Pressure stabilizing pump

A technology of a voltage stabilizer pump and a pump body, applied in the field of voltage stabilizer pumps, can solve the problems of complex structure, the influence of implanted electronic equipment, and the inability to output continuous and stable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] The pressure stabilizing pump described in the invention application includes a pump body, the pump body is provided with more than two input pipes, more than one output pipe and more than two piston cylinders, and the number of input pipes and piston cylinders is equal and connected in one-to-one correspondence , a one-way valve that can only close the input pipe is provided in the inlet passage of the input pipe and the piston cylinder, and each piston cylinder communicates with the output pipe through its own outlet passage, and there is a valve between the output pipe and the piston cylinder that can be closed alternately. Reversing valve for either outlet channel.

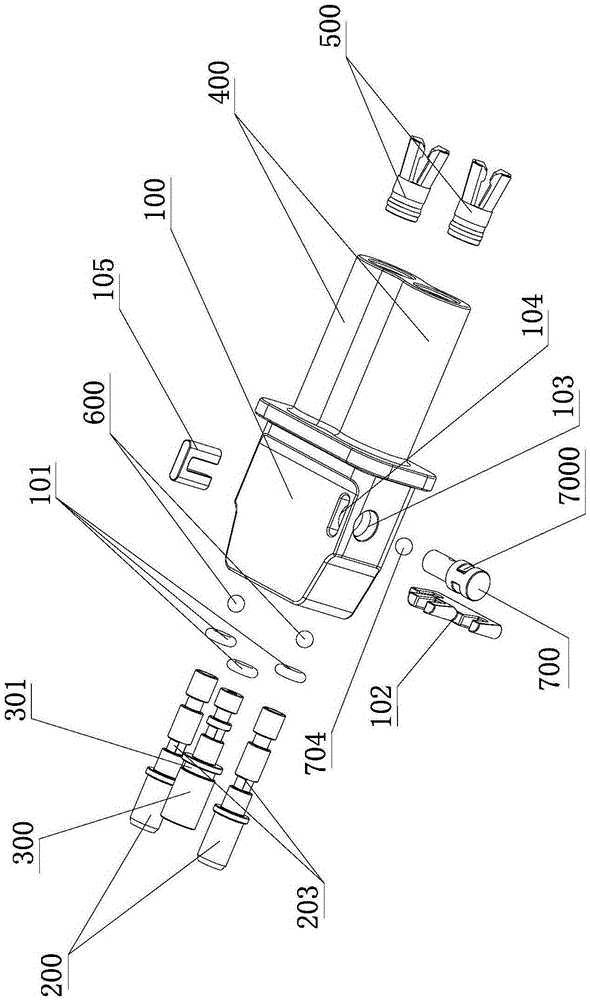

[0084] Such as figure 1 Shown is the double pump structure of the application embodiment of the present invention, including the pump body 100, the number of input pipes 200 is two, one output pipe 300, and the number of piston cylinders 400 is two, and the piston cylinder 400 can be loaded with pistons...

Embodiment 2

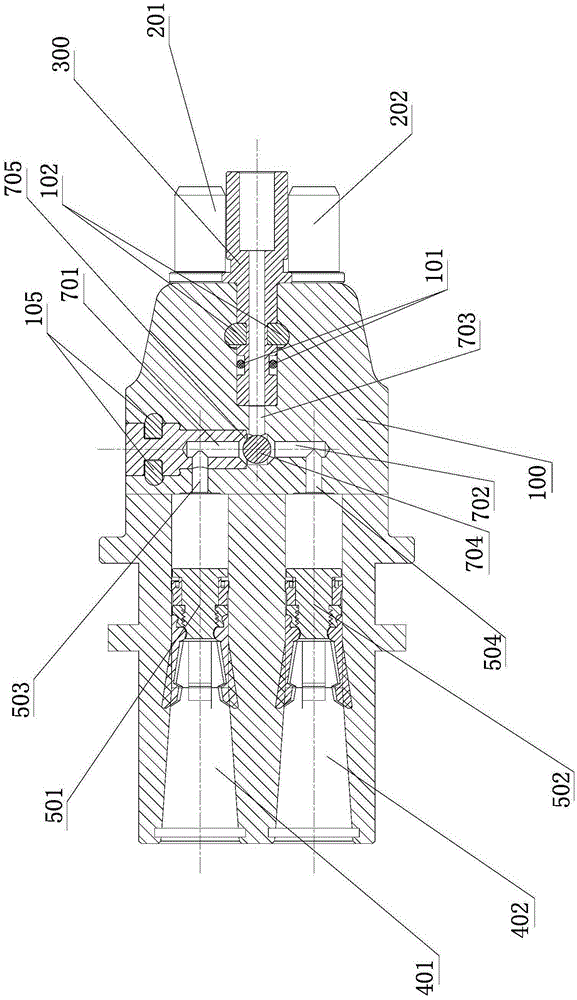

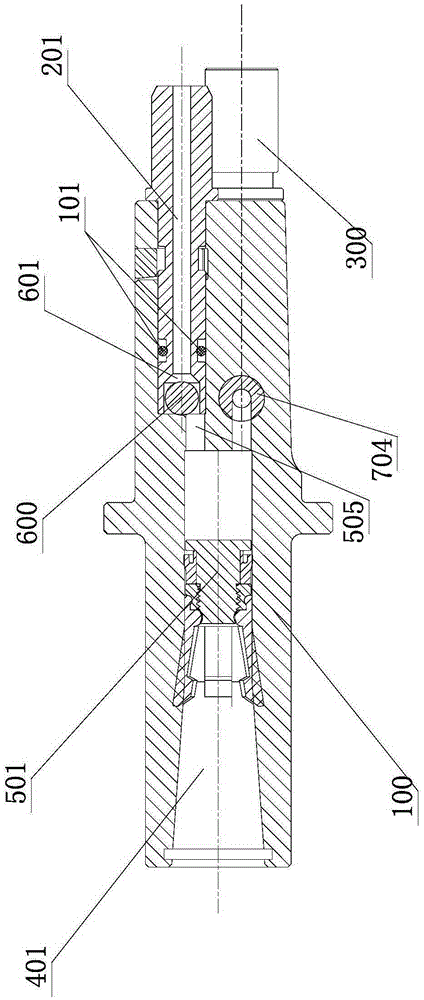

[0086] figure 2 and image 3 It shows a structural schematic diagram of different cross-sections of another embodiment of the present application, figure 2 The position and connection relationship between the piston cylinder, the reversing valve and the output pipe are specifically shown in the figure. In this embodiment, there are two piston cylinders, the first piston cylinder 401 and the second piston cylinder 402. A piston 501 and a second piston 502, the first piston cylinder 401 communicates with the first input passage 701 of the reversing valve through the first outlet passage 503 of the first piston cylinder, and the second piston cylinder 402 communicates with the first input passage 701 of the reversing valve through the second piston cylinder 402. The outlet passage 504 communicates with the second input passage 702 of the reversing valve, and the reversing valve includes a lumen 705, which communicates with the output pipe 300 through the output passage 703, an...

Embodiment 3

[0089] Figure 4 and Figure 5 It shows a schematic diagram of the working principle of an embodiment of the application of the present invention. As shown in the figure, the first input pipe 201 and the second input pipe 202 are respectively connected to the low-pressure fluid, the output pipe 300 is connected to the high-pressure pipeline, and the low-pressure fluid enters through the input pipe. The pump body, after being pumped and pressurized by the piston, is discharged through the output pipe at high pressure. Due to the asynchronous reciprocating motion between the pistons, and the regulation of the one-way valve and the reversing valve, a stable high-pressure output is formed.

[0090] Specifically, when the first piston 501 is pushed forward, the inner cavity of the first piston cylinder 401 generates high pressure, the corresponding one-way valve closes the first input pipe 201, and the reversing valve opens the connection between the first piston cylinder 401 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com