Three-ball diaphragm pump with composite shaft

A diaphragm pump and composite shaft technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve problems such as installation and disassembly difficulties, and achieve the effects of low cost, fast reversing seal, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

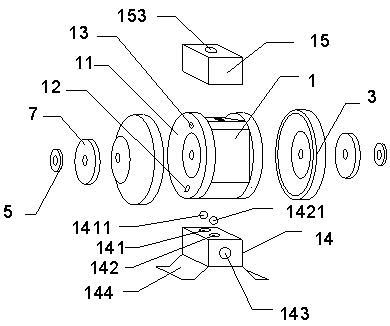

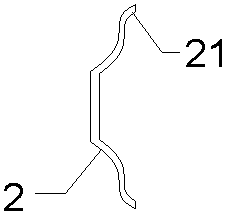

[0033] A composite shaft three-ball diaphragm pump, such as Figure 1~6 As shown, it includes a diaphragm pump body 1, a diaphragm 2 on both sides, and a partial cover 3. The partial cover 3 is connected and fixed to the diaphragm pump body 1, and the diaphragm 2 seals and isolates the two.

[0034] Specifically, both sides of the diaphragm pump body 1 are symmetrical chamber plates 11, and the lower side of the symmetrical chamber plate 11 is provided with a liquid inlet 12, and the upper side is provided with a liquid outlet 13, and the liquid inlets 12 on both sides are connected with the lower side. The double-ball inlet ball valve seat 14 on the side is connected, and the upper side of the diaphragm pump body 1 is provided with a single-ball outlet ball valve seat 15.

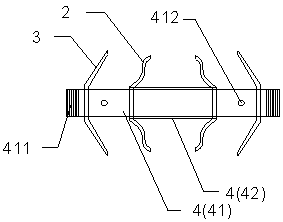

[0035] The shaft 4 is used as the connecting part of the diaphragm pump body 1 , the diaphragm 2 and the partial cover 3 , and is specifically a composite shaft including an inner shaft 41 and an outer sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com