a reciprocating pump

A technology of reciprocating pumps and crankshafts and connecting rods, applied in the field of reciprocating pumps, can solve the problems of large water tank occupation and achieve the effects of reducing energy waste, improving cooling effect, and improving flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

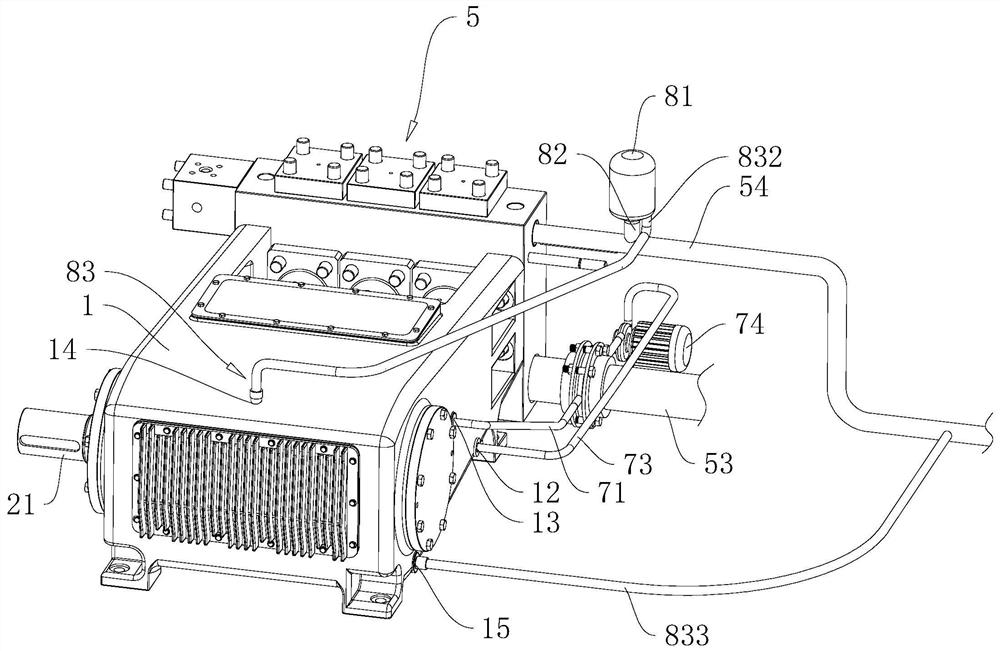

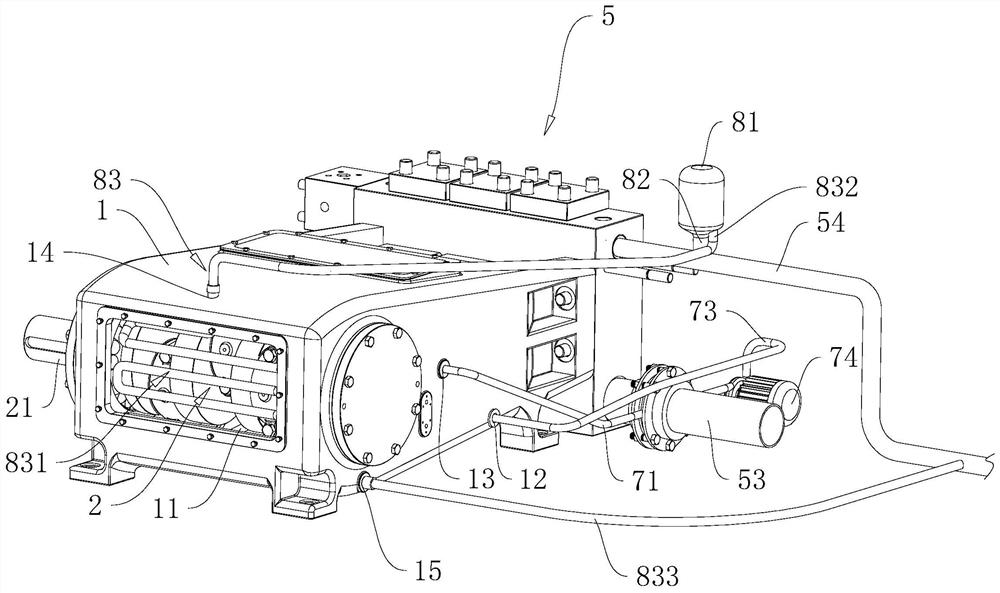

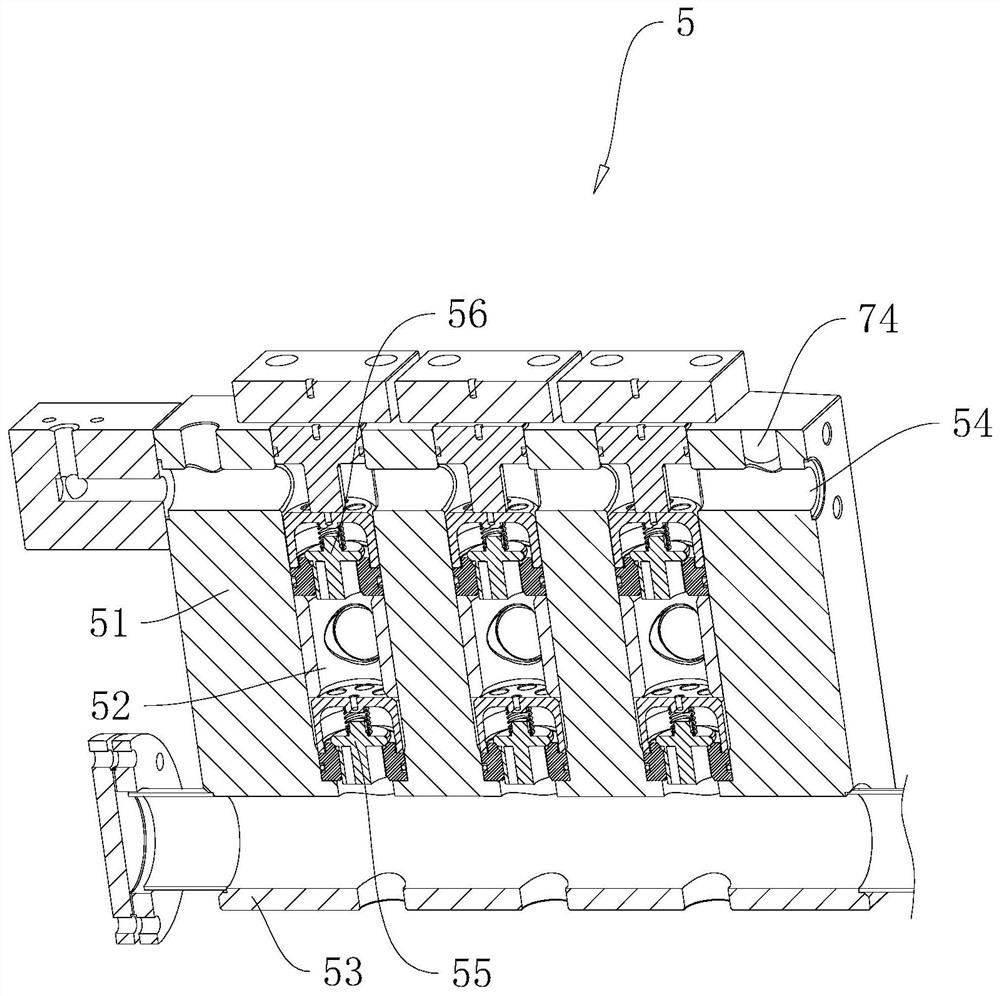

[0040] Attached to the following Figure 1-7 This application will be described in further detail.

[0041] The embodiment of the present application discloses a reciprocating pump. refer to figure 1 and figure 2 , a reciprocating pump, including a casing 1, a crankshaft connecting rod mechanism 2, a plunger, a cylinder liner assembly and a suction and discharge valve group 5 arranged in the casing 1. The casing 1 is provided with a power chamber 11, and the crankshaft connecting rod mechanism 2 And the plunger is installed in the power chamber 11 . There are three crankshaft connecting rod mechanisms 2, and the three crankshaft connecting rod mechanisms 2 are driven by the same crankshaft 21; the crankshaft 21 is provided with three connecting rod journals, and the three connecting rod journals are arranged along the axis of the crankshaft 21 at intervals, so that the three crankshaft connecting rods are The mechanism 2 performs reciprocating motion in sequence, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com