Energy saving type gas-free spraying coater

An airless spraying, energy-saving technology, used in spraying devices, liquid spraying devices, etc., can solve the problems of difficult manufacturing and processing, long intake and exhaust passages, and difficult manufacturing, and achieve long service life, large thickness, and weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

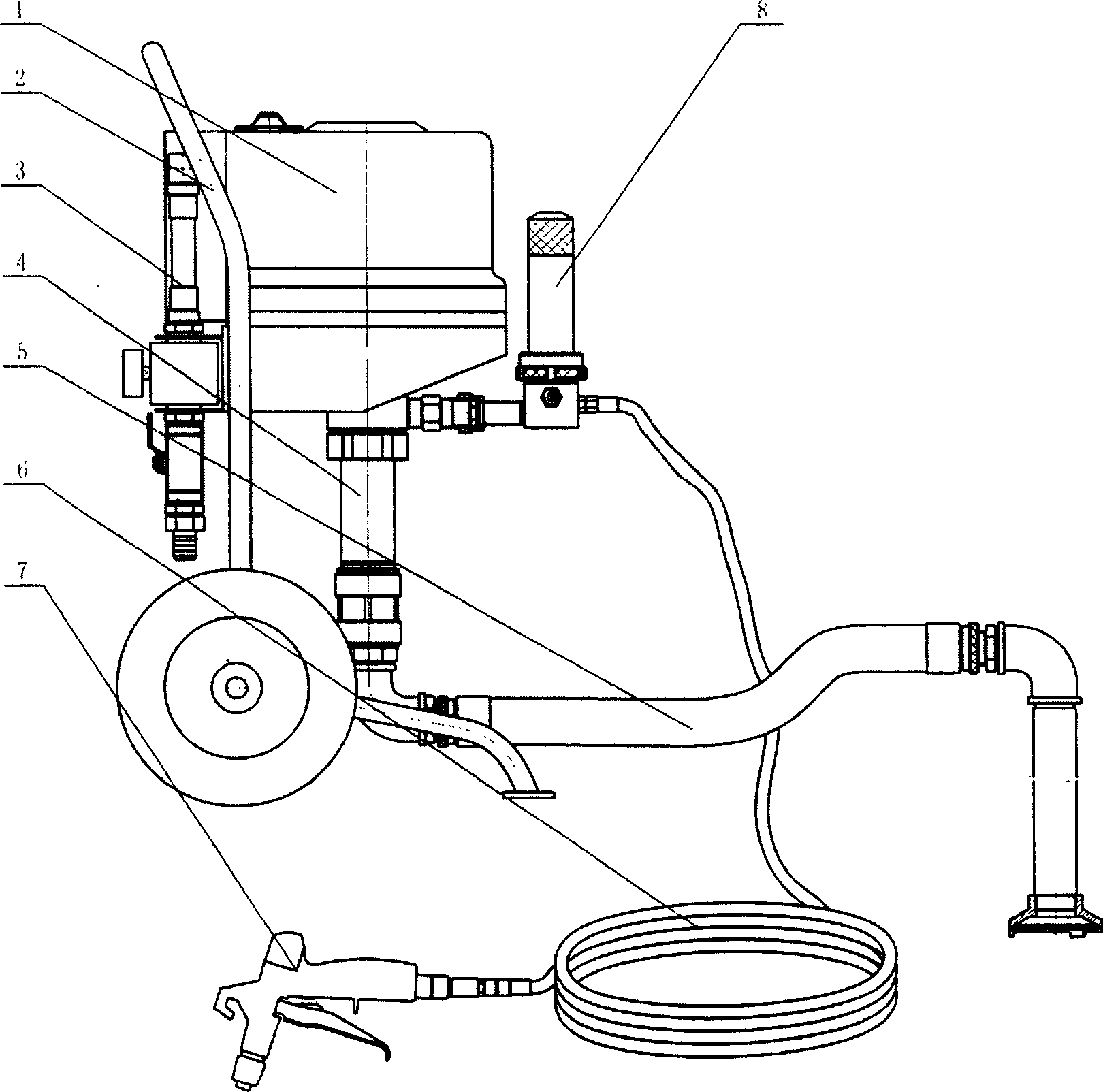

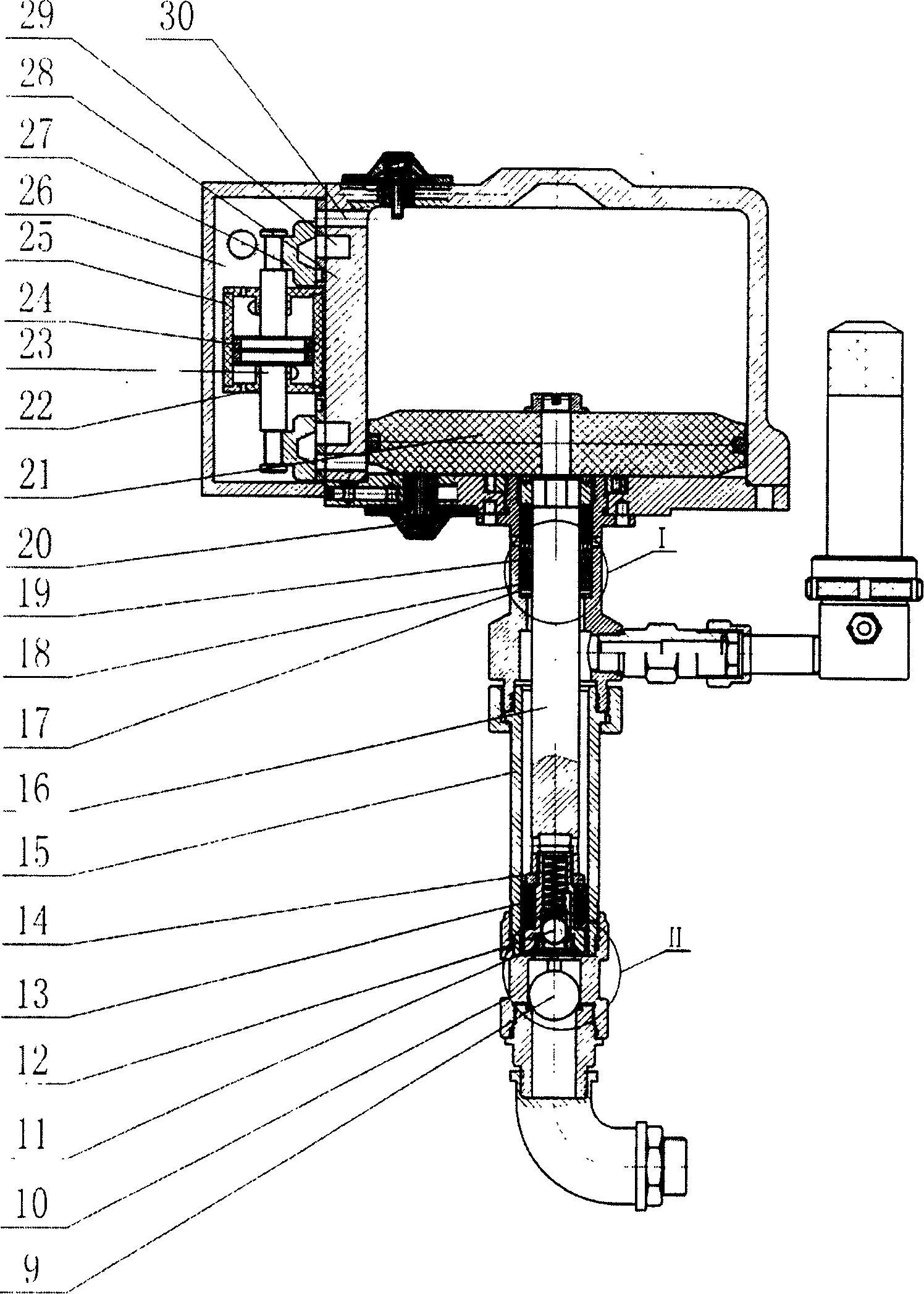

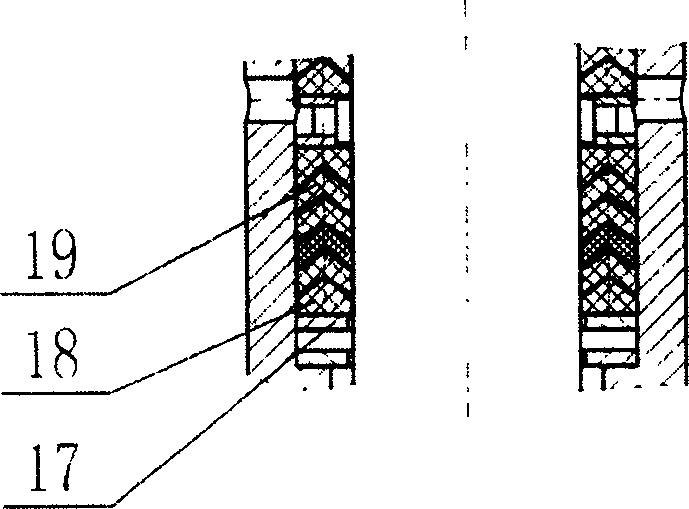

[0020] Such as Figure 1~5 As shown, the energy-saving airless sprayer of the present invention includes an air motor 1, a trolley frame 2, an air intake system 3, a hydraulic booster pump 4, a suction system 5, a high-pressure hose 6, a spray gun 7 and a filter 8, wherein The suction system 5 is connected with the hydraulic booster pump 4, the spray gun 7 is connected with the high-pressure hose 6, the high-pressure hose 6 is connected with the filter 8 and then connected with the hydraulic booster pump 4, and the intake system 3 and the hydraulic booster pump 4 are respectively connected with the The air motor 1 is connected, and these devices are all placed on the trolley frame 2. The air motor 1 of the present invention uses a pressure relief reversing mechanism for reversing, and is composed of a cylinder 28 and a reversing mechanism. The reversing mechanism includes two quick release valves 20, an independent pressure relief integrated reversing module and two air Roads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com