Frame fixing base machining device and fence machining production line

A technology of processing device and fixed seat, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of troublesome assembly and disassembly, inconvenient transportation, poor stability, etc., to achieve high production efficiency and enhance urban culture The effect of quality and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

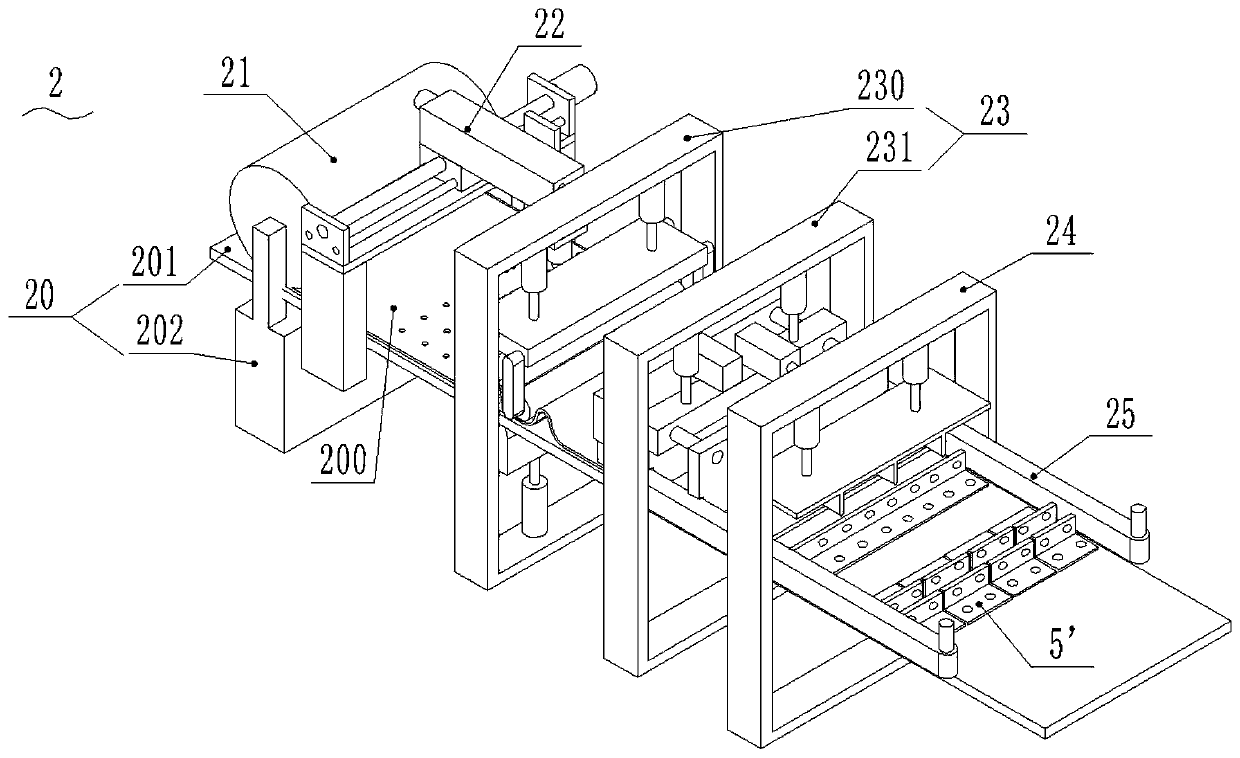

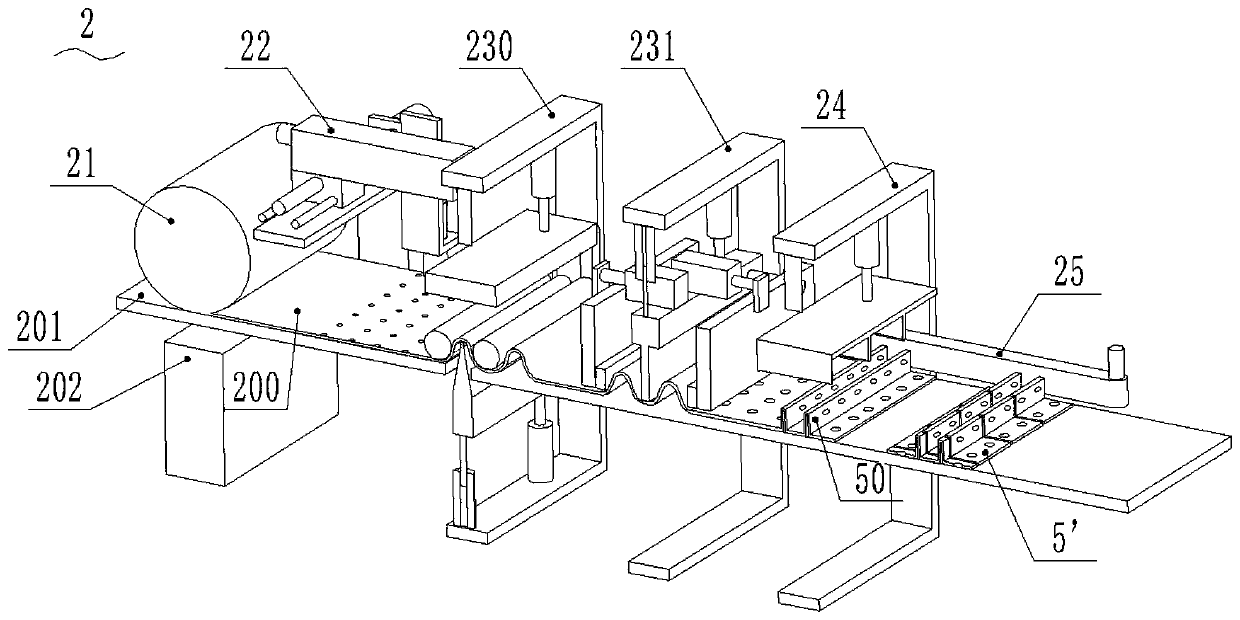

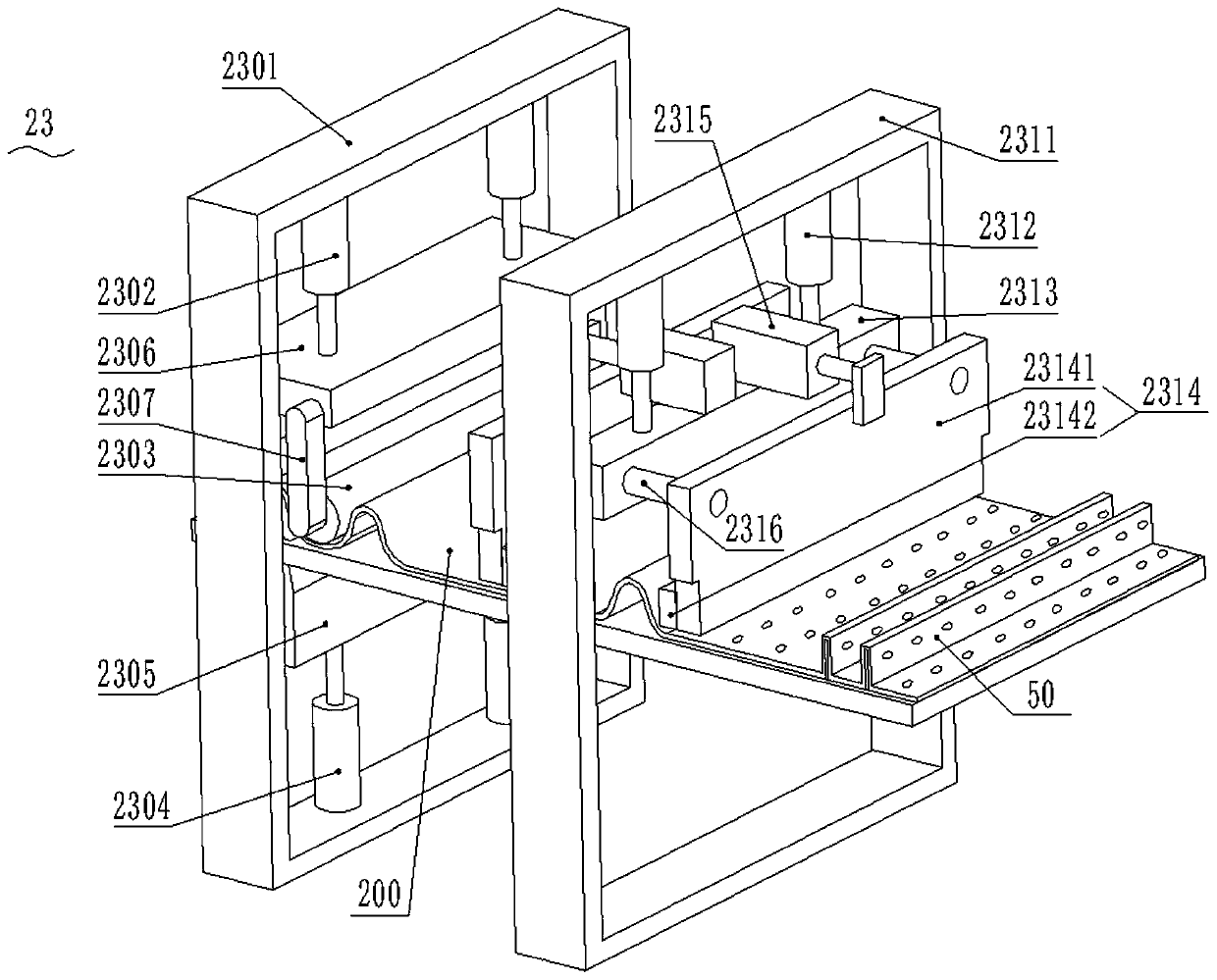

[0067] Such as Figure 1-7 As shown in , 28, the processing device 2 for the frame fixing seat provided in this embodiment, the frame fixing seat 5' includes a fixing plate 51', and two splints 50' arranged in parallel and alternately in the middle of the fixing plate 51' , the splint 50' is provided with a first through hole 501', and both edges of the fixing plate 51' are provided with a second through hole 510'; the frame holder processing device 2 includes a second working platform 20, The second reel mechanism 21 for winding the second iron plate 200, the second extruding mechanism 23 for extruding the two straight plates 50 parallel to each other on the second iron plate 200, for the second iron plate 200 The third cutting mechanism 24 for cutting the board 200 and two straight boards 50, the width of the straight board 50 is equal to the width of the splint 50', and the length of the straight board 50 is N times the length of the splint 50', N ≥1, N is a natural number...

Embodiment 2

[0094] Such as Figure 1-30As shown, a fence production and processing system provided in this embodiment, the fence 100' includes a mesh plate 1', a frame 2', a frame fixing seat 5', a support rod 3' and a support rod fixing seat 6' , the frame 2' includes an outer frame 20' and a plurality of inner reinforcing tubes 21'; the enclosure production and processing system includes:

[0095] A blanking machine for blanking the mesh plate 1', the support rod 3' and the inner reinforcing tube 21';

[0096] An outer frame processing device 3 for processing the outer frame 20';

[0097] The frame fixing seat processing device 2 described in Embodiment 1 for processing the frame fixing seat 5';

[0098] A support rod holder processing device 1 for processing the support rod holder 6';

[0099] A butt welder for welding the outer frame 20' and the inner reinforcing tube 21', as well as the welding of the mesh plate 1' and the frame 2';

[0100] A paint spraying machine for spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com