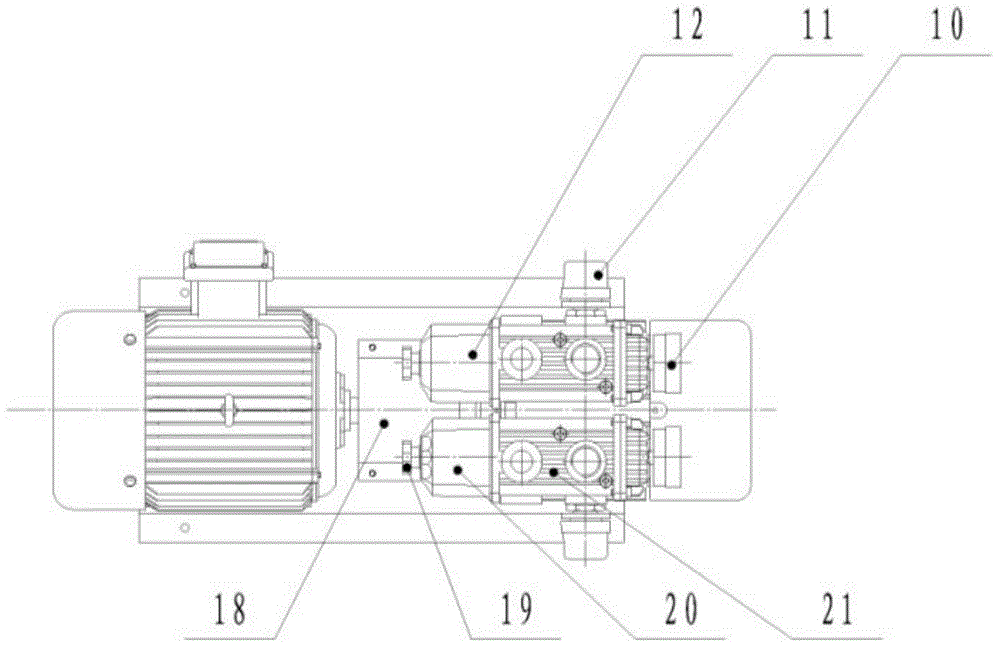

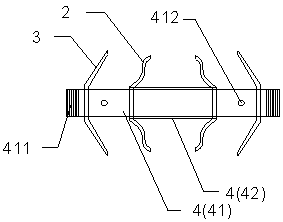

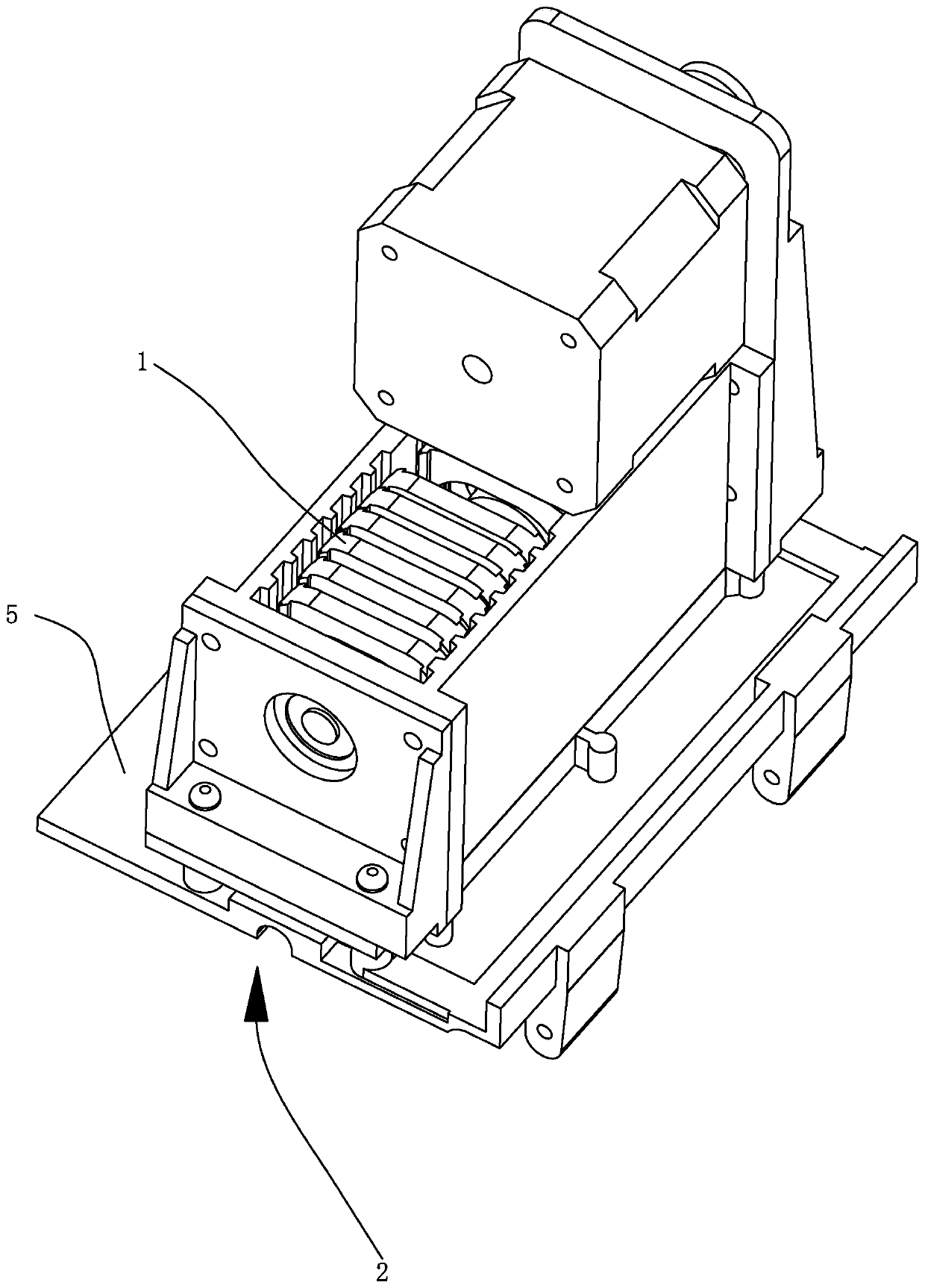

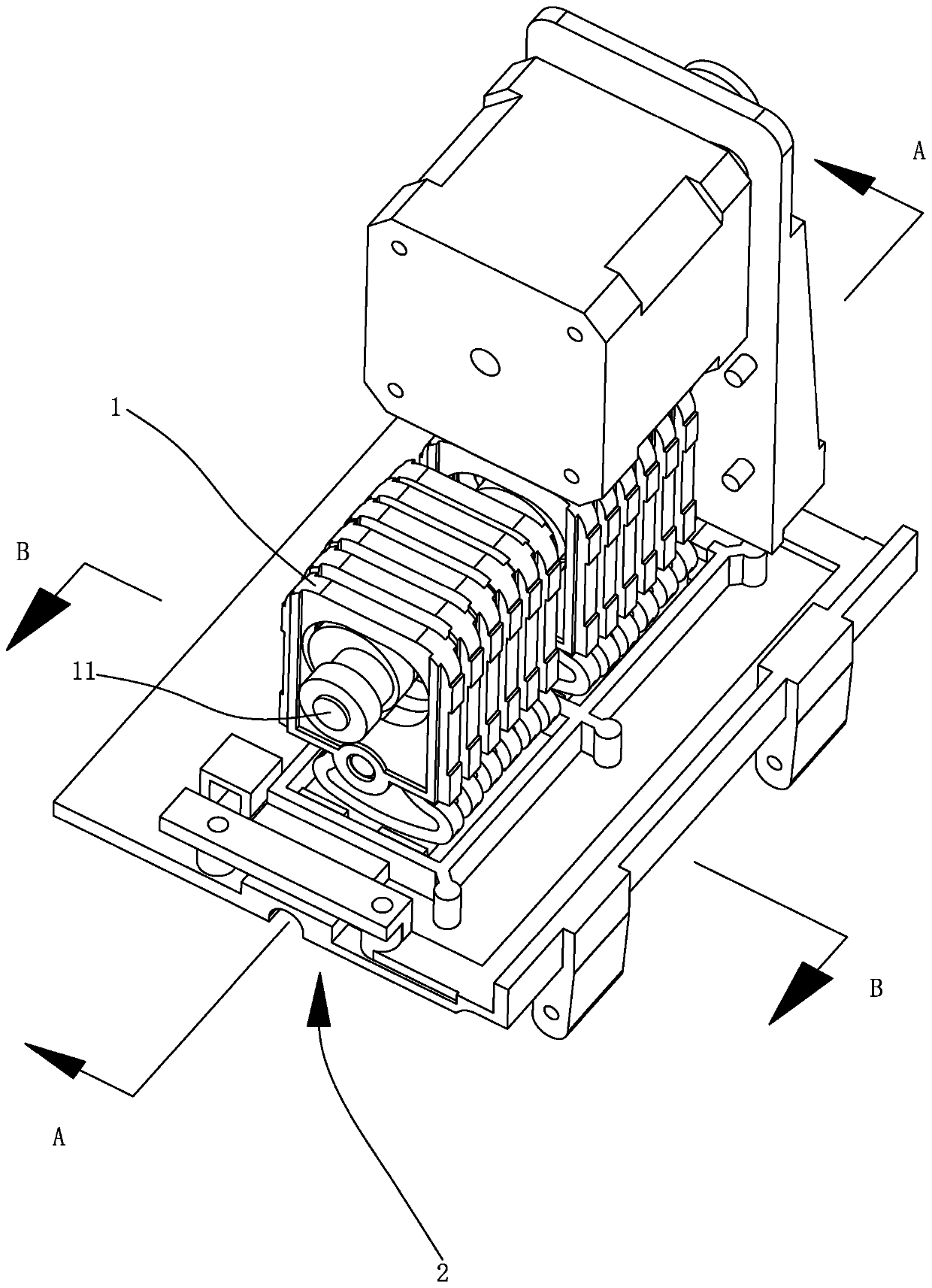

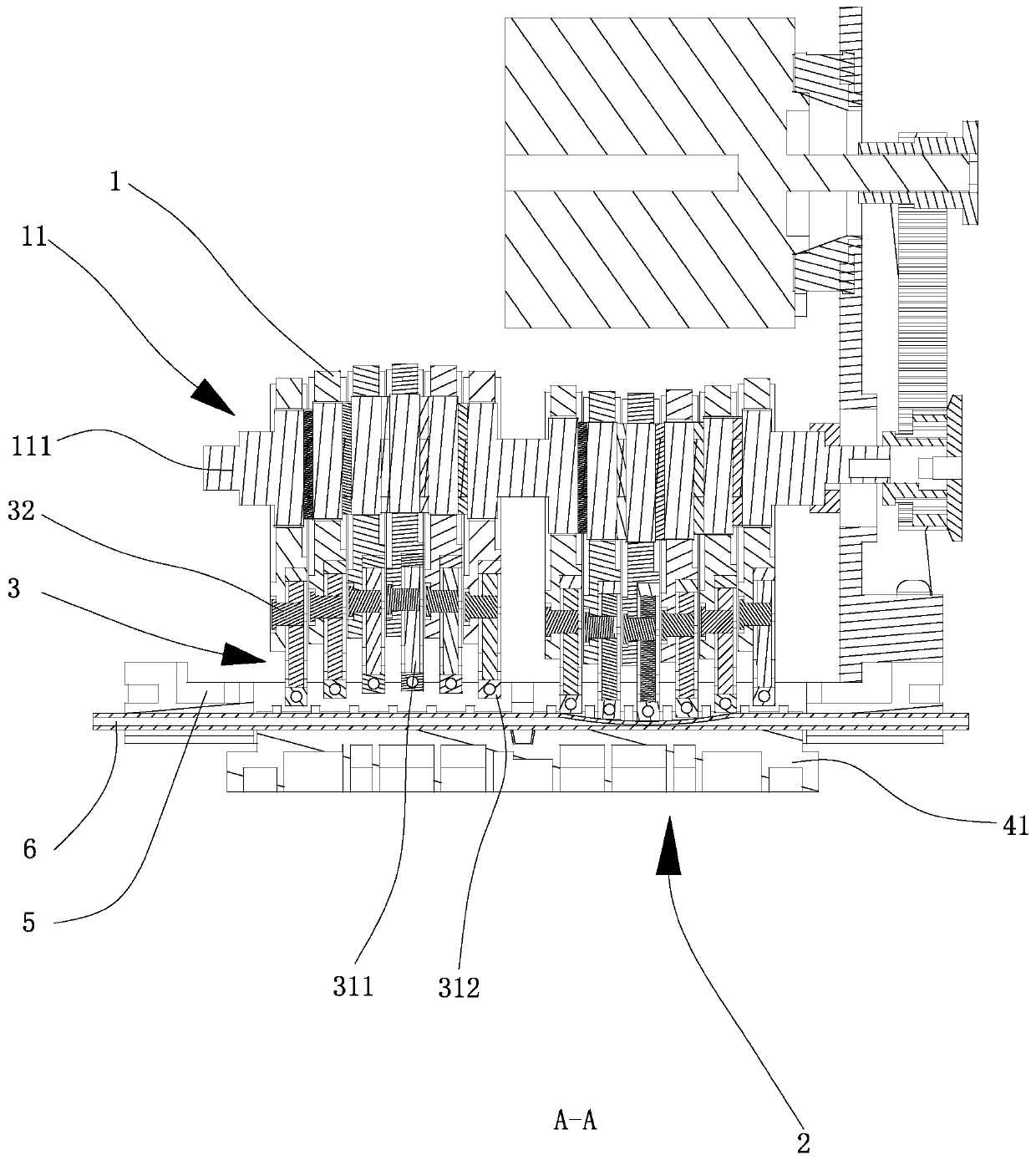

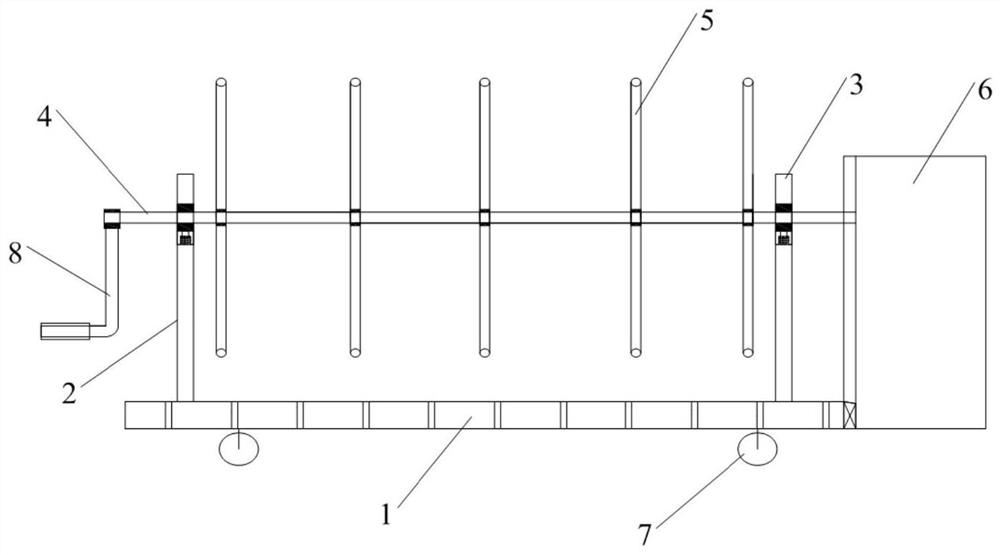

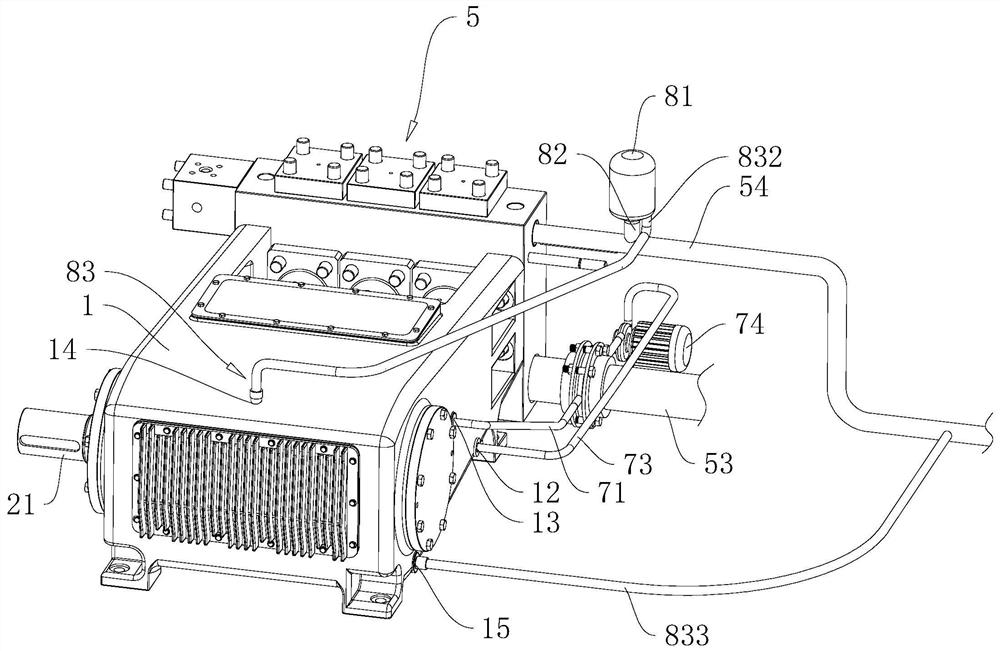

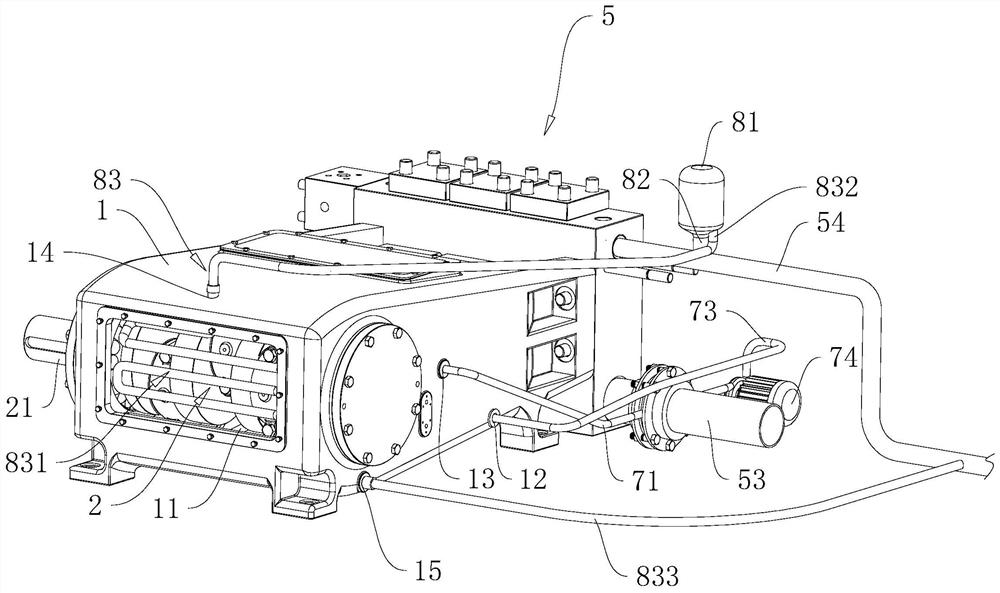

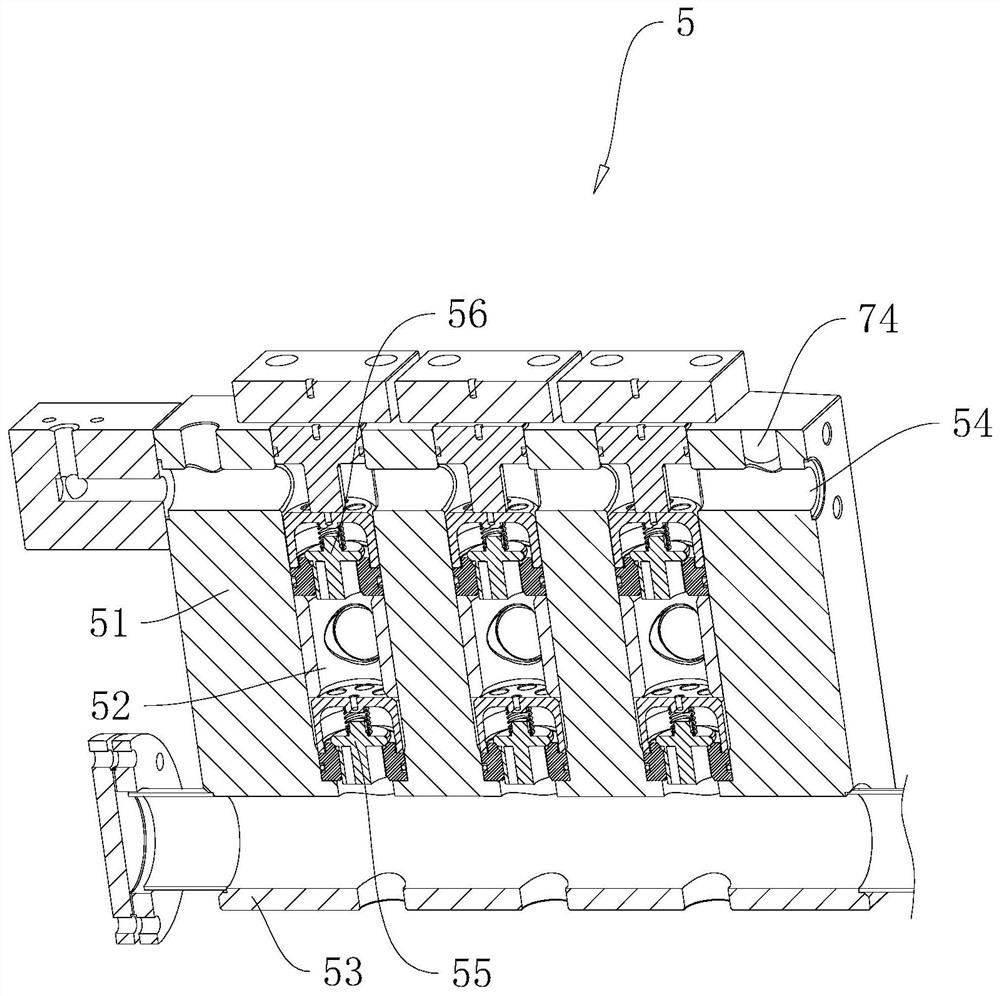

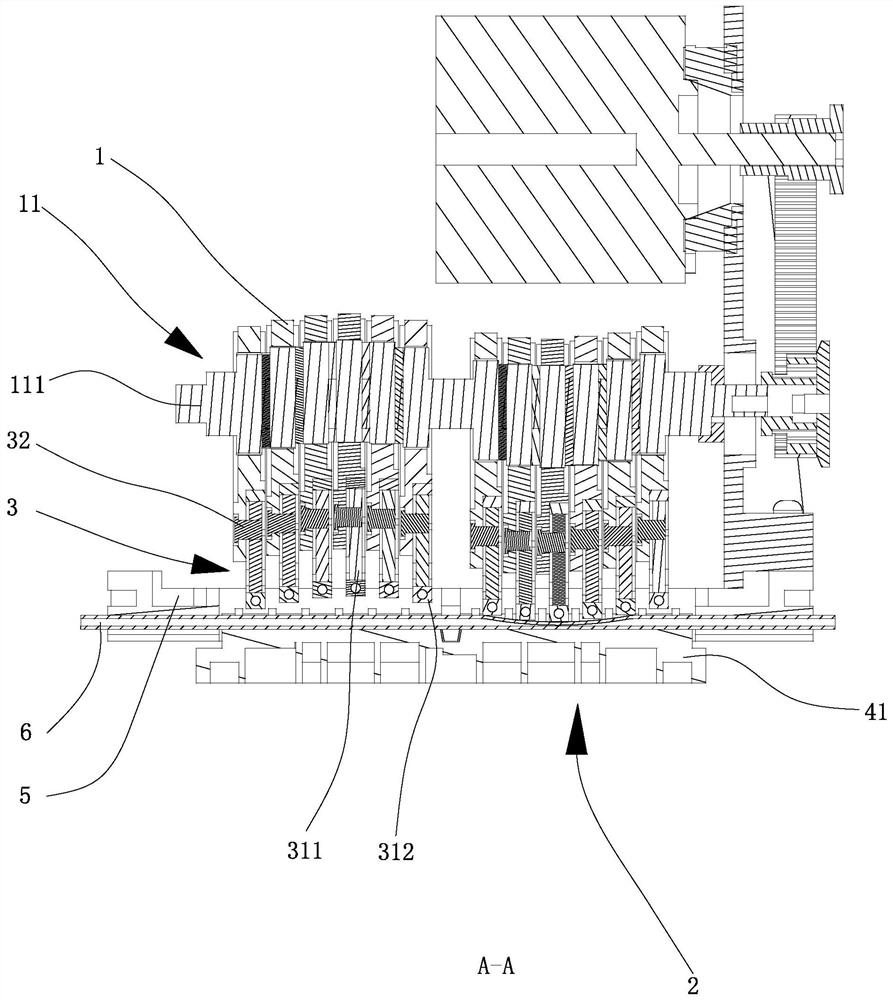

Well drilling five-cylinder pump and method for installing helical gears thereof

ActiveCN103541880APeace of mindEasy to assemble and disassemblePositive displacement pump componentsPumpsWell drillingPinion

The invention discloses a five-cylinder pump and a method for installing helical gears thereof. The five-cylinder pump comprises a framework, a crankshaft, a motor and a pinion shaft; the crankshaft is arranged on the framework, and the pinion shaft is connected with the motor; pinions are arranged at two ends of the pinion shaft; bearings for supporting the crankshaft are arranged on the crankshaft of the five-cylinder pump; the two helical gears are arranged at two ends of the crankshaft, turning directions of teeth of the helical gears are opposite to each other, and the helical gears are connected with the crankshaft by expansion sleeves; stepped holes are formed in the end surfaces of the helical gears, large holes of the stepped holes are expansion sleeve mounting holes, and small holes of the stepped holes are crankshaft mounting positioning holes and are positioned in the inner end surfaces of the helical gears; pressure plates are arranged on the outer end surfaces of the helical gears, are connected with the helical gears by bolts and are abutted to bolts on the outer end surfaces of the expansion sleeves; kidney-shaped holes are formed in the end surfaces of the helical gears, and bolts penetrate the kidney-shaped holes to connect the helical gears with the crankshaft; the helical gears on the crankshaft are in mesh transmission with the pinions. The five-cylinder pump and the method have the advantages that the five-cylinder pump is small in size, long in service life and convenient to disassemble and assemble.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

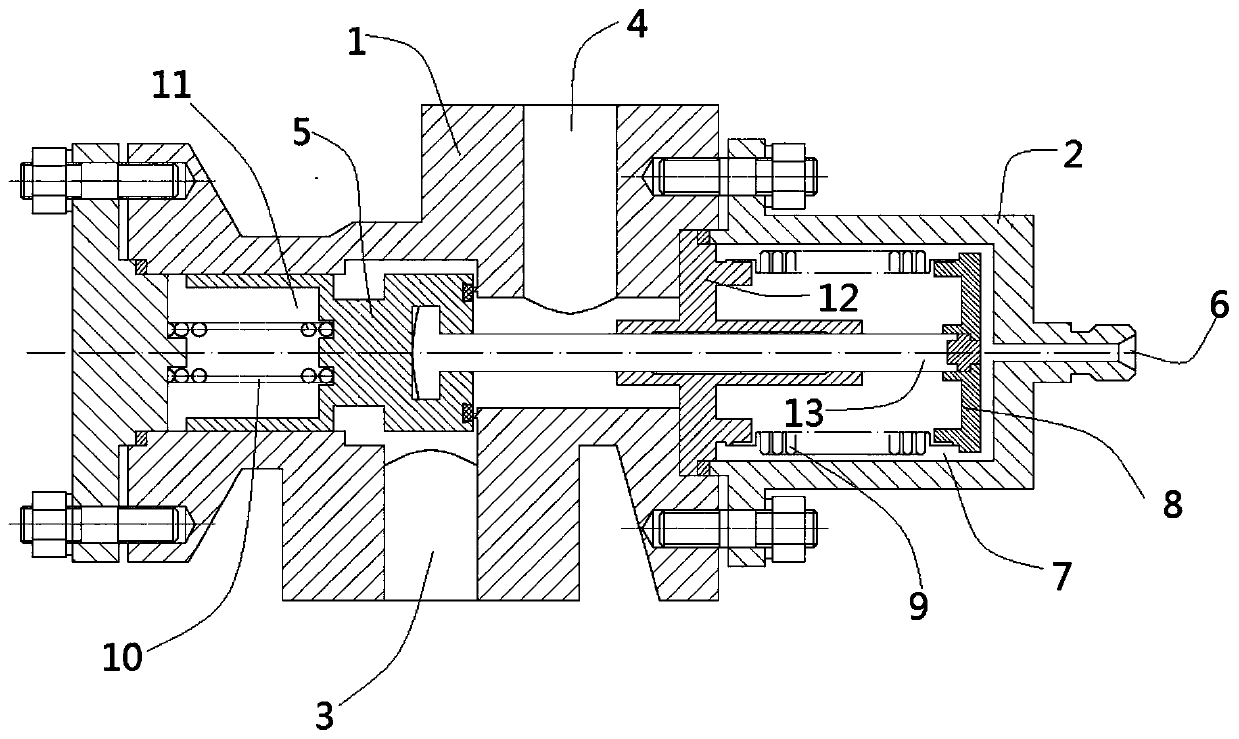

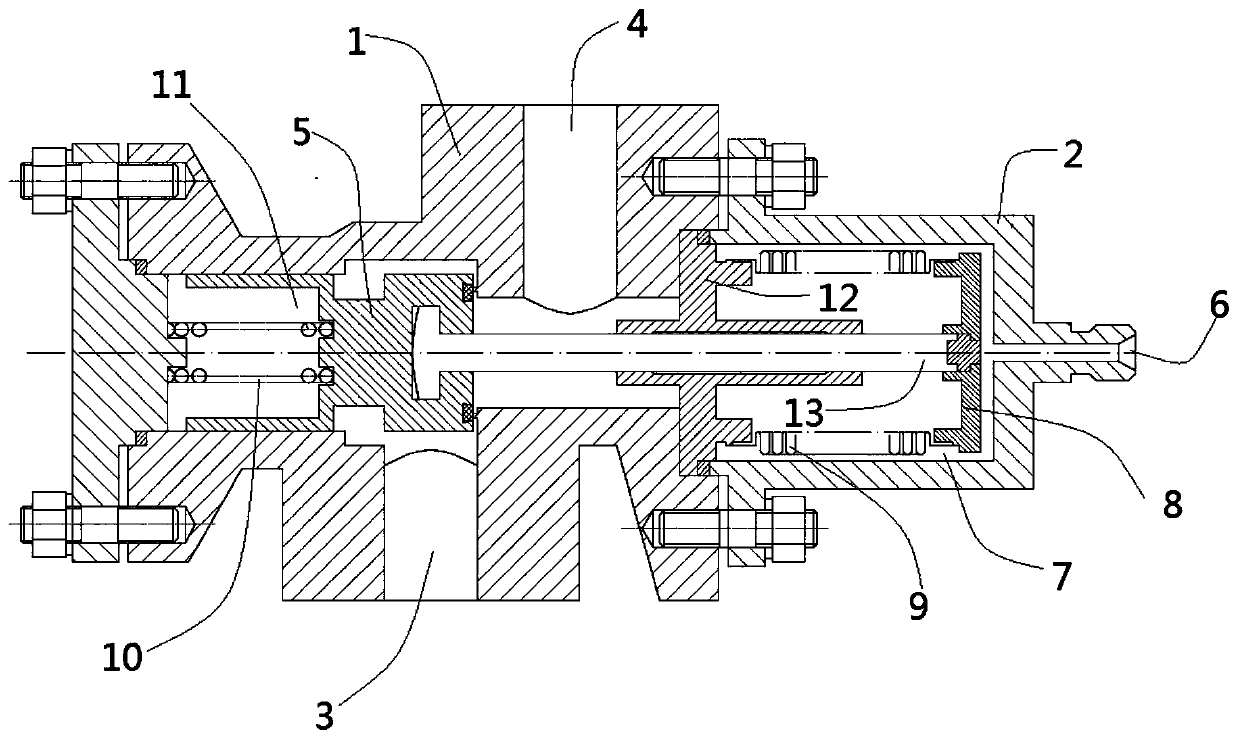

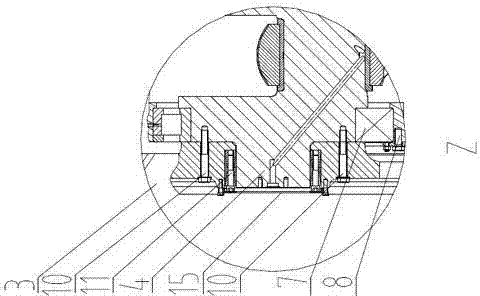

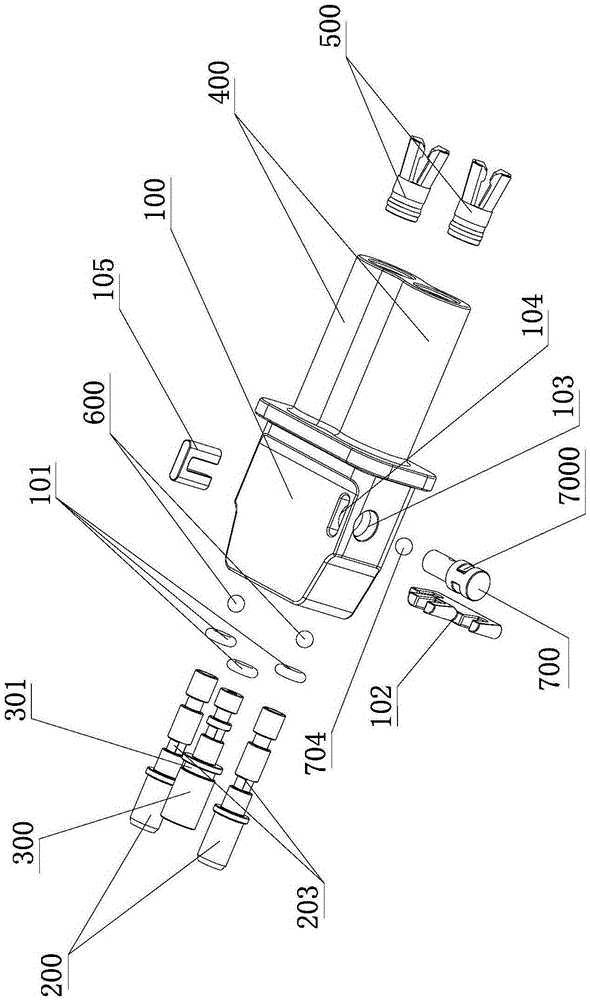

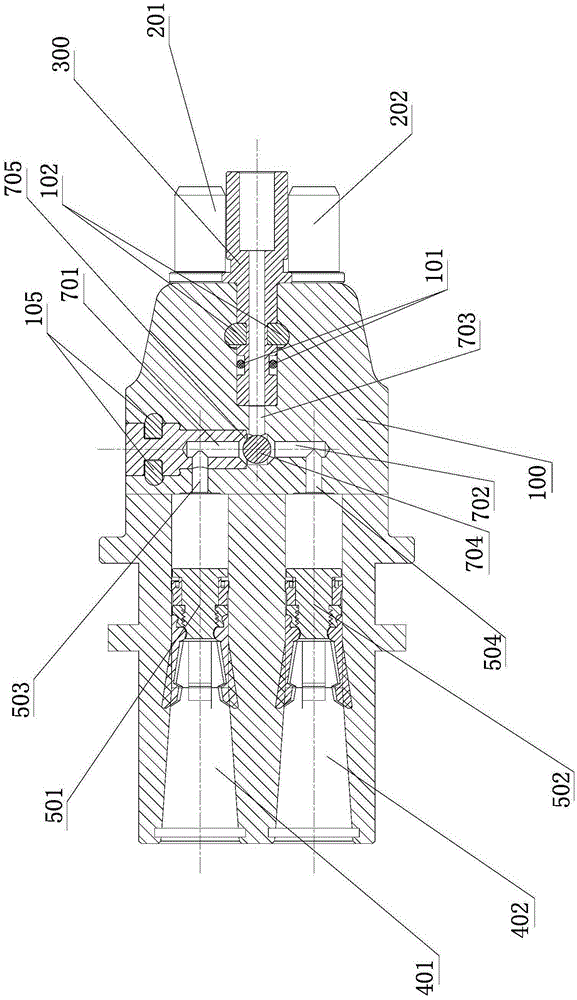

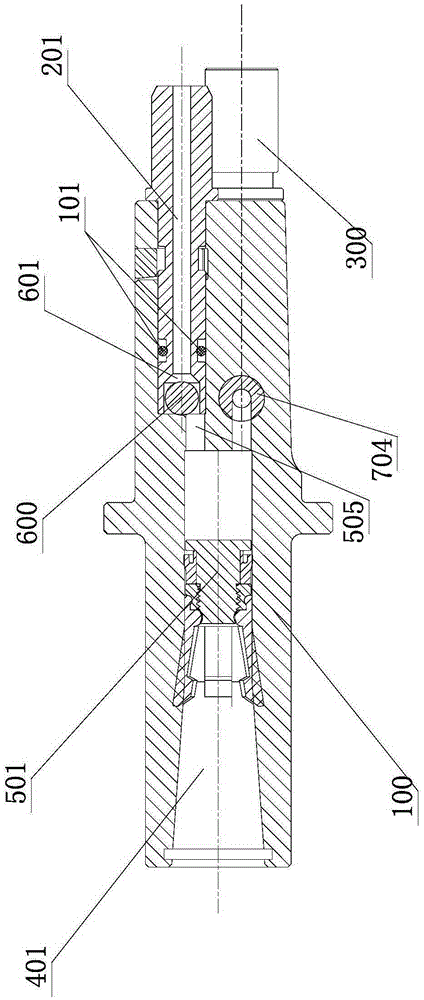

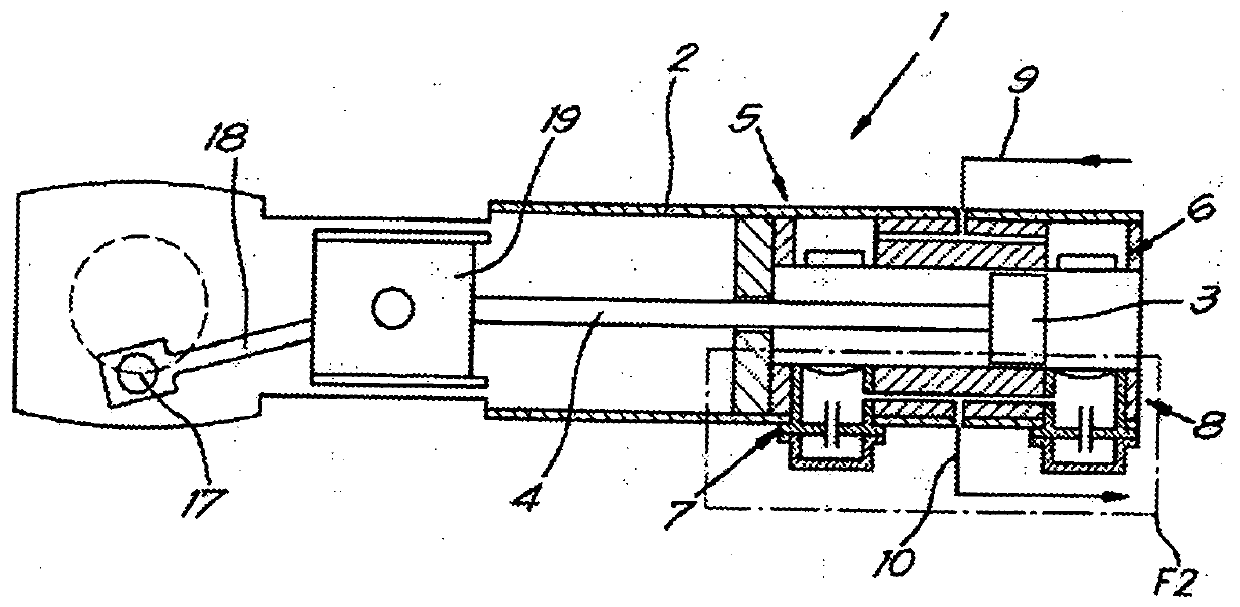

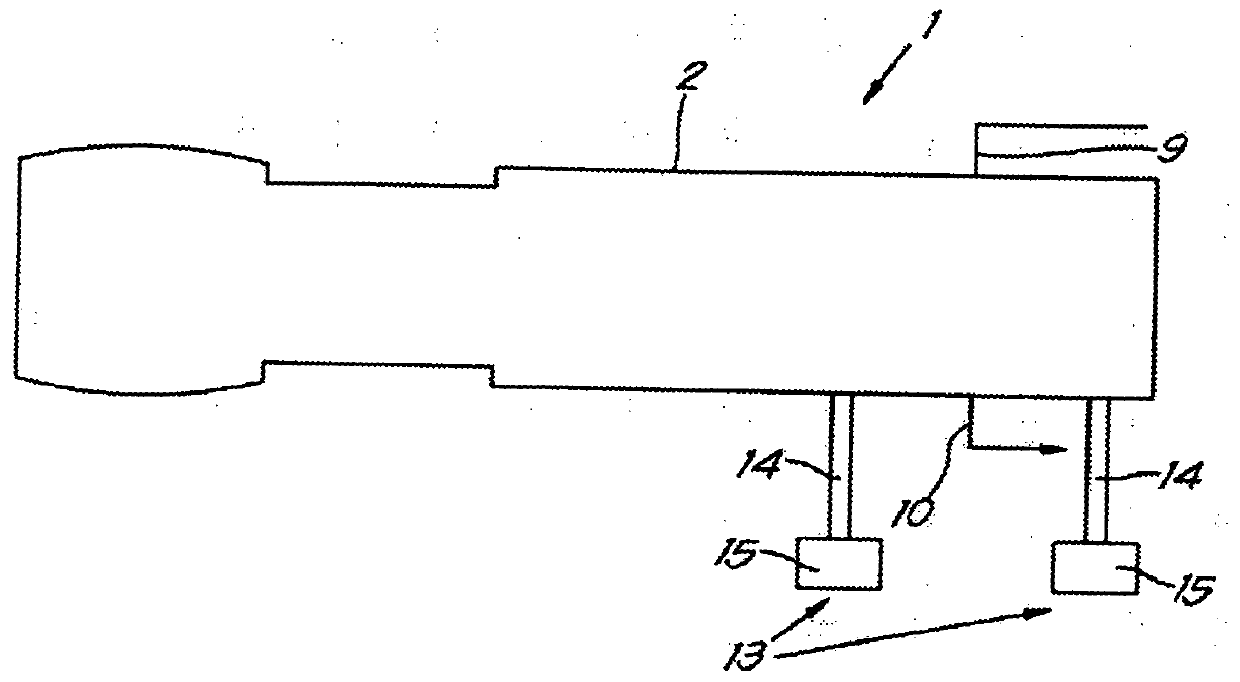

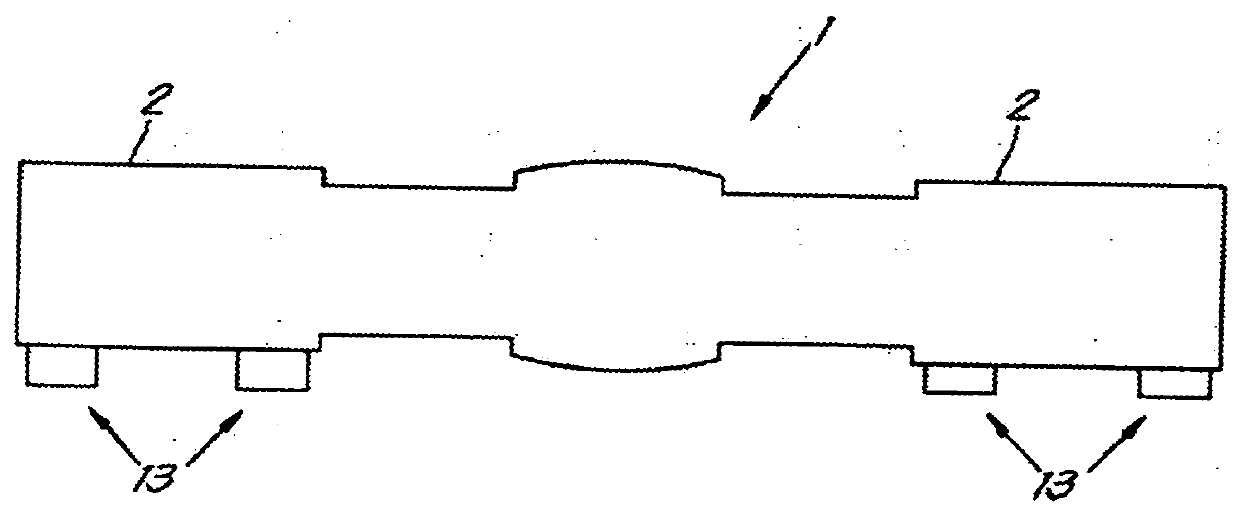

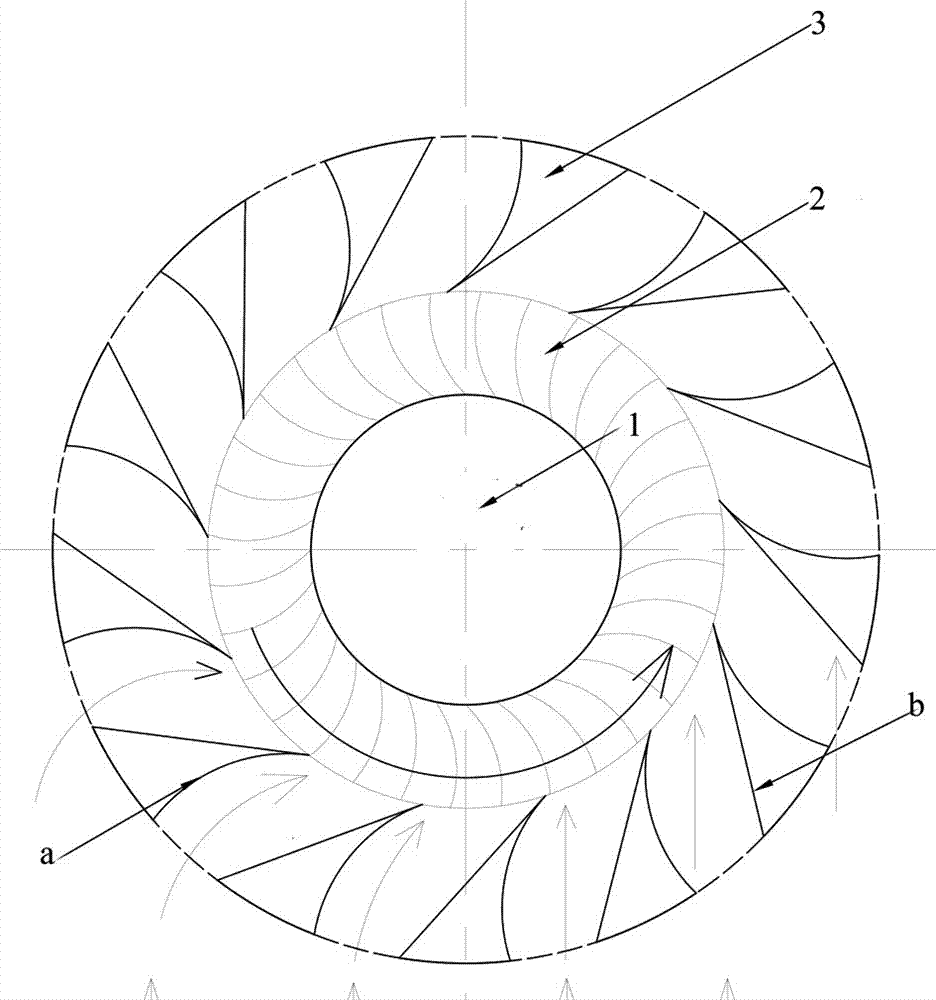

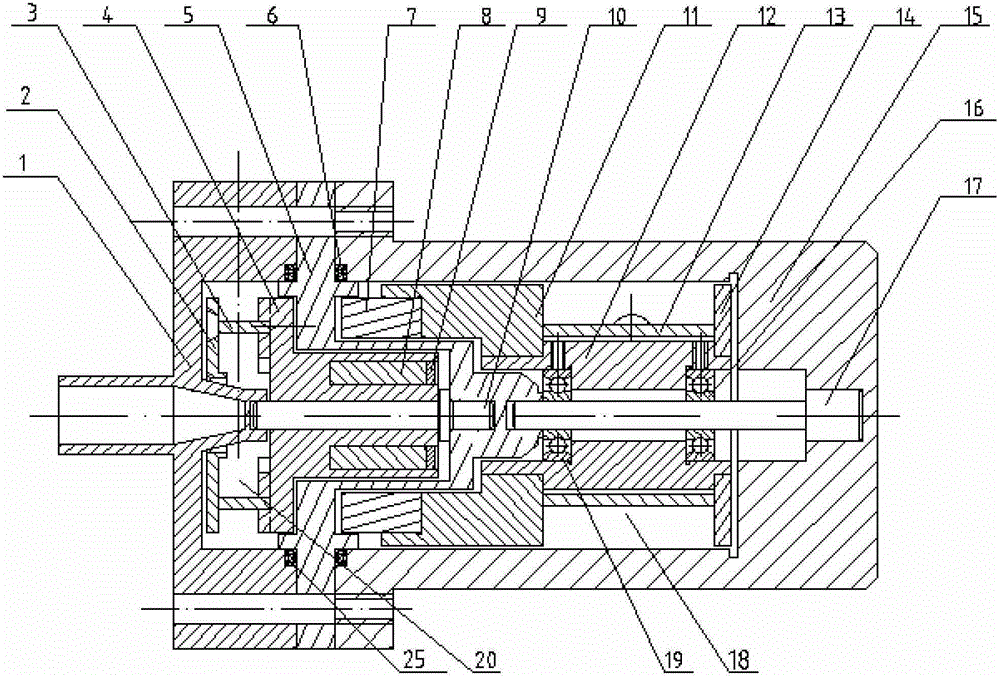

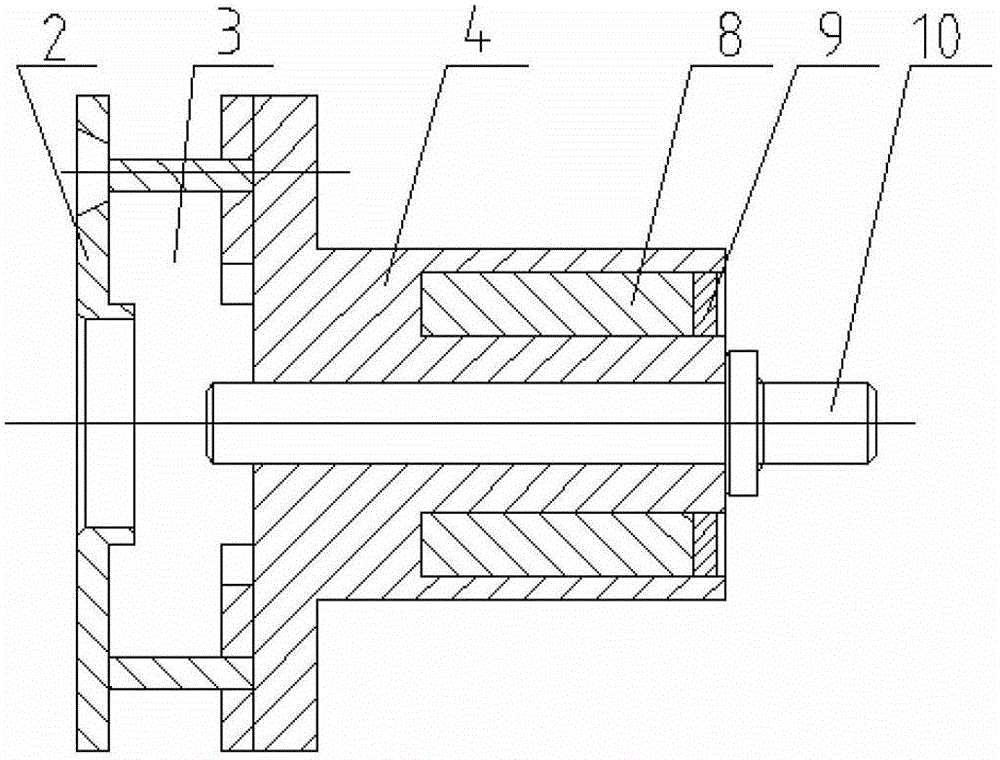

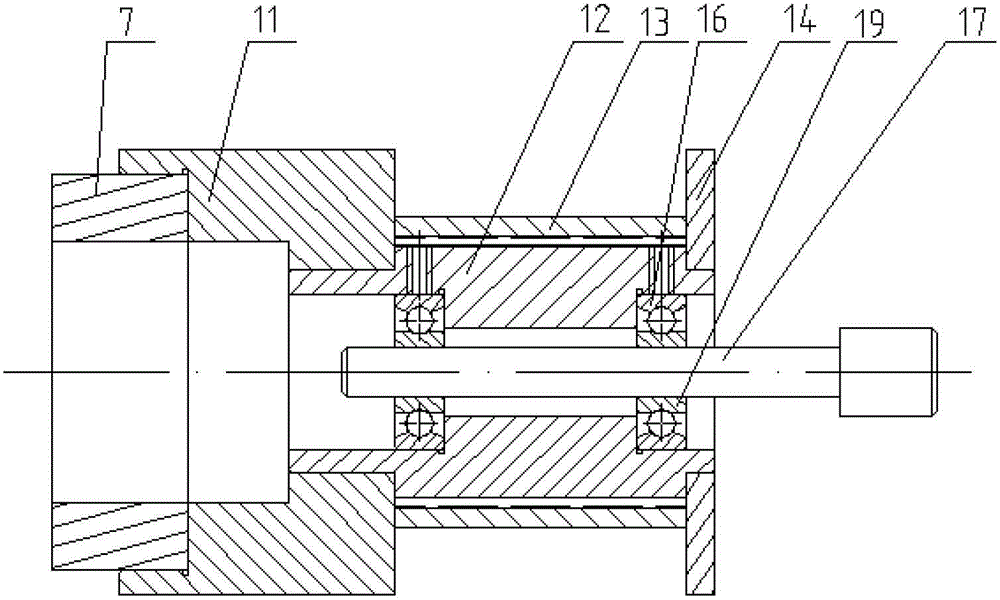

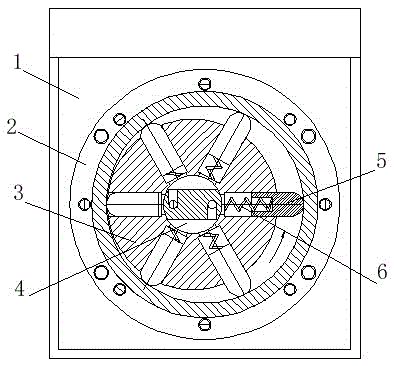

Heavy truck cab hydraulic hoisting radial plunger pump

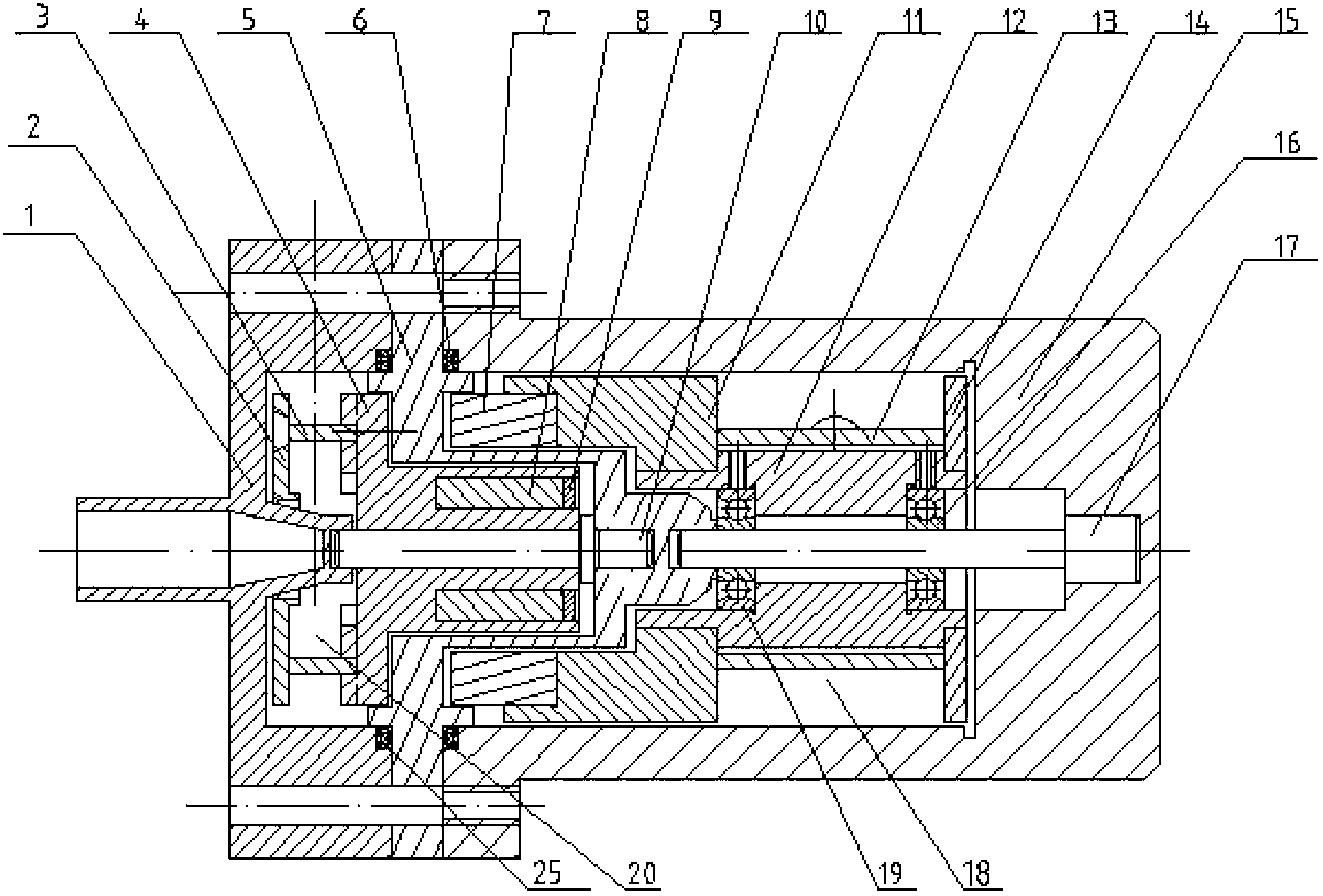

InactiveCN103075315ASmall pulseImprove stabilityPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpCar driving

The invention provides a heavy truck cab hydraulic hoisting radial plunger pump, which aims at solving the problems of the existing heavy truck cab hydraulic hosting mechanism in the prior art that the labor intensity is large, the pulse is large, the stability is poor, the speed is slow and the manufacturing cost is high, and the heavy truck cab hydraulic hoisting radial plunger pump comprises a pump body, a stator, a rotor, an oil distribution disc and a reversing valve; plunger units are uniformly arranged in the radial direction of the rotor; the stator and the rotor are eccentrically arranged; the oil distribution disc is arranged on the center of the rotor and provided with an oil inlet passage and an oil outlet passage, and the oil inlet passage and the oil outlet passage are respectively connected with an external pipeline; the reversing valve is arranged on the external pipeline and can switch an oil inlet pipeline and an oil outlet pipe of a cab hoisting oil cylinder; and each plunger unit comprises a plunger and a spring, and the spring is arranged between a bottom hole of the plunger and a root step of the plunger hole. The heavy truck cab hydraulic hoisting radial plunger pump has the beneficial effects that the pulse is small, the stability is high, the speed is high, simplicity in structure is realized, and the manufacturing cost is low.

Owner:重庆拓泰汽车零部件有限公司

Oilless vacuum single pump

InactiveCN106246548ADoes not affect operationExtended service lifePumpsRotary/oscillating piston pump componentsCouplingSlide plate

The invention discloses an oil-free vacuum single pump, which comprises a base and a compression cylinder installed on the base, the compression cylinder is connected to a motor through a coupling; a fan device is installed at one end of the compression cylinder, and The top of the compression cylinder is connected to the muffler equipment; the rotor inside the compression cylinder has a slide set. The invention solves the problem of high operating noise of the traditional oil-type vacuum pump. It is driven by an electric motor and has a slide group on the rotor. The suction and blowing of the compressed air cylinder are stable, and it is especially suitable for indoor machines such as printing machines and photoplate-making machines. , and can be widely used in vacuum lifters, liquid mixers, etc.

Owner:NANTONG BEIKE VACUUM MACHINERY CO LTD

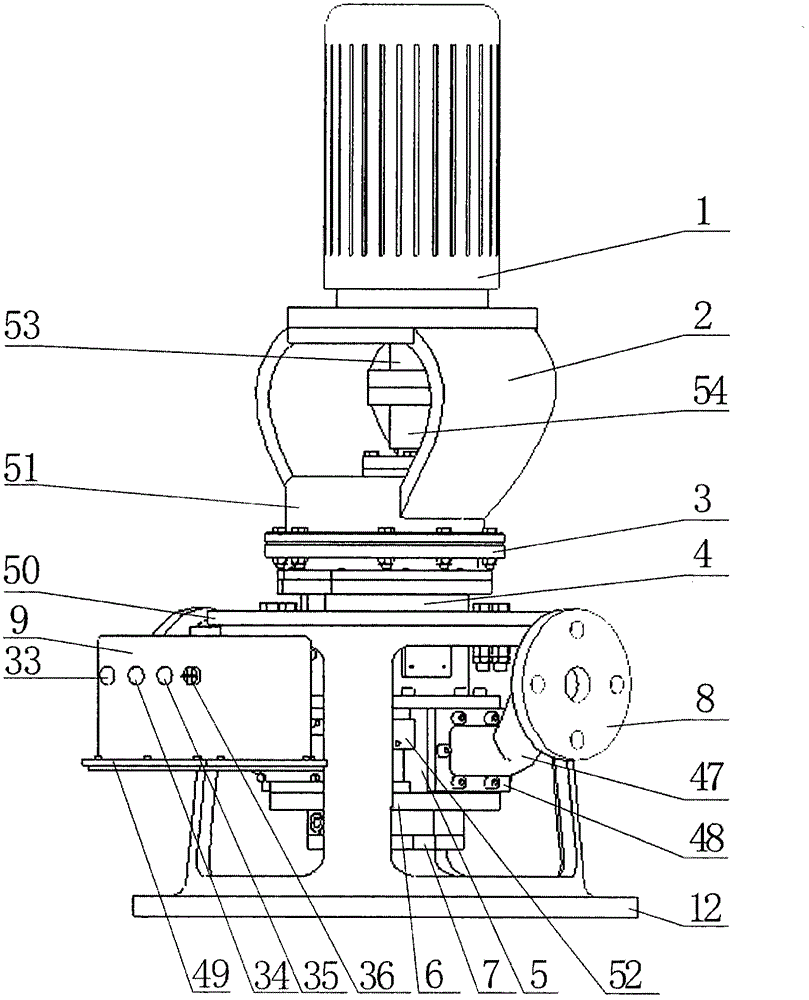

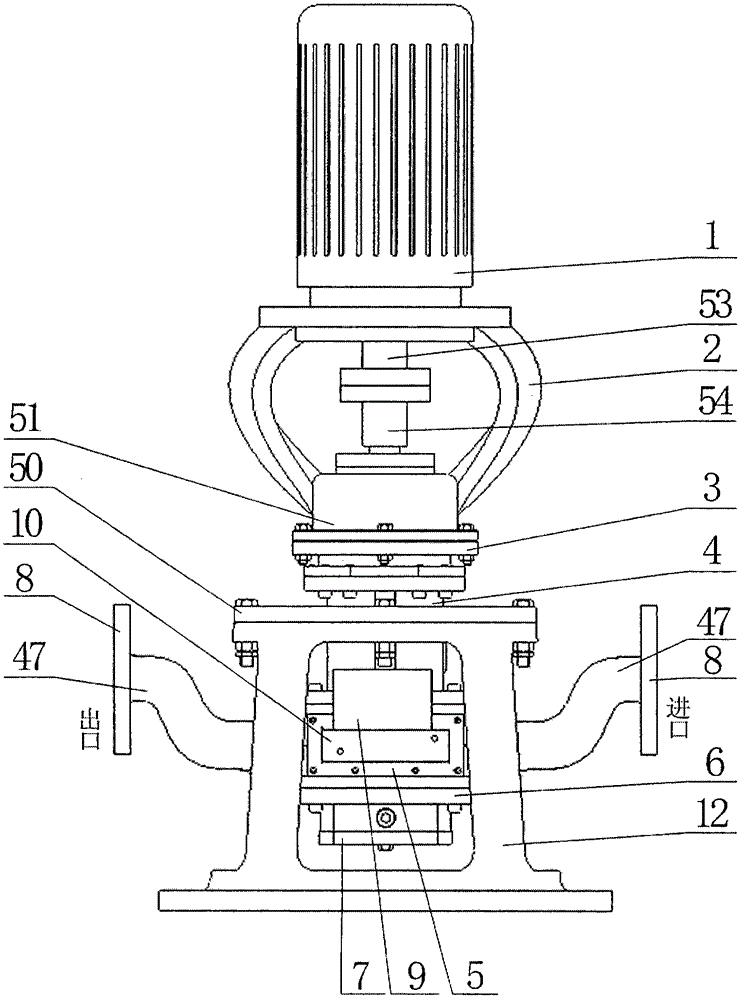

Vertical anti-freezing self-priming piston pump

ActiveCN104405643AReduce continuityShort self-priming timePump componentsPriming pumpInterference fitAnti freezing

The invention discloses a vertical anti-freezing self-priming piston pump. The vertical anti-freezing self-priming piston pump comprises a bracket, and an outer bracket positioned at the upper part of the bracket and formed integrally with a synchromesh gear case through casting. A reduction gearbox bearing base, a reduction gearbox cover, a motor bracket and an explosion-proof motor are arranged at the upper part of the synchromesh gear case in sequence. The vertical anti-freezing self-priming piston pump is characterized in that an upper sealing plate is arranged at the upper end of a cavity while a lower sealing plate is arranged at the lower end of the cavity; synchronous pistons are arranged between the upper sealing plate and the lower sealing plate; the two synchronous pistons are engaged with each other and rotate and the outer diameters of the pistons are in interference fit with the cavity; convex edges of upper and lower end surfaces are respectively in interference fit with the upper sealing plate and the lower sealing plate; an upper machine dynamic sealing ring, an upper machine static sealing ring, a lower machine dynamic sealing ring and a lower machine static sealing ring for sealing an auxiliary transmission shaft and a synchronous shaft are arranged at the upper parts and the lower parts of the synchronous pistons; and an electric heating water circulating device is disposed in an explosion-proof box at the upper part of a rear separated chamber of the cavity. The vertical anti-freezing self-priming piston pump has the advantages of small size, compact structure, good sealing performance and strong self-priming capacity, and effectively solves problems in freezing prevention and thermal insulation of a pump body.

Owner:任丘市本溪石油设备有限公司

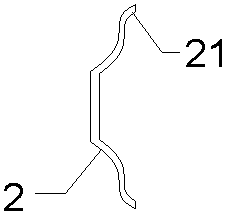

Three-ball diaphragm pump with composite shaft

PendingCN108061023ARealize commutationLow costPositive displacement pump componentsFlexible member pumpsDiaphragm pumpRemote control

The invention discloses a three-ball diaphragm pump with a composite shaft. The diaphragm pump comprises a diaphragm pump body, diaphragms at the two sides, inclined covers at the outermost sides anda shaft rod, and the diaphragm pump body, the diaphragms and the inclined covers are fixedly connected at the center of the shaft rod; the shaft rod is a composite shaft rod and comprises an inner shaft and an outer shaft; the outer shaft is movably connected to the center of the diaphragm pump body and can slide on the inner shaft, and the portions, close to the inner shaft, of the two ends of the outer shaft are in sealed connection with the diaphragms; screw threads are arranged at the two ends of the inner shaft, the shaft rod is internally hollow, air outlets are formed in the outer endsof the diaphragms, and the inclined covers, the diaphragms and the diaphragm pump body are in sealed connection by screwing nuts and the screw threads; reversing valves are connected to the two ends of the inner shaft and are pneumatic reversing valves or electromagnetic valves. The three-ball diaphragm pump with the composite shaft is reasonable in structural design, a liquid outlet end is sealedby adopting a single ball, different from a traditional four-ball double-diaphragm pump, reversing sealing can be more conveniently conducted, the pulse is reduced, the steering valves can be connected with the exterior through the electromagnetic valves at the same time, and remote control is achieved.

Owner:昆山华亿丰涂装设备科技有限公司

Three-dimensional flow efficient energy-saving water pump

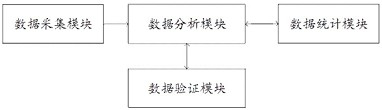

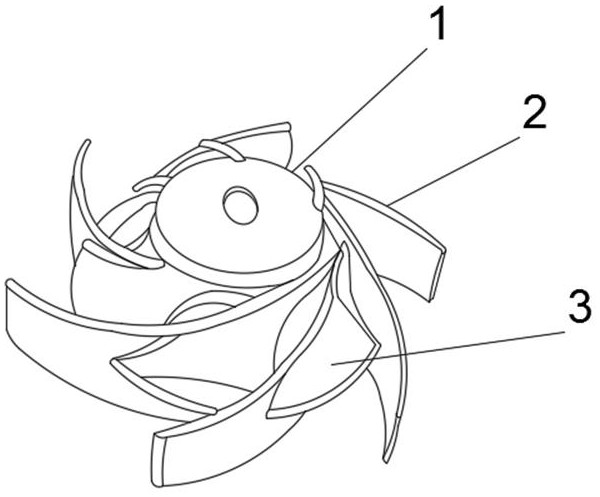

ActiveCN113586511AImprove accuracyImprove operational efficiencyDigital data information retrievalPump componentsImpellerSource Data Verification

The invention discloses a three-dimensional flow efficient energy-saving water pump. The three-dimensional flow efficient energy-saving water pump comprises a water pump body, an impeller body is rotationally connected into the water pump body, a plurality of main blades are fixedly installed on the outer surface of the impeller body, auxiliary blades are fixedly installed among the main blades, and a plurality of channels are formed in the outer surface of the impeller body. The water pump body comprises a data acquisition module, a data statistics module, a data analysis module and a data verification module, the data acquisition module comprises a pump body acquisition unit and a liquid acquisition unit, the pump body acquisition unit is used for acquiring operation information of the water pump body, and the liquid acquisition unit is used for acquiring information of a water sample conveyed by the water pump body. The three-dimensional flow efficient energy-saving water pump is used for solving the technical problem that in an existing scheme, under the condition that a pump shell and other parts are shaped, a single three-dimensional flow impeller cannot change water resistance and water loss of all flow passing parts in the whole water pump, and the running effect of the three-dimensional flow water pump is poor.

Owner:长沙天康泵业科技有限公司

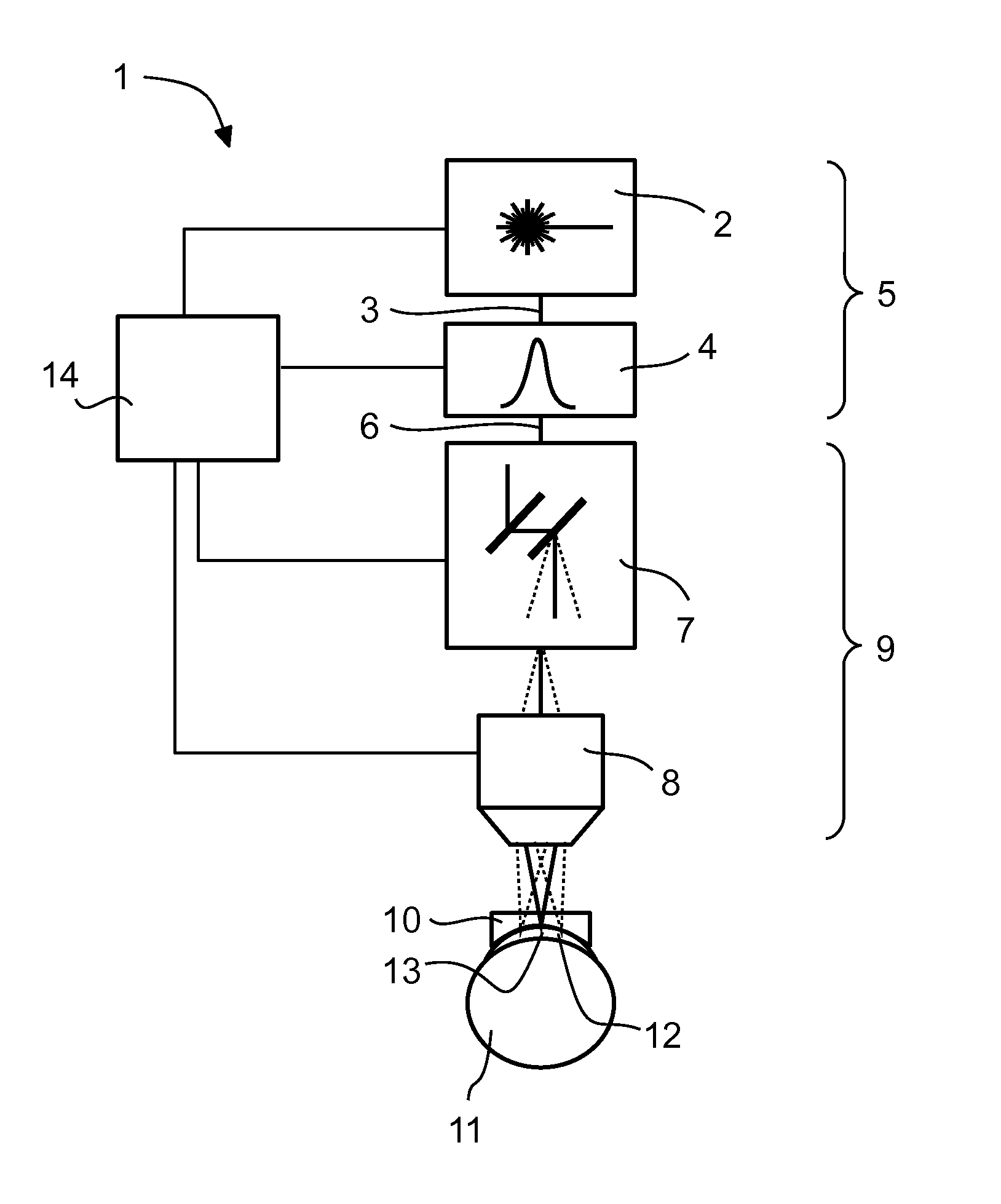

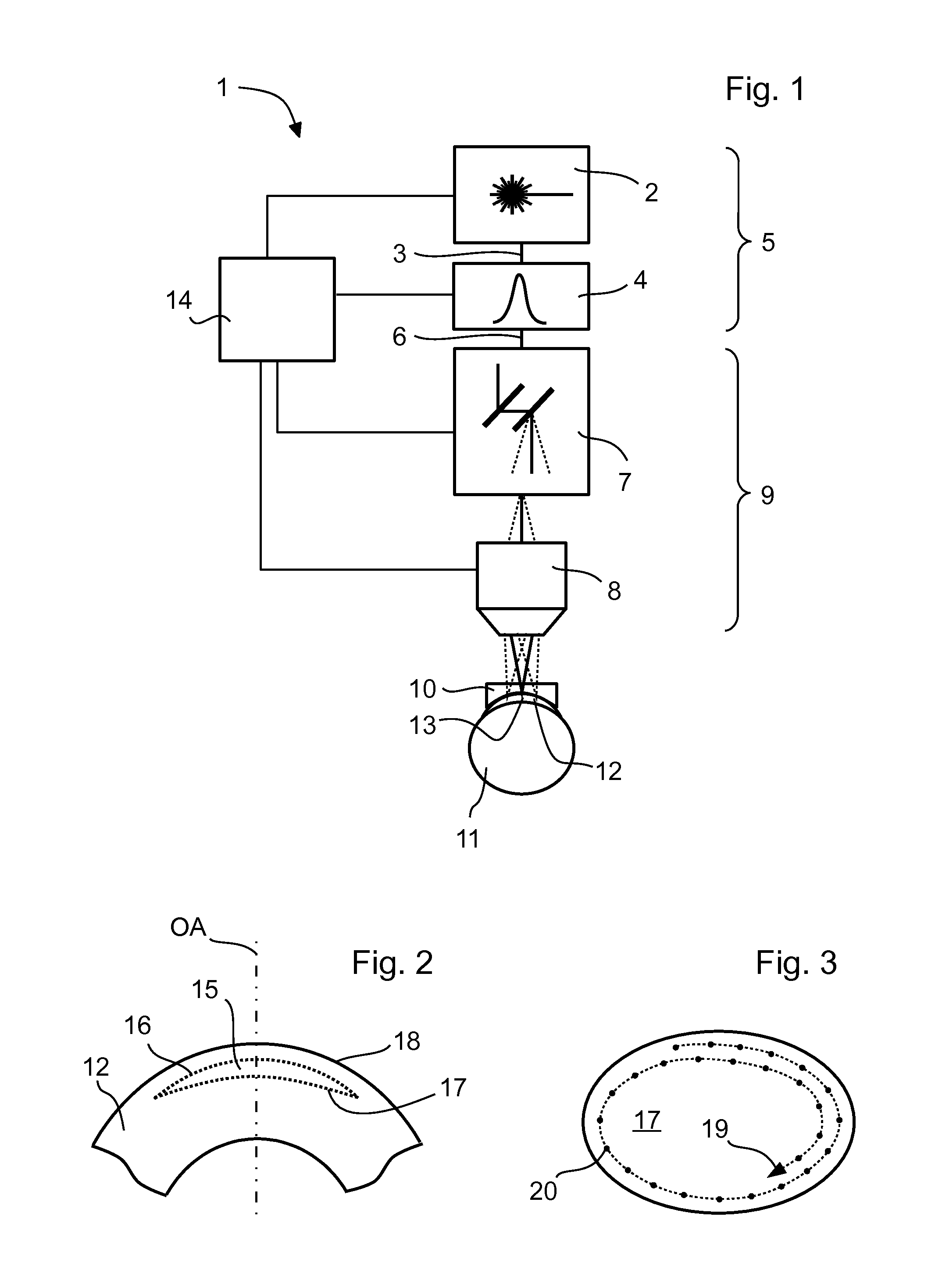

Creation of curved cuts in the inside of the eye cornea

ActiveUS20160022494A1Create quicklyImprove accuracyLaser surgerySurgical instrument detailsMaximum diameterLaser beams

A device for isolating a lenticle in the cornea of an eye. The device includes: a laser beam source to emit pulsed laser radiation having a pulse frequency of 1.2 MHz to 10 MHz, a pulse energy of 1 nJ to 200 nJ and a wavelength penetrating the cornea; a beam-forming unit having beam optics with an image field and that bundles pulsed laser radiation into a focus located inside the image field, and which has a maximum diameter of less than 3 μm; a beam-deflection unit shifting the focus in the cornea and inside the image field, the focus moving along a path when the image field is resting; and a control unit to control the source and the beam-forming unit to isolate the lenticle by specifying the path. The lenticle is delimited by a cut surface which is curved with regard to a front surface of the cornea.

Owner:CARL ZEISS MEDITEC AG

Pressure stabilizing pump

InactiveCN106640571AStable pressureSmall pulsePositive displacement pump componentsPositive-displacement liquid enginesInlet channelEngineering

The invention provides a pressure stabilizing pump aiming at shortcomings of a pressure stabilizing pump used at present. The pressure stabilizing pump can output continuous and stable high pressure, is small in size and facilitates asepsis treatment. The pressure stabilizing pump comprises a pump body which is provided with two or more input pipes, one or more output pipes and two or more piston cylinders. The input pipes and the piston cylinders are equal in number and communicate in a one-to-one corresponding manner. One-way valves which can only close the input pipes are arranged in inlet channels of the input pipes and inlet channels of the piston cylinders. Each piston cylinder communicates with the corresponding output pipe through the respective outlet channel. Reversing valves capable of closing any outlet channel alternately are arranged between the output pipes and the piston cylinders. A piston and a piston rod driving the piston to move are arranged in each piston cylinder.

Owner:罗凤玲

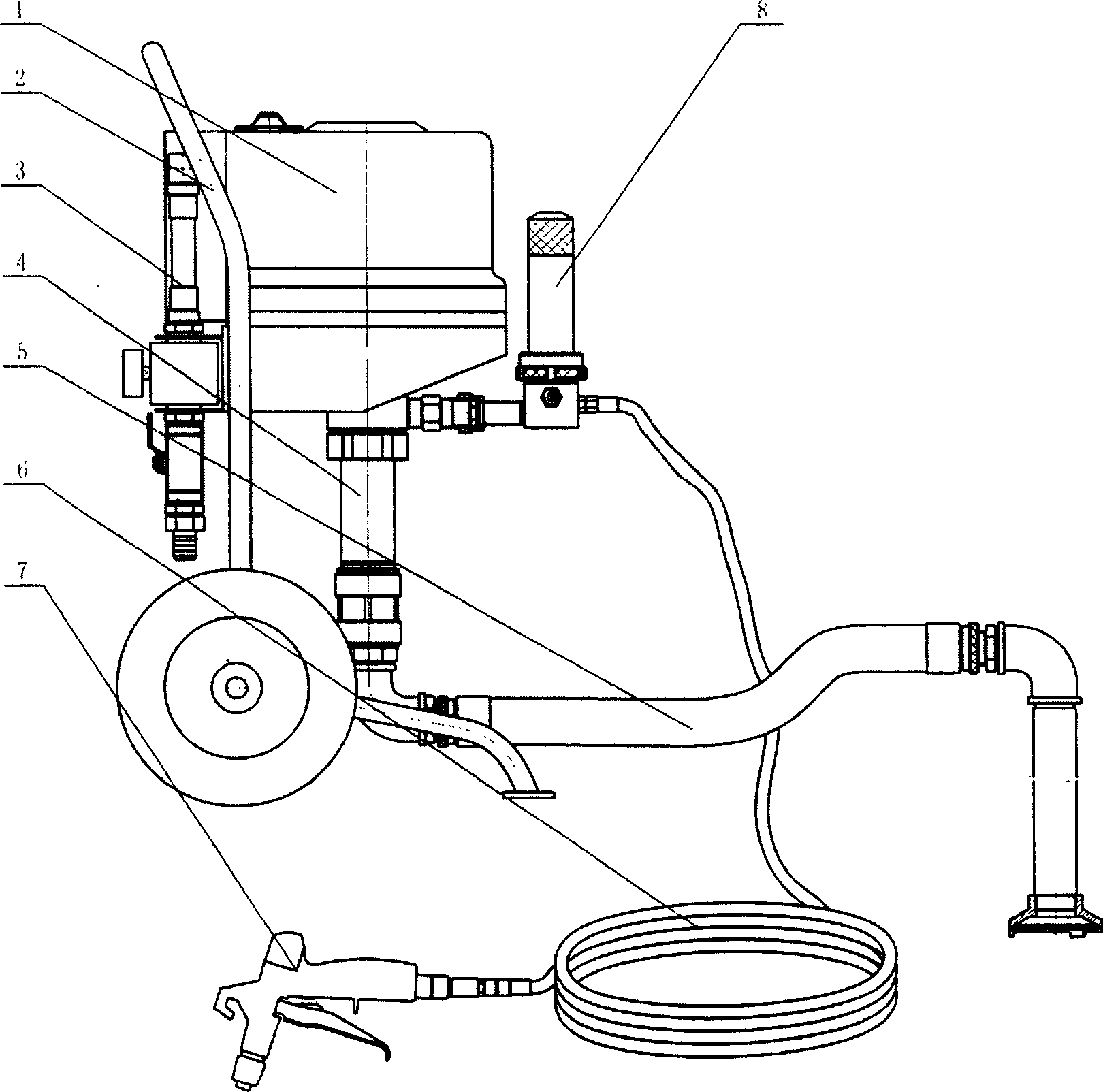

Energy saving type gas-free spraying coater

InactiveCN1631552AShorten the working gas pathSmooth exhaustLiquid spraying apparatusSpool valveWorking pressure

This is about a kind of no air spraying machine of saving energy. Air energy motor uses press-deposit direction changing fix to change the direction. The direction changing fix includes two fast valves, self press-deposit pieces and two air ways. The self press-deposit piece is constituted by air store direction changing room, direction changing valve and two self directions changing active valve. The two air ways are connected with two fast valves and direction changing valve, which is between the two direction changing active valves. The two direction changing valves are fixed on the two air entrance and two air exit on the air energy motor. The two direction changing valves control the motor air going in and out by the direction changing valve. The invention spraying machine has the features of little air to use, high press, steady working press, large power and long life, increases and guarantees the quality of spraying.

Owner:广州珠江物资集团有限公司

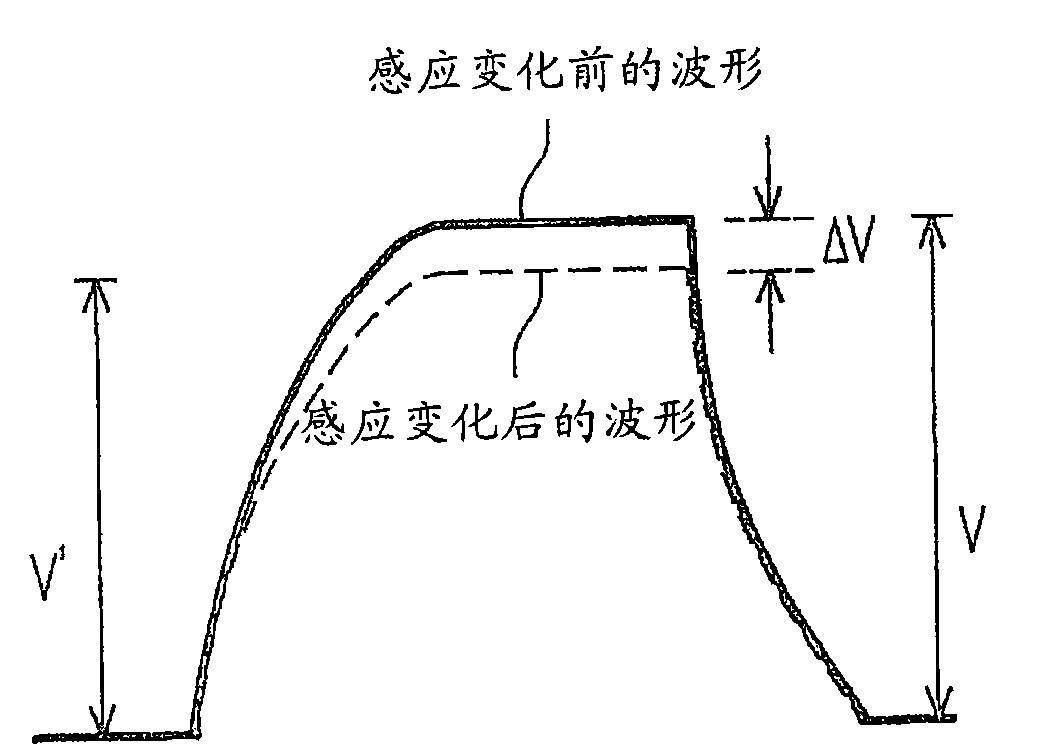

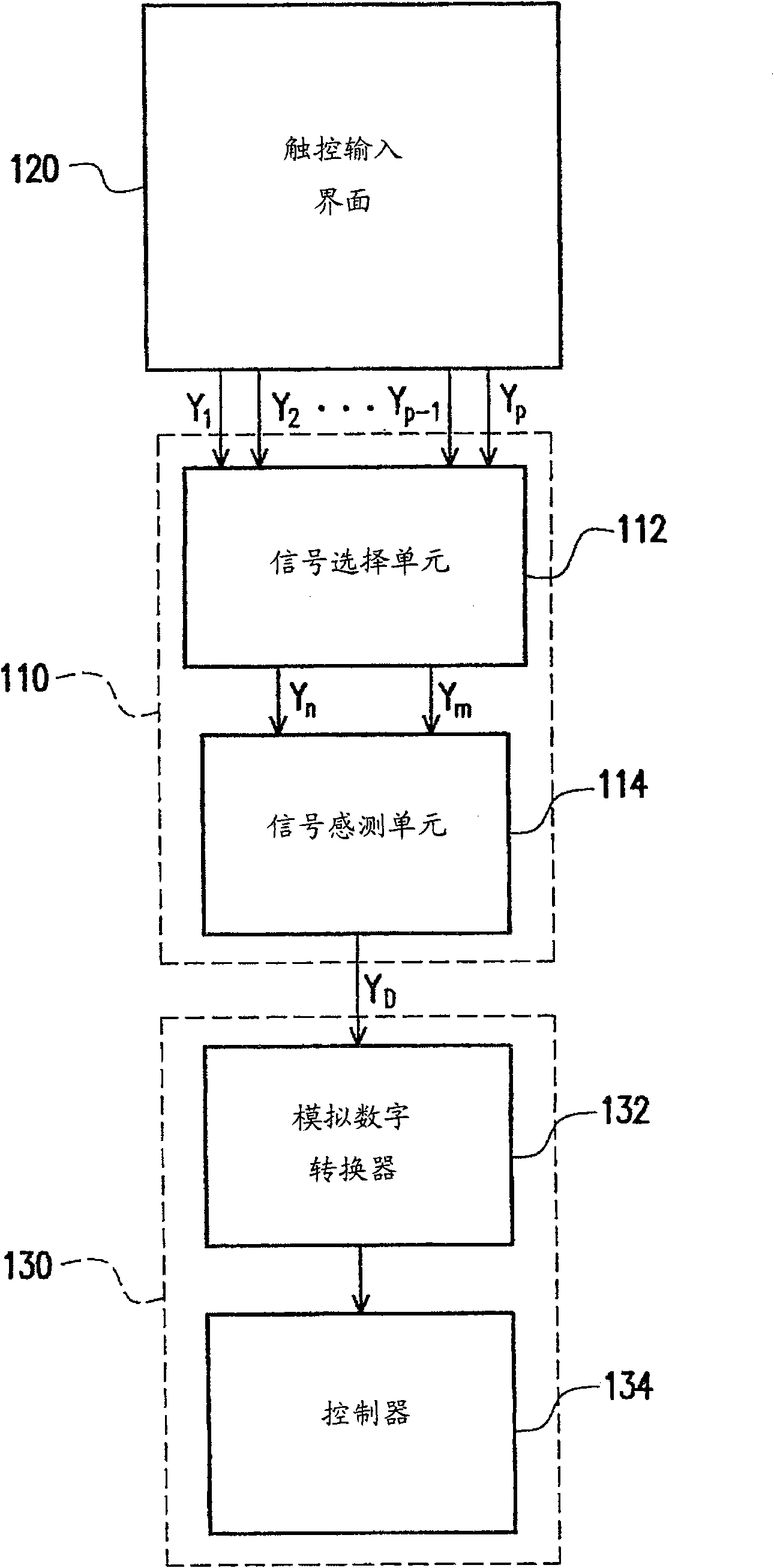

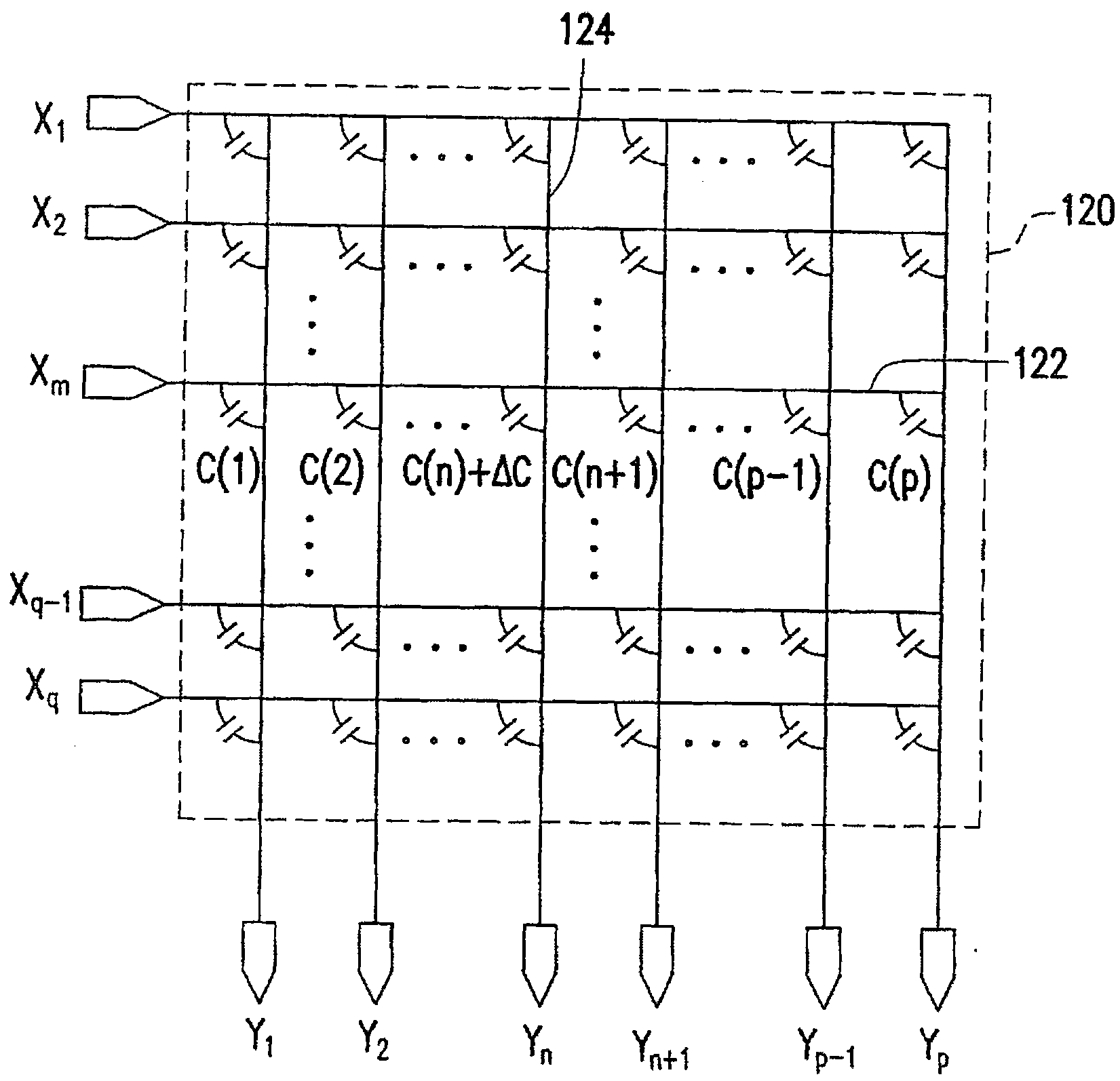

Touch-control sensing system, capacitance sensing circuit and capacitance sensing method

ActiveCN102156595AImprove signal-to-noise ratioSmall pulseInput/output processes for data processingCapacitanceEngineering

The invention provides a touch-control sensing system that comprises a touch-control input interface and a capacitance sensing circuit, wherein the touch-control input interface comprises a plurality of sensing capacitors that are used for outputting at least one waveform to be tested and at least one reference waveform; and the capacitance sensing circuit comprises a difference comparing unit that is used for receiving the waveform to be tested and the reference waveform and outputting a difference signal according to at least one positive edge difference and at least one negative edge difference between the waveform to be tested and the reference waveform. Furthermore, the invention also provides a capacitance sensing method.

Owner:NOVATEK MICROELECTRONICS CORP

Reciprocating compressor

ActiveCN109690077BAvoid damageNo need to increase the overall sizePositive displacement pump componentsValve members for absorbing fluid energyExhaust valveEngineering

Owner:ATLAS COPCO CREPELLE

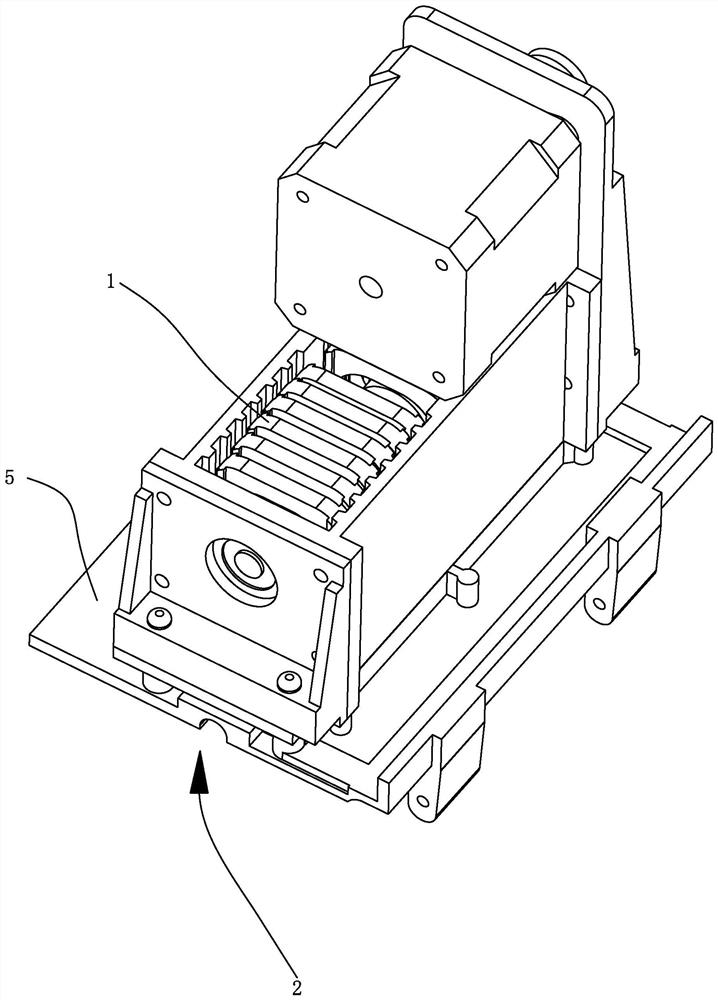

Sliding shoe auxiliary squeezing device of peristaltic pump and peristaltic pump

ActiveCN110630479AAvoid damageAvoid destructionFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

The invention provides a sliding shoe auxiliary squeezing device of a peristaltic pump. The sliding shoe auxiliary squeezing device comprises a squeezing sliding block and a driving mechanism used fordriving the squeezing sliding block to slide. The end, far away from the driving mechanism, of the squeezing sliding block is provided with a squeezing mechanism for implementing arc-shaped squeezingon a liquid delivery pipe in the cross-section direction of the liquid delivery pipe. The invention further discloses the peristaltic pump. The peristaltic pump comprises the sliding shoe auxiliary squeezing device of the peristaltic pump. According to the sliding shoe auxiliary squeezing device of the peristaltic pump, the driving mechanism drives the squeezing sliding block to slide, so that the squeezing mechanism on the squeezing sliding block implements arc-shaped squeezing on the liquid delivery pipe in the cross-section direction of the liquid delivery pipe. During arc-shaped squeezing, squeezing force of the squeezing mechanism on the liquid delivery pipe increases gradually and then decreases gradually. The squeezing process has the transitivity. Pulses generated during squeezingare reduced. damage to rigid squeezing on the liquid delivery pipe is avoided. A substance in the liquid delivery pipe is also protected against damage.

Owner:SHENZHEN LE-MEDICAL TECH CO LTD

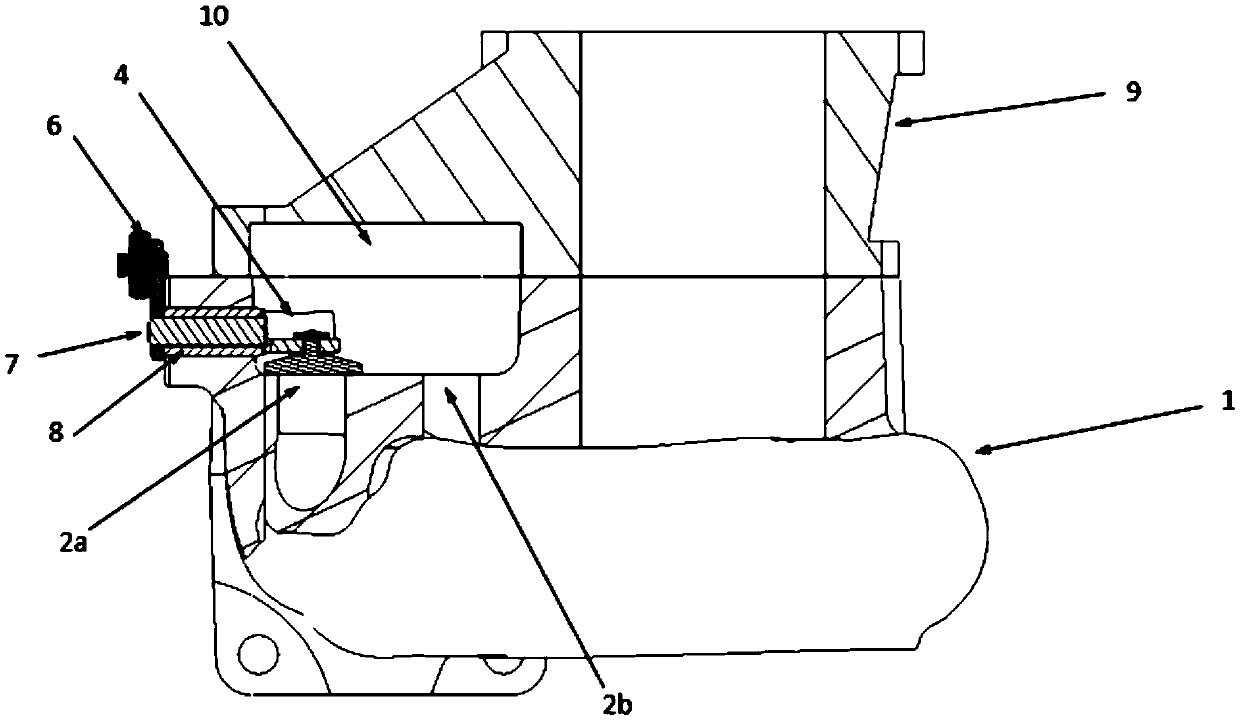

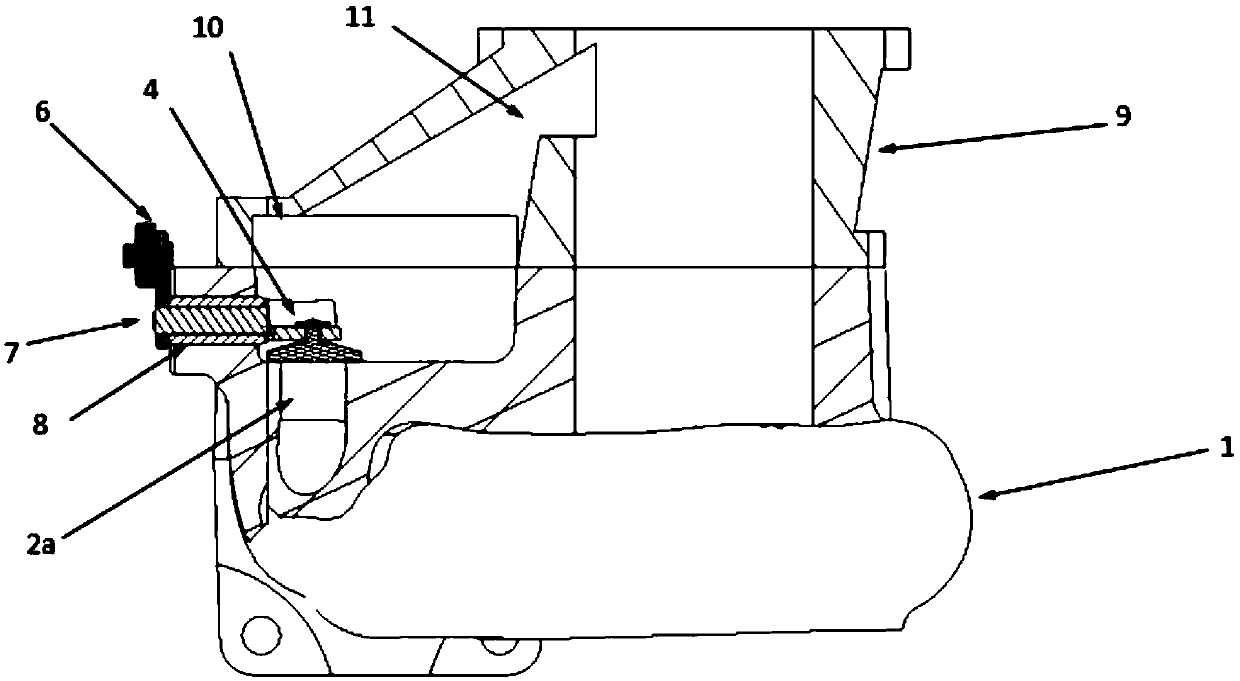

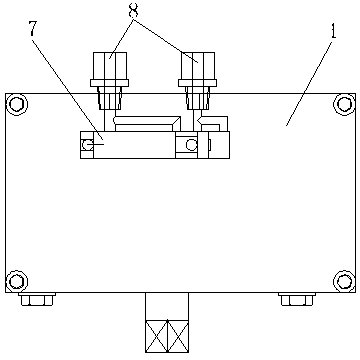

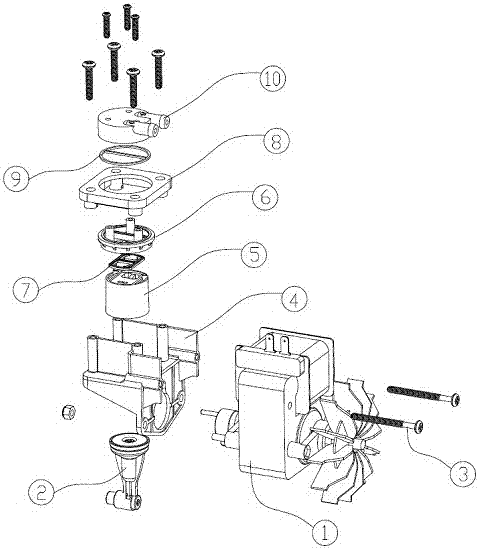

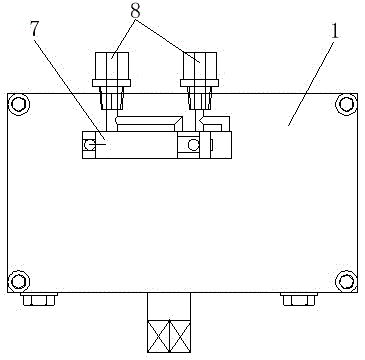

A medical nebulizer silencer compressor air pump

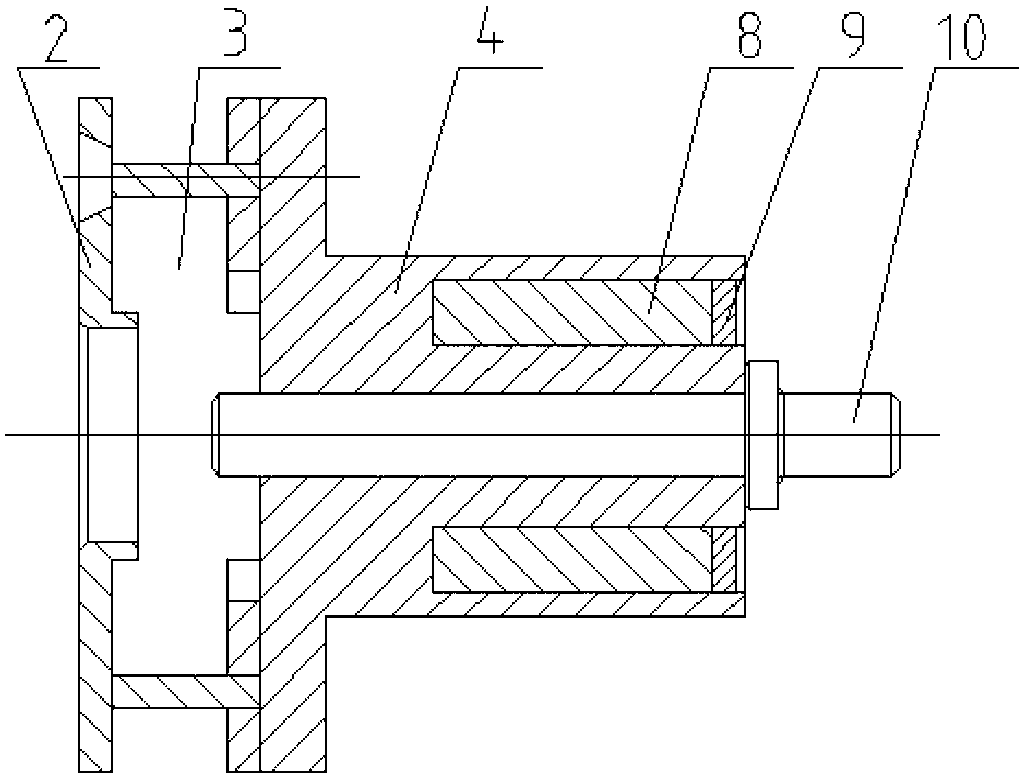

ActiveCN105781943BImprove adaptabilityReduce manufacturing costPositive displacement pump componentsPositive-displacement liquid enginesAir pumpEngineering

The invention discloses a medical vaporizer noise reduction compressor air pump. The medical vaporizer noise reduction compressor air pump comprises a support (4), an air cylinder (5), a pump head (6), a valve piece (7), a pump head pressing plate (8), a sealing ring (9) and a pump head cover (10). The support (4) is fixed to a motor through two screws and two nuts, the air cylinder (5) is a cylindrical body, an opening in one end of the air cylinder allows a connecting rod to be inserted, a valve device is arranged at the other end of the air cylinder, and the end with the valve device is provided with two asymmetric cylinders. The air cylinder can be arranged in the support in the 360-degree random direction.

Owner:SHENZHEN JIACOM TECH

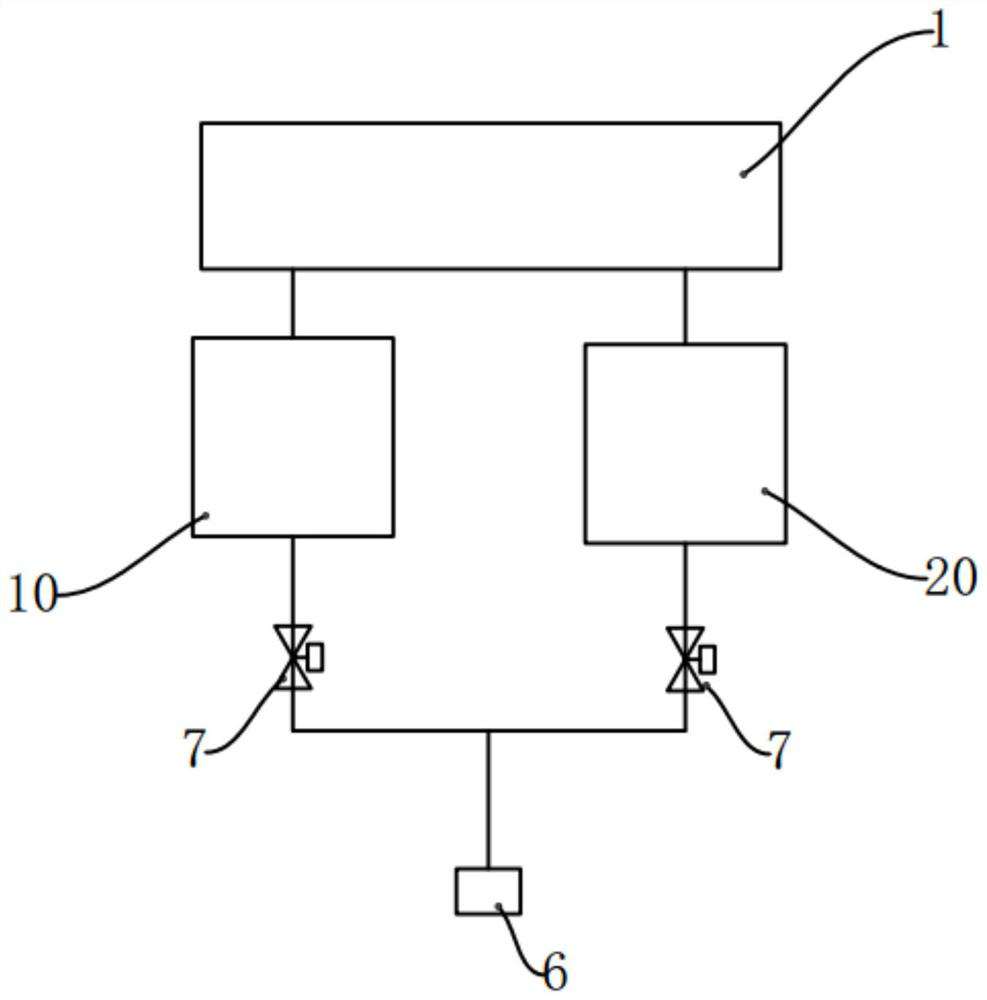

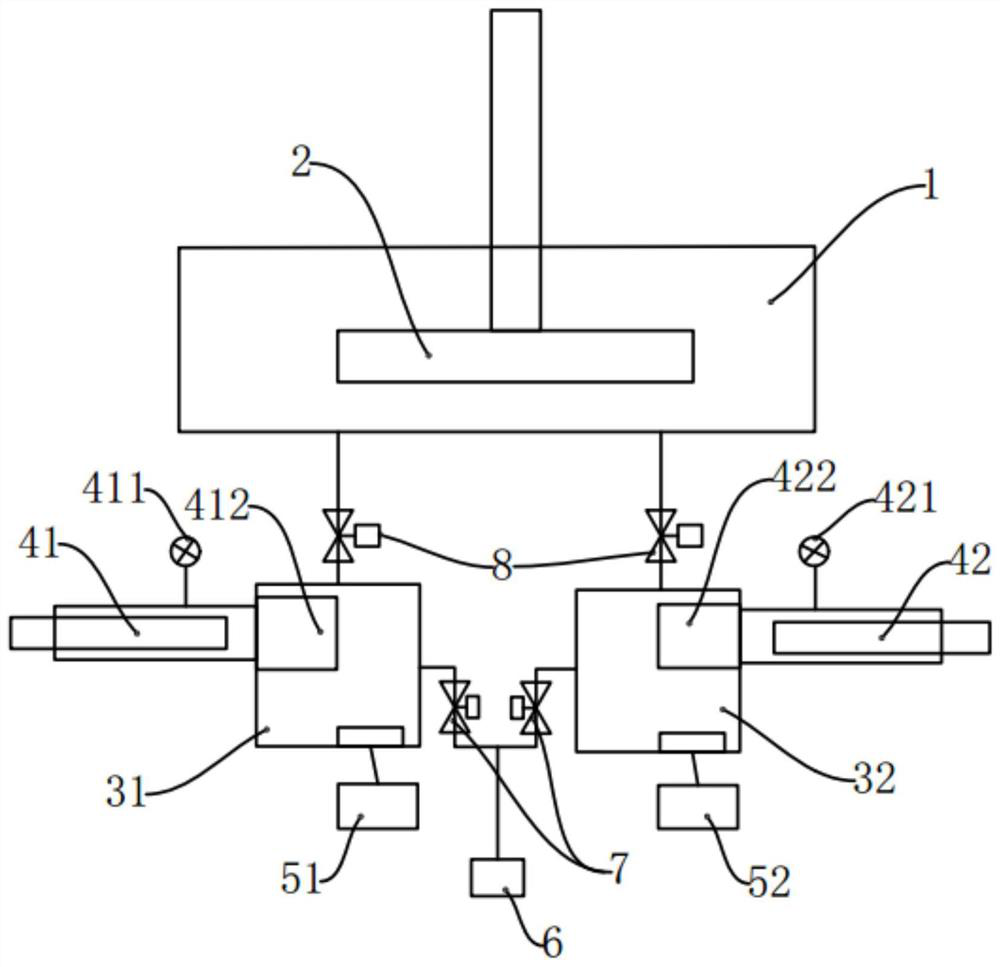

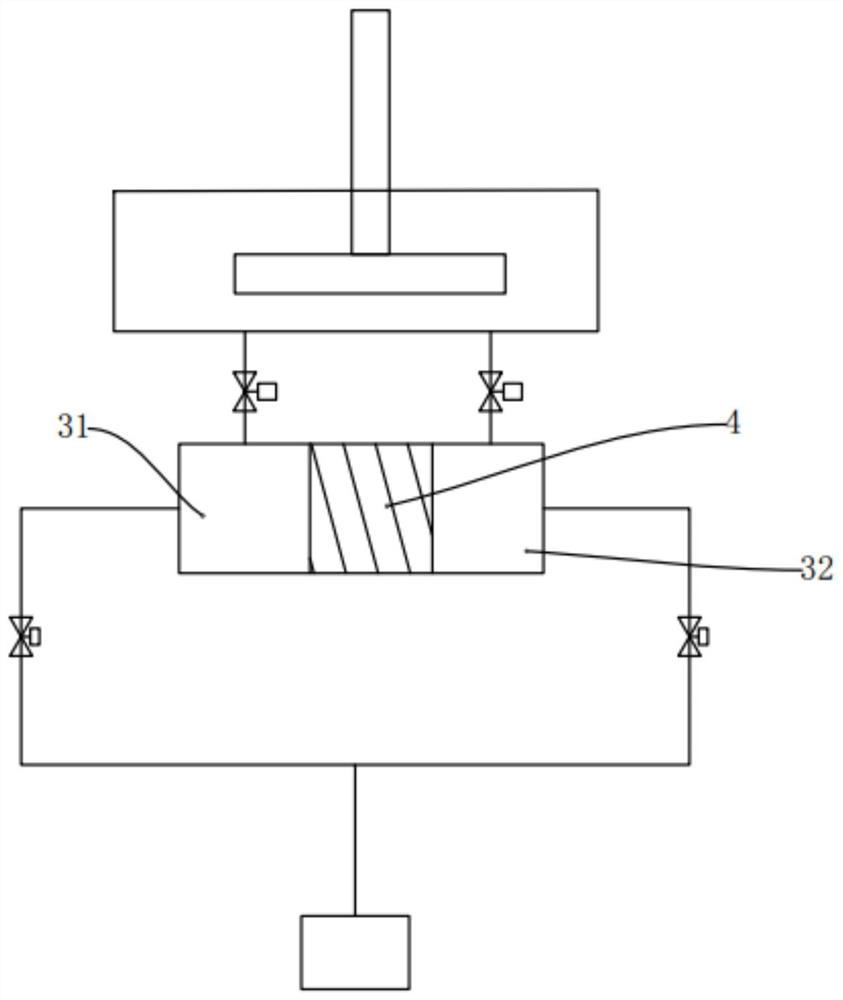

Continuous conveying system and method for solid-liquid mixed materials

InactiveCN113044582ARealize continuous deliveryRealize isolated deliveryBulk conveyorsControl engineeringProcess engineering

The invention discloses a continuous conveying system for solid-liquid mixed materials. The continuous conveying system comprises a discharging main path, a first conveying branch path and a second conveying branch path, the first conveying branch path and the second conveying branch path are mutually independent and are used for discharging and feeding according to a set period, when the first conveying branch path is used for discharging, the second conveying branch path is used for feeding, and when the second conveying branch path is used for discharging, the first conveying branch path is used for feeding; and the first conveying branch path and the second conveying branch path alternately communicate with the discharging main path through a discharging switching valve, the first conveying branch path and the second conveying branch path are in communication with the discharging main path in respective discharging periods and are cut off from the discharging main path in respective feeding periods, so that the discharging main path keeps continuously conveying materials, the pulse is small, the conveying efficiency is high, and the product service life is long. The invention further discloses a continuous conveying method for the solid-liquid mixed materials.

Owner:杭州精进科技有限公司

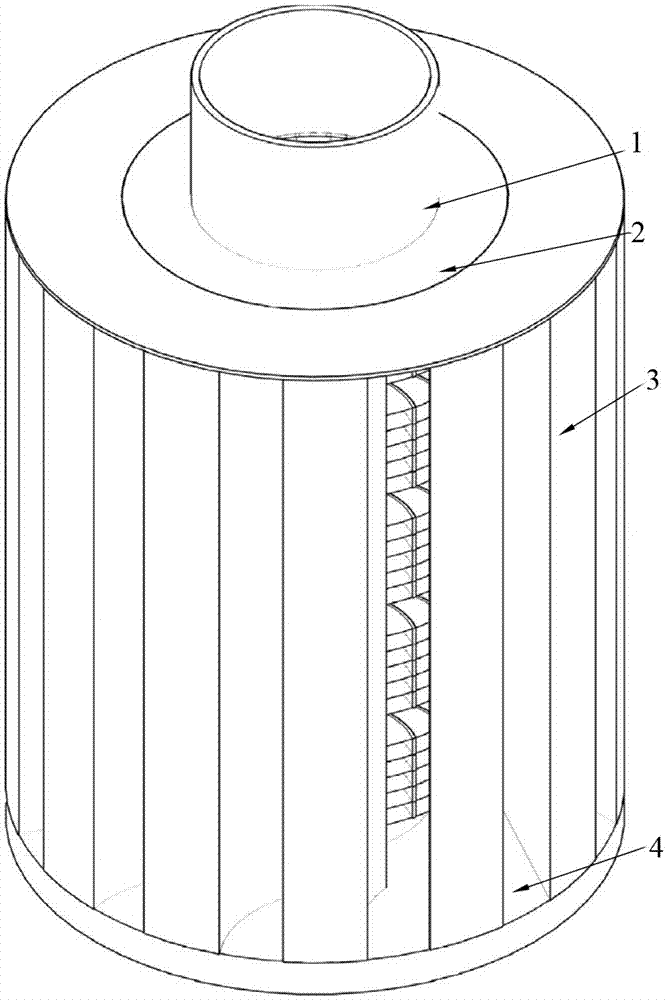

Twin-turbocharged speed-up vertical shaft wind turbine

InactiveCN107035620BImprove wind energy utilizationIncrease wind areaRenewable energy generationWind motor combinationsCouplingVertical axis wind turbine

The invention discloses a twin-turbocharged speed-increasing vertical-shaft wind power generator, which comprises an outer turbine, an inner turbine and a hollow shaft. An annular guide rail is installed on the outer periphery of the shaft, and the inner turbine is installed on the annular guide rail; the wind gathering deflector is evenly distributed on the outer periphery of the inner turbine, and a generator is installed on the hollow shaft, and a transmission device is connected between the generator and the inner turbine. The invention has the advantages of large wind-receiving area, large effective wind-receiving angle, high utilization rate of wind energy and the like.

Owner:南京众心点生态科技有限公司

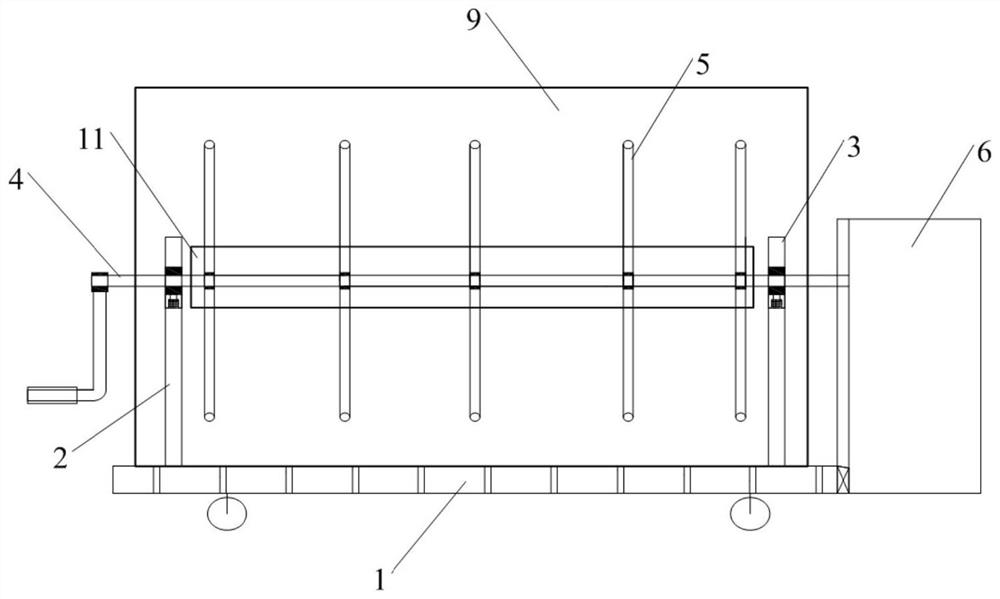

Network cable pay-off rack for construction

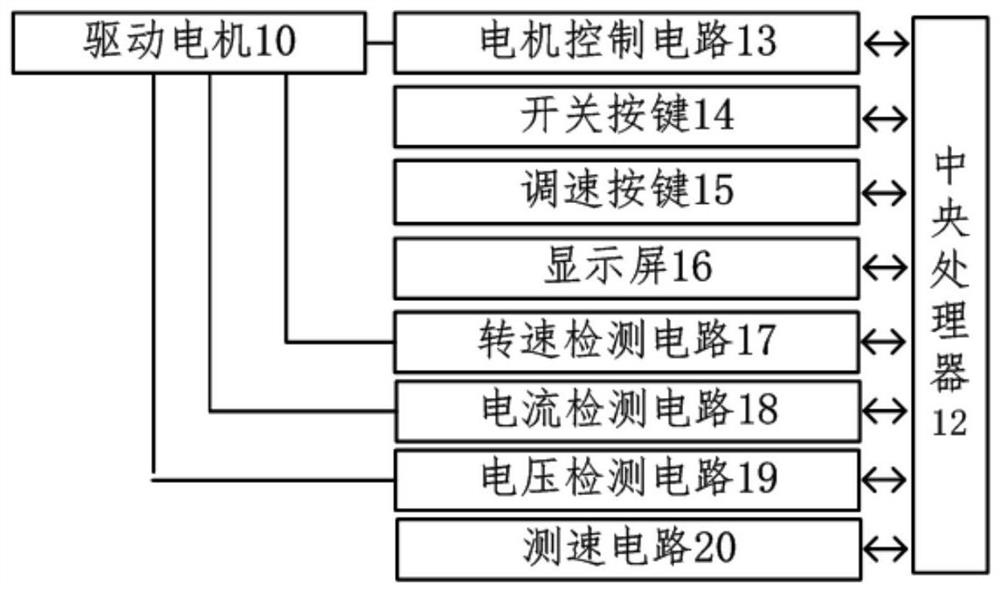

PendingCN113830625ASolve tension instabilityWon't distortApparatus for laying cablesCouplingElectric machinery

The invention provides a network cable pay-off rack for construction. The network cable pay-off rack comprises a pay-off base, a first support plate and a second support plate are connected to the pay-off base side by side, the first support plate and the second support plate are separately and rotatably connected with a pay-off rotating shaft, the pay-off rotating shaft is connected with a plurality of wire blocking discs in a sleeved manner, an equipment box is arranged at one side of the second support plate, a driving motor is arranged in the equipment box, an output end of the driving motor is connected with one end of the pay-off rotating shaft through a coupling, a switch button and a speed regulation button are arranged on the equipment box, and at least four universal wheels are arranged at the bottom of the pay-off base. The network cable pay-off rack can move to the cable take-up and pay-off positions according to actual requirements, take-up and pay-off are driven by the driving motor without manual operation, the problem that tension is unstable in the pay-off process due to the fact that the friction coefficient is changed due to the influence of the speed is solved, the movement in a short distance is very convenient, the rack can be easily moved by one or two persons on the ground, the usage is simple and convenient, and network cables and optical cables won't be twisted, and the twisting phenomenon is avoided.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO BINZHOU CITY BINCHENG DISTRICT POWER SUPPLY CO

A pneumatic magnetic pump

InactiveCN103185010BAvoid shockAvoid corrosionPump installationsNon-positive displacement fluid enginesImpellerDiaphragm pump

The invention discloses a pneumatic magnetic pump and belongs to the technical field of magnetic driving and pneumatics. A conveying impeller shaft is positioned between a left pump body and a shielding sleeve; a conveying component is sleeved on the conveying impeller shaft; a driving impeller shaft is positioned between the shielding sleeve and a right pump body and is connected with a driving component through a deep groove ball bearing; the driving component is formed by sequentially connecting an outer magnetic ring, a driving impeller left baffle, a driving impeller framework, a driving vane and a driving impeller right baffle; the conveying component is formed by sequentially connecting a conveying impeller left baffle, a conveying vane, a conveying impeller framework, an inner magnetic ring and a conveying impeller right baffle; and the left pump body, the shielding sleeve and the right pump body are connected through bolts, and are sealed by O-shaped rubber sealing rings, with high tightness. The pneumatic magnetic pump has superior performance to a pneumatic diaphragm pump, has the significant advantages of no leakage, continuous and uniform liquid conveying, energy conservation, environment friendliness, safety, reliability, convenience for use and the like, and is wide in application.

Owner:BEIJING UNIV OF TECH

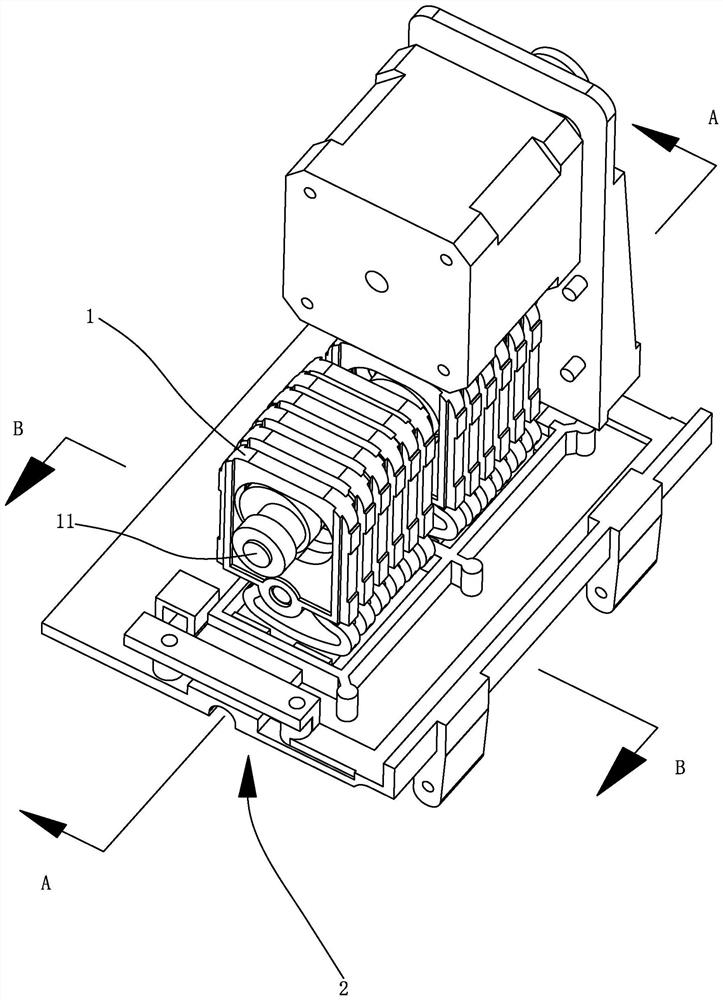

a reciprocating pump

ActiveCN112302893BReduce wasteImprove cooling effectPositive displacement pump componentsPositive-displacement liquid enginesHydraulic pumpEngineering

The application relates to a reciprocating pump, which belongs to the technical field of hydraulic pumps. It includes a casing, a valve body and a cooling assembly, the valve body is provided with a liquid discharge pipeline, the casing is provided with a power chamber, the casing is provided with a liquid inlet and a liquid outlet that communicate with the power chamber, and the cooling assembly includes a heat sink. Oil pipe, cooling part, cold oil pipe and circulating pump. One end of the hot oil pipe is connected with the liquid outlet, the other end of the hot oil pipe is connected with the cooling element, one end of the cold oil pipe is connected with the liquid inlet, the other end of the cold oil pipe is connected with the cooling element, and the drain pipe The method of connecting the suction pipe for absorbing liquid on the road, the cooling part includes a clamping part and a heat dissipation part, the clamping part is annular and the inner hollow is clamped to the flange plate and the suction pipe of the drainage pipeline. Between the blue and the plate, the radiating part includes at least one radiating pipe. Both ends of the radiating pipe are fixed to the inner ring of the clamping part and communicate with the clamping part. The present application has the advantage of not requiring a separate water tank.

Owner:NINGBO QIANHU PETROLEUM EQUIP

Heavy truck cab hydraulic lift radial piston pump

InactiveCN103075315BSmall pulseImprove stabilityPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpCar driving

The invention provides a heavy truck cab hydraulic hoisting radial plunger pump, which aims at solving the problems of the existing heavy truck cab hydraulic hosting mechanism in the prior art that the labor intensity is large, the pulse is large, the stability is poor, the speed is slow and the manufacturing cost is high, and the heavy truck cab hydraulic hoisting radial plunger pump comprises a pump body, a stator, a rotor, an oil distribution disc and a reversing valve; plunger units are uniformly arranged in the radial direction of the rotor; the stator and the rotor are eccentrically arranged; the oil distribution disc is arranged on the center of the rotor and provided with an oil inlet passage and an oil outlet passage, and the oil inlet passage and the oil outlet passage are respectively connected with an external pipeline; the reversing valve is arranged on the external pipeline and can switch an oil inlet pipeline and an oil outlet pipe of a cab hoisting oil cylinder; and each plunger unit comprises a plunger and a spring, and the spring is arranged between a bottom hole of the plunger and a root step of the plunger hole. The heavy truck cab hydraulic hoisting radial plunger pump has the beneficial effects that the pulse is small, the stability is high, the speed is high, simplicity in structure is realized, and the manufacturing cost is low.

Owner:重庆拓泰汽车零部件有限公司

Sliding shoe pair extrusion device of peristaltic pump and peristaltic pump

ActiveCN110630479BAvoid damageAvoid destructionFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

The invention provides a sliding shoe auxiliary squeezing device of a peristaltic pump. The sliding shoe auxiliary squeezing device comprises a squeezing sliding block and a driving mechanism used fordriving the squeezing sliding block to slide. The end, far away from the driving mechanism, of the squeezing sliding block is provided with a squeezing mechanism for implementing arc-shaped squeezingon a liquid delivery pipe in the cross-section direction of the liquid delivery pipe. The invention further discloses the peristaltic pump. The peristaltic pump comprises the sliding shoe auxiliary squeezing device of the peristaltic pump. According to the sliding shoe auxiliary squeezing device of the peristaltic pump, the driving mechanism drives the squeezing sliding block to slide, so that the squeezing mechanism on the squeezing sliding block implements arc-shaped squeezing on the liquid delivery pipe in the cross-section direction of the liquid delivery pipe. During arc-shaped squeezing, squeezing force of the squeezing mechanism on the liquid delivery pipe increases gradually and then decreases gradually. The squeezing process has the transitivity. Pulses generated during squeezingare reduced. damage to rigid squeezing on the liquid delivery pipe is avoided. A substance in the liquid delivery pipe is also protected against damage.

Owner:SHENZHEN LE-MEDICAL TECH CO LTD

Concrete mixing bunker as well as concrete wet-process injection system and method based on concrete mixing bunker

InactiveCN102814863BDrill core sampling with high intensityIncrease profitMixing operation control apparatusBuilding material handlingPlastic materialsBunker

The invention discloses a concrete mixing bunker as well as a concrete wet-process injection system and method based on the concrete mixing bunker. The concrete mixing bunker comprises a feeding pipe, wherein the feeding pipe is provided with a blending bunker, a water adding ring is connected to the feeding pipe and the front part of the blending bunker and connected with a water atomization chamber through a pipeline, and an inlet of the water atomization chamber is connected with a spherical nozzle; an air inlet of the spherical nozzle is connected with an air pipe, and a water inlet is connected with a water pipe; and a branch divided from an air pipe is connected to the feeding pipe behind the blending bunker. The injection system provided by the invention is additionally provided with the concrete mixing bunker for blending a moist concrete material into wet plastic material; and due to the adoption of the design of the mixing bunker, not only is a dry material wet spraying process realized, but also the problems of pipe blockage by concrete and discharge pulse can be avoided.

Owner:陕西金石混凝土科技发展有限公司

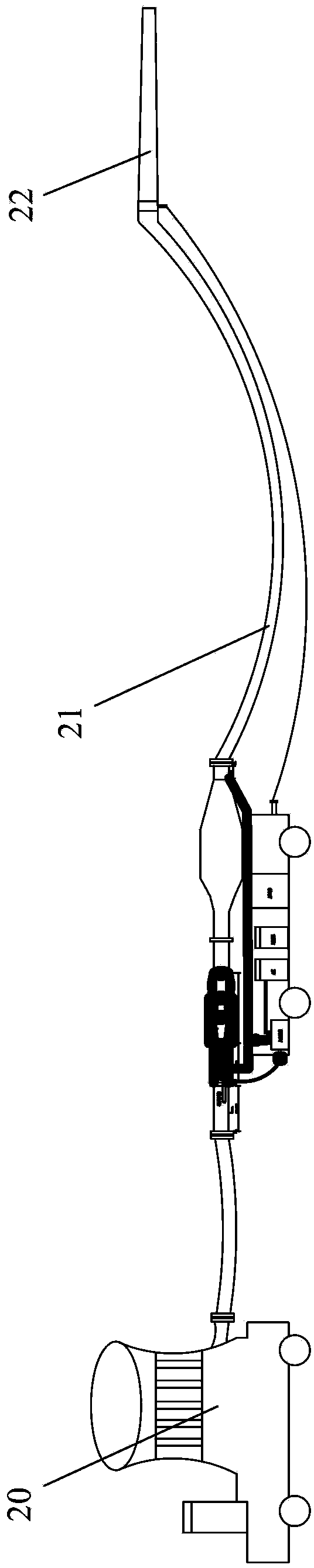

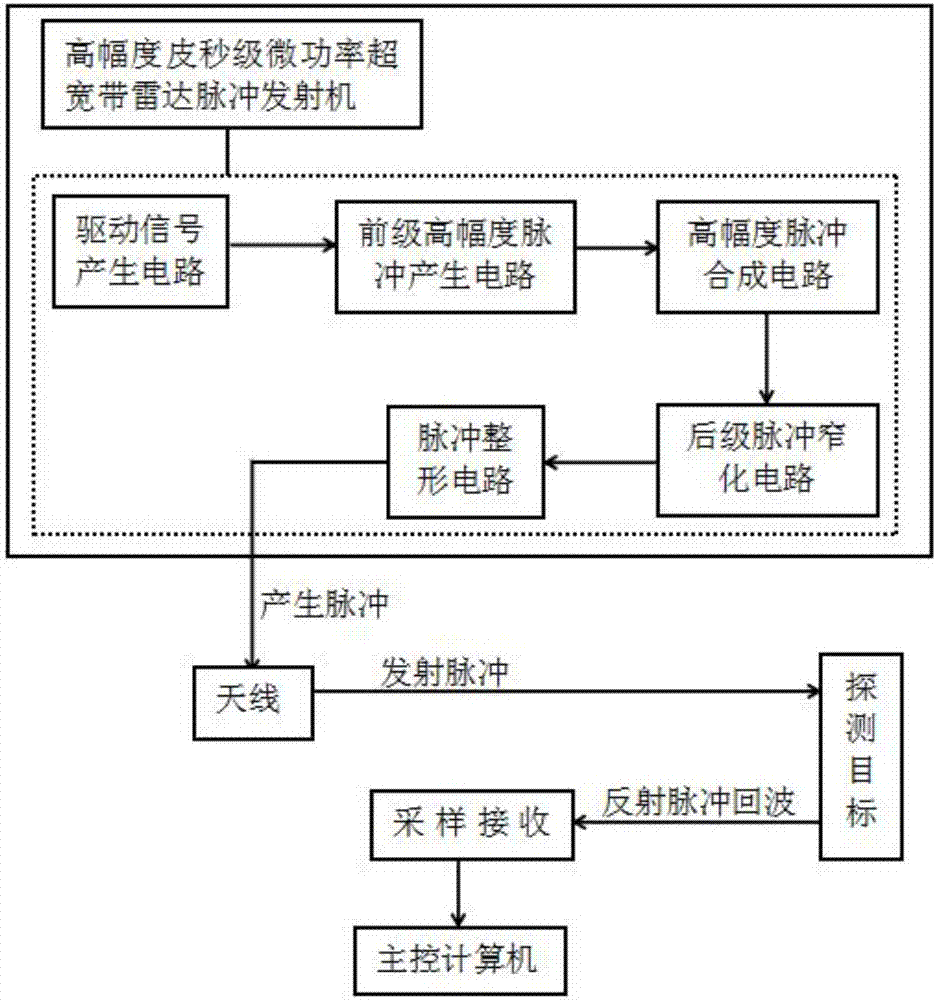

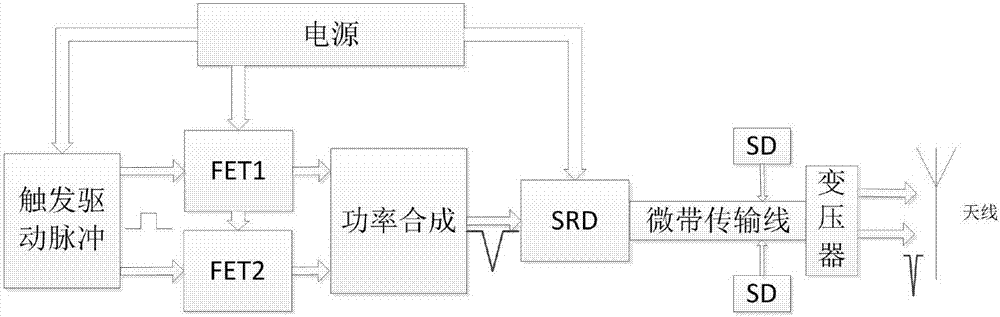

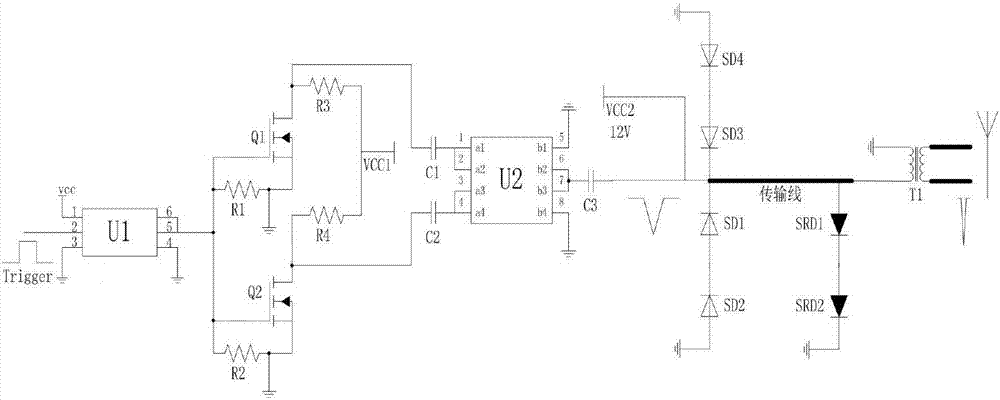

High-amplitude picosecond-level micro-power ultra-wideband radar detection system

InactiveCN107329118ASuppress overshootShort pulse widthWave based measurement systemsPicosecondMicropower

The invention discloses a high-amplitude picosecond-level micro-power ultra-wideband radar detection system, which is mainly composed of a high-amplitude picosecond-level micro-power ultra-wideband radar pulse transmitter, a sampling receiver, a main control computer and an antenna, and is characterized in that a pulse source in the pulse transmitter is a high-amplitude picosecond-level micro-power ultra-wideband radar pulse source, and the pulse source comprises a driving signal generating circuit, a pre-stage high-amplitude pulse generating circuit, a high-amplitude pulse synthesizing circuit, a post-stage pulse narrowing circuit and a pulse shaping circuit. The high-amplitude picosecond-level micro-power ultra-wideband radar detection system fully combines characteristics and advantages of a field effect transistor and a step recovery diode (SRD), enables the pulse width of high-amplitude pulses generated by the preceding stage to be greatly reduced by using a characteristic of steep cut-off conduction edges of the SRD, and thus enables the output pulses to reach the picosecond level through further compression and overshoot inhibition. The high-amplitude picosecond-level micro-power ultra-wideband radar detection system can improve the impact pulse radar resolution and the detection distance, and provides technical support for applications of ultra-wideband radar.

Owner:CENT SOUTH UNIV

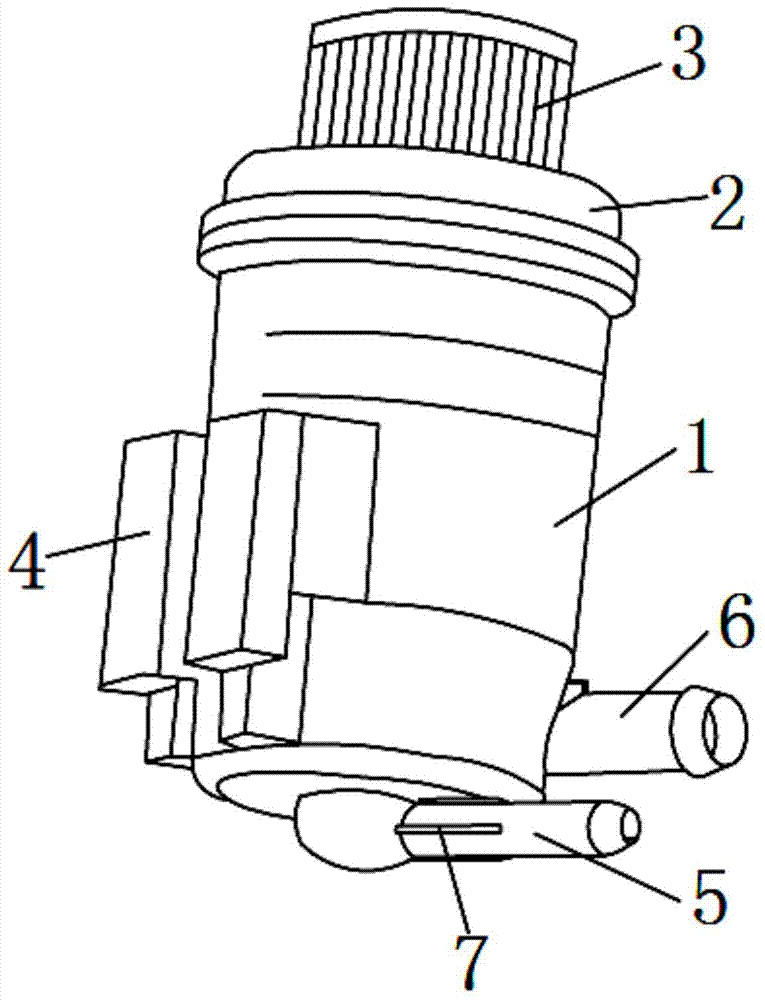

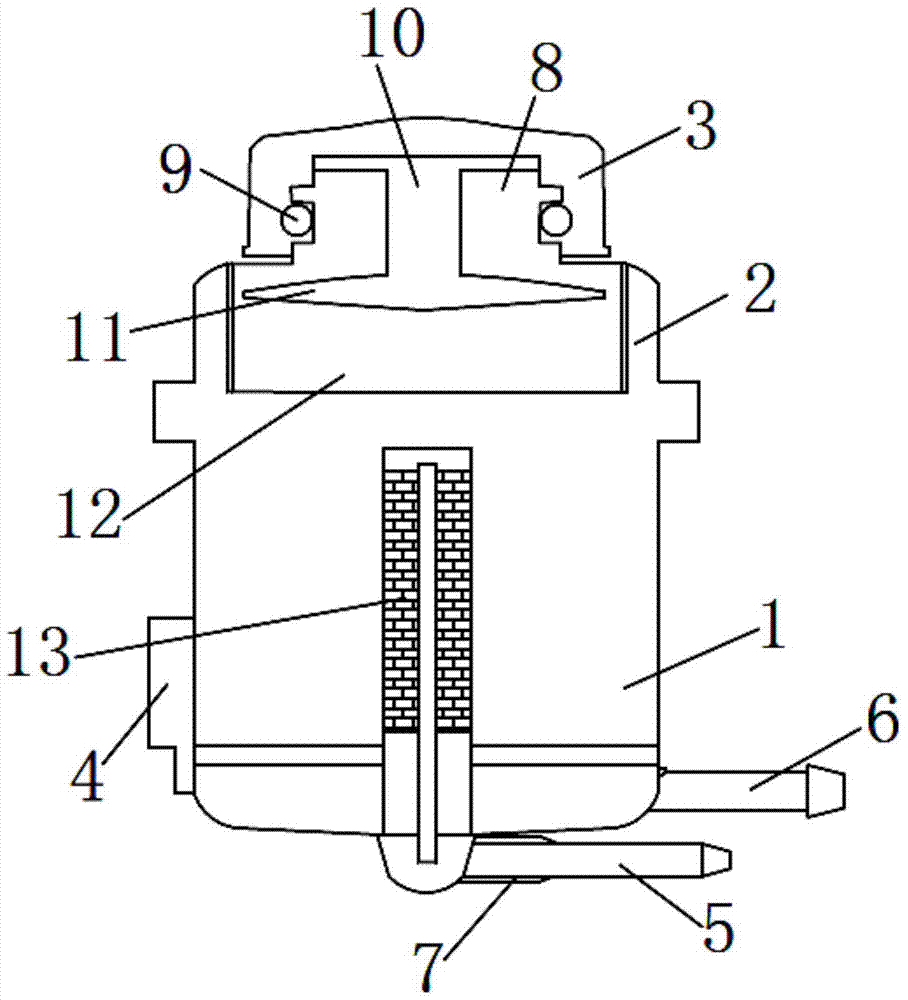

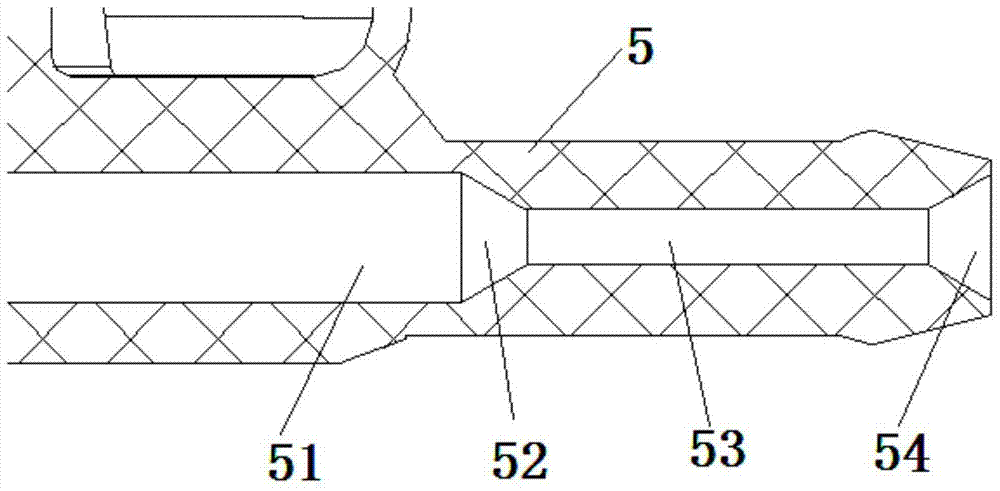

A kind of automobile steering liquid storage tank

ActiveCN104806581BImprove positionEasy to usePump assembliesFluid-pressure actuator componentsLiquid storage tankPetroleum engineering

The invention discloses an automobile steering liquid storage tank. The automobile steering liquid storage tank comprises an upper tank body (2), a lower tank body (1), and a tank cover (3) which is arranged on the upper tank body (2); an oil return opening (5) and an oil outlet (6) are formed in the lower tank body (1); an oil hole, which is communicated with a tank body, in the oil return opening (5) comprises a first oil hole section (51) and a second oil hole section (53); the first oil hole section (51) is close to the tank body; the aperture of the first oil hole section (51) is greater than that of the second oil hole section (53); the first oil hole section (51) is connected with the second oil hole section (53) through a gradient trumpet-shaped transition section (52). The automobile steering liquid storage tank disclosed by the invention is simple in structure, convenient and quick to machine and assemble, low in cost and high in using performance and structural performance; high automobile power-assisted steering performance can be achieved.

Owner:CHERY COMML VEHICLE ANHUI

Heat pipe and heat exchanger

PendingCN110132037AEliminate wickPrevent burstIndirect heat exchangersPlate heat exchangerEngineering

The invention discloses a heat pipe. The heat pipe comprises an outer pipe body and an inner pipe body, the inner pipe body is arranged in the outer pipe body in a penetrating manner, and a cooling channel allowing outer cooling liquid to pass through is formed; two opposite ends of the inner pipe body extend out of the outer pipe body, and a liquid inlet and a liquid outlet are correspondingly formed; the liquid inlet and the liquid outlet communicate with the cooling channel, a vacuum cavity is formed in the gap between the inner pipe body and the outer pipe body, and a working medium is injected into the vacuum cavity. According to the heat pipe, a liquid absorbing core and a water tank can be omitted, and the safety hidden danger of burst and the like when the heat pipe is applied to aheat exchanger and other devices can be avoided. The invention further discloses the heat exchanger.

Owner:广东棣浩智能科技有限公司

valve

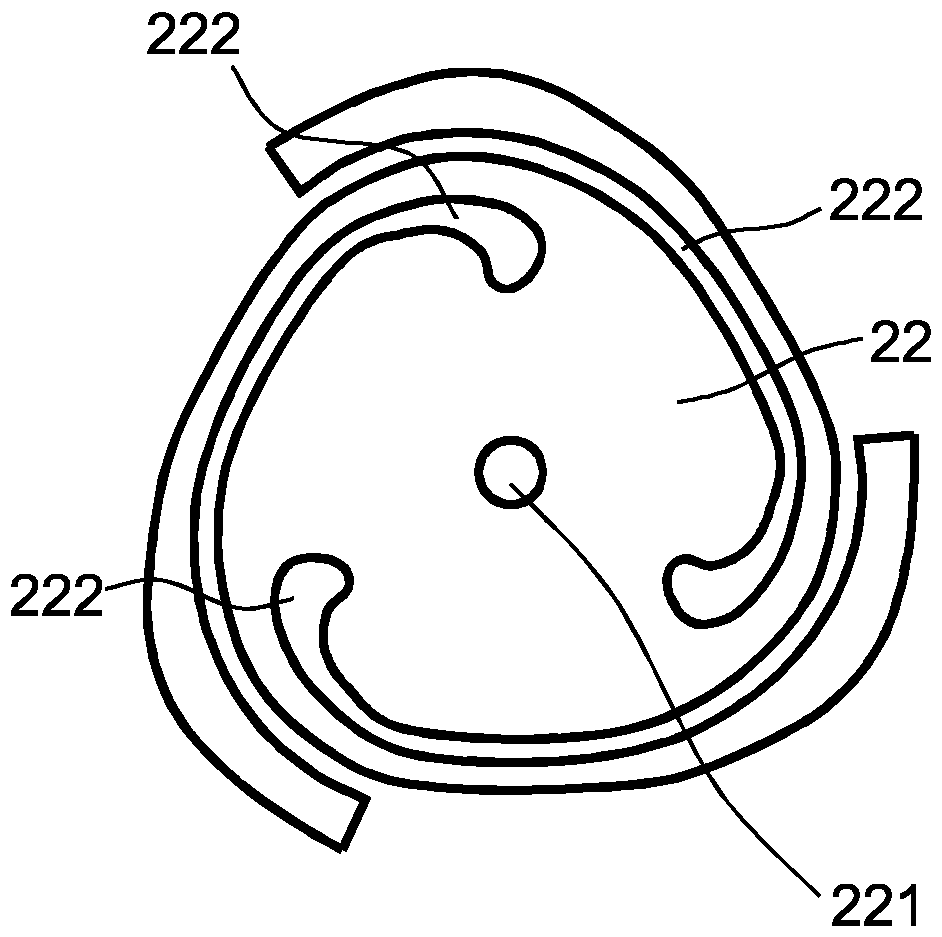

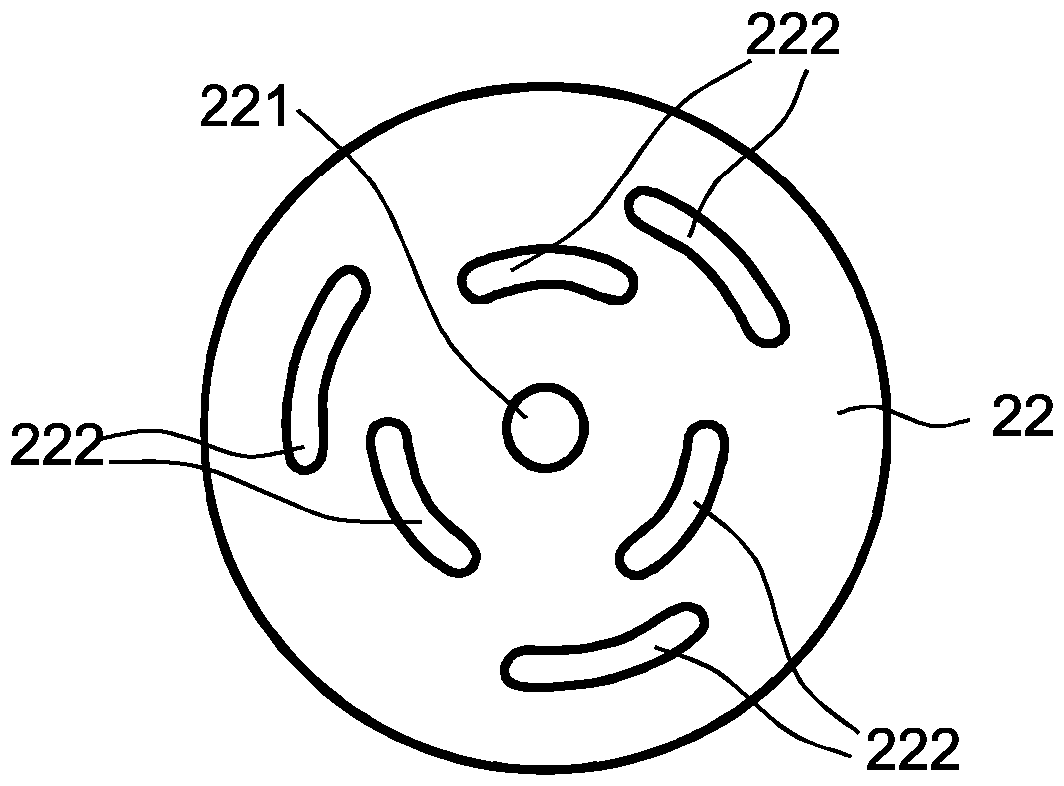

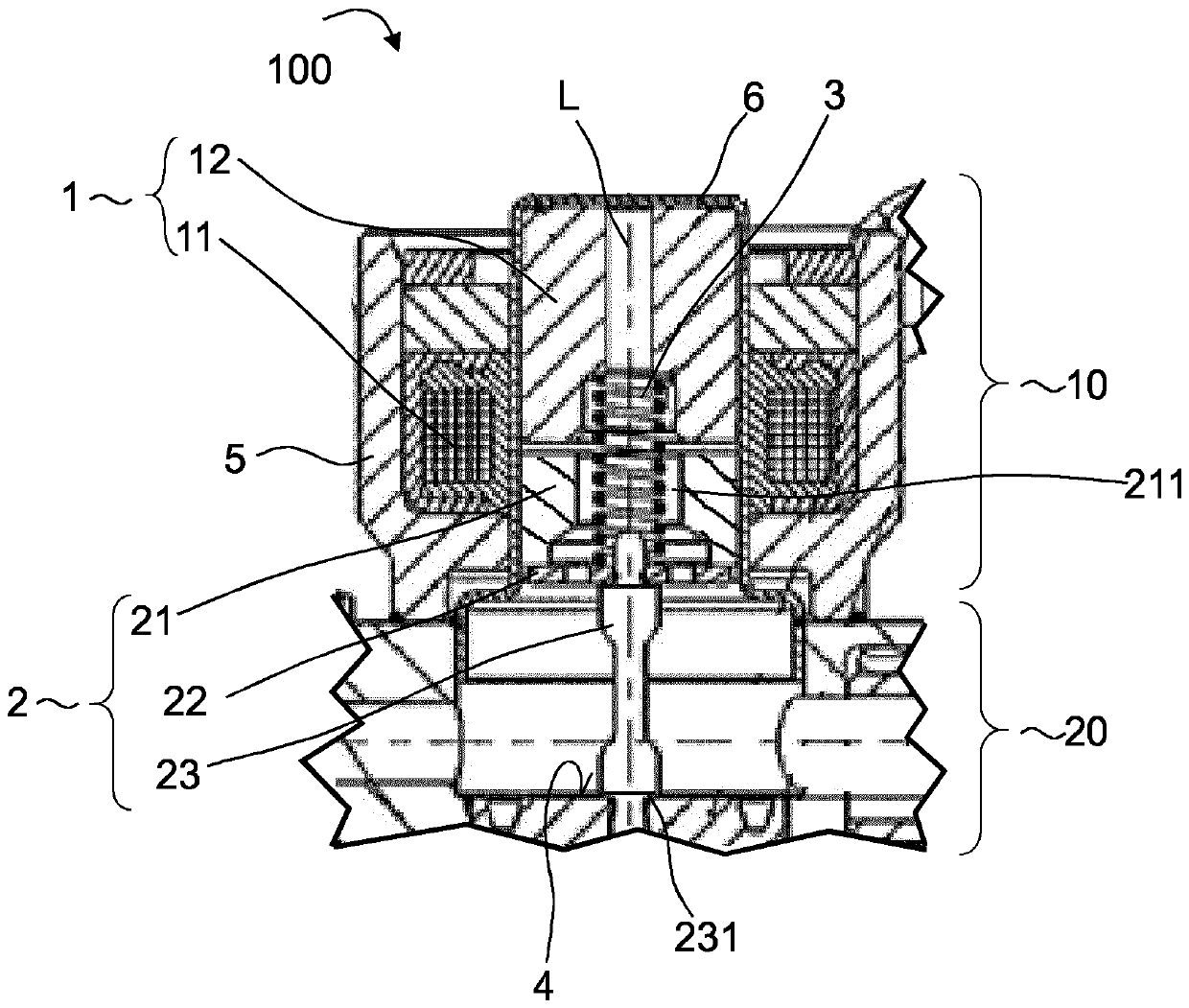

ActiveCN105637213BSmall pulseReduce noiseOperating means/releasing devices for valvesMachines/enginesEngineeringControl unit

The present invention relates to a valve, which comprises a control unit for controlling the valve element (20) (10). The control unit (10) having an electromagnet (1) and a armature set (2); the solenoid (1) having a coil (11) and a core (12), the armature set (2) having a magnetic armature capable of moving through the electromagnet (1) (21), an intermediate element (22) and a control pin for controlling the valve element (20) (23); the control pin (23) is connected to the magnetic armature (21) by the intermediate element (22), and can be moved with the magnetic armature (21). The intermediate element (22) is elastic and the control pin (23) is elastically coupled to the magnetic armature (21).

Owner:VTESCO TECH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com