Muck transporter used for pipe-jacking construction method

A technology of conveying device and construction method, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem that the slag truck cannot return in time, the screw machine cannot continuously discharge the slag, and it is difficult to accommodate multiple slag trucks operating in parallel, etc. problem, to achieve the effect of avoiding the accumulation of muck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

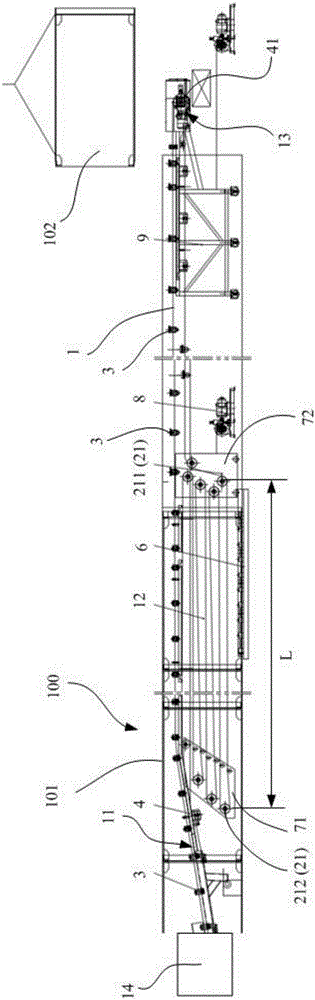

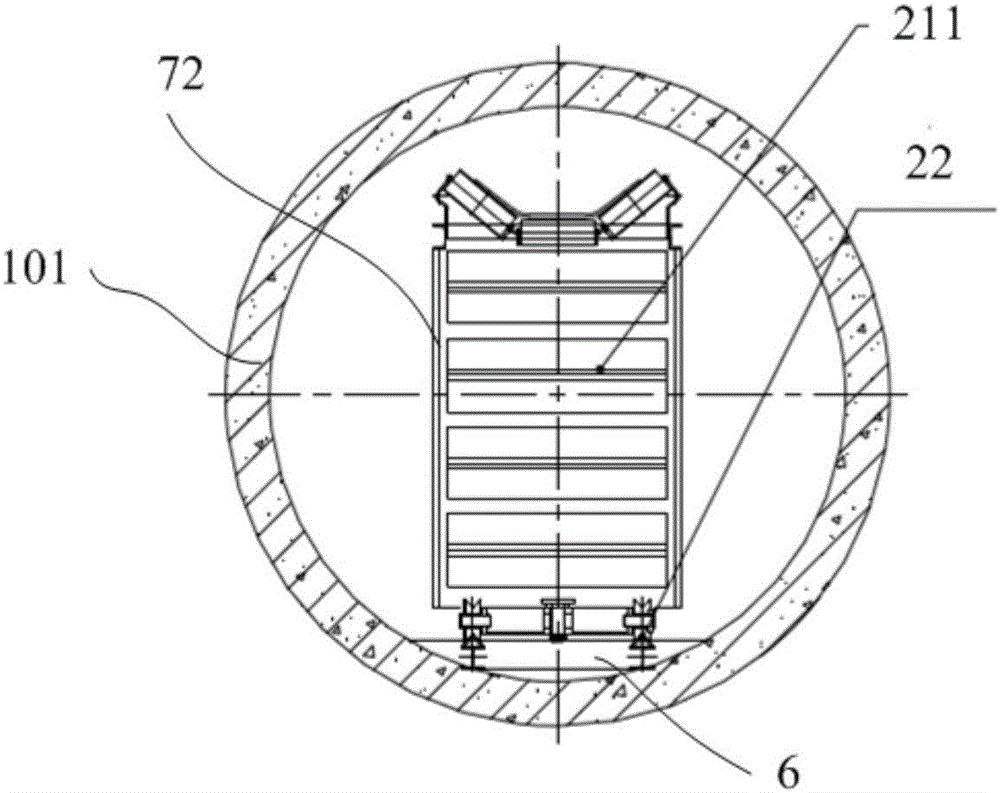

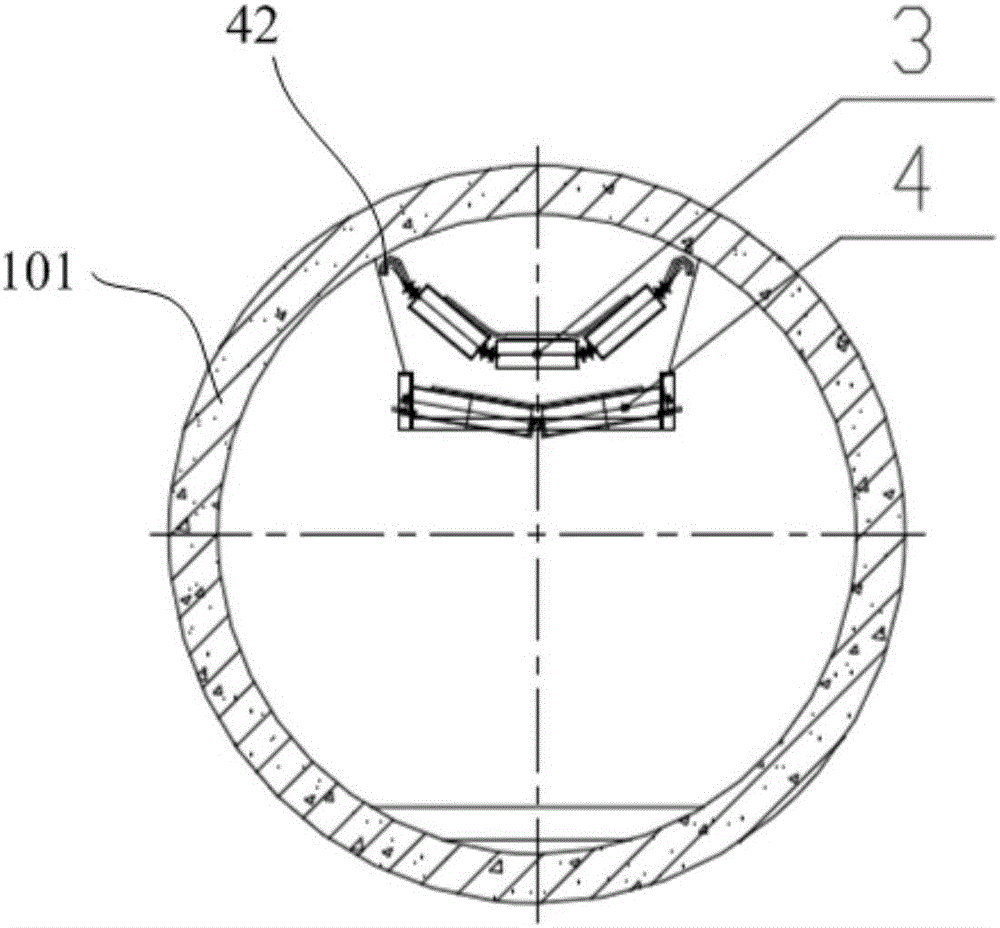

[0022] figure 1 Schematically shows a muck conveying device 100 for a pipe jacking construction method according to the present invention, which is integrally arranged in a tunnel pipe 101 . Such as figure 1 As shown, the muck conveying device 100 includes a conveyor belt 1 , which extends axially in the tunnel pipe 101 and moves in a circular motion to continuously transport the muck to the exit of the tunnel pipe 101 . The muck conveying device 100 also includes a support assembly supporting the conveyor belt 1 and a driving machine 41 (such as Figure 4 shown).

[0023] The conveyor belt 1 includes a muck receiving section 11 in the front area, a coil running section 12 in the middle area, and a muck releasing section 13 in the tail end area. These sections of conveyor belt 1 are supported and held by support assemblies, which will be described in detail below. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com