Auxiliary welding tool for flange of winding drum

An auxiliary welding and reeling technology, applied in auxiliary welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of affecting the stability of the reel support, destroying the overall structure of the reel, and easily generating axial jumps, so as to avoid moving , Avoid secondary clamping and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

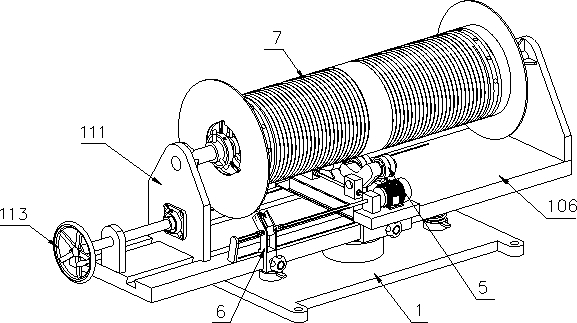

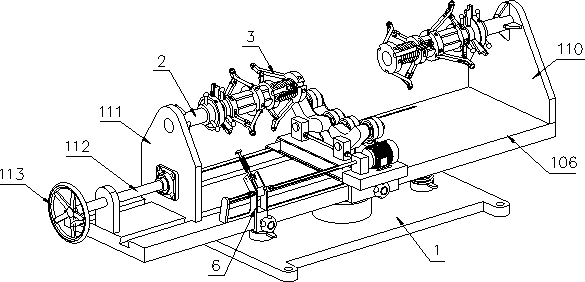

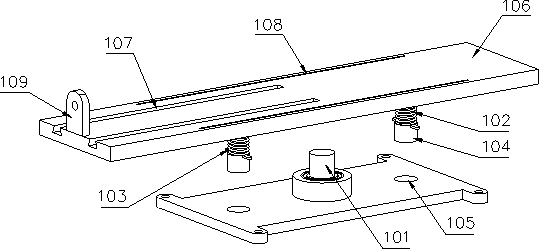

[0052] like Figure 1-3As shown, a reel sidewall auxiliary welding tool includes a bottom plate 106, a reel clamping fixture 3, and a sidewall fixture 4. The upper side of the bottom plate 106 is provided with a number of first guide grooves 107, and one end of the bottom plate 106 is provided with a The fixed seat 110, the other end of the bottom plate 106 is provided with a sliding seat 111 that is slidably mounted inside the first guide groove 107, and one end of the bottom plate 106 close to the sliding seat 111 is provided with a support plate 109, and the support plate 109 is threadedly connected with an adjusting screw 112 , one end of the adjusting screw 112 is movably connected with the sliding seat 111, and the other end of the adjusting screw 112 is provided with a hand wheel 113; the adjusting screw 112 is used to adjust the distance between the fixed seat 110 and the sliding seat 111, so as to facilitate the reels of different lengths Supporting use; one side of t...

Embodiment 2

[0059] The difference from Example 1 is that, as Figure 11 As shown, in this embodiment, the reel pressing fixture 3 includes a plurality of L-shaped fixing brackets 313 fixedly installed on the support arm 2 and a cone 309 slidably installed on the support arm 2. One end is provided with a first bushing 314, a third support rod 311 is slidably installed inside the first bushing 314, the upper end of the third support rod 311 is rotatably connected with a support wheel 312, and the cone 309 is provided with several The guide rail 310 and the lower end of the third support rod 311 are connected with a guide wheel, and the guide wheel is slidably installed inside the guide rail 310 . When the reel 7 is pressed tightly, the first screw sleeve 308 is rotated to move the cone 309 to the middle of the reel 7. When the cone 309 moves, the guide wheel at the lower end of the third support rod 311 slides on the outer wall of the cone 309 to drive the first The three support rods 311 ...

Embodiment 3

[0063] The difference from Example 1 is that, as Figure 12-14As shown, in this embodiment, the beating mechanism includes a second drive bevel gear 612 fixedly mounted on the connecting sleeve 604, and two sets of second shaft sleeves 614 are connected to the inner side of the support frame 601. A drive shaft 615 is rotatably connected to the second bushing 614. The lower end of the drive shaft 615 is provided with a second driven bevel gear 613 meshing with the second drive bevel gear 612, and the upper end of the drive shaft 615 is provided with a plurality of drive teeth 617. The upper second shaft sleeve 614 is provided with a beating shaft 616, and there are several guide grooves (not shown in the figure) on the side wall of the jumping shaft 616. A guide bar (not shown in the figure), so that the jumping shaft 616 can only slide up and down in the second sleeve 614, but cannot rotate in the second sleeve 614; the lower end of the jumping shaft 616 is provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com