Continuous conveying system and method for solid-liquid mixed materials

A solid-liquid mixing and conveying system technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of large conveying pulses, gear wear, and reduce the service life of gear pumps, and achieve small pulses and long service life. , The effect of high conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

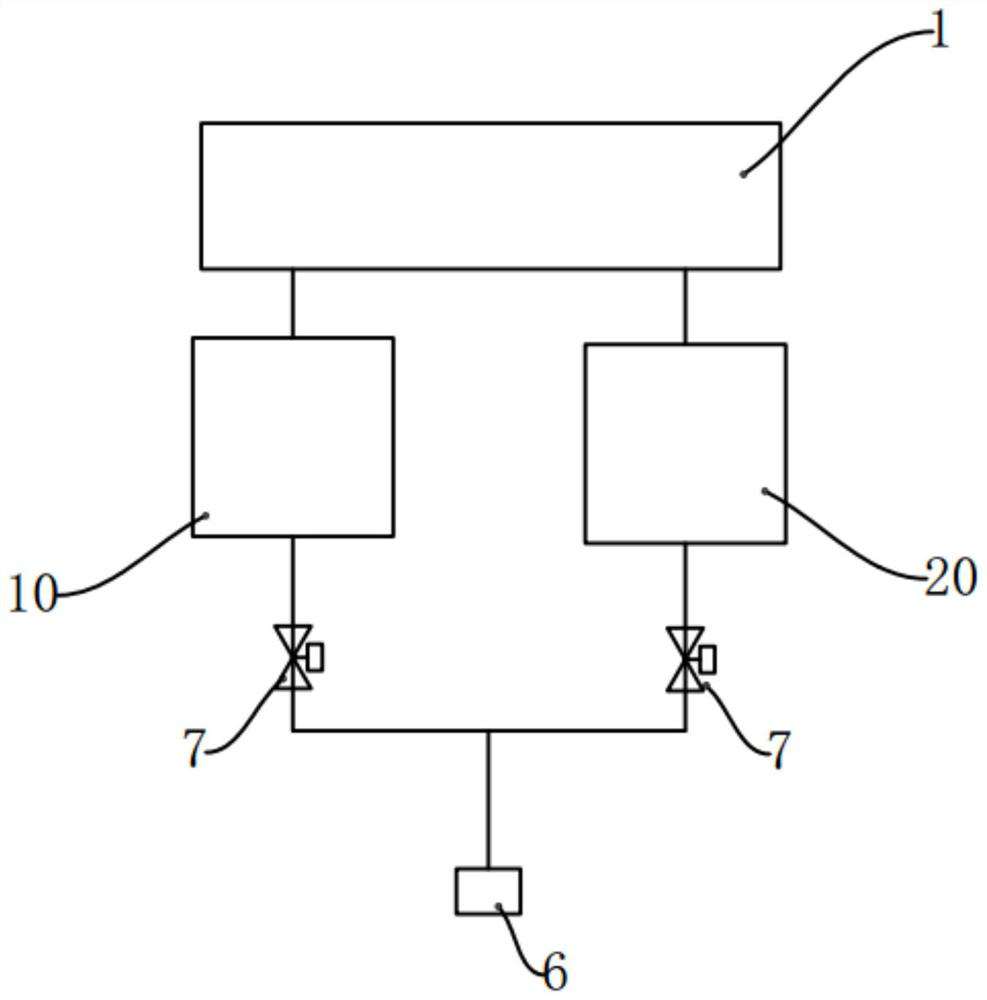

[0035] see figure 1 , which is a schematic block diagram of Embodiment 1 of the continuous delivery system for solid-liquid mixture materials of the present invention. An embodiment of the present invention discloses a continuous conveying system for solid-liquid mixture materials, including a discharge main path 6, a first conveying branch 10 and a second conveying branch 20, wherein the first conveying branch 10 and the second conveying branch The two conveying branches 20 are independent of each other and both discharge and feed according to the set cycle, and when the first conveying branch 10 is discharging, the second conveying branch 20 is fed from the storage container 1, and the second When the conveying branch 20 is discharging, the first conveying branch 10 is fed from the material container 1; Road 6 communicates, and the first conveying branch 10 and the second conveying branch 20 are communicated with the discharge main road 6 during their respective discharge p...

Embodiment 2

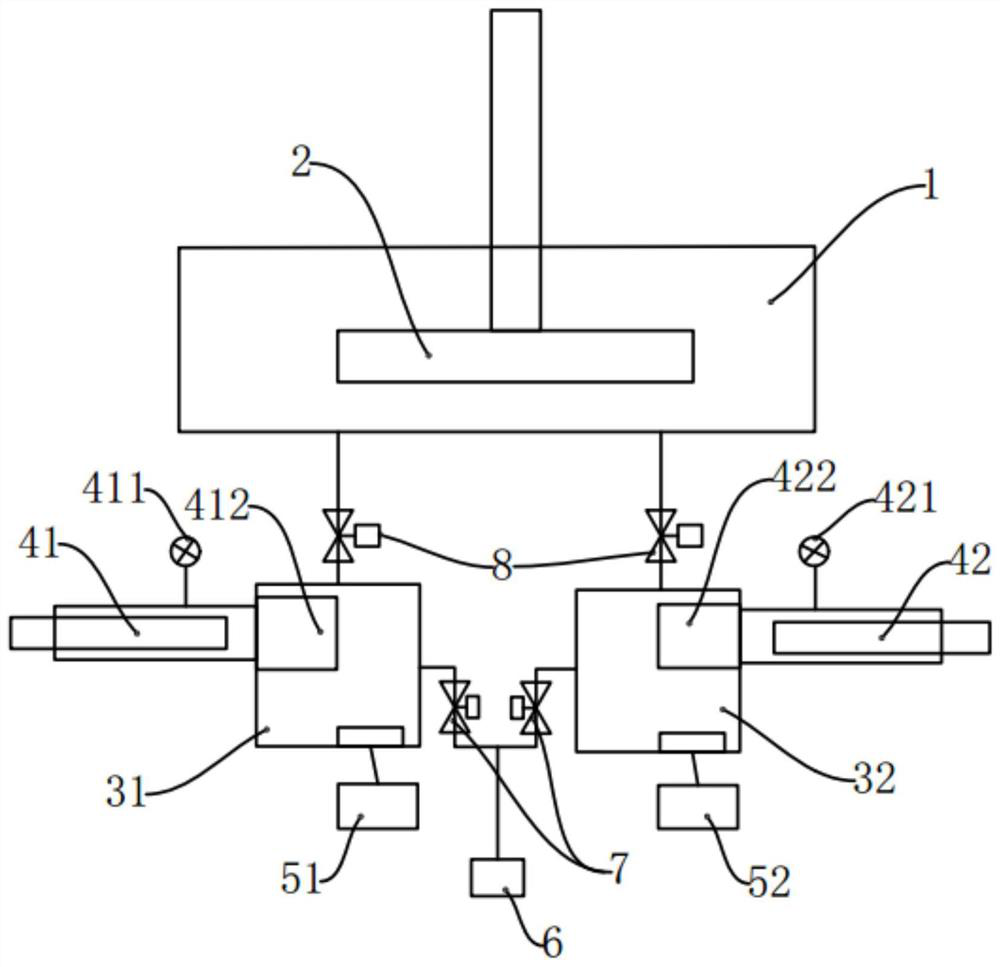

[0039] see figure 2 , which is a schematic block diagram of Embodiment 2 of the continuous delivery system for solid-liquid mixture materials of the present invention. It is further optimized on the basis of Embodiment 1.

[0040] In this embodiment, the first delivery branch includes a first plunger pump 41 and a first feeding chamber 31, and the first plunger pump 41 acts on the first feeding chamber 31 through a first isolation device 412 to generate Volume changes for feeding and feeding. The first isolating device 412 is a bellows. When the first conveying branch discharges, the first plunger pump 41 pushes inward, and the bellows expands in the first feeding chamber 31, so that the first feeding chamber 31 The volume decreases, and the materials in the first feeding cavity 31 are pushed out. The first isolation device 412 may also be an isolation film. Through the setting of the isolation device, the isolation between the plunger pump and the material can be realize...

Embodiment 3

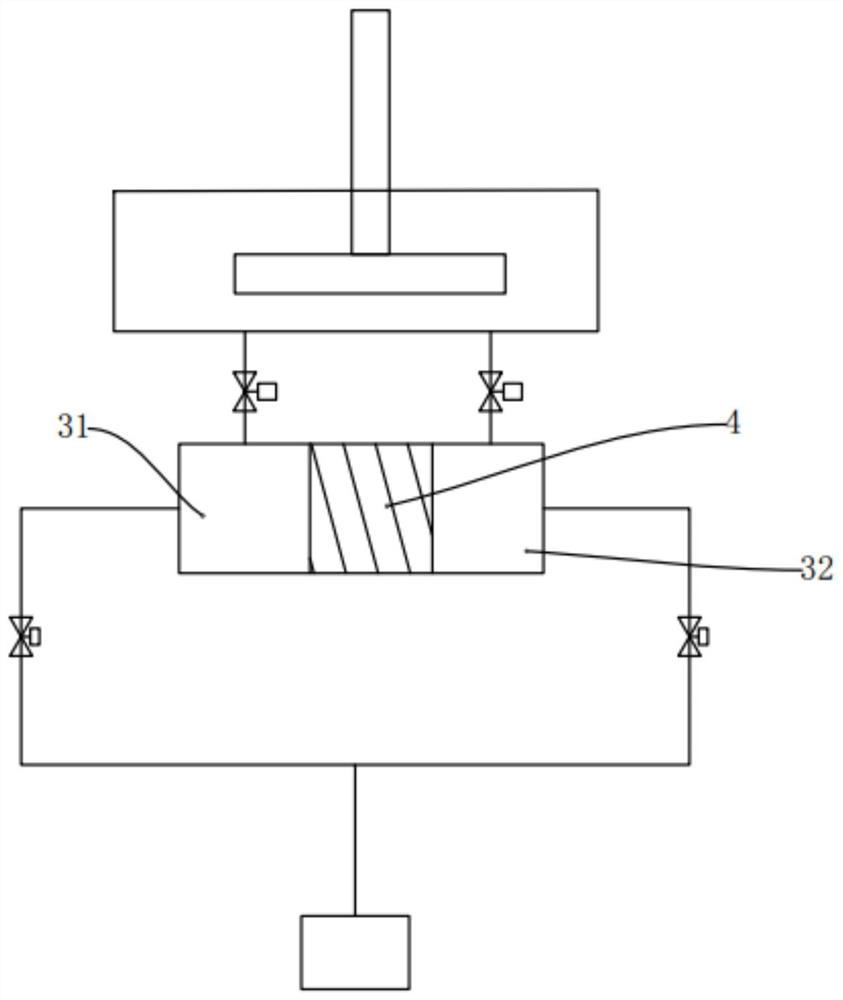

[0045] see image 3 , which is a schematic block diagram of Embodiment 3 of the continuous conveying system for solid-liquid mixture materials of the present invention. The main difference between it and Embodiment 2 lies in the part of the pushing device. There are two pushing devices in the second embodiment, that is, the first plunger pump and the second plunger pump; and there is one pushing device 4 in this embodiment.

[0046] Specifically, the pushing device 4 is placed in the feeding chamber, and divides the space in the feeding chamber into a first feeding chamber 31 and a second feeding chamber 32 , one left and one right. The pushing device 4 can reciprocate left and right in the feeding chamber, so that the volumes of the first feeding chamber 31 and the second feeding chamber 32 on both sides of the pushing device 4 in the feeding chamber increase or decrease. For example image 3 As shown, when the pushing device 4 moved to the left, the volume of the first fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com