Oilless vacuum single pump

A vacuum and single-pump technology, applied in the direction of pumps, pump components, rotary piston type/oscillating piston type pump components, etc., to achieve the effects of stable positive and negative pressure, clean energy, and stable suction and blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

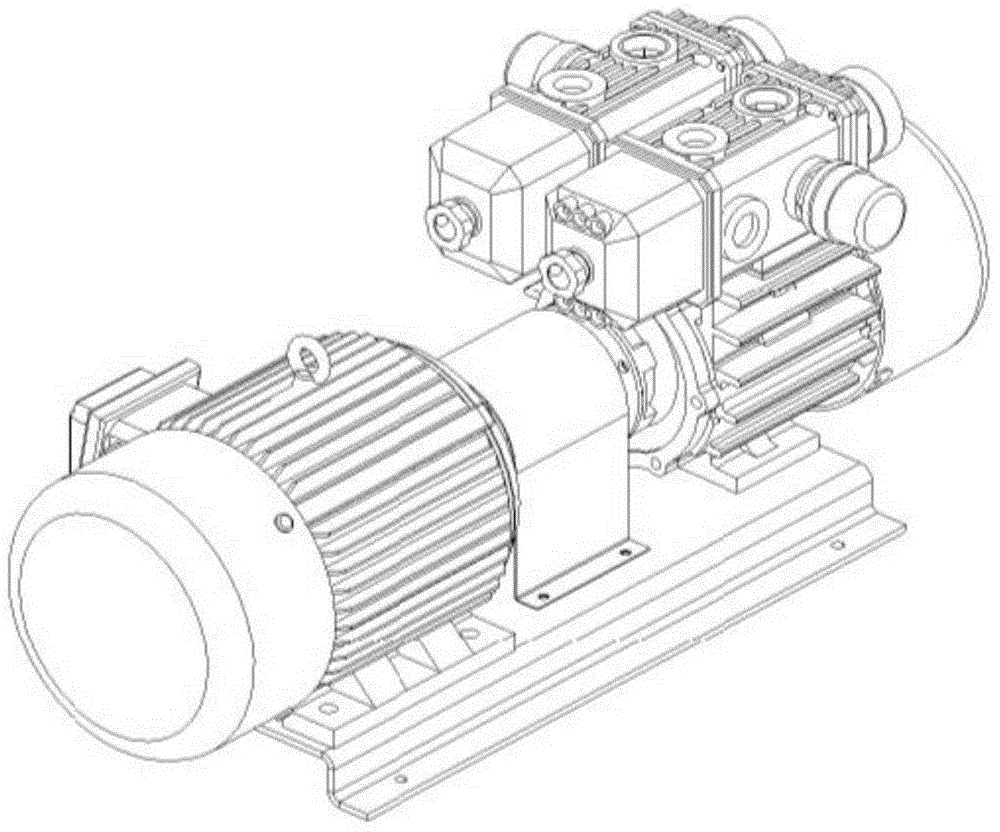

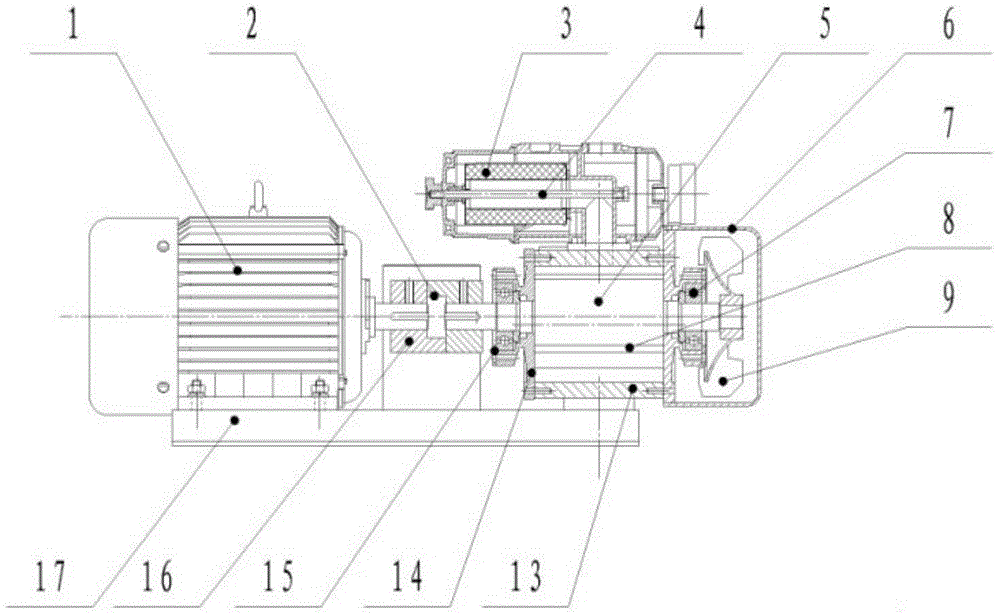

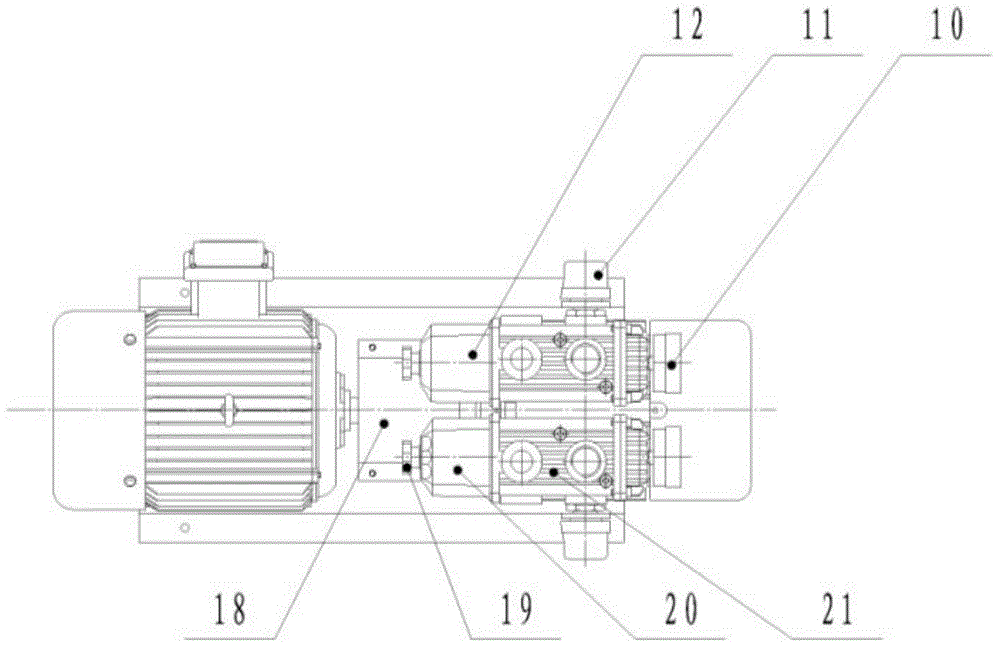

[0024] The present invention will be further described below in conjunction with the drawings.

[0025] Such as Figure 2-4 , Is an oil-free vacuum single pump, including a base 17 and a compression cylinder 13 installed on the base 17, the compression cylinder is connected to the motor 1 through a coupling 16; one end of the compression cylinder 13 is equipped with a fan device, and the top of the compression cylinder 13 Connect the muffler equipment; the rotor 5 inside the compression cylinder 13 has a sliding plate group. At the same time, in order to improve this new oil-free vacuum pump, the present invention makes corresponding changes to various components.

[0026] Such as figure 2 , The coupling cushion 2 is installed on the coupling 16 to make the connection between the motor and the compression cylinder more stable. At the same time, a bearing gland 15 is installed at the entrance of the compression cylinder 13 to further ensure the stability of the connection. At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com