Manufacturing method for absorbent products and manufacturing device for absorbent products

A manufacturing method and absorbent technology, applied in the field of absorbent article manufacturing and absorbent article manufacturing equipment, can solve problems such as difficult cutting of shearable lines, complicated control, and impossibility of continuously conveying flaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

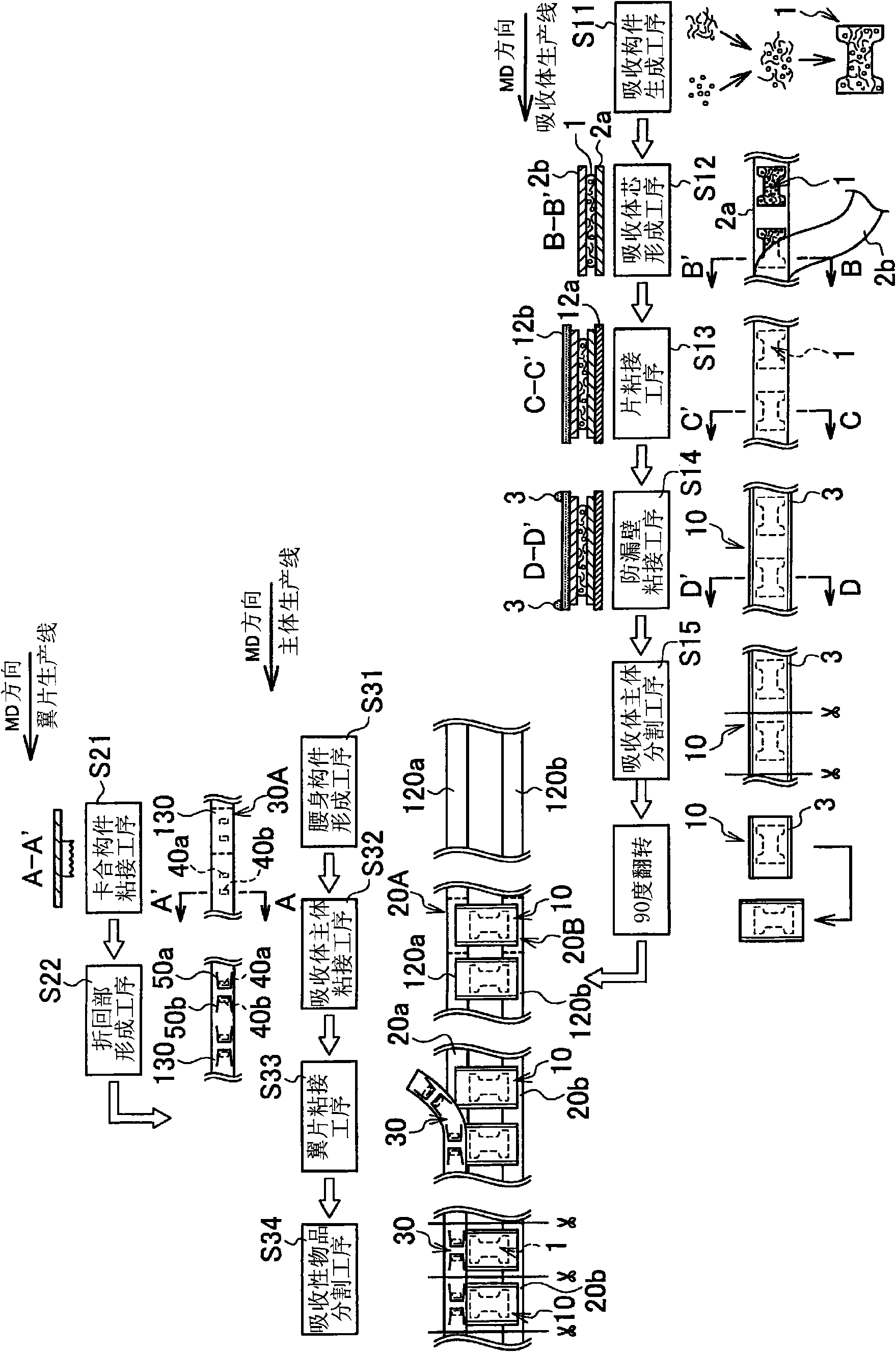

[0025] refer to figure 1 and figure 2 , and the method for manufacturing the absorbent article according to the first embodiment of the present invention will be described.

[0026] According to the manufacturing method of the absorbent article according to the first embodiment of the present invention, it is possible to manufacture the crotch member (absorbent body) including the front waist member 20b, the rear waist member 20a, and the front waist member 20b and the rear waist member 20a. The absorbent article of 10 is, for example, an unfolded diaper.

[0027] Below, refer to figure 1 , the manufacturing method of the absorbent article of this embodiment will be described.

[0028] like figure 1 As shown, in the manufacturing method of the absorbent article according to the present embodiment, a flap production line that conveys a continuous body 130 of elongated flaps, an absorbent body production line that conveys a continuous body 110 of elongated crotch members, ...

change example 1

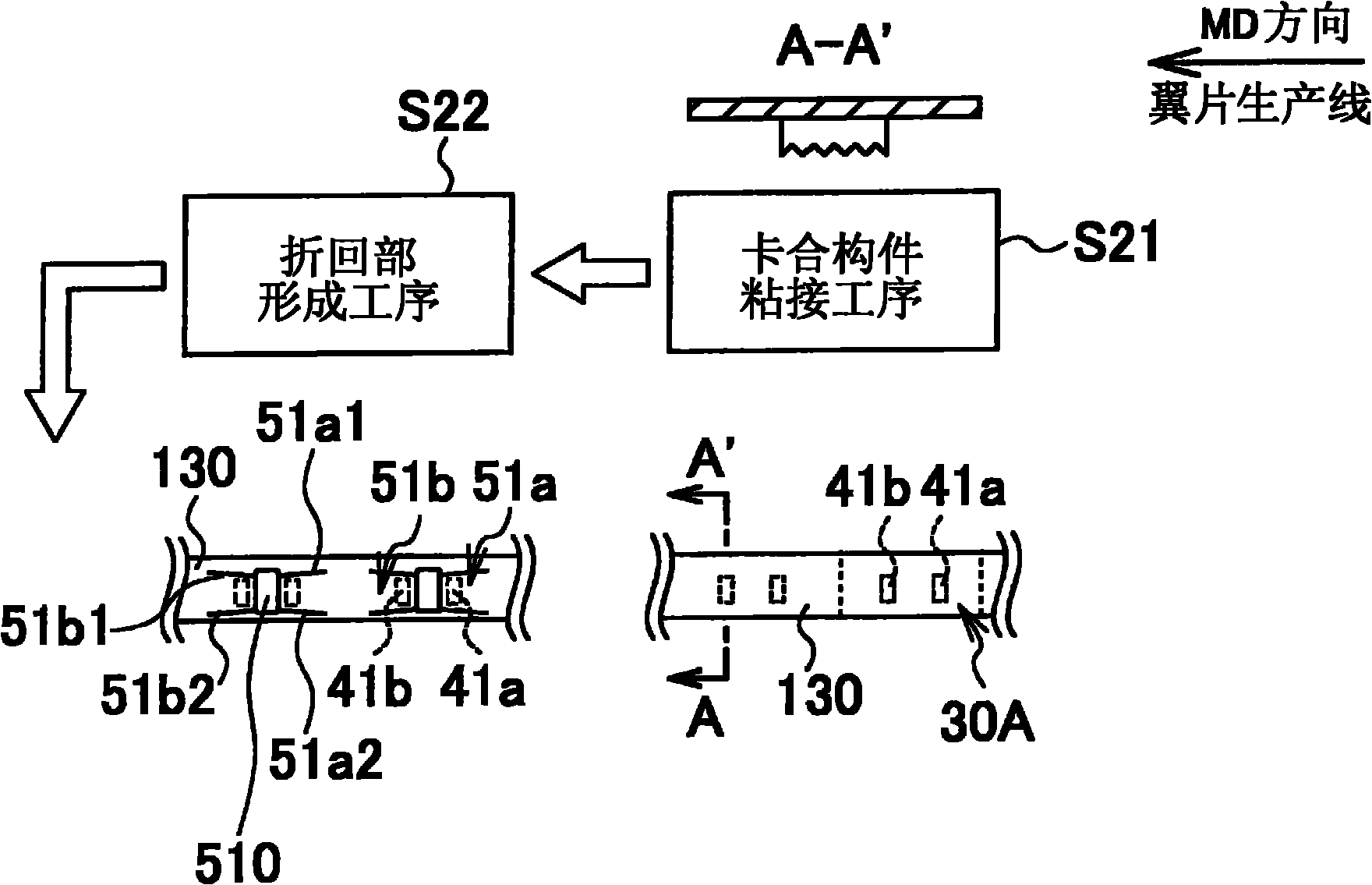

[0067] refer to image 3 , the manufacturing method of the absorbent article according to Modification 1 of the present invention will be described. Hereinafter, the manufacturing method of the absorbent article of the modification 1 of this invention is demonstrated focusing on the difference from the manufacturing method of the absorbent article of 1st Embodiment of this invention.

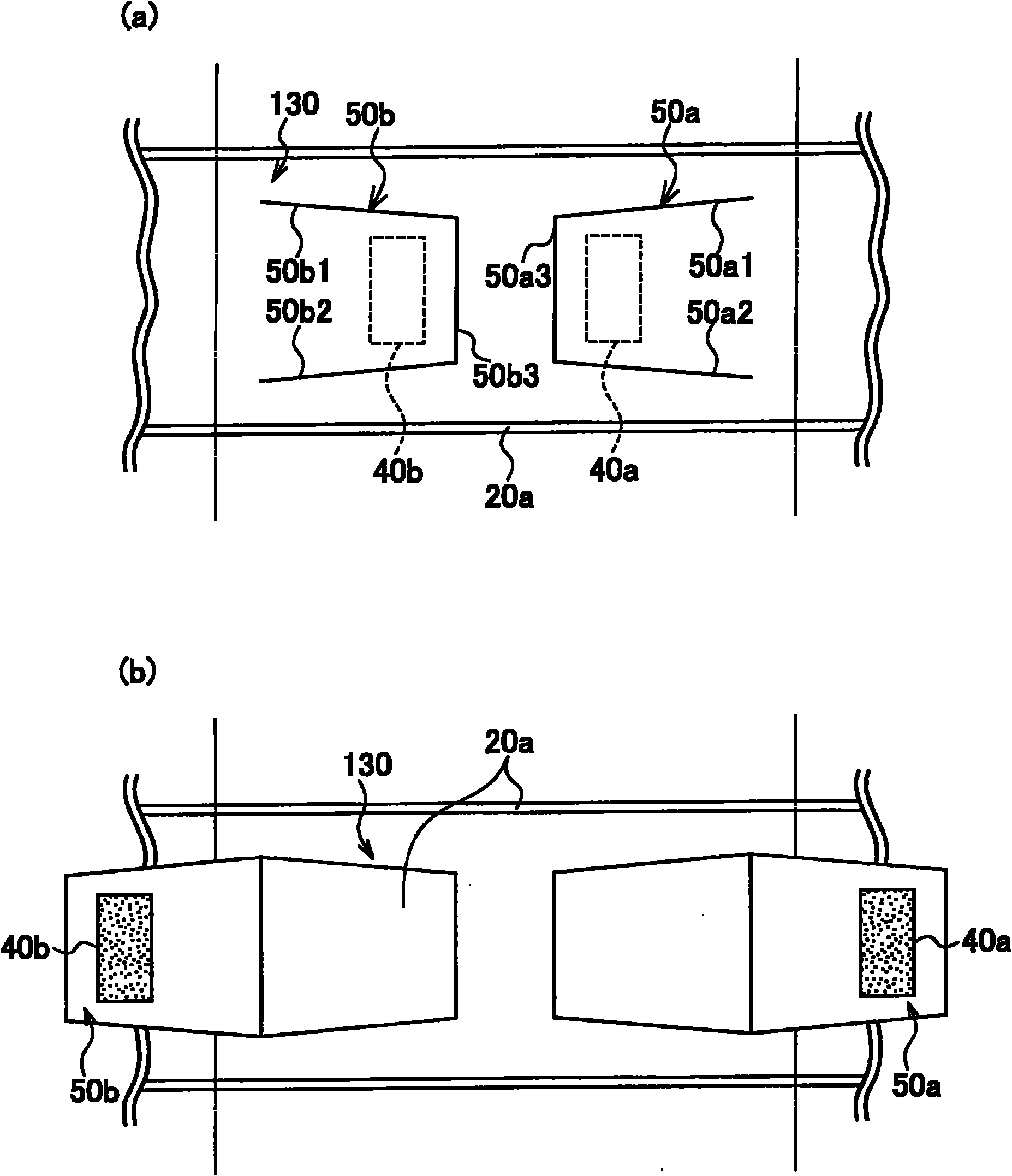

[0068] like image 3 As shown, in the process performed on the airfoil production line, in step S21, each of the regions 30A constituting one airfoil 30 in the elongated airfoil continuum 130 that is continuously conveyed on the airfoil production line Engagement members 41a, 41b capable of engaging with predetermined regions are arranged on a part.

[0069] In step S22, a pair of folded portions 51a, 51a, 51b that can be folded back in the MD direction of the flap production line and in a direction opposite to the MD direction are formed in a part of the above-mentioned area 30A, in the area ...

change example 2

[0074] refer to Figure 4 , and the method for manufacturing an absorbent article according to Modification 2 of the present invention will be described. Hereinafter, the manufacturing method of the absorbent article of the modification 2 of this invention is demonstrated focusing on the difference from the manufacturing method of the absorbent article of 1st Embodiment of this invention.

[0075] like Figure 4 As shown, in the process performed on the airfoil production line, in step S21, a part of the area 30A constituting one airfoil 30 in the elongated airfoil continuum 130 continuously conveyed on the airfoil production line Engagement members 42a, 42b capable of engaging with predetermined regions are arranged on the upper side.

[0076] In step S22, a pair of folded portions 52a, 52a, 52b that can be folded back in the MD direction of the flap production line and in the direction opposite to the MD direction are formed in a part of the above-mentioned area 30A, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com