Concrete mixing bunker as well as concrete wet-process injection system and method based on concrete mixing bunker

A technology of wet spraying and concrete, which is applied in the direction of chemical instruments and methods, mixing operation control, mixing operation control device, etc. It can solve the problems of high construction cost, large dust on the construction site, large strength dispersion, etc., and achieve raw material utilization rate High, high sampling intensity, high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

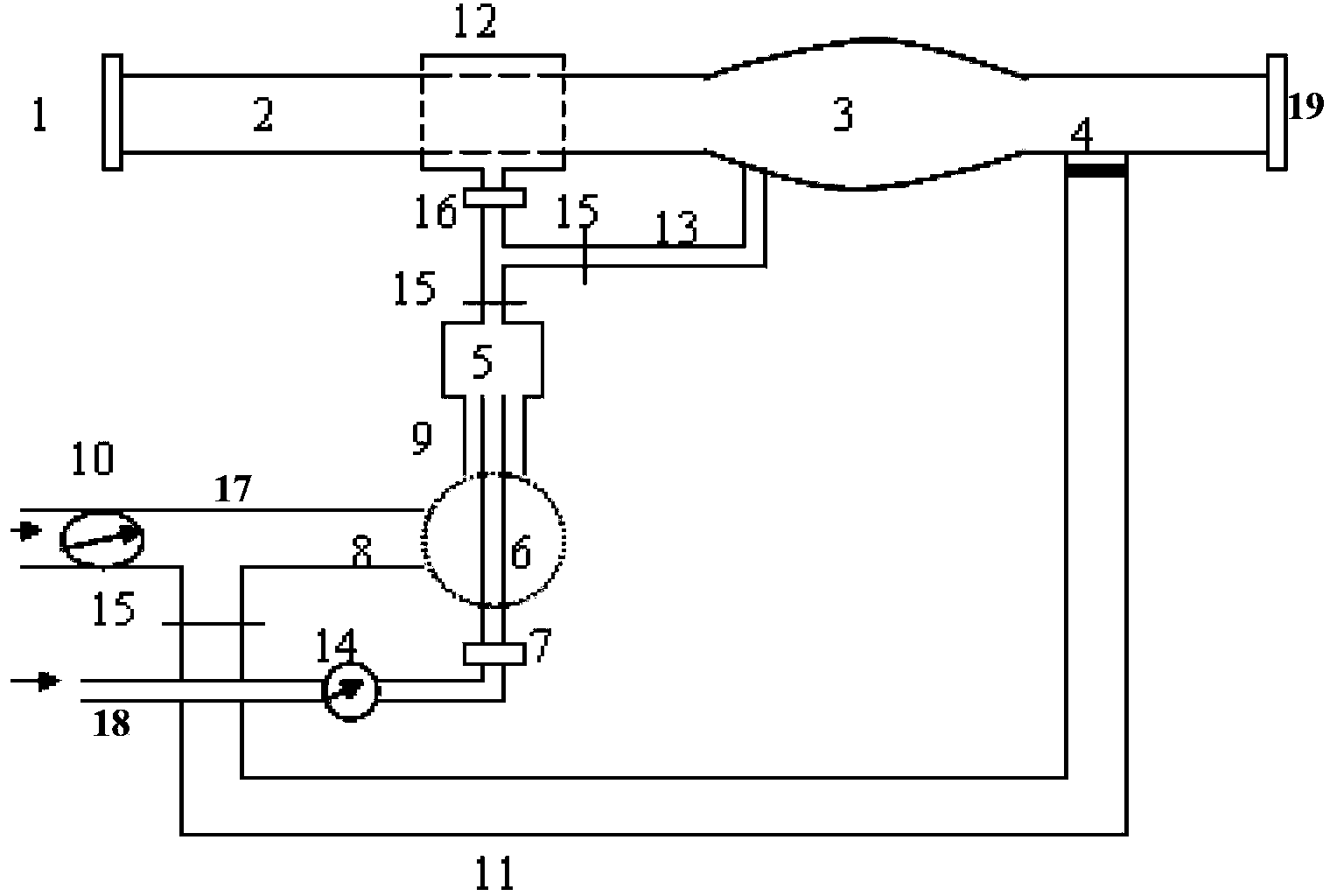

[0039] Step 1, at first mix the aggregates of the concrete evenly in the mixer according to the gray-water ratio of 1:0.15~0.2, transport them to the construction site with a tank truck or a dump truck, and add it to the injection machine of the present invention manually or mechanically in the hopper;

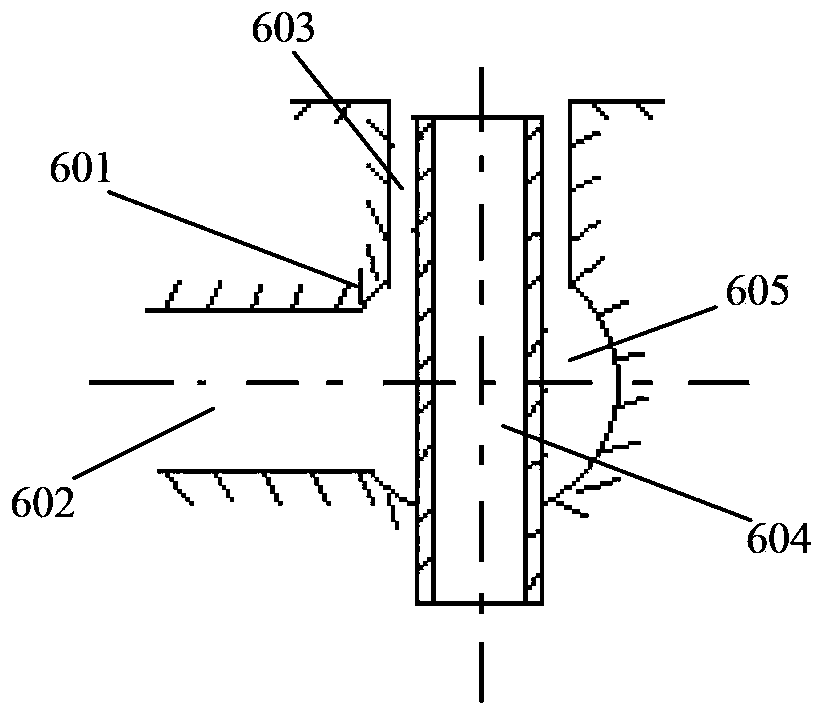

[0040] Step 2: Use compressed air to transport the mixture to the concrete mixing chamber. The mixture passes through the material mixing chamber (hereinafter referred to as the mixing chamber) twice and then adds water to form a plastic mixture in the mixing chamber. Here, the water passes through first. The air-water mixer is atomized and then added to the water adding ring and the mixing chamber respectively. The amount of water added is determined by the concrete mix ratio and controlled by flow meters and valves;

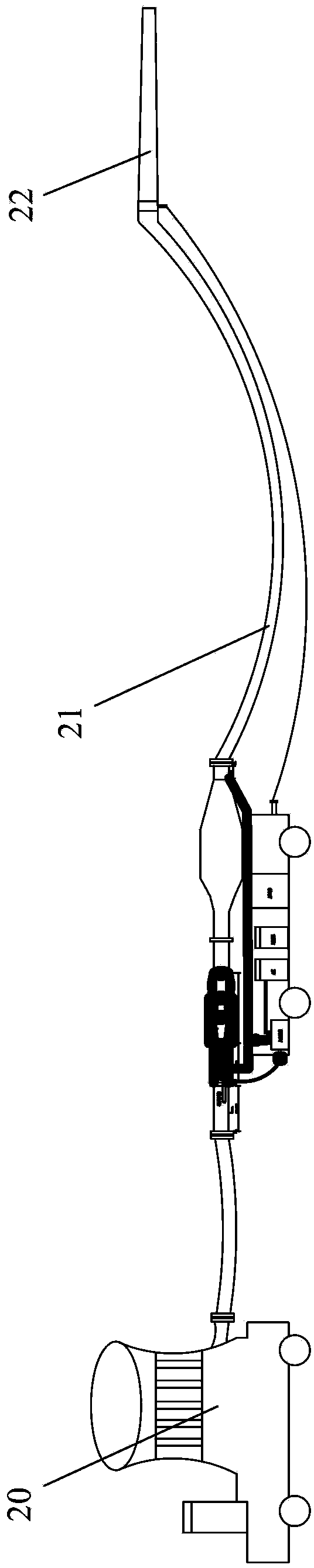

[0041] Step 3: The plastic mixture is transported to the nozzle under the action of the compressed air in the delivery pipe and the auxiliary compressed air, a...

Embodiment 2

[0043] Step 1, at first mix the aggregates of the concrete evenly in the mixer according to the gray-water ratio of 1:0.15~0.2, transport them to the construction site with a tank truck or a dump truck, and add it to the injection machine of the present invention manually or mechanically in the hopper;

[0044] Step 2: Use compressed air to transport the mixture to the concrete mixing chamber. The mixing chamber has been removed from the mixing chamber here. The water passes through the air-water mixer and then enters the water adding ring and then enters the conveying pipeline, and is mixed with the liquid at the nozzle. Spray out after the accelerator works.

Embodiment 1

[0046] Step 1, mix the concrete aggregate evenly, and add the mixture into the hopper of the dry spraying machine by manual feeding, and manually sprinkle the powdered quick-setting agent in the hopper after starting the spraying machine;

[0047] Step 2: The mixing material and quick-setting agent are transported to the nozzle under the action of compressed air, and are sprayed out quickly by the action of the water added to the nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com