Patents

Literature

120results about How to "Won't distort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

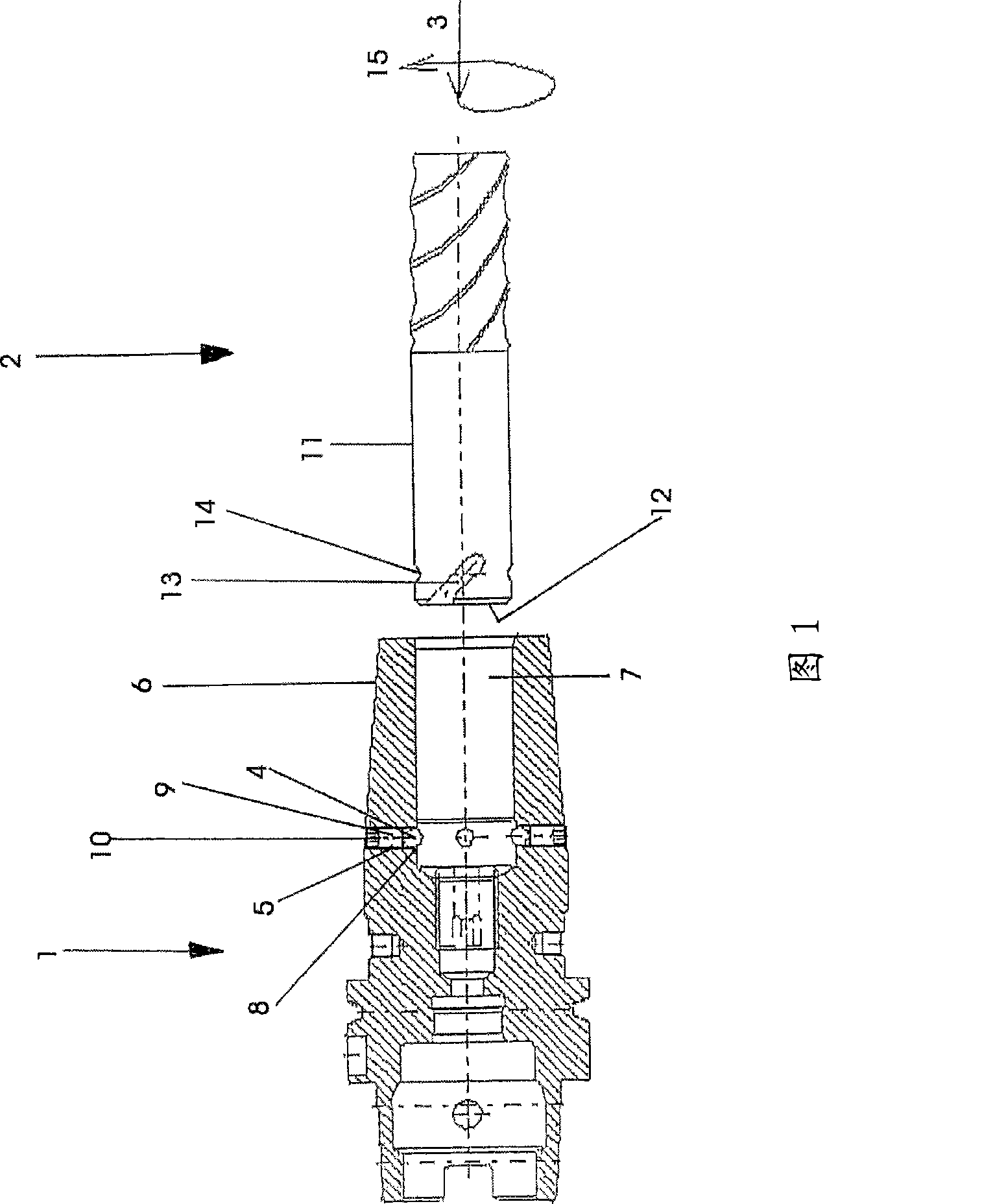

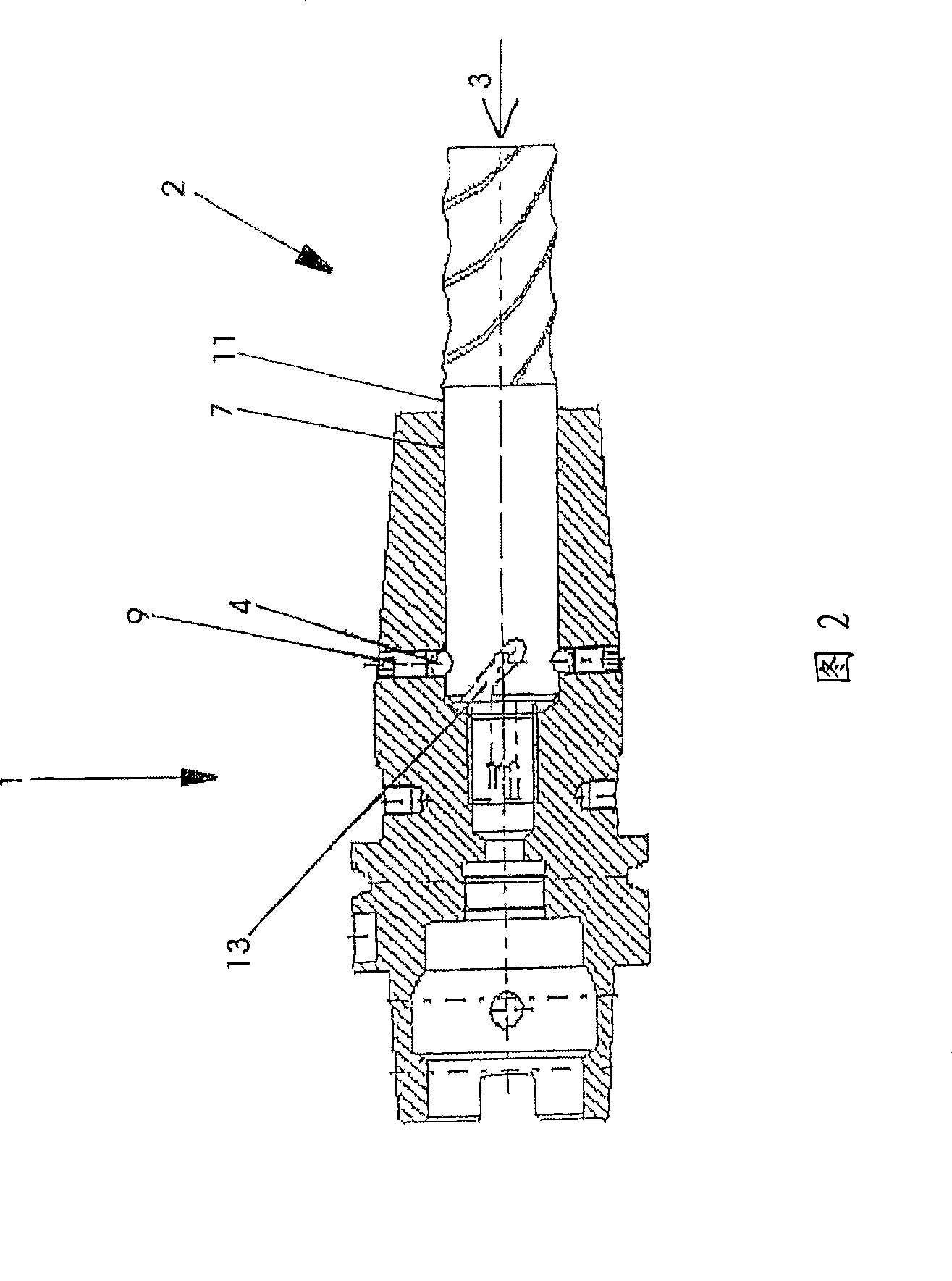

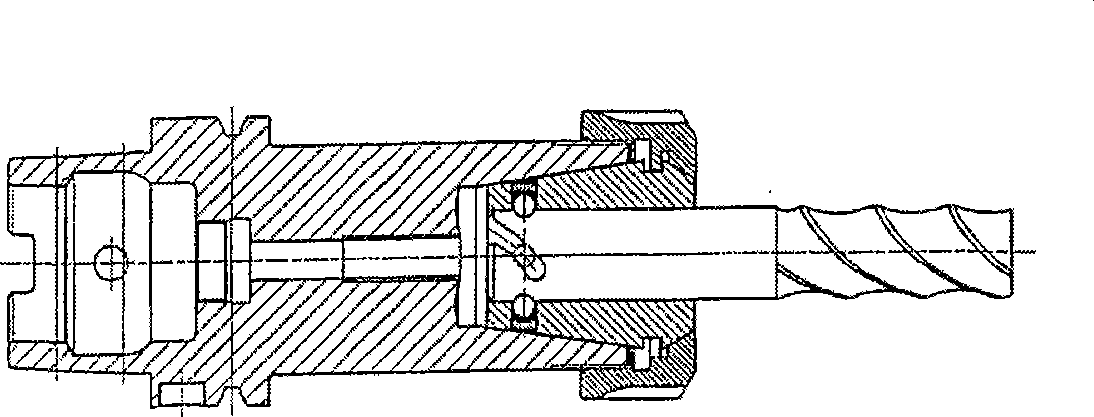

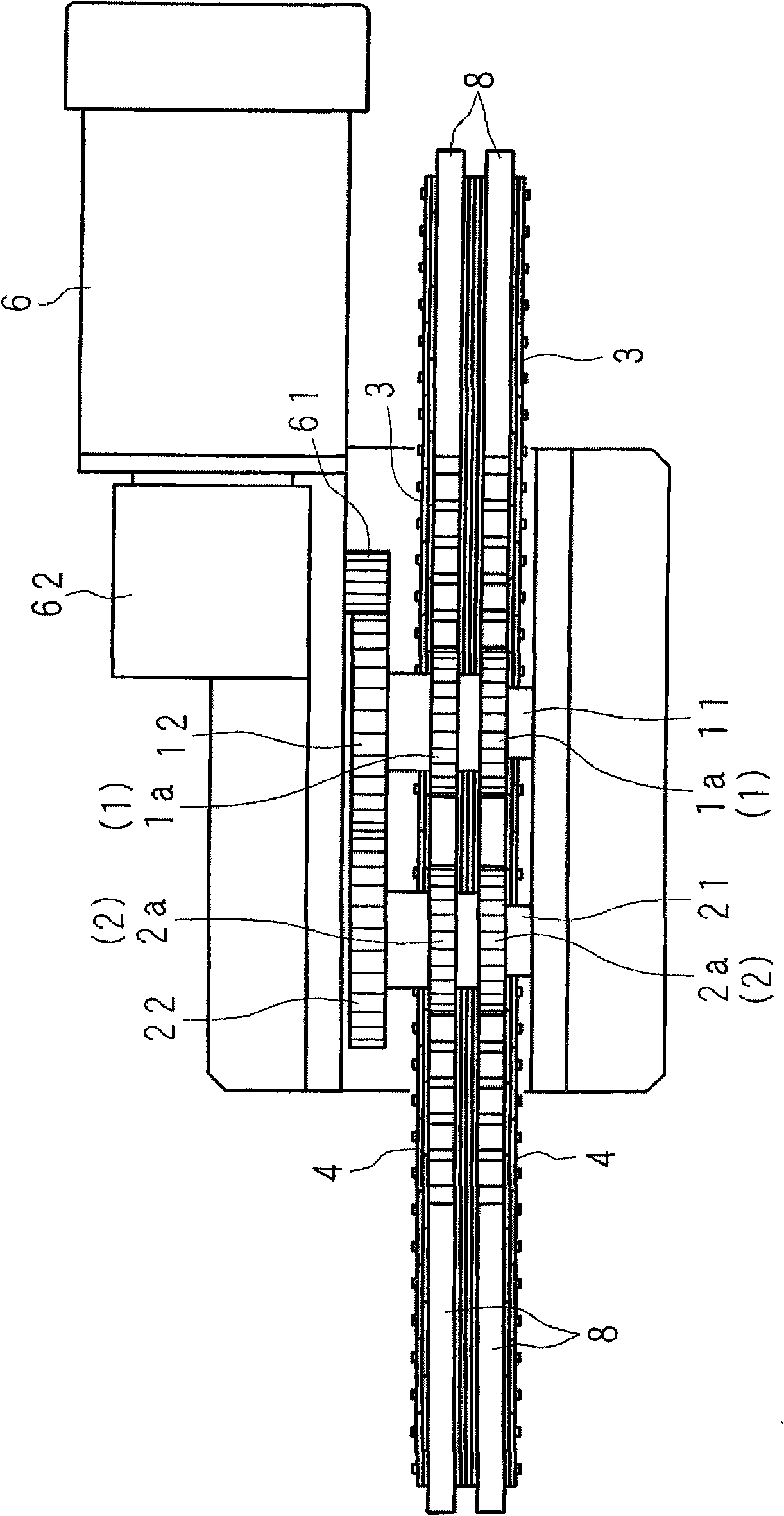

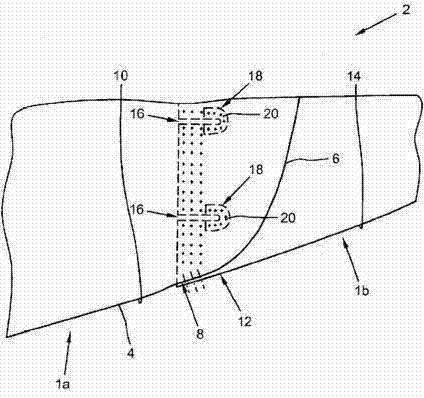

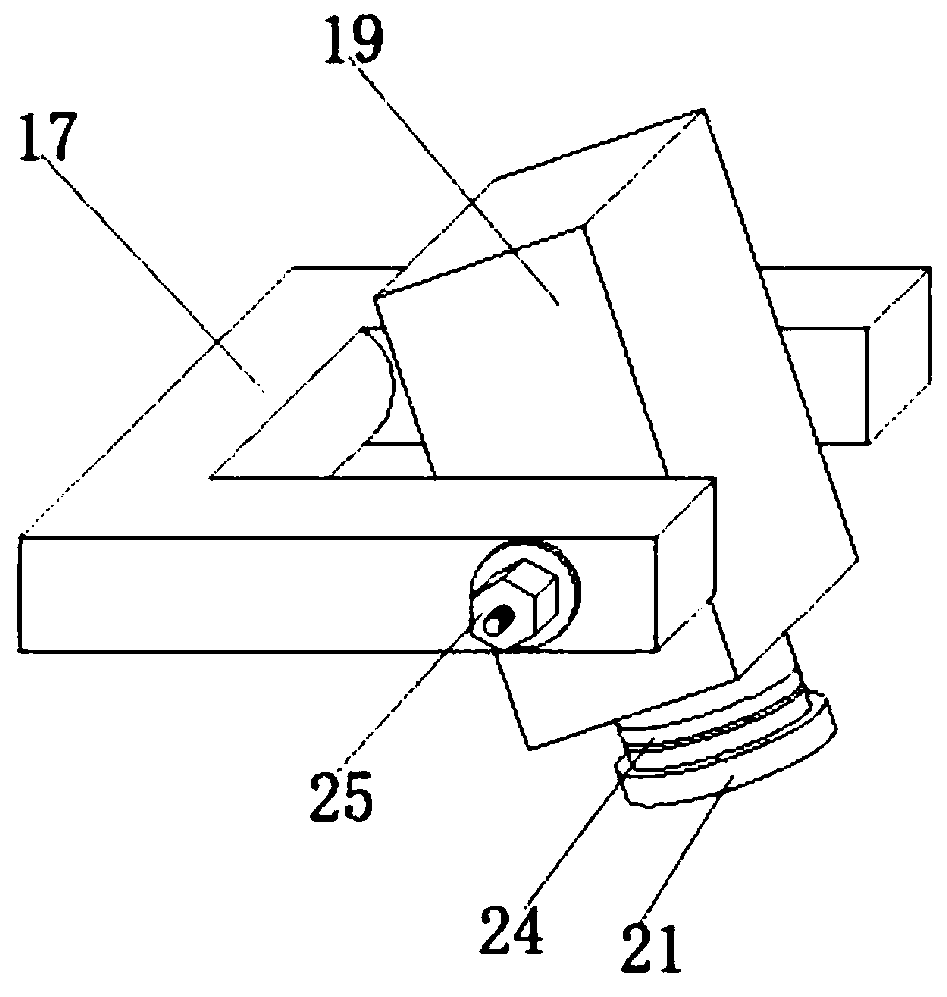

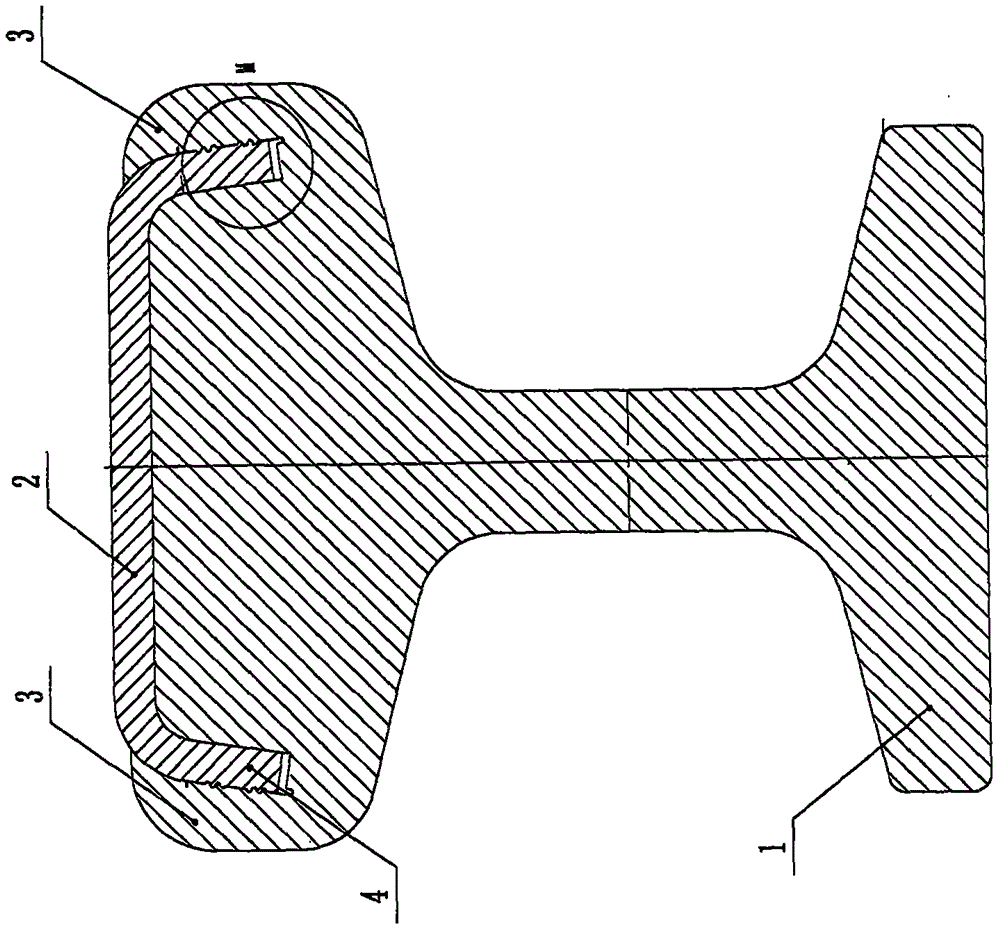

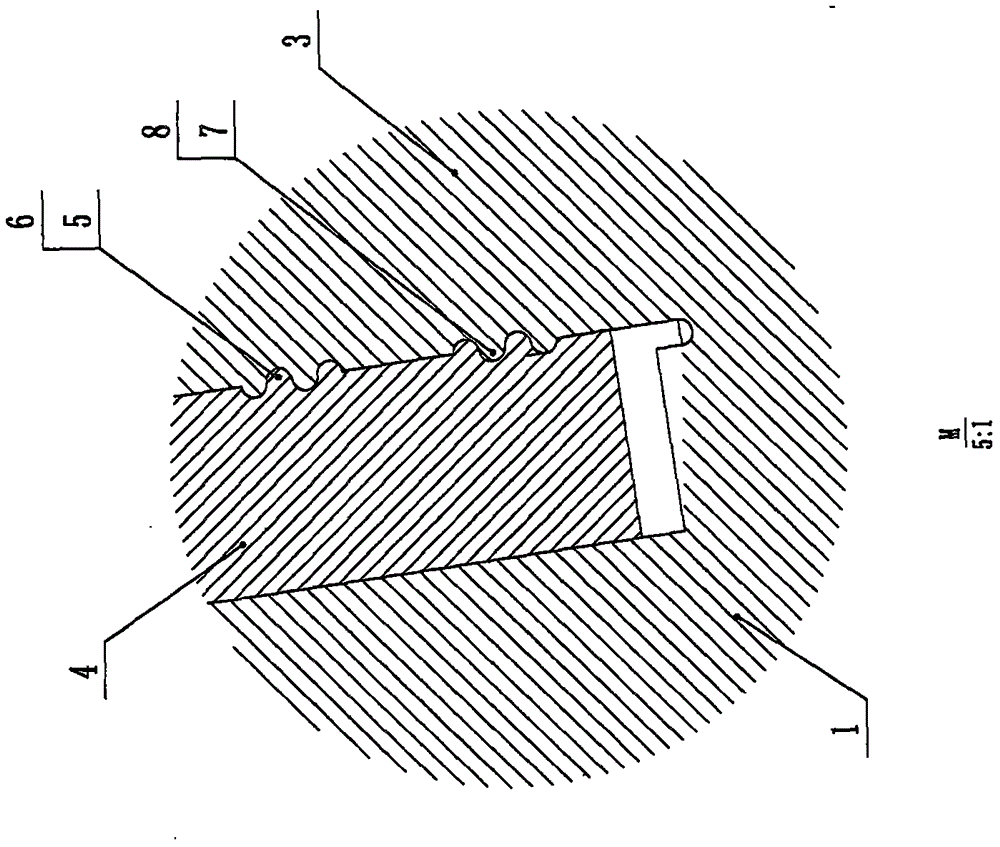

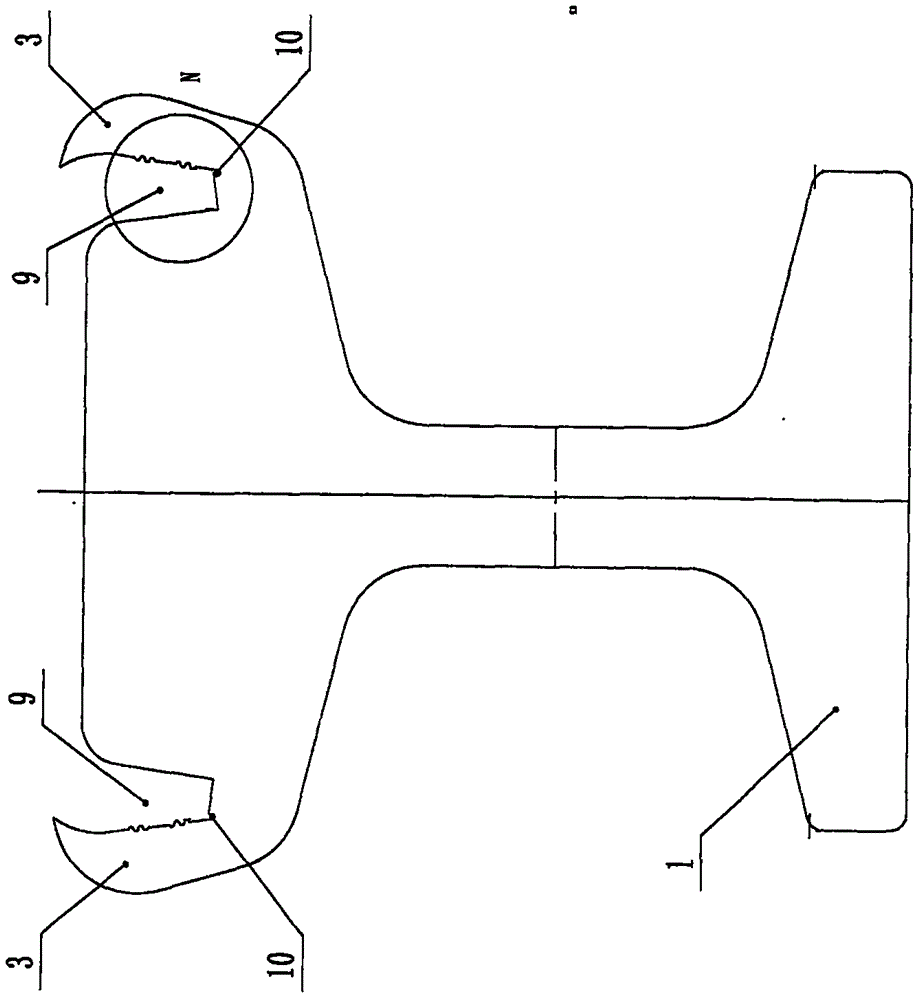

Means for preventing tools from being pulled out from tool holders with a tool holding fixture

ActiveCN101432088AEliminate the risk of accidentsPrecise processingSleeve/socket jointsGrinding wheel securing apparatusEngineeringTool holder

The present invention relates to a cutter holding device which is provided with a cutter receiving part, especially a clamping disc, such as a thermal shrinking chuck, a nipper chuck, a hydraulic expanding chuck and a high-precision chuck. The handle of cutter, especially the handle of rotating cutter is accommodated in the cutter receiving part, wherein the cutter holding device comprises a pulling-out preventing fixing device which fixes the cutter and prevents the axial pulling-out. The pulling-out preventing device comprises at least one fixing component and at least one fixing groove which is corresponding with the fixing component and accommodates the fixing component. The fixing component cooperates with the fixing groove with a mode of forming locking. According to the invention, the fixing component and the fixing groove are all designed to at least partial sphere-head shaped. Preferably the cutter is provided with the locking groove. As the fixing groove is preferably spirally rotating along the cylindrical handle of cutter, the rotation direction is corresponding with the slotting direction of cutter, and axial fixing can be executed to the cutter. Thereby the cutter will not be axially pulled out from the cutter holding device in the running period. A component for exerting force is additionally installed. The component forms a gapless attachment on the pulling-out preventing fixing device after shrinking and installation.

Owner:FRANZ HAIMER MASCHINENBAU KG

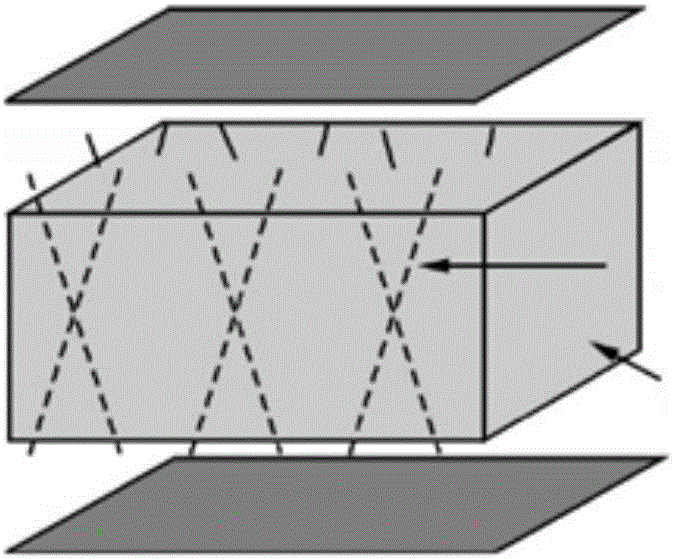

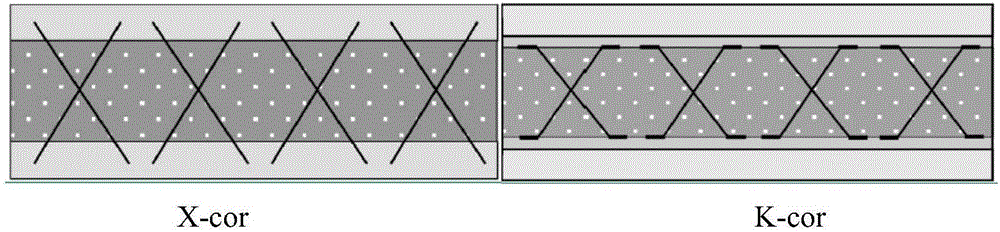

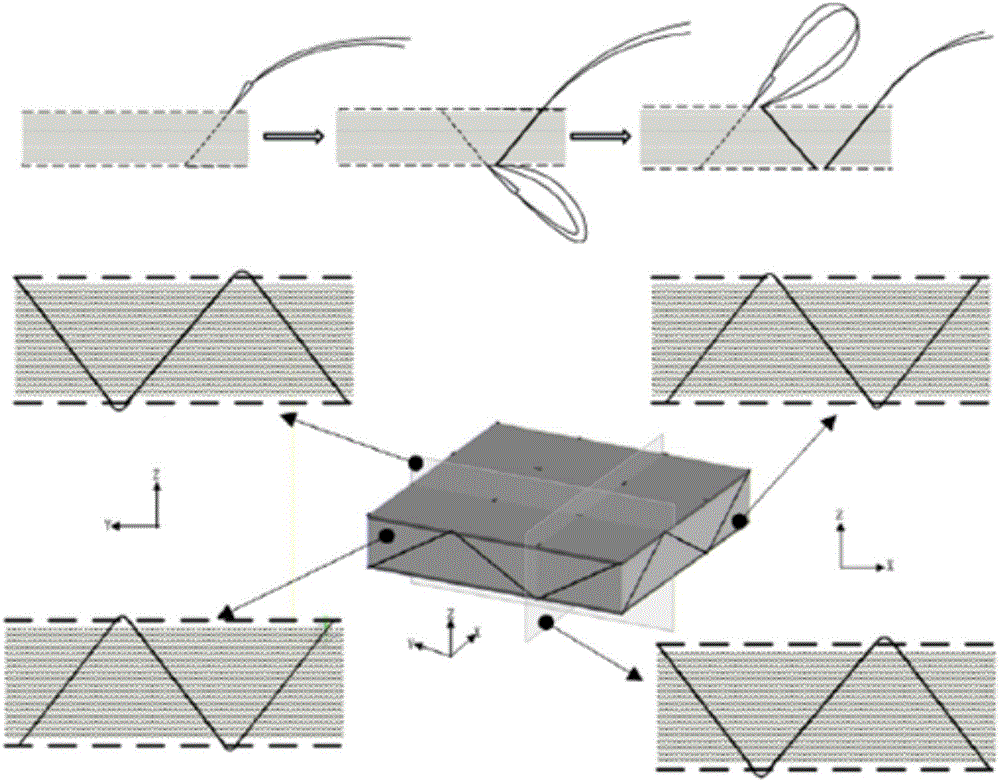

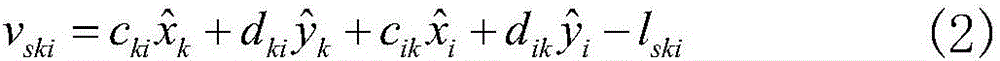

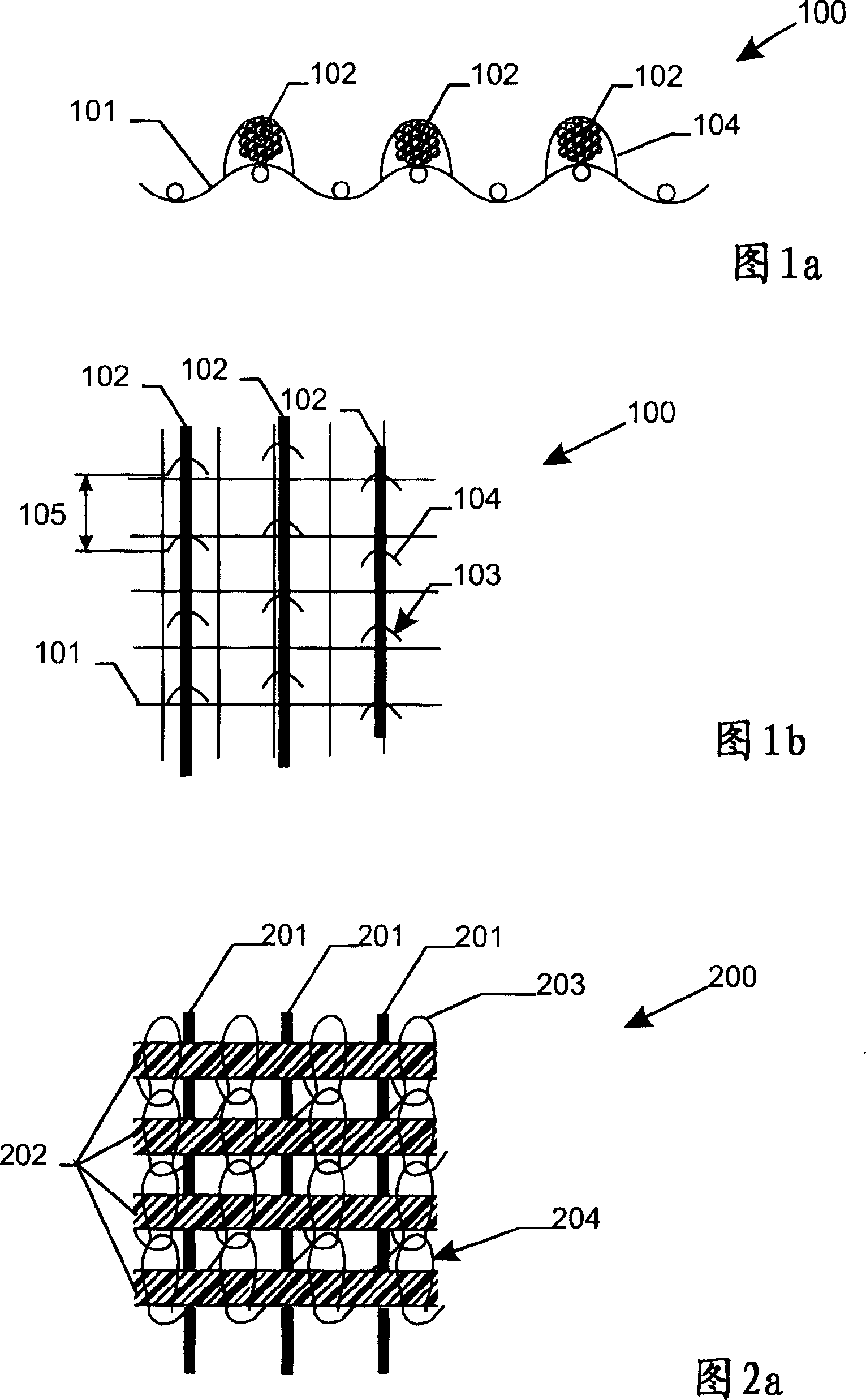

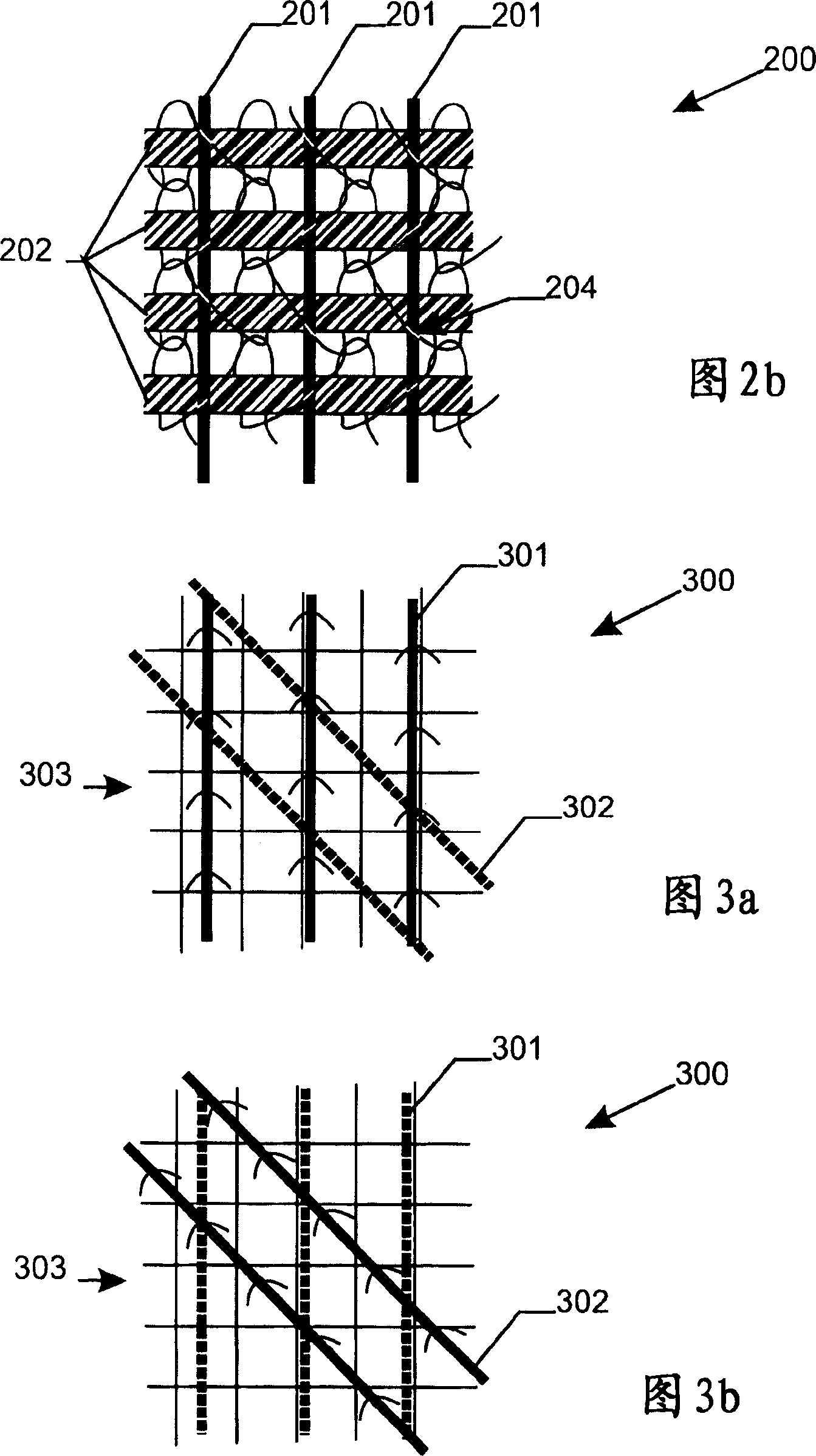

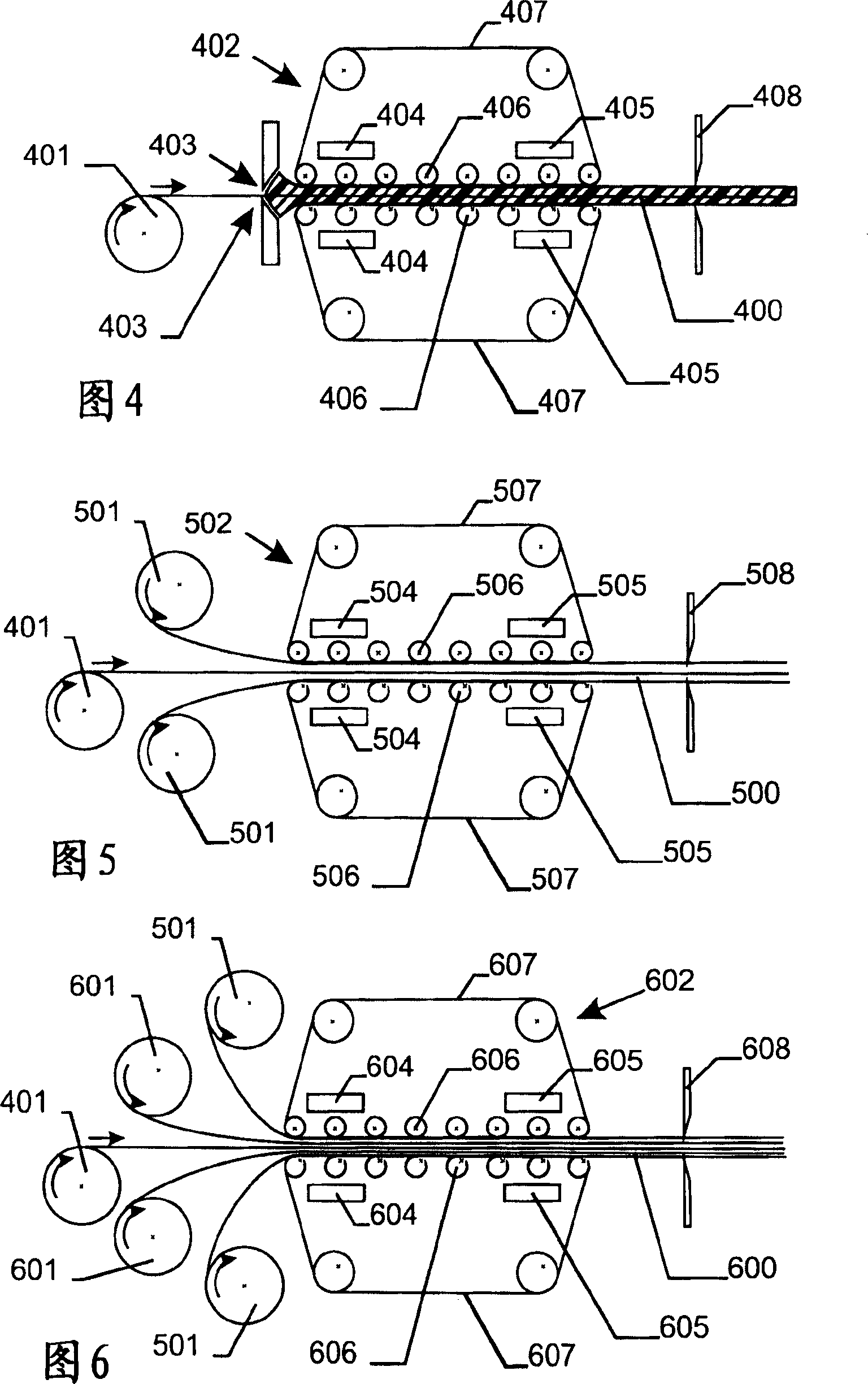

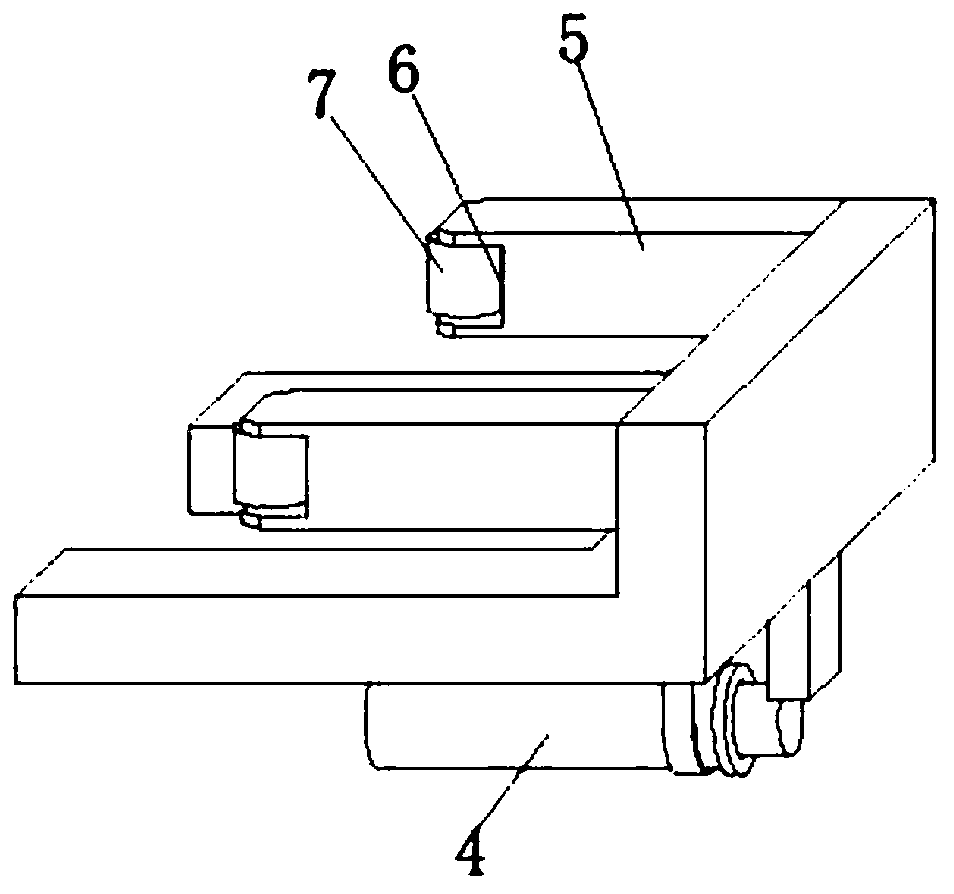

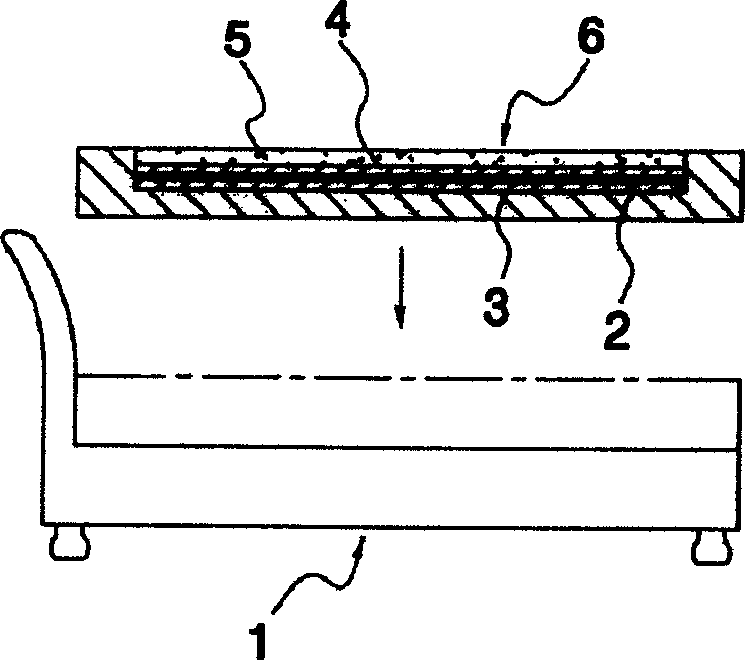

Lattice reinforced foam sandwich preform, and production method and application thereof

ActiveCN106494022AImprove anti-scourabilityWill not deformSynthetic resin layered productsGlass/slag layered productsYarnFiber

The invention discloses a lattice reinforced foam sandwich preform, and a production method and an application thereof. The lattice reinforced foam sandwich preform comprises an upper fiber fabric, a foam core material, a lower fiber fabric and yarns; and the upper fiber fabric, the foam core material and the lower fiber fabric are sequentially superposed, and are stitched through the yarns. The production method comprises the following steps: cutting a fiber cloth and the foam core material with the same dimension, respectively covering the upper surface and the lower surface of the foam core material with the cut fiber cloth, and carrying out glue spraying and pasting to form a sandwich structure; and stitching the sandwich structure by using the yarns to obtain the lattice reinforced foam sandwich preform. The lattice reinforced foam sandwich preform has the advantages of good scour resistance, and close interlayer lamination of the fiber fabrics, and can be applied to production of stable composite materials with good mechanical performances, used for tank rotation baseboards.

Owner:NAT UNIV OF DEFENSE TECH

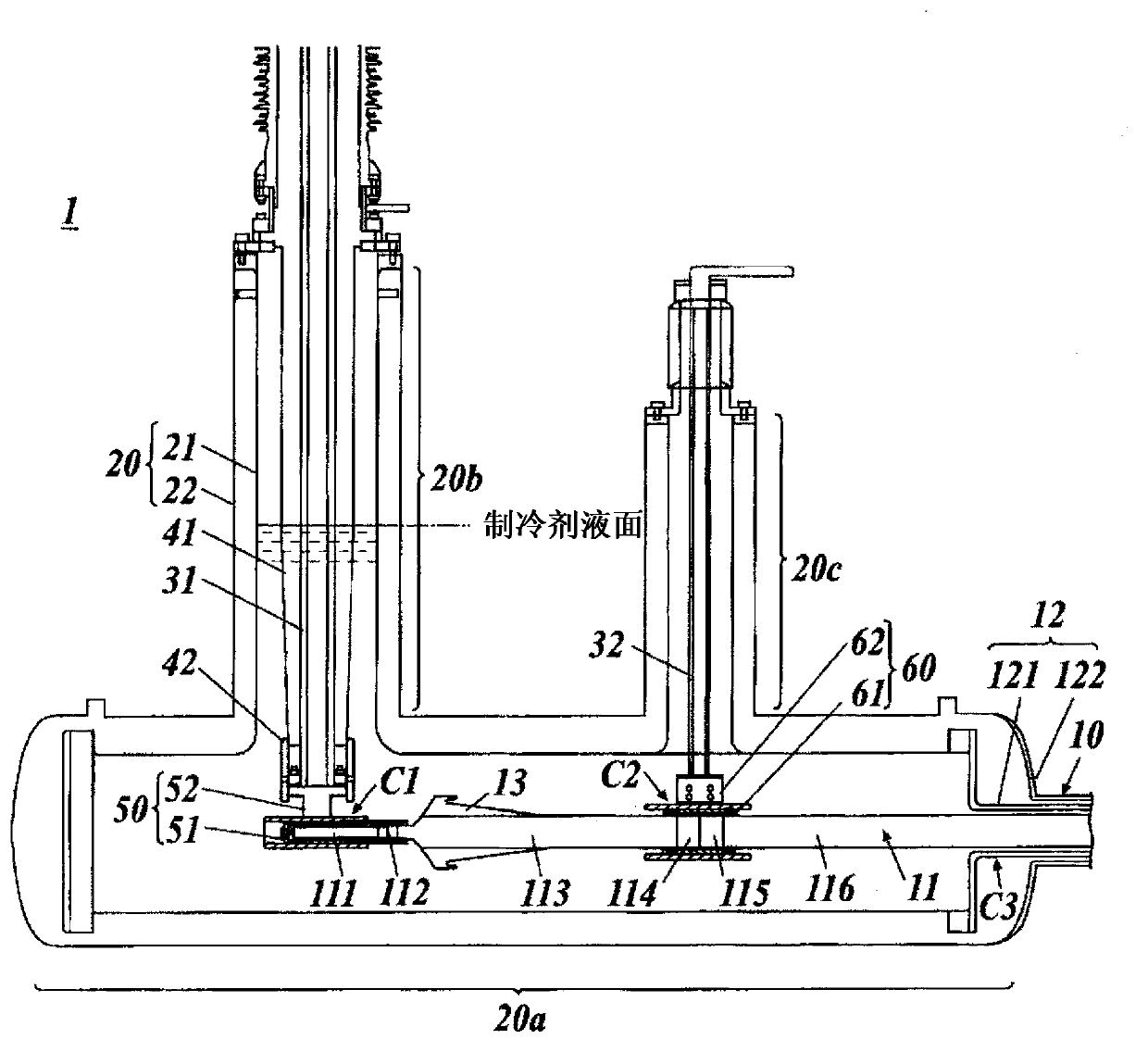

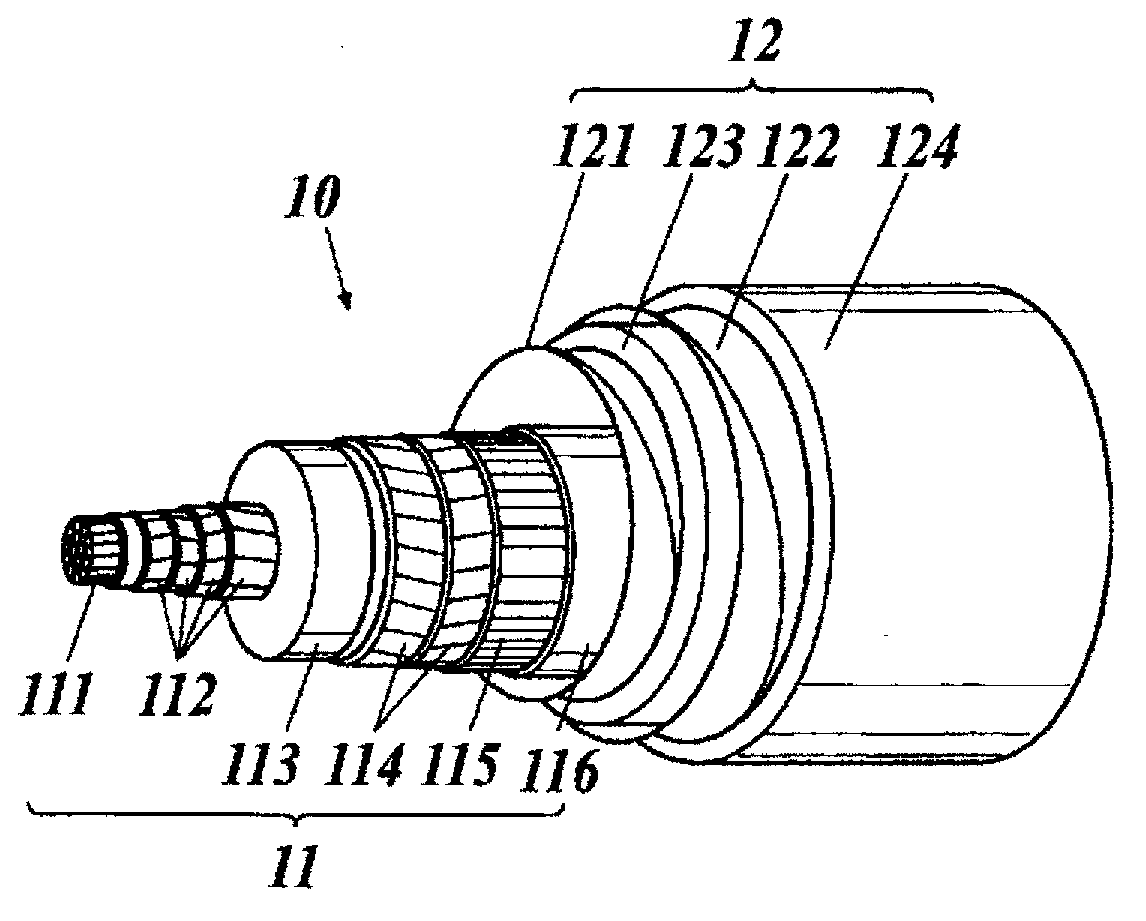

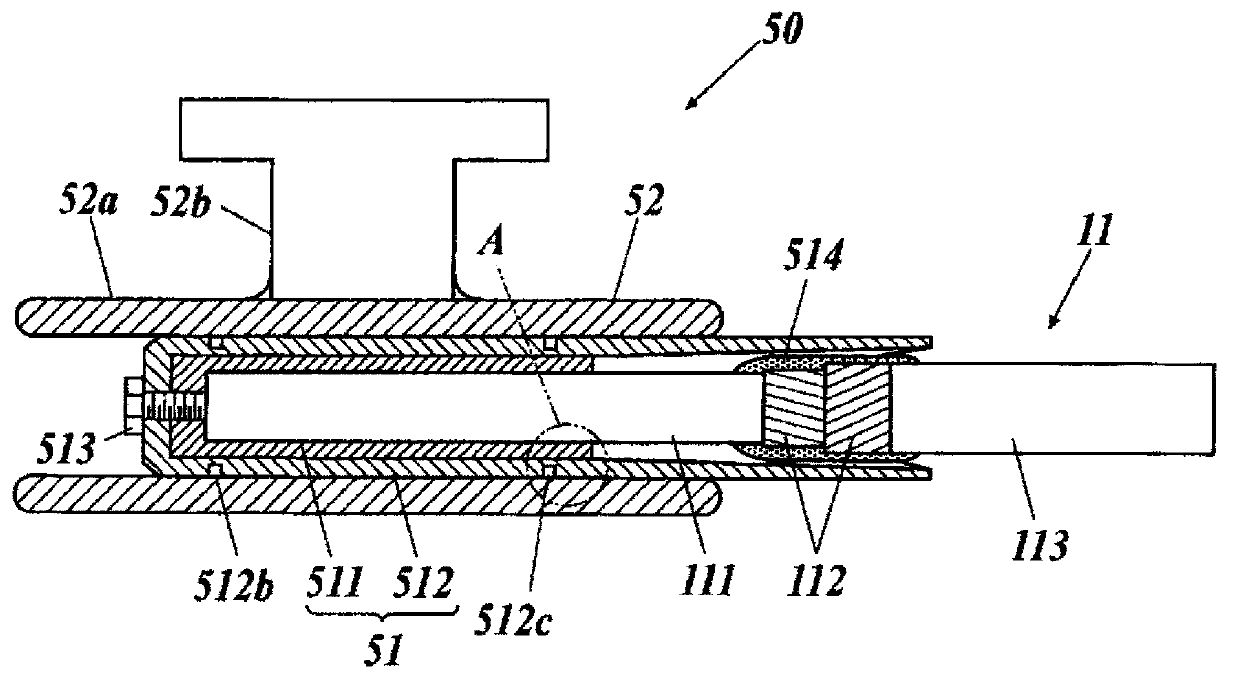

Termination connection for superconductive cable

ActiveCN103004046AMaintain integrityEasy to miniaturizeSuperconductors/hyperconductorsSuperconductor detailsRefrigerantElectricity

A termination connection is configured by being provided with: a low-temperature container filled with a refrigerant; a current lead for a conductor, one end of the current lead being immersed in the refrigerant while the other end is pulled out to a normal temperature section; and a movable connection terminal for a conductor, the movable connection terminal electrically connecting the current lead for a conductor with the superconductive conductor layer of a superconductive cable. The superconductive conductor layer of a superconductive cable, of which the ends are stripped, is connected to the current lead for a conductor via the movable connection terminal for a conductor. The cable core of the superconductive cable can move in the lengthwise direction and rotate in the circumferential direction while keeping the superconductive conductor layer electrically connected to the current lead for a conductor. Moreover, the cable core is horizontally supported within the low-temperature container. As a consequence of the aforementioned configuration, the thermal expansion of the cable core under a heat cycle is absorbed, thereby being able to provide a simplified termination connection of which the size is reduced.

Owner:FURUKAWA ELECTRIC CO LTD

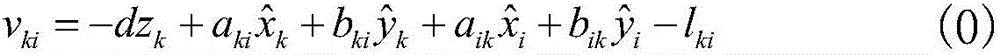

CPIII (control points of III level) control net adjustment method

The invention relates to a CPIII (control point of III level) control net adjustment method; a CPIII control net acquired by using constraint adjustment method is adverse to the evaluation and regulation of internal geometric dimensions of a rail; the method focuses only on meeting the requirement for external geometric dimensions of a rail; a correction numerical matrix for direction observation and horizontal distance observation are acquired by using an error equation of direction observation and horizontal distance observation, an additional condition matrix is acquired through the correction numerical matrix of the error equation, an additional condition equation and adjustment rules, namely an adjustment model is established, and adjustment calculation is finished by solving the model; the method of the invention gives the priority to meet the requirement for internal geometric dimensions of a rail, can meet the requirement for external geometric dimensions of the rail, and is free of influence form original data errors, the CPIII control net is never distorted, the CPIII control net is introduced to a line design coordinate system through position reference and direction reference, and the CPIII control net can meet the requirement for 'triply play' on high-speed railway.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

A textile product comprising metal cords and non-metallic fibers, and a semifinished sheet comprising such textile product

Owner:NV BEKAERT SA +1

Intelligent grabbing device for automobile part production

InactiveCN111070181ALarge grabbing rangeImprove practicalityProgramme-controlled manipulatorArmsProduction lineEngineering

Owner:浙江华威设备制造有限公司

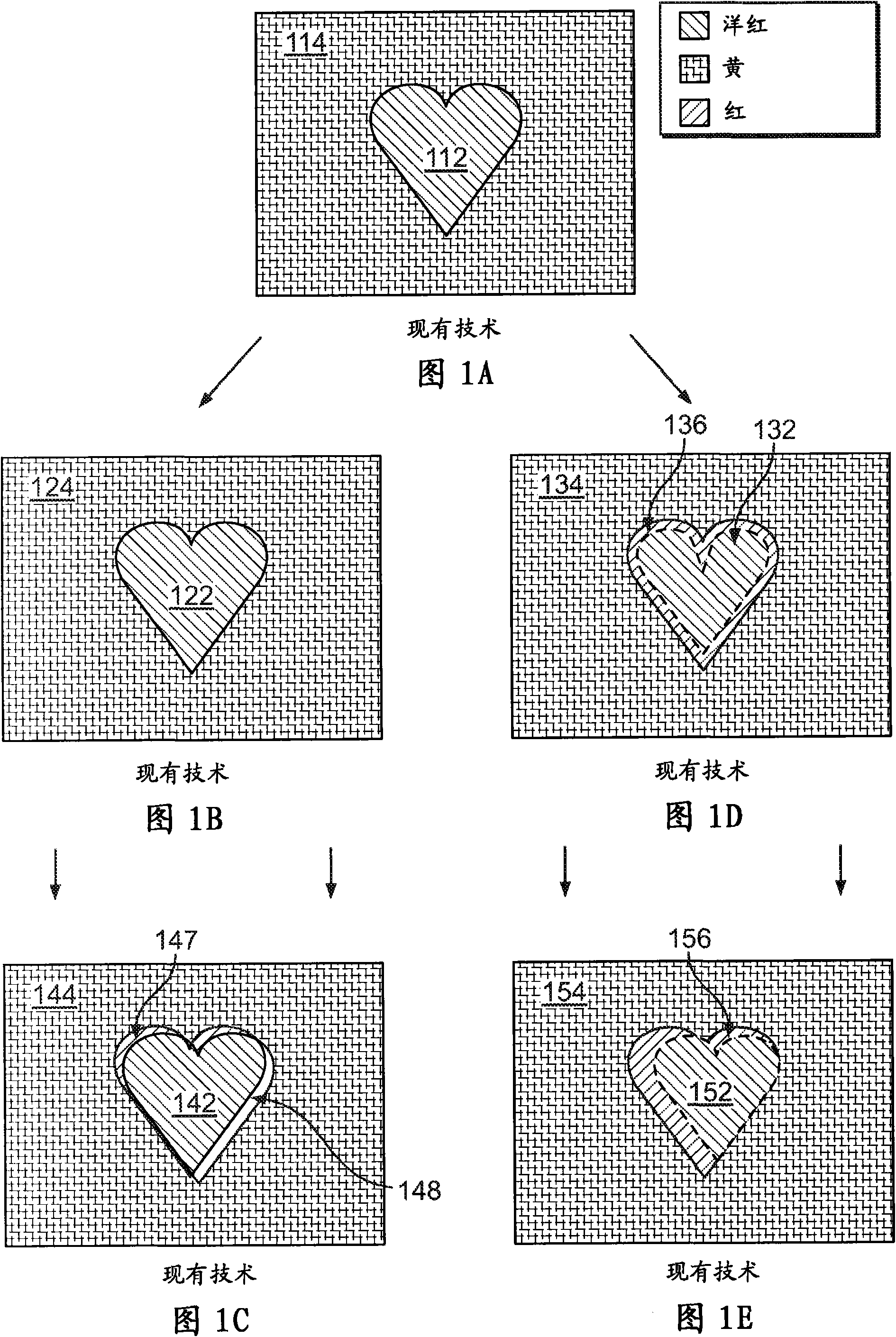

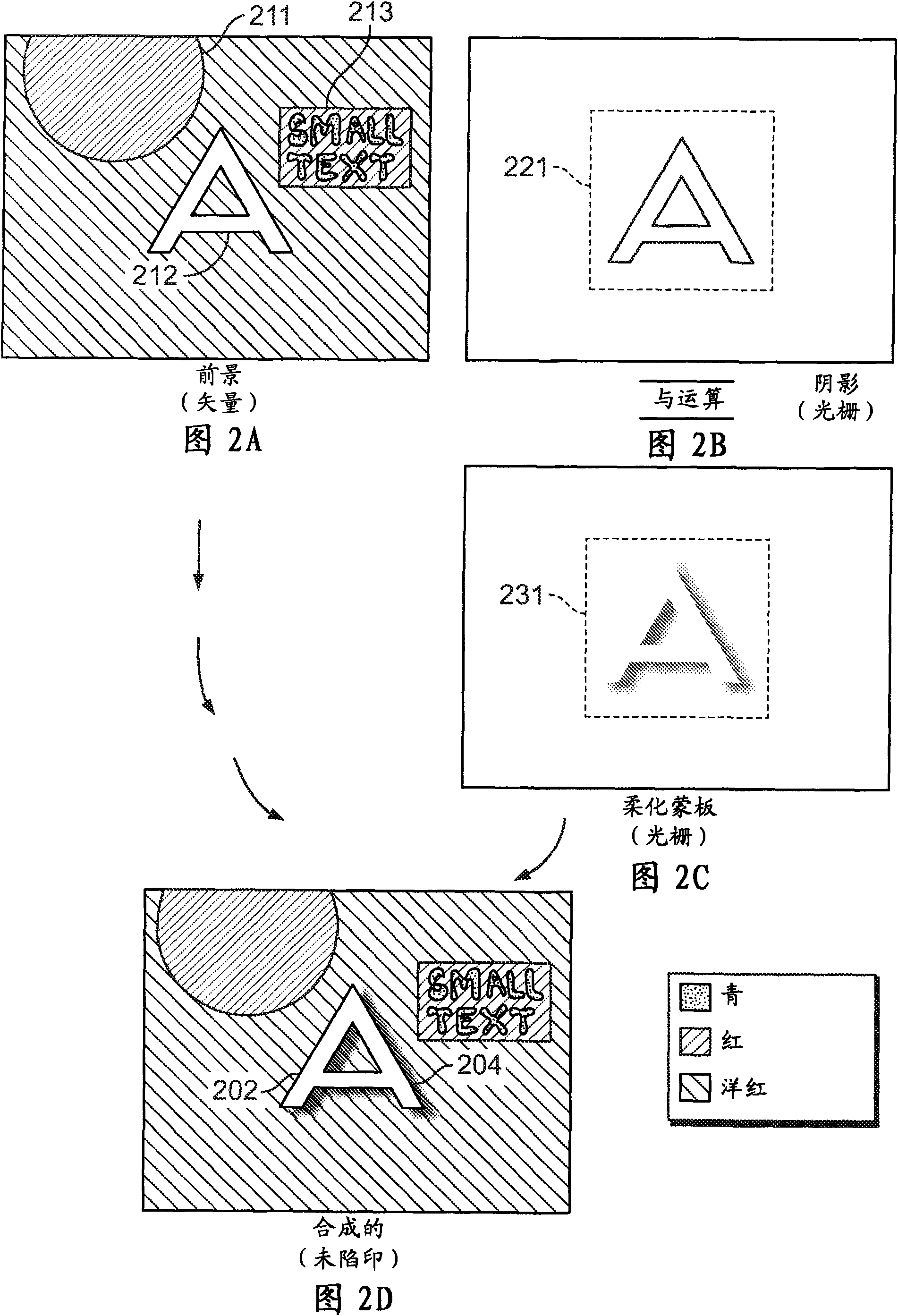

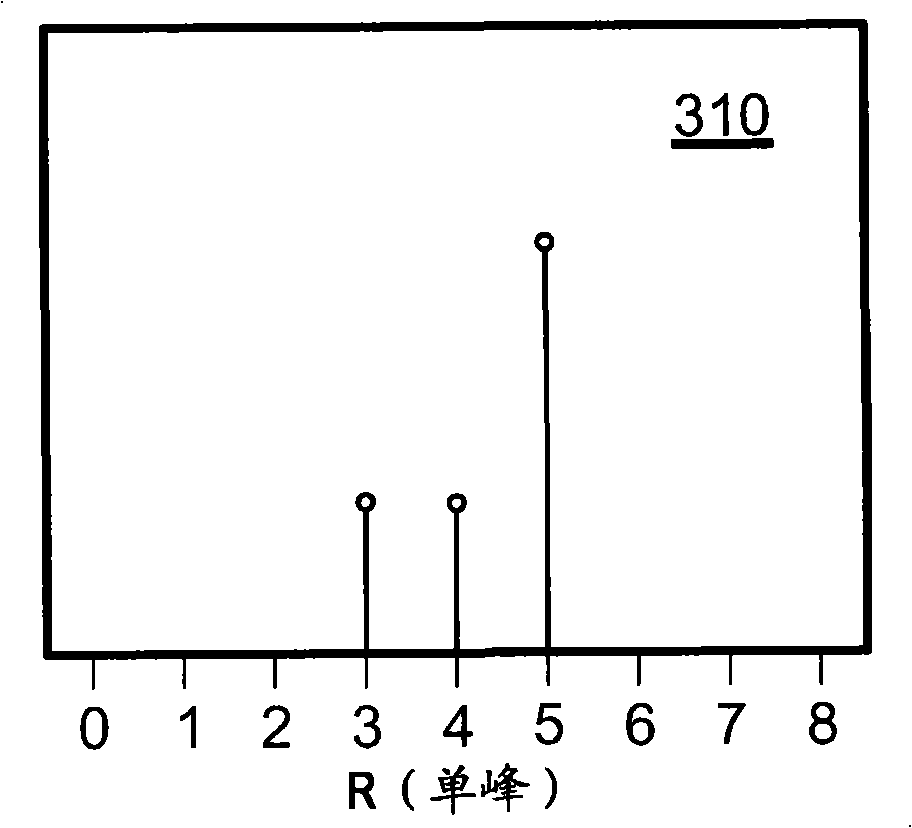

Automatic trapping of drop shadows

ActiveCN101542539AShorten the timeWon't distortCharacter and pattern recognitionCathode-ray tube indicatorsTrappingDrop shadow

Methods, program products and systems for automatically trapping drop shadows. For at least one segment incident to an atomic region which includes a drop shadow, and for each side of the segment, determining a first flattened color of the side's incident atomic region, and if the atomic region includes a drop shadow, additionally determining a second flattened color omitting the color of the drop shadow. An effective neutral density from the side's first flattened color is determined and, if the side has a second flattened color, the side's second flattened color. The two atomic regions incident to the segment are trapped based upon the effective neutral densities for the respective sides.

Owner:ADOBE INC

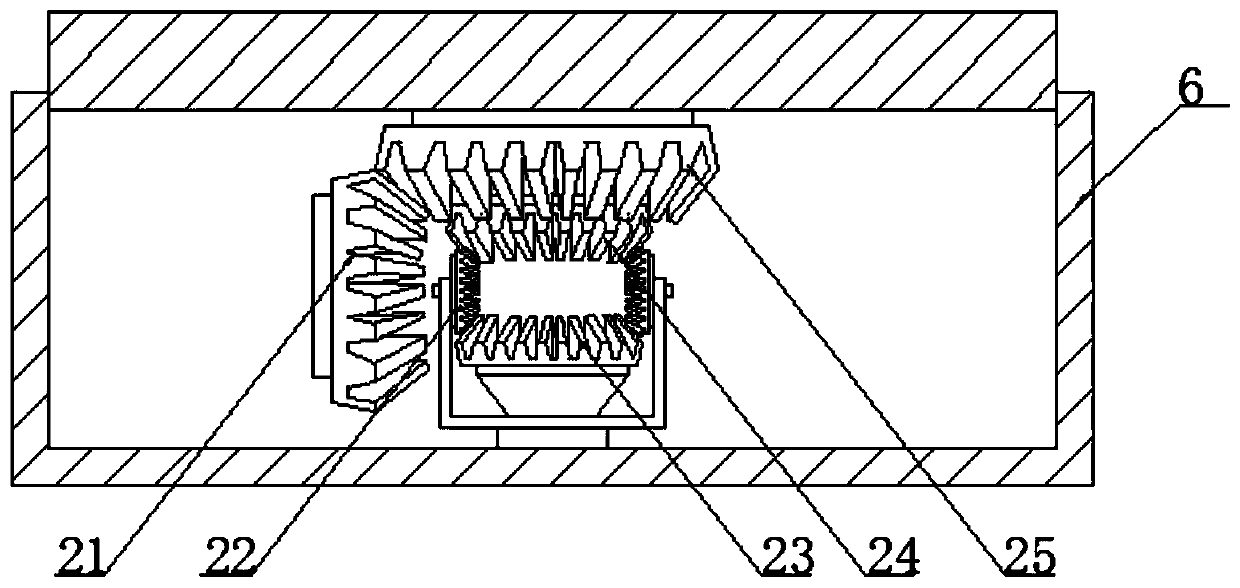

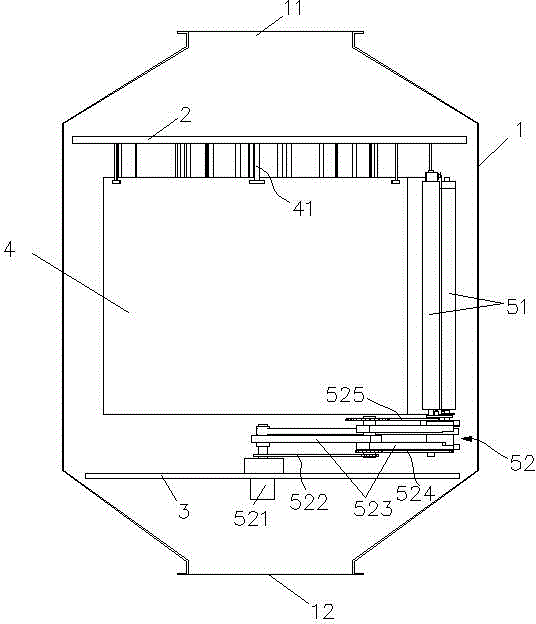

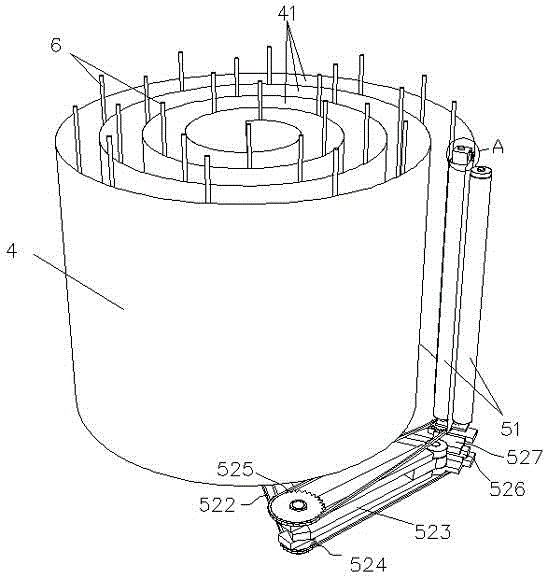

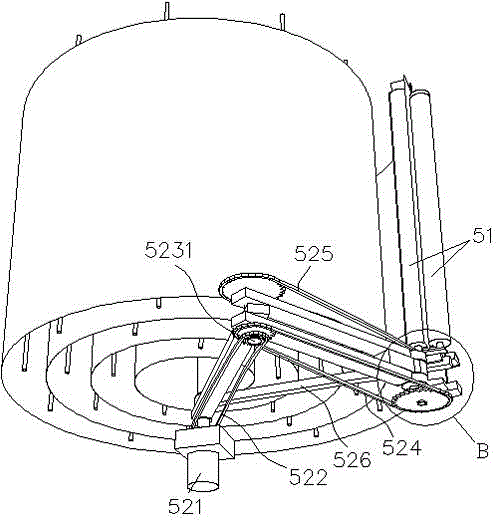

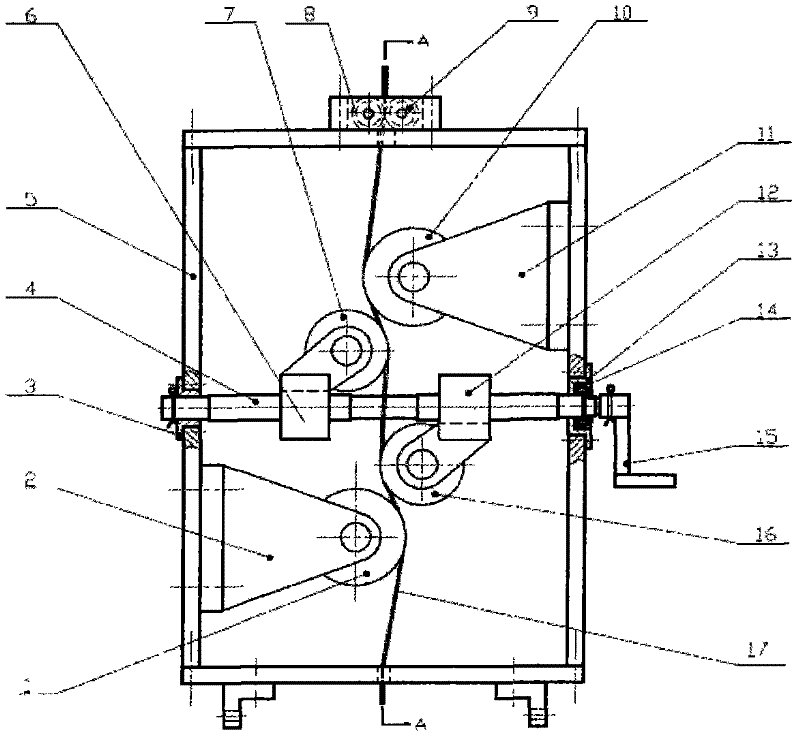

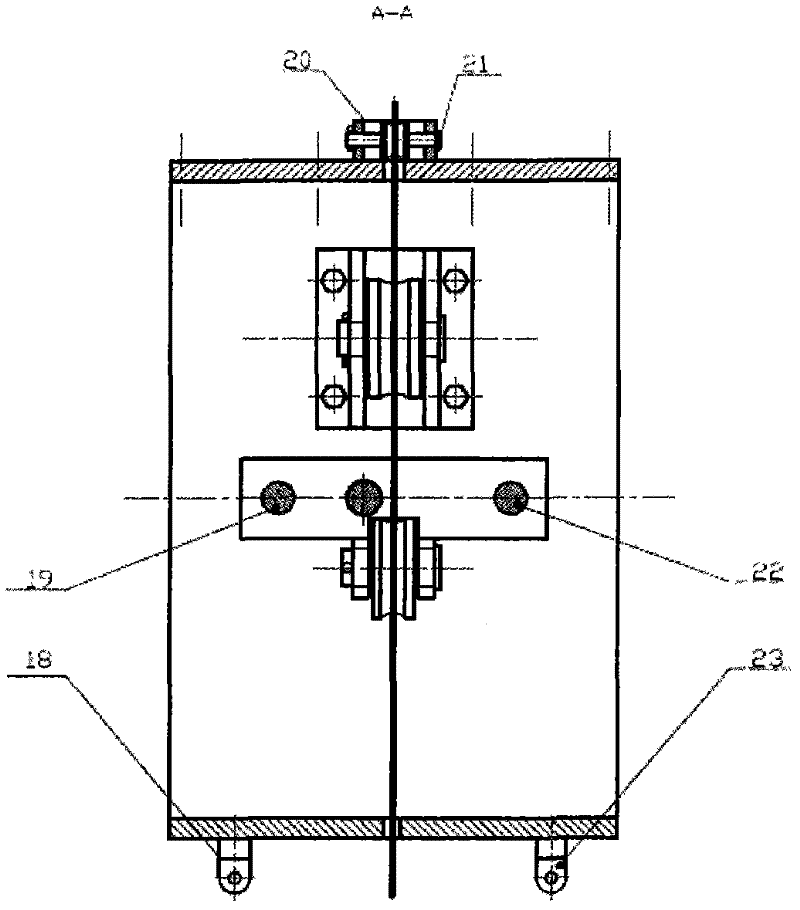

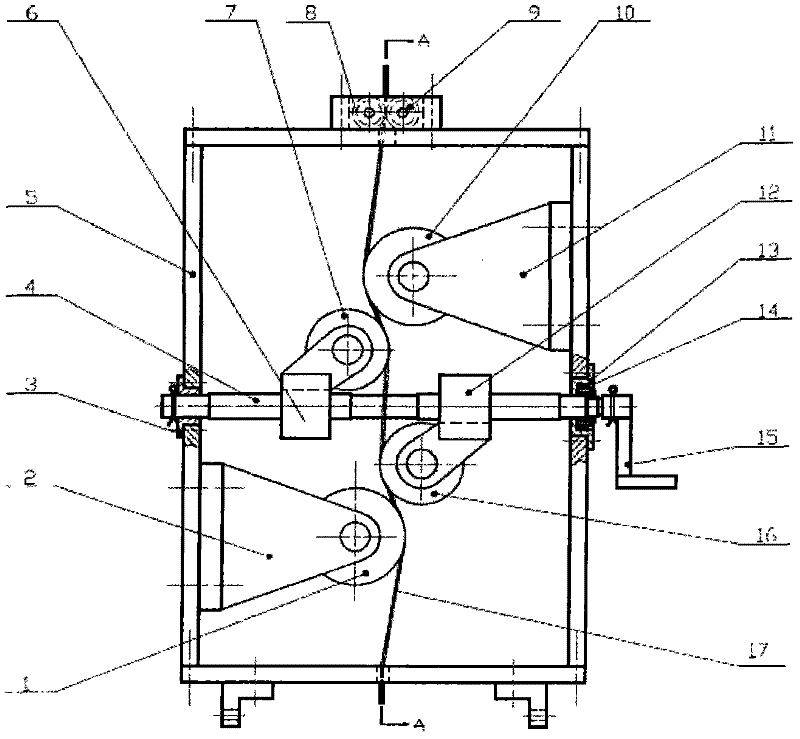

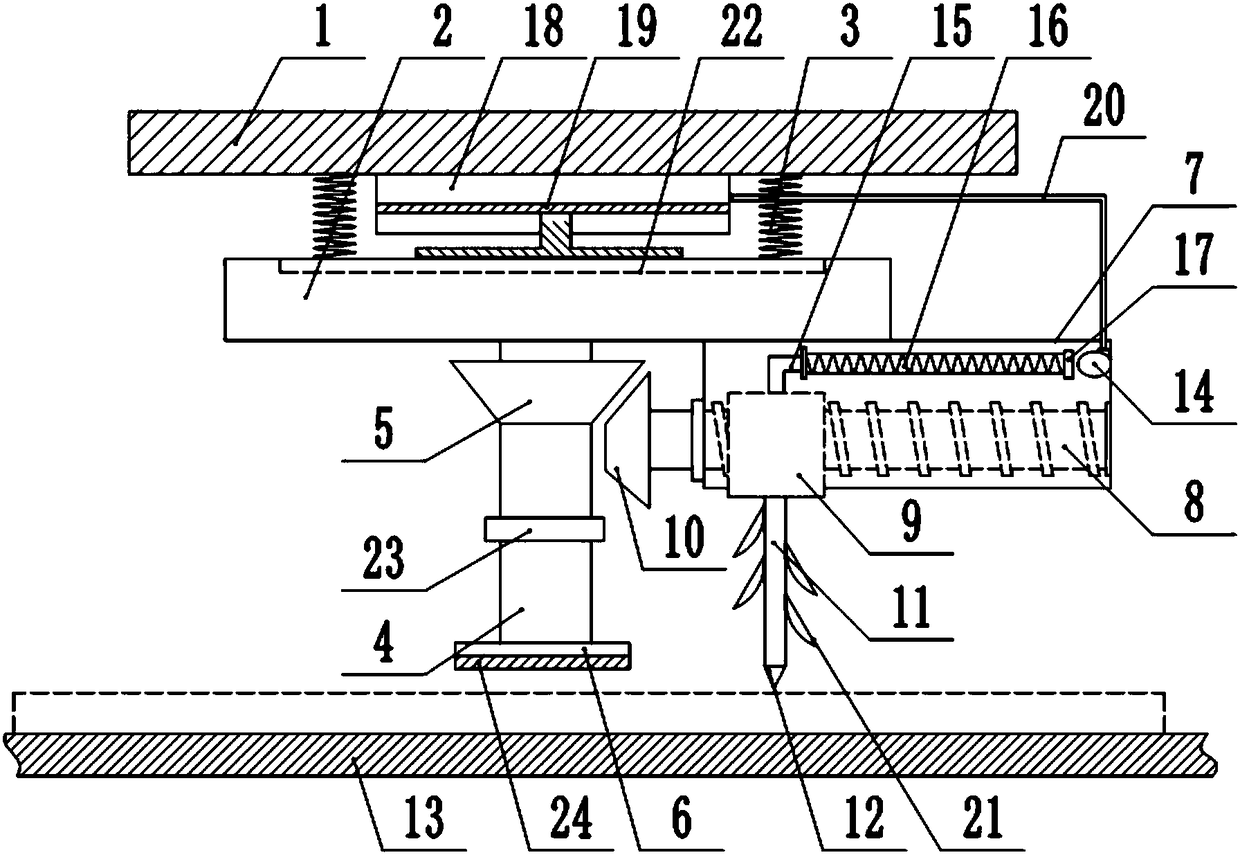

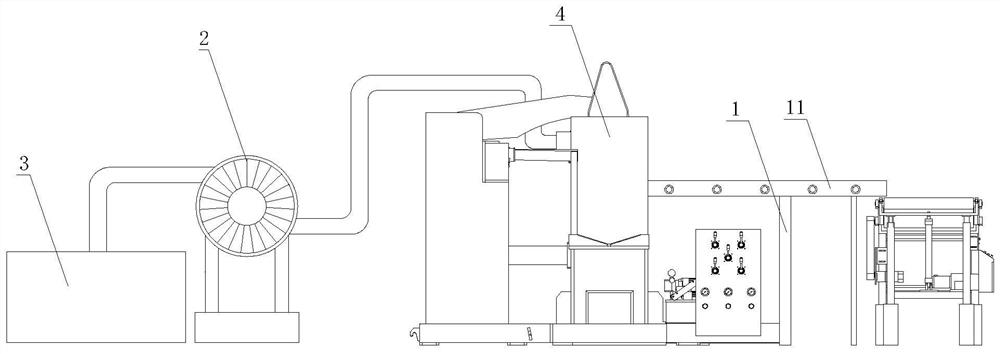

Automatic ash-cleaning spiral dust collection pole electric dedusting machine

InactiveCN104815754ASimple structureCompact structureExternal electric electrostatic seperatorElectrode constructionsEngineeringHigh pressure

The invention relates to an automatic ash-cleaning spiral dust collection pole electric dedusting machine, which comprises a shell, corona poles, a dust collection pole, a dust collection pole plate support and a corona pole support, a high voltage power supply device, cylindrical dedusting brushes, and a dedusting brush drive device. The dust collection pole is a vertically disposed isometric spiral dust collection pole plate, the cross section of which is a planar spiral line. The corresponding positions on the inner side and outer side of the spiral dust collection pole plate are provided with a pair of cylindrical dedusting brushes that contact the inner side and outer side of the dust collection pole plate and can roll to brush ash. The thread line type dust collection pole plate involved in the invention makes the dust collection pole plate structure very simple, convenient for making and processing, production and assembling, maintenance and disassembly, and more convenient for implementation of ash-cleaning automation. Compared with traditional dust collection plates, the electric dedusting machine saves more space, has larger dust collection area, can clean ash automatically, ensures high efficiency dust removal of products, has more stable and reliable working performance, avoids the hardship of human ash cleaning, and improves the work efficiency.

Owner:广州高唐科技发展有限公司

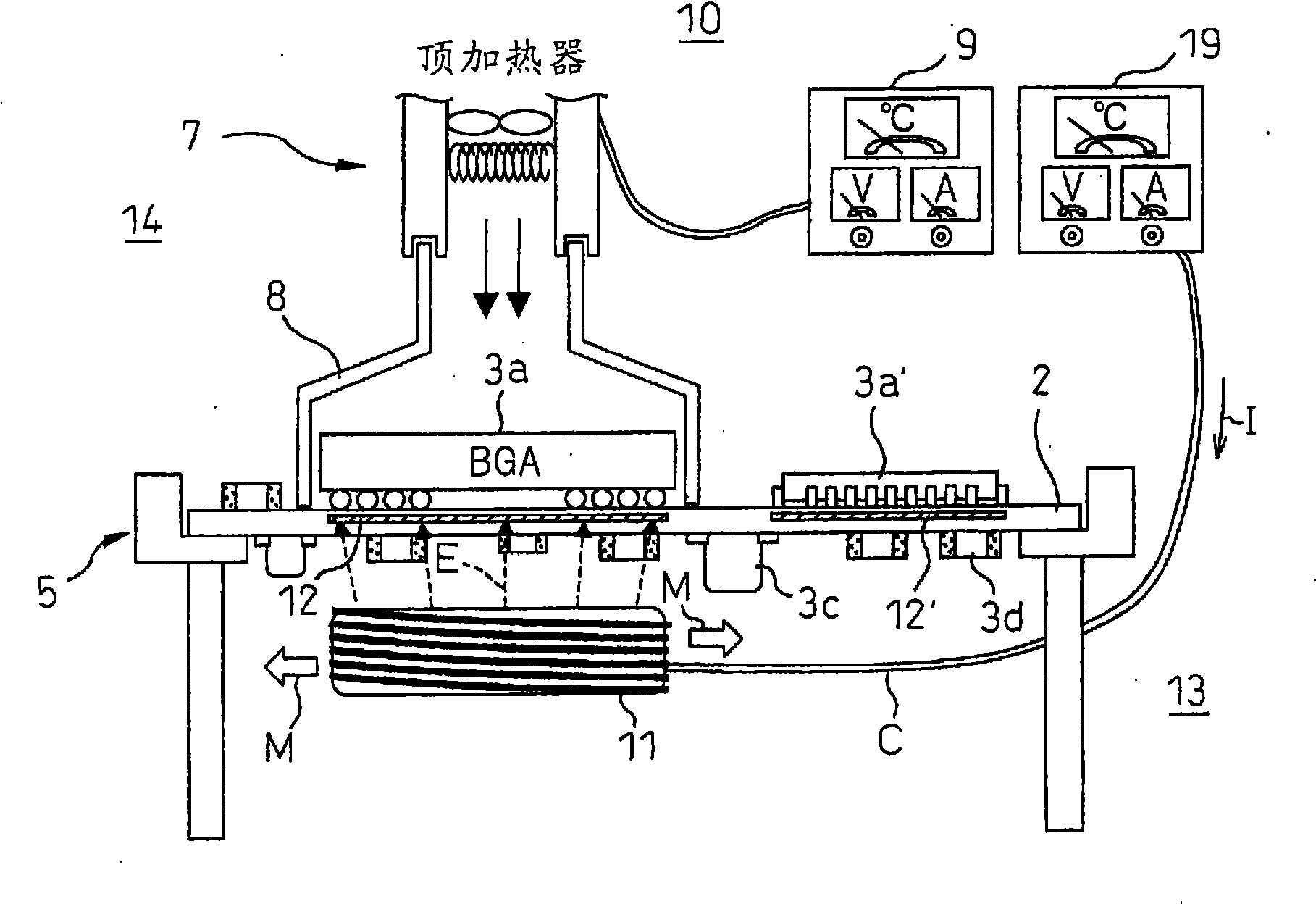

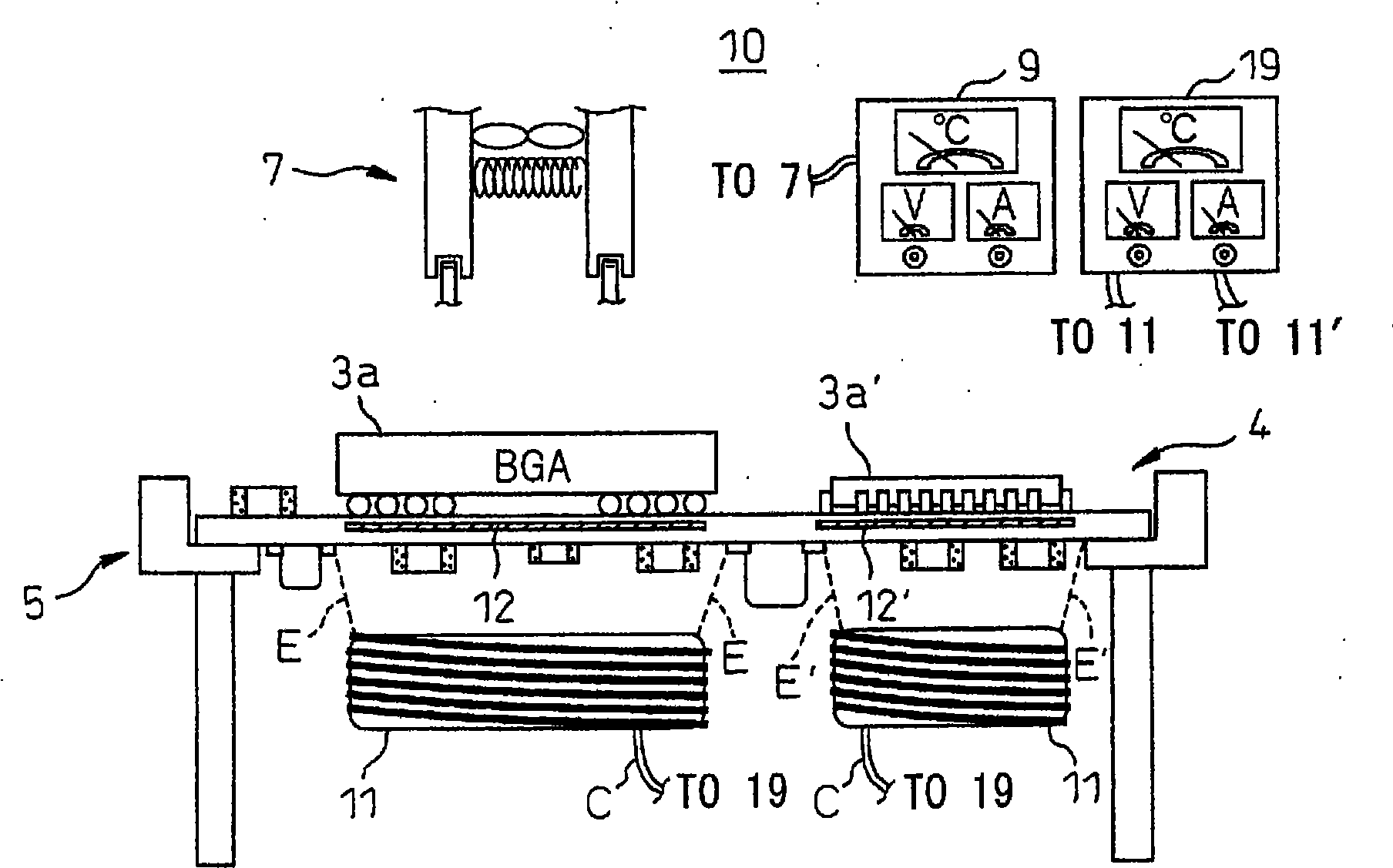

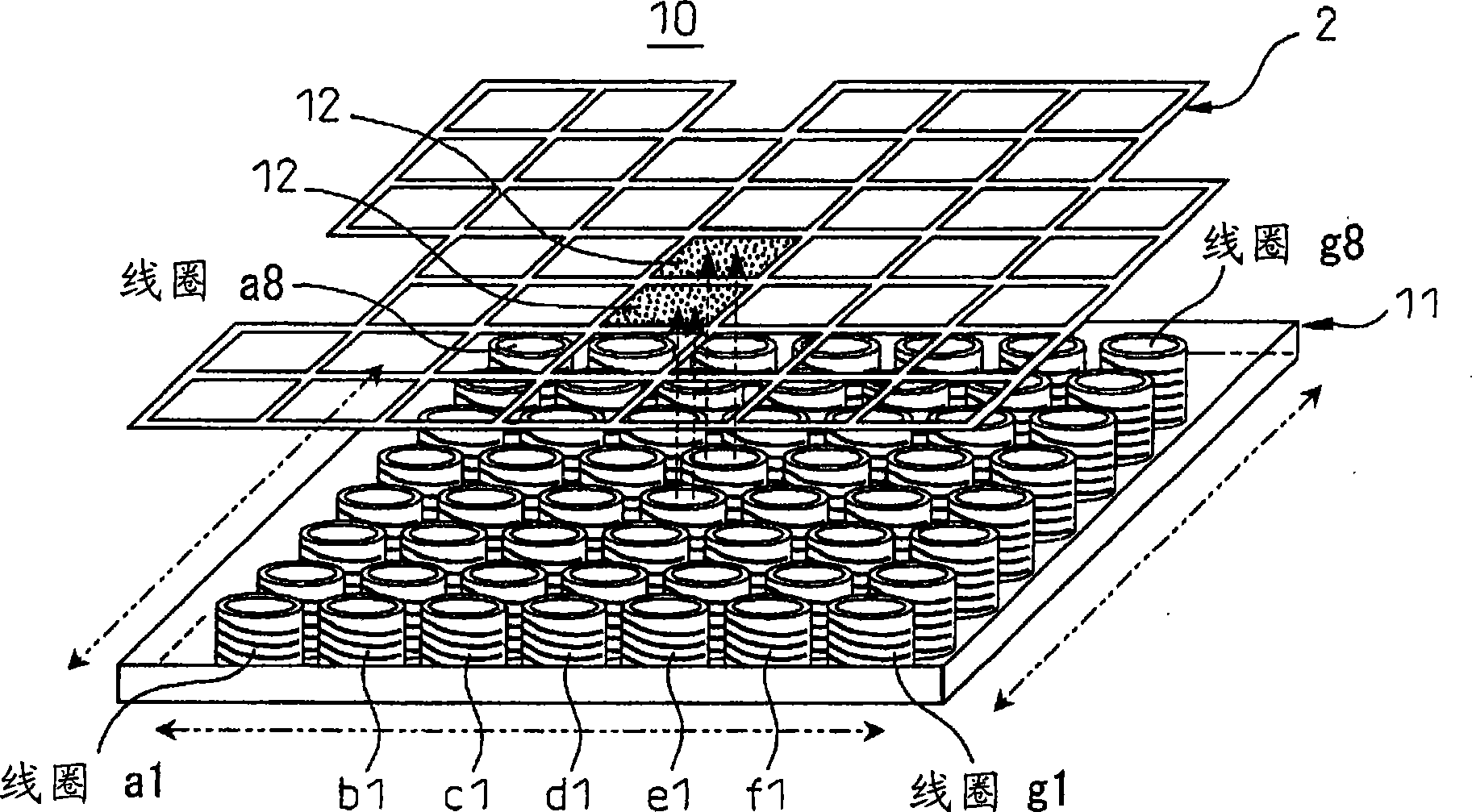

Method of repair of electronic device and repair system

InactiveCN101483978AWon't distortSuppression of distortionPrinted circuit assemblingHeating appliancesEngineeringElectromagnetic induction

A repair system which prevents heating of weakly heat resistant devices together and causing deterioration of the quality when preheating a first surface of the circuit board, wherein an electromagnetic induction material is buried in advance inside the circuit board near a specific electronic device envisioned as needed repair when becoming a defective electronic device in a production process and an electromagnetic coil emitting electromagnetic waves to an electromagnetic induction member in the vicinity of the repair device is provided and the heat generated by the electromagnetic induction member due to the electromagnetic waves enables the repair device to be heated and detached from the circuit board.

Owner:FUJITSU LTD

Freight container

ActiveCN108045287AReduce residualRelieve pressureVehicle with tipping movementTransportation itemsRear quarterOn board

The invention relates to the field of transportation and specifically discloses a freight container. An air collection cavity is arranged in a front board of the container; a telescopic board is arranged in the container; one end of the telescopic board is hinged to a bottom board at the rear part of the container and the other end of the telescopic board is capable of sliding vertically at the front board; the two sides of the telescopic board respectively abut against a left side board and a right side board; a return spring is arranged under the telescopic board; a compression cavity is formed under the telescopic board; the compression cavity communicates with the air collection cavity; the telescopic board comprises a first board and a second board which are connected to each other ina sliding manner; an inner cavity is arranged in the first board; a piston fixed to the end of the second board is arranged in the inner cavity; an air flow passage which communicates with the innercavity is arranged in the second board; a pressing valve for communicating the air collection cavity with the air flow passage is arranged at the bottom of the front board; the left side board and theright side board are provided with air outlets; the left side board and the right side board are provided with slideways communicating the air collection cavity with the air outlets; and blocking-upblocks for isolating the air collection cavity from the air outlets when the container is in a horizontal state are arranged in the slideways. The freight container facilitates the removal of residualmaterials.

Owner:重庆曙光安装工程有限公司

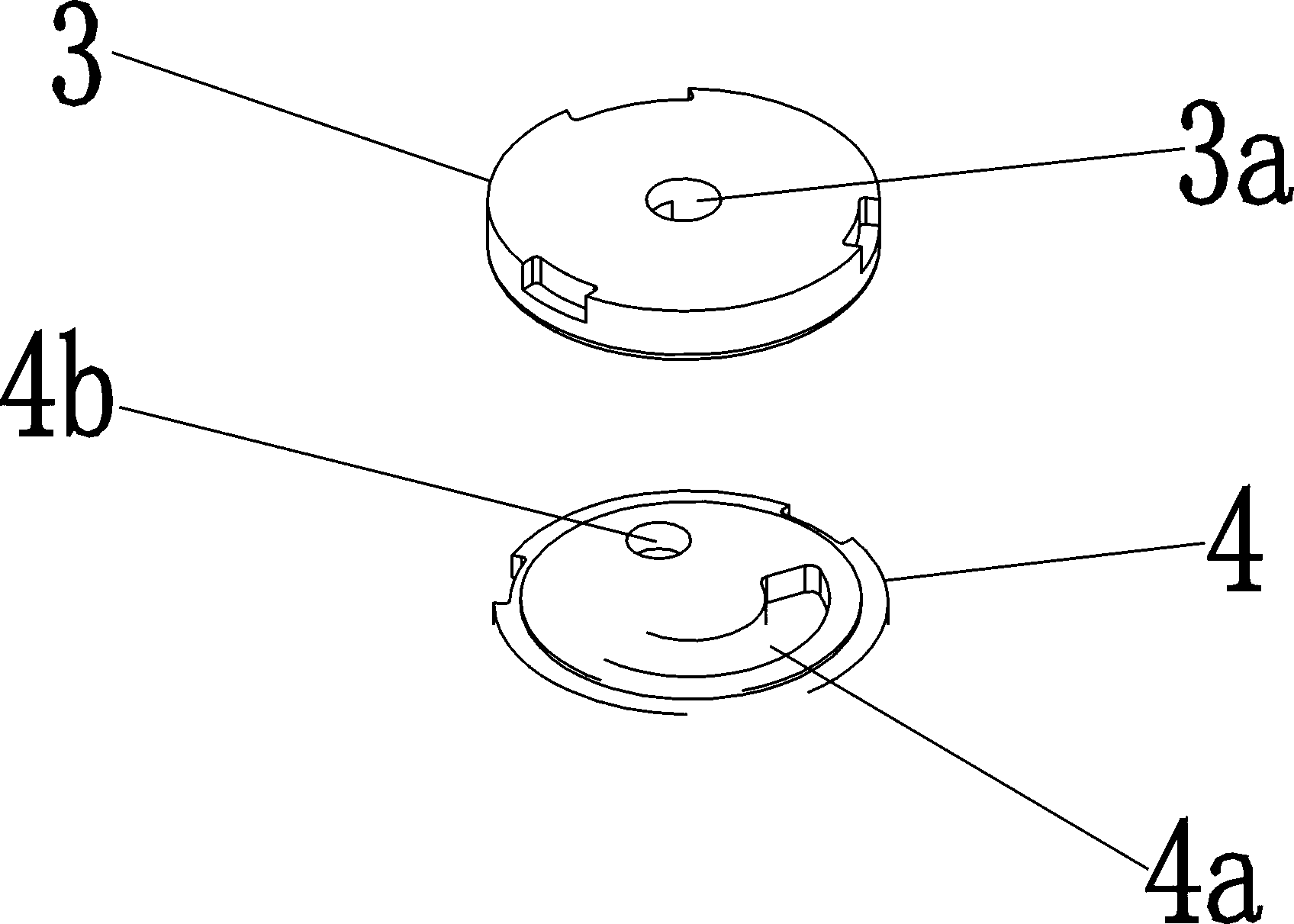

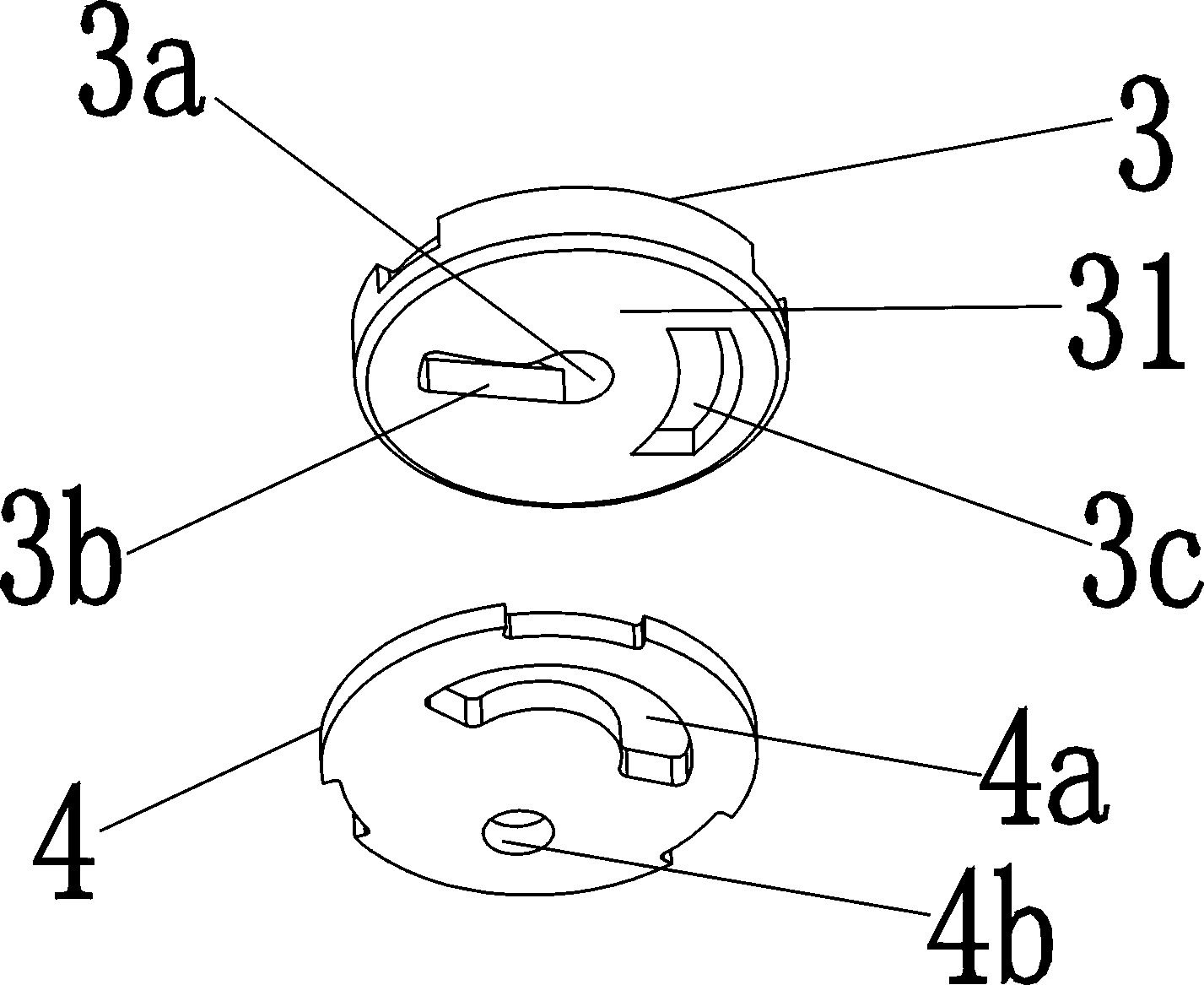

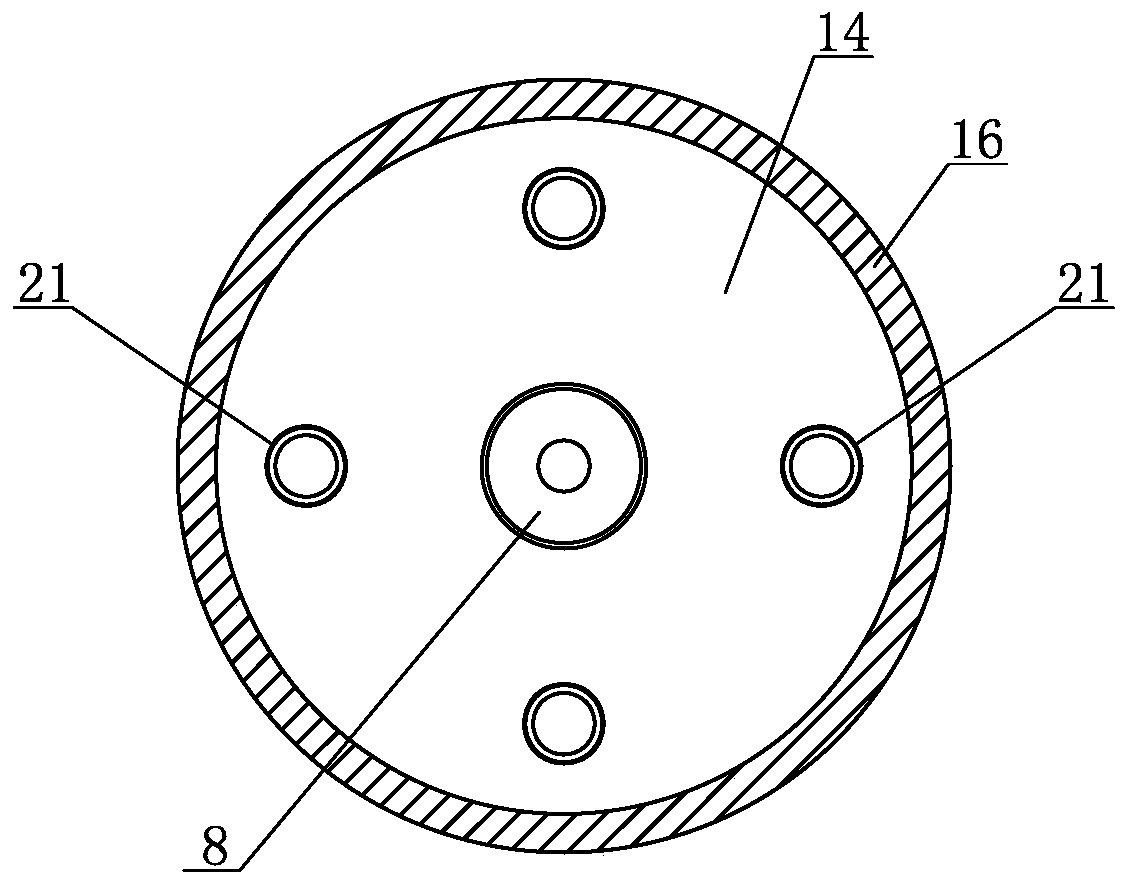

Ceramic valve plate for water outlet control

The invention discloses a ceramic valve plate for water outlet control, which can be applied to a water outlet device of a water dispenser or a tea making machine at home or office. The ceramic valve plate comprises an upper precise ceramic wafer and a lower precise ceramic wafer, and is closed since the upper ceramic wafer is attached to the lower ceramic wafer. The ceramic valve plate is characterized in that a central through hole is formed in the middle of the upper ceramic wafer; an annular blind hole surrounded around the central through hole and a guiding groove guided out from the central through hole are formed in the bottom surface of the upper ceramic wafer; an annular through hole and a circular through hole which are surrounded around the central position are formed in the lower ceramic wafer; the upper ceramic wafer is attached to the lower ceramic wafer and rotates; the guiding groove and the annular through hole can be opposite and staggered; when the guiding groove and the annular through hole are staggered and closed, the annular blind hole can cover the circular through hole and partial annular through hole at the same time. The valve plate can provide different water outlet pipelines and different water outlets through swinging so as to meet different requirements, and can meet the azimuth adjustment during the swinging.

Owner:GUANGDONG XINGONG ELECTRICAL APPLIANCES

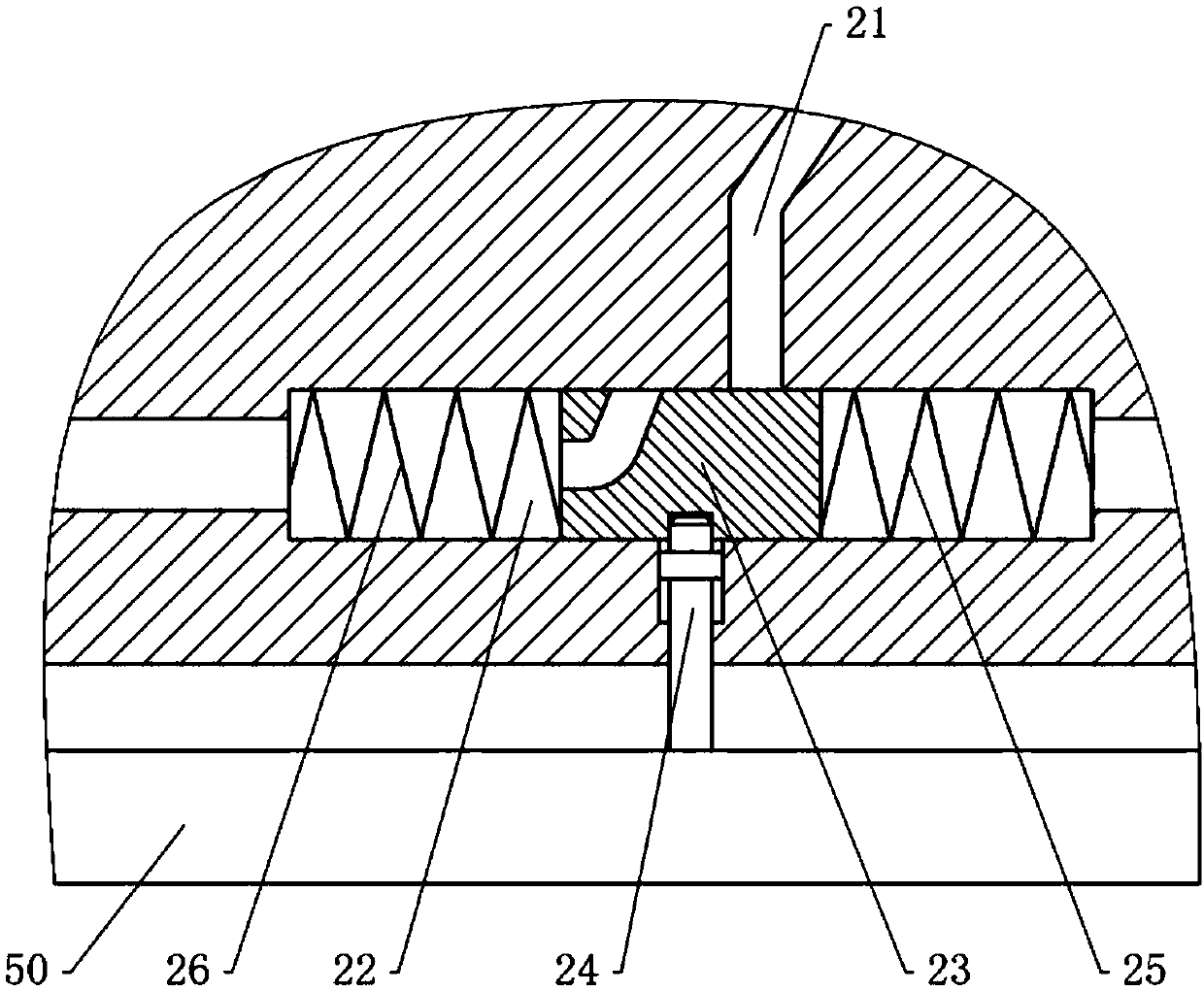

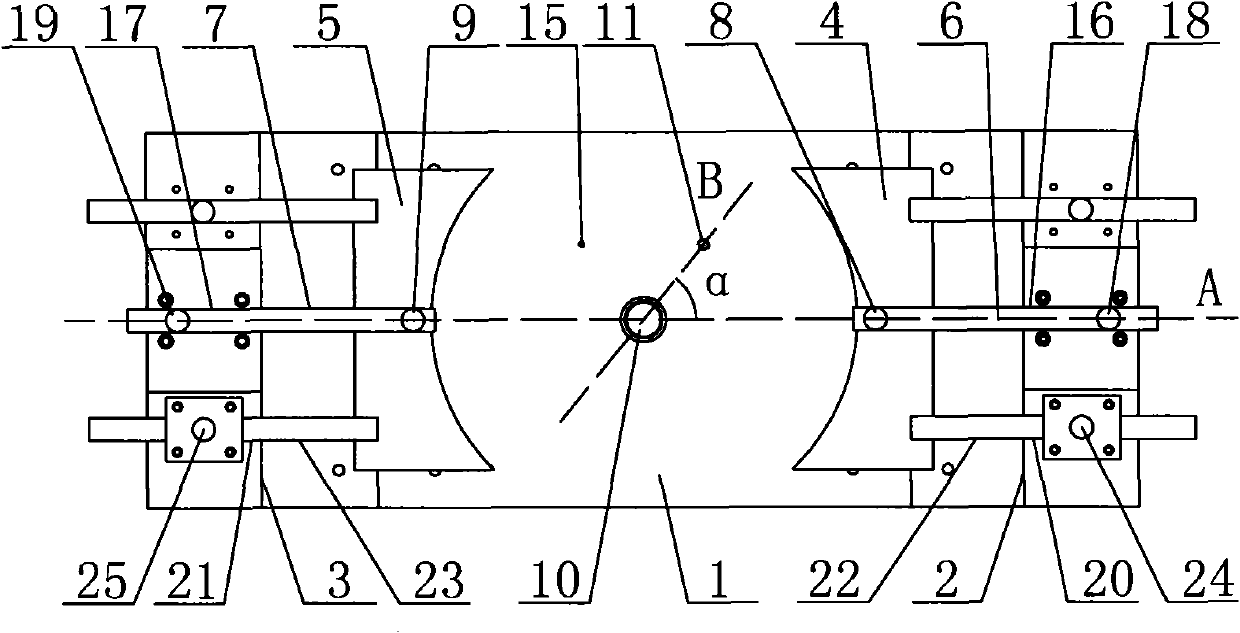

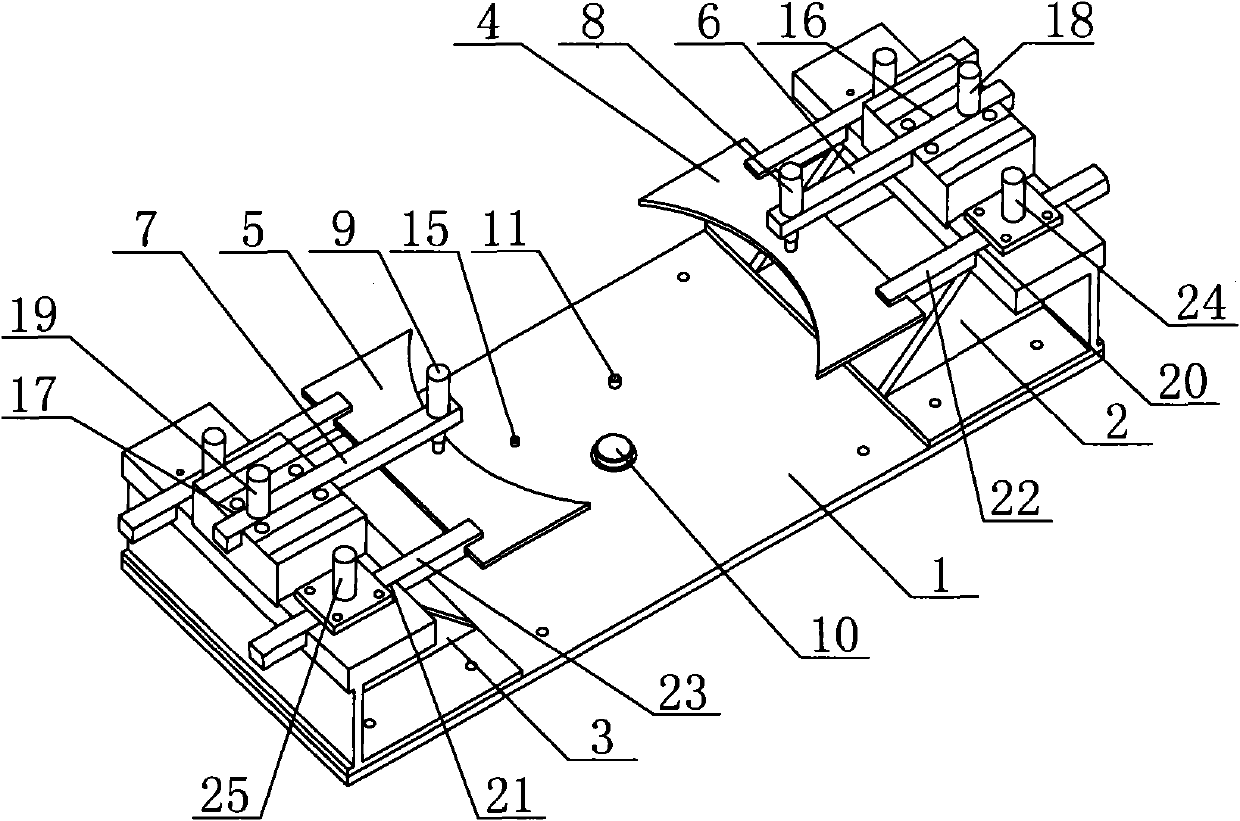

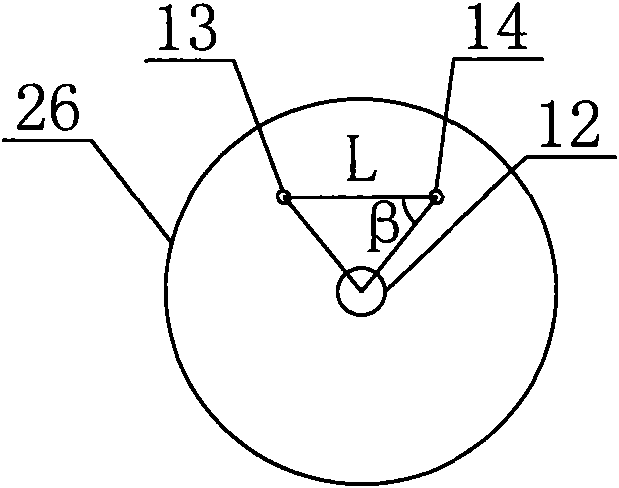

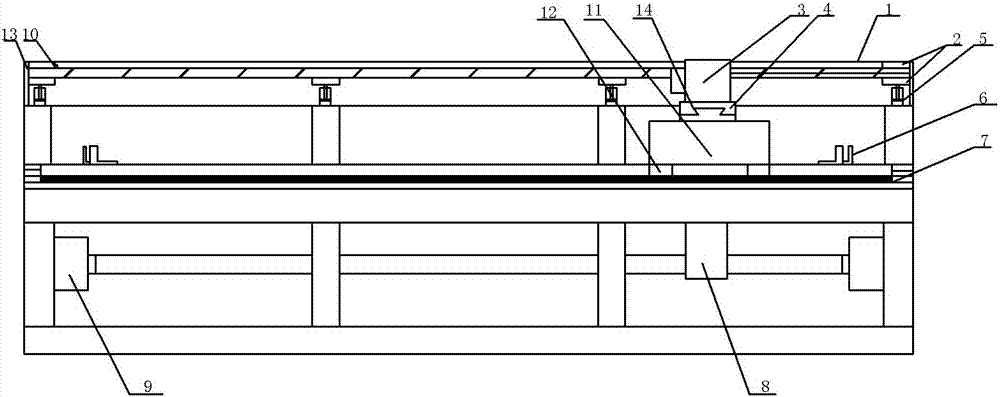

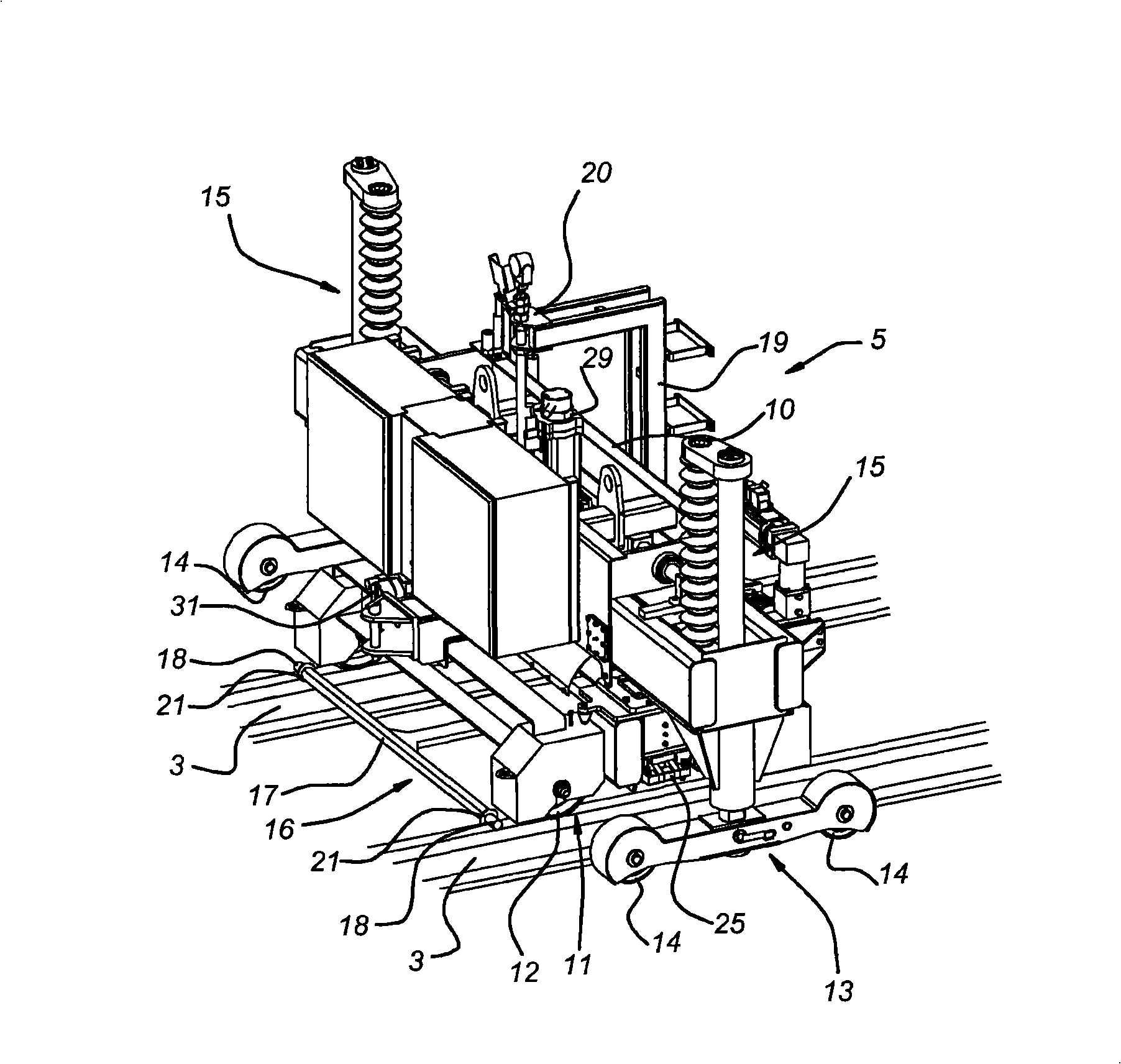

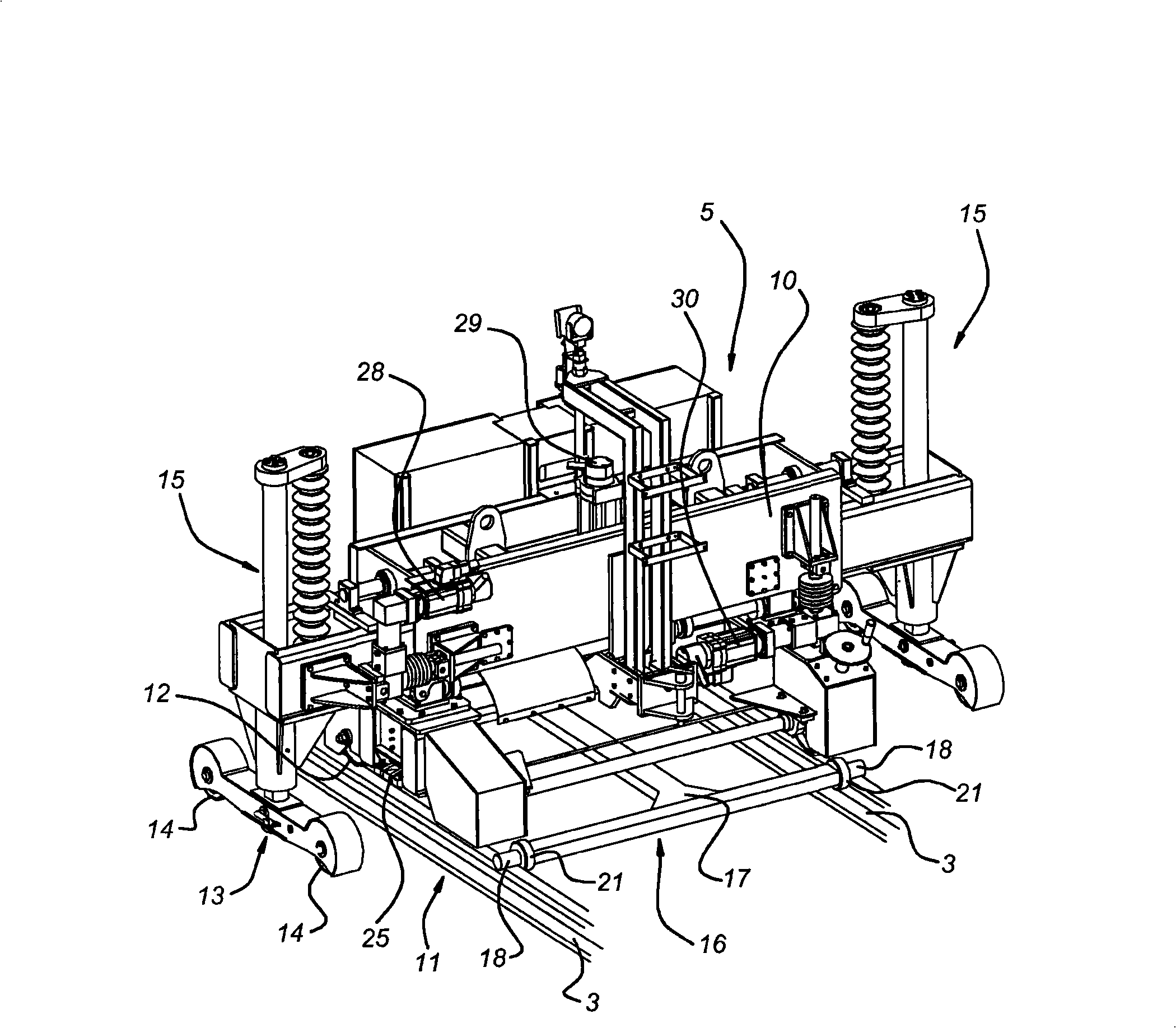

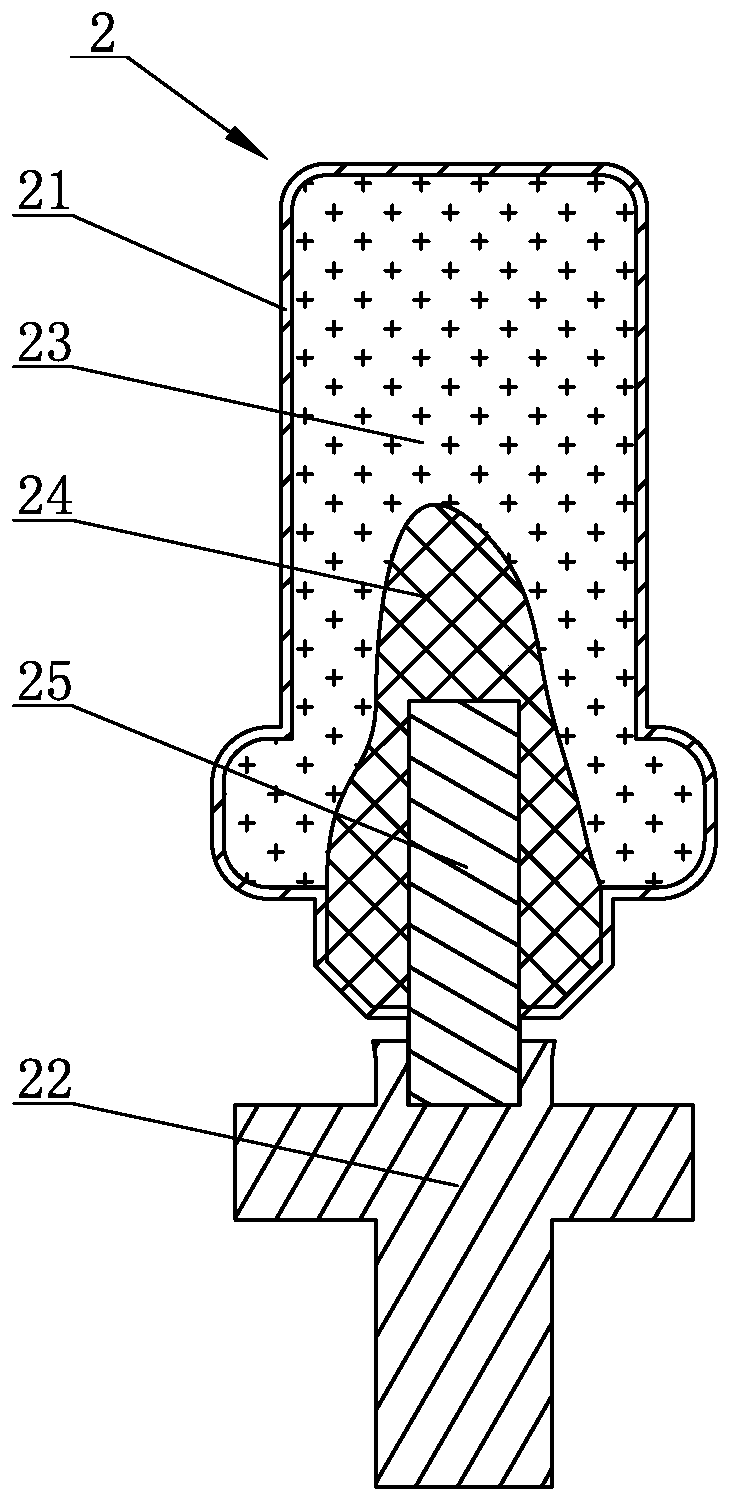

Bogie air spring assembling tool and method for assembling air spring by utilizing same

The invention relates to a bogie air spring assembling tool, comprising a baseboard, and supports at two sides of the baseboard. Supporting boards and slide bars are arranged on the supports, wherein the supporting boards can slide towards each other and are used for supporting air spring retaining rings, and the slide bars also can slide towards each other; vertical through holes are arranged at the front ends of the slide bars; retaining ring locating pins matched with air spring retaining ring screw holes are inserted in the vertical through holes; the baseboard is provided with a central hole locating pin matched with an air spring pedestal central hole and a screw hole locating pin matched with a first air spring pedestal screw hole; the center of the central hole locating pin and the centers of the vertical through holes of the two slide bars are throughout located on a same plane A which is perpendicular to the baseboard; an included angle between a plane B and the plane A equals to the base angles of an isosceles triangle formed by the air spring pedestal central hole and the two air spring retaining ring screw holes, wherein the plane B crosses the central hole locating pin centre and the screw hole locating pin centre and is perpendicular to the baseboard; and a connecting line of the two air spring pedestal screw holes is parallel to the plane A after air spring pedestals are placed on the baseboard. The bogie air spring assembling tool has the advantages of high assembling precision and high efficiency.

Owner:CRRC NANJING PUZHEN CO LTD

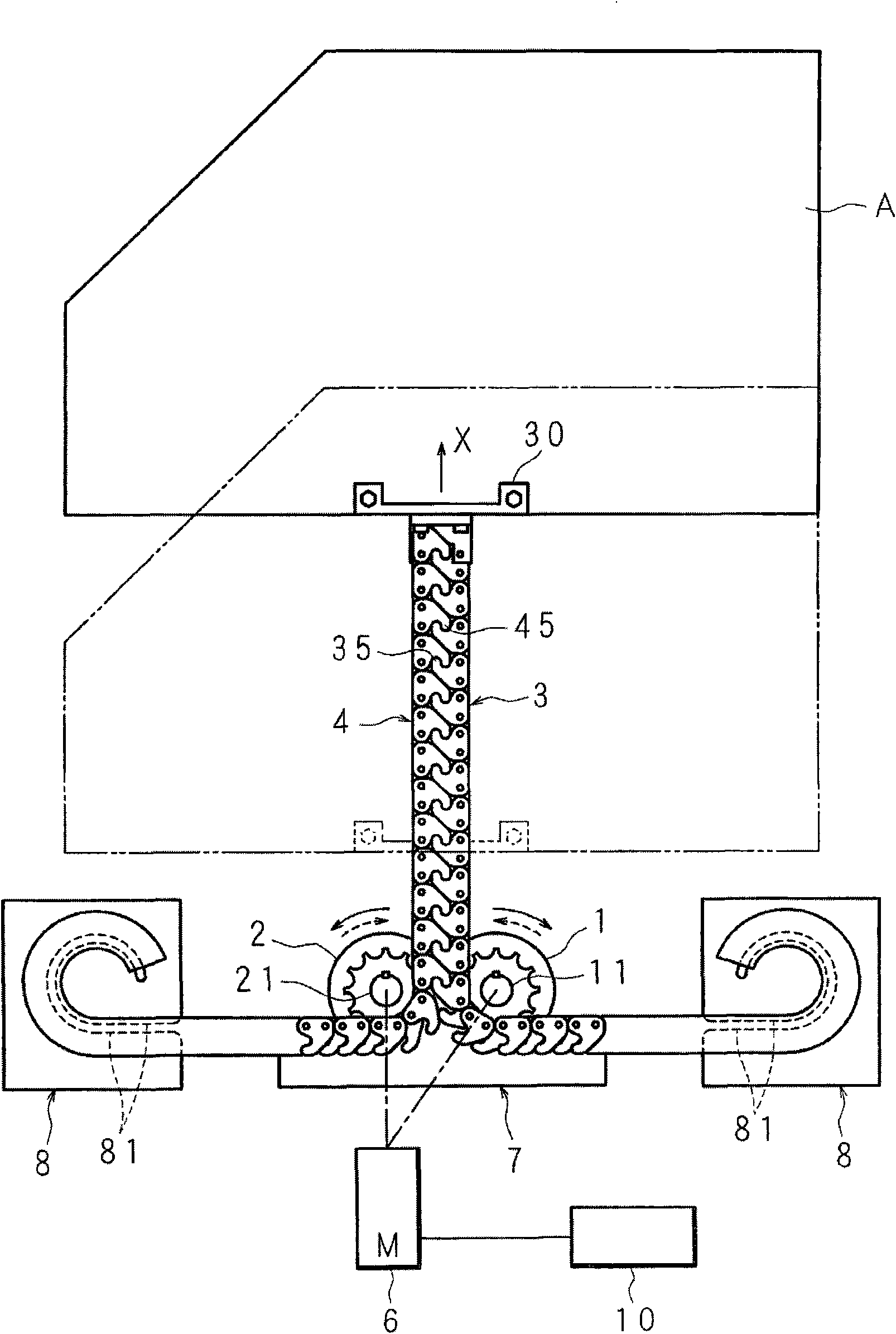

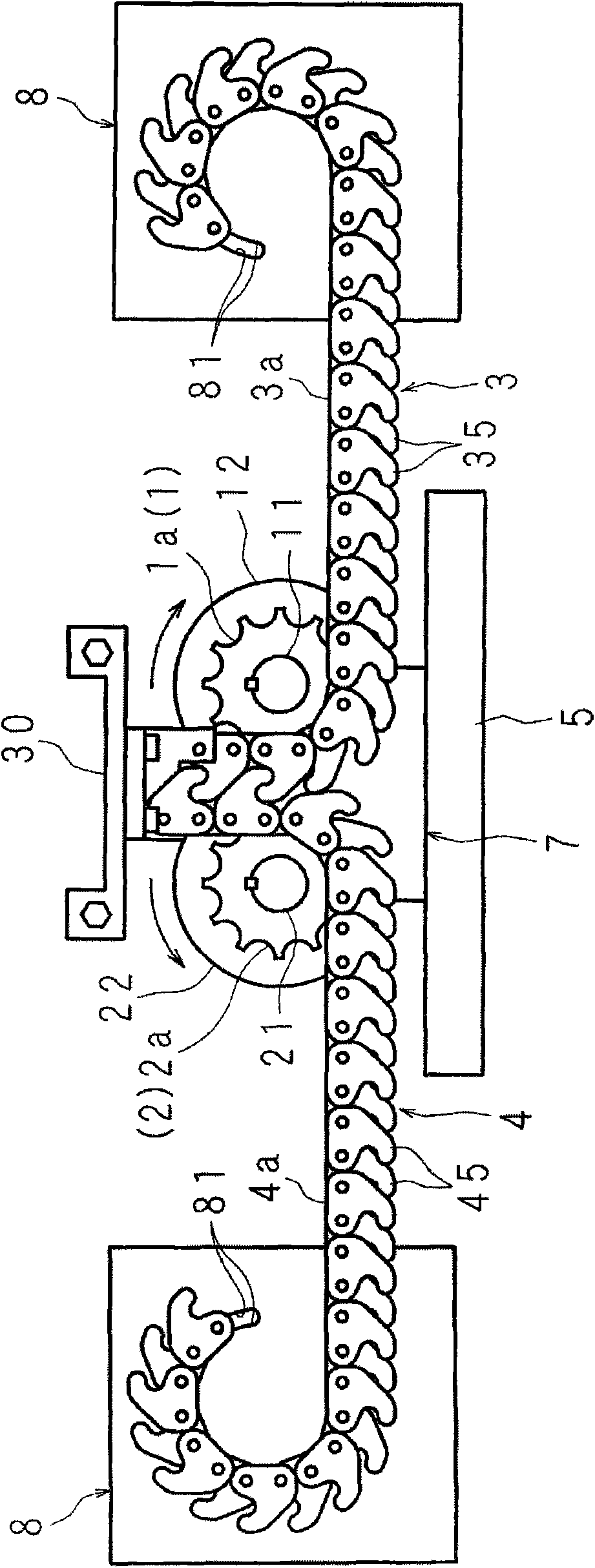

Opening/closing unit and opening/closing unit for vehicle windows

InactiveCN101832082AFree flexIncrease freedomMan-operated mechanismPower-operated mechanismMechanical engineeringEngineering

An opening / closing unit includes rotary gears spaced apart from each other in a radial direction, and chains which are placed to face each other, engage individually with the respective rotary gears and move in an interlocking manner, have flexible chain sections and flexure preventing sections which project from the chain sections and come into engagement with each other at a point located on one end side with respect to an engaged portion where the chains engage with the rotary gears, and are attached at their one ends to a sliding body such as a window glass, the flexure preventing sections are brought into engagement with each other to prevent the chains from flexing in separating directions and join them together to make one end side of the chains a non-flexible portion in the form of an angular bar.

Owner:TSUBAKIMOTO CHAIN CO

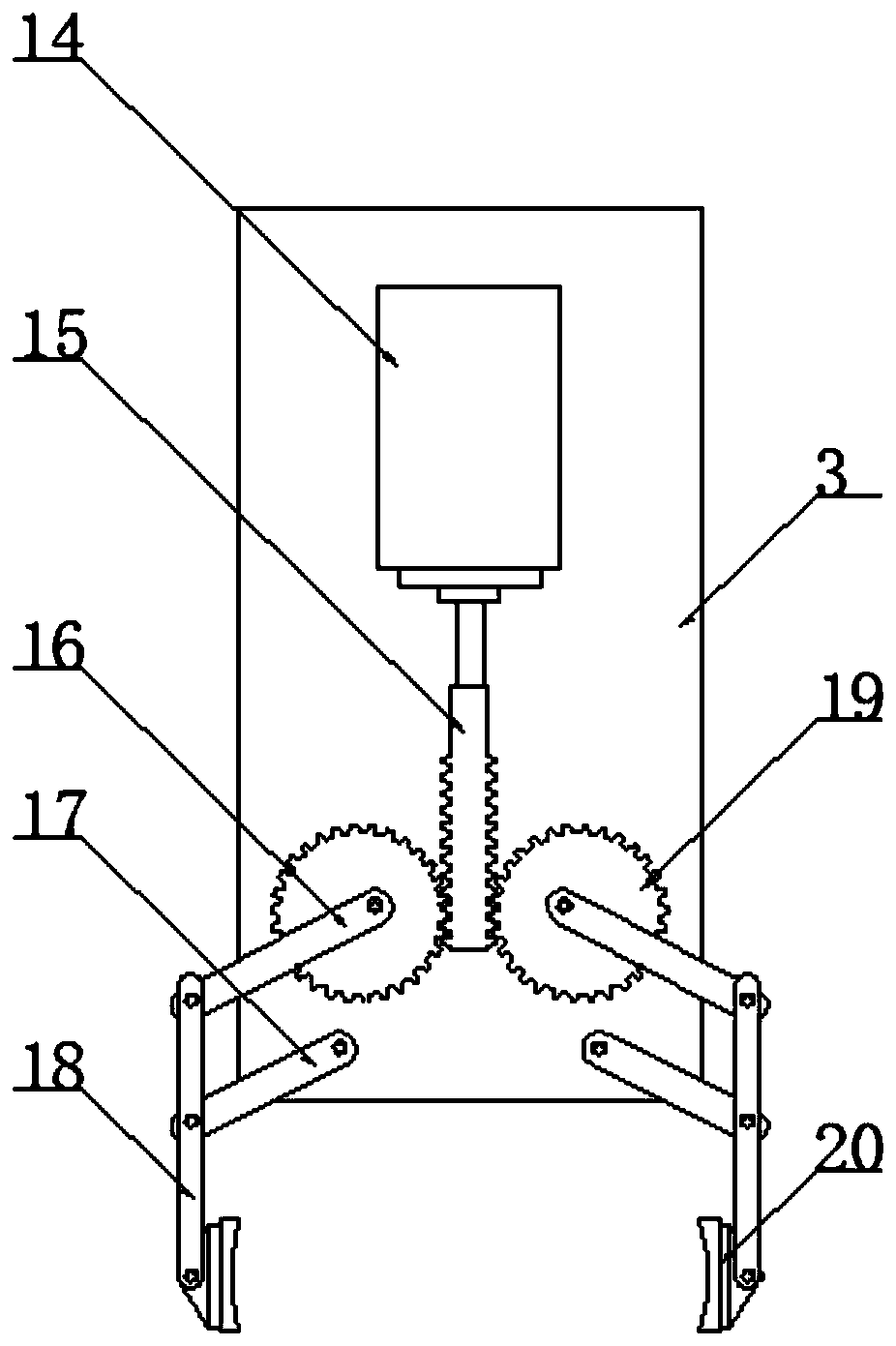

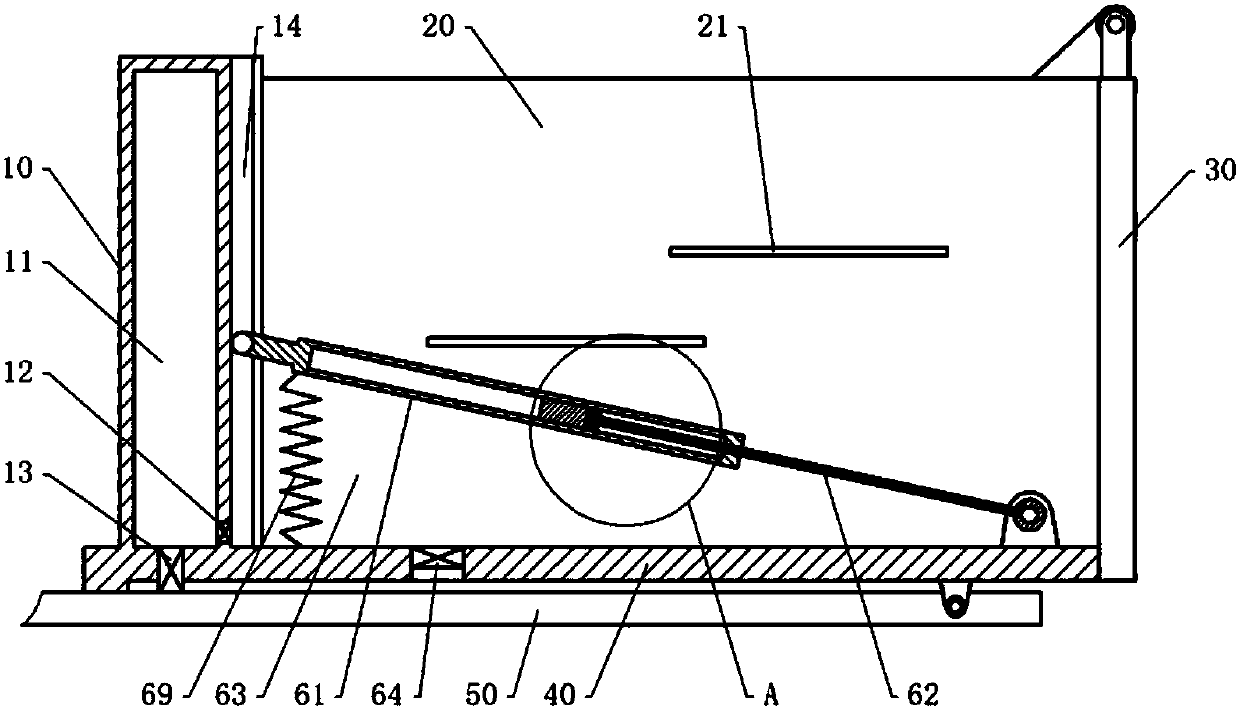

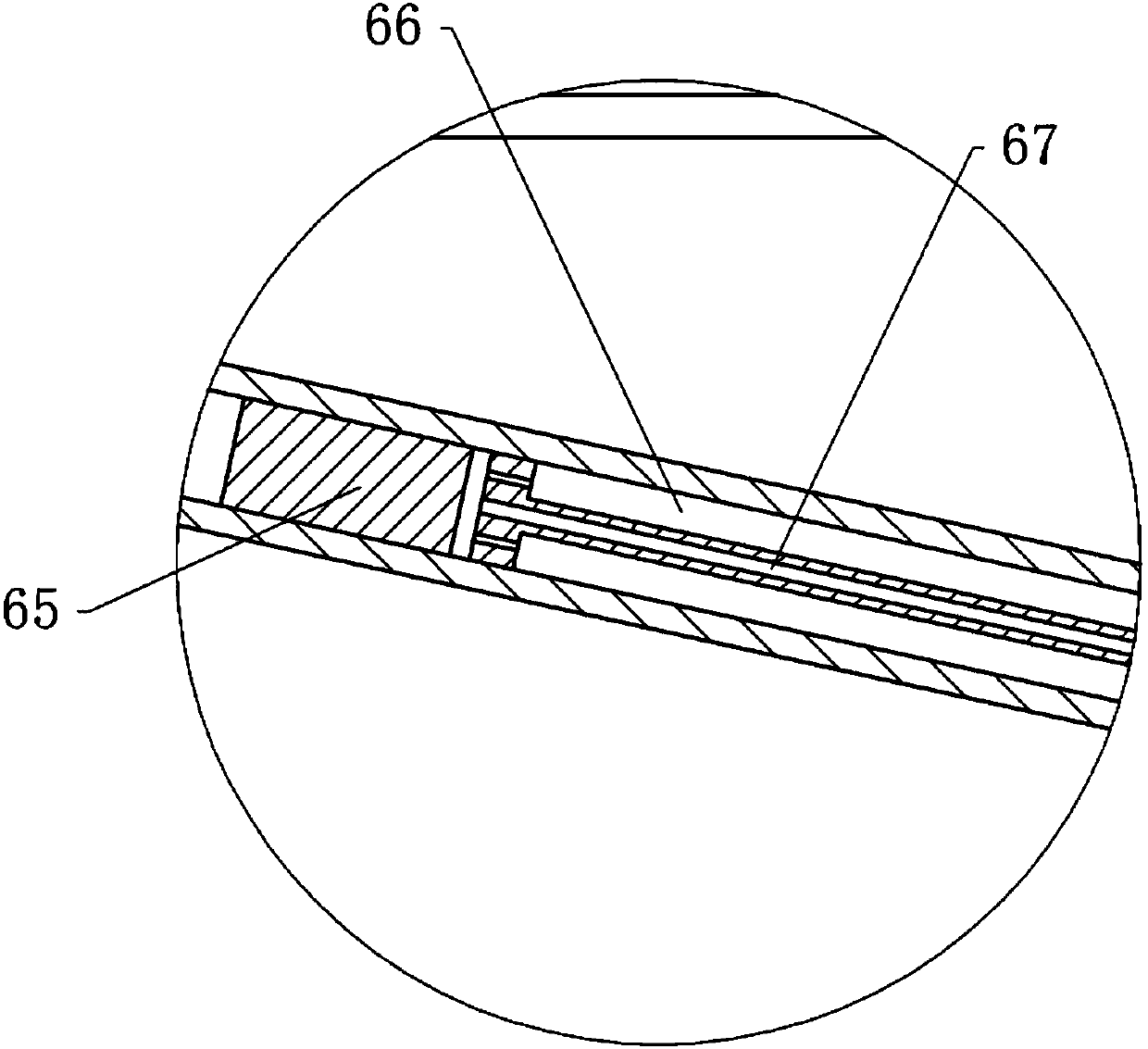

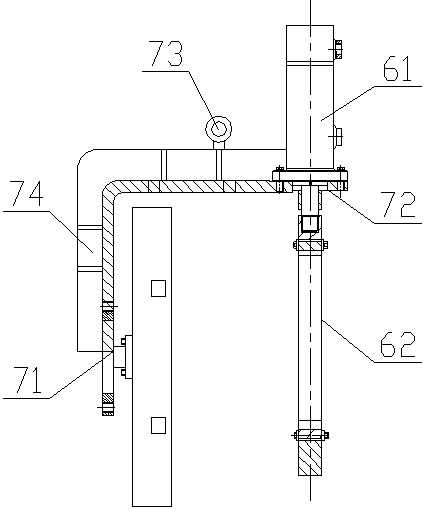

High-altitude escape self-rescue device

InactiveCN102526902AChange the size of the wrap angleControlled descent speedBuilding rescueEngineeringPulley

The invention relates to a high-altitude escape self-rescue device, which comprises a shell and a rope, wherein a handle is fixedly connected with a lead screw in the shell; the left and right elliptical threads of the lead screw are connected with left and right slide blocks respectively; the left and right slide blocks are connected with two feeding rods in a sliding way; left and right movable pulleys are hinged with the left and right slide blocks respectively; two fixed pulleys are hinged with left and right brackets respectively; the left and right brackets are fixedly connected with the shell; the rope is wound on the two fixed pulleys in a staggered way, and is arranged between the two movable pulleys; the top surface of the shell is provided with a rope inlet positioning mechanism; and the bottom surface of the shell is provided with a rope outlet and a lug where a safety vest is arranged. The device has a simple structure, high manufacturability, small size and light weight, is smooth and safe, and is easy and convenient for operating.

Owner:YANCHENG INST OF TECH

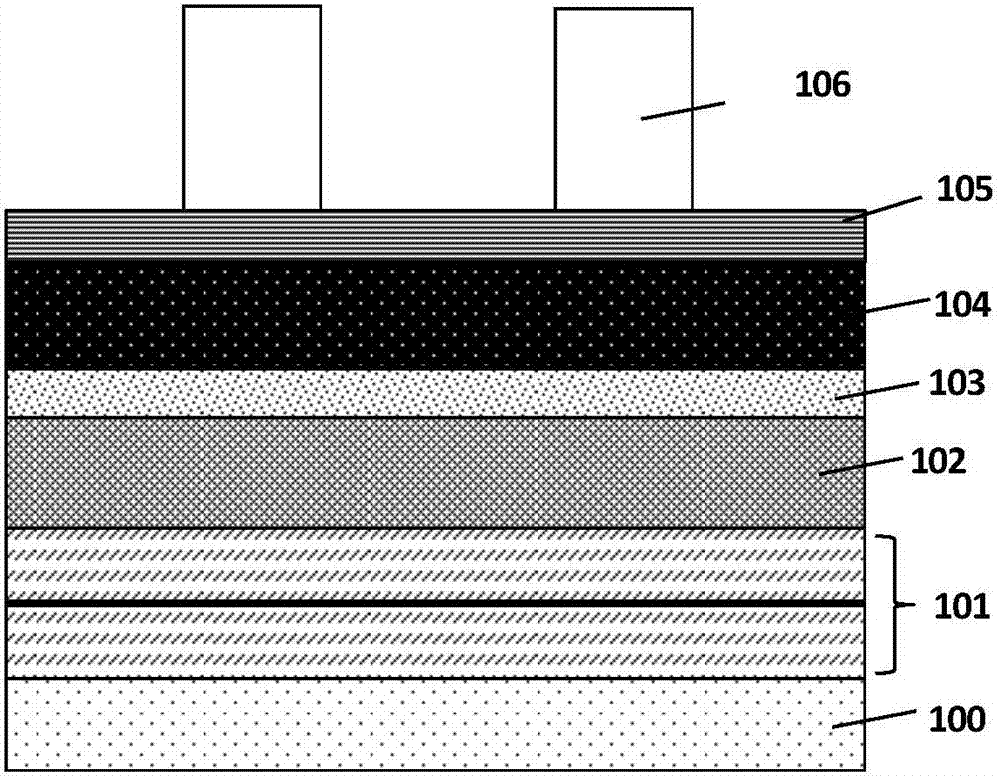

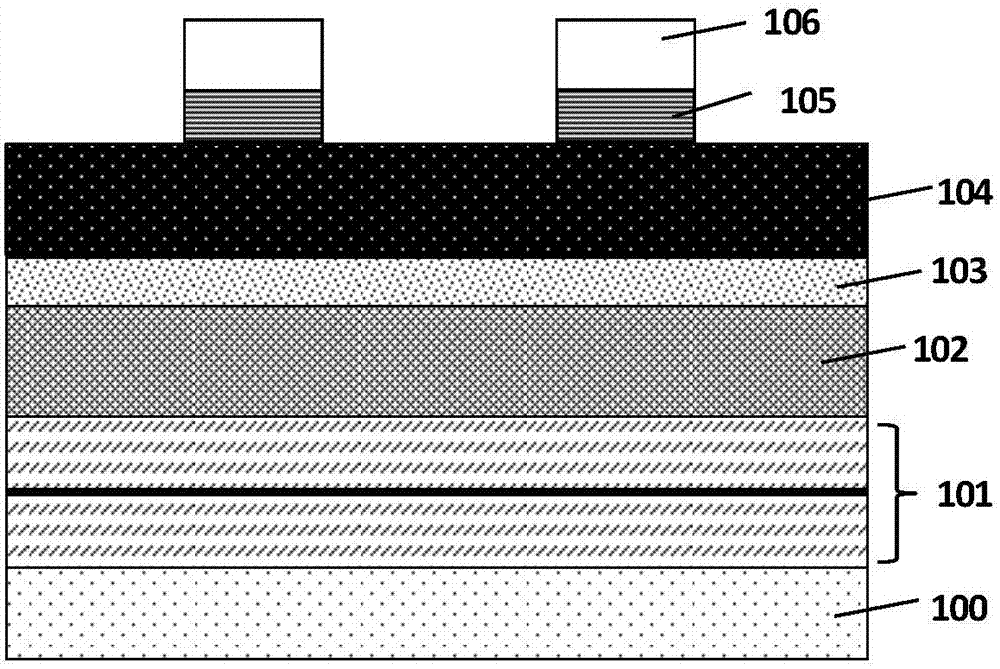

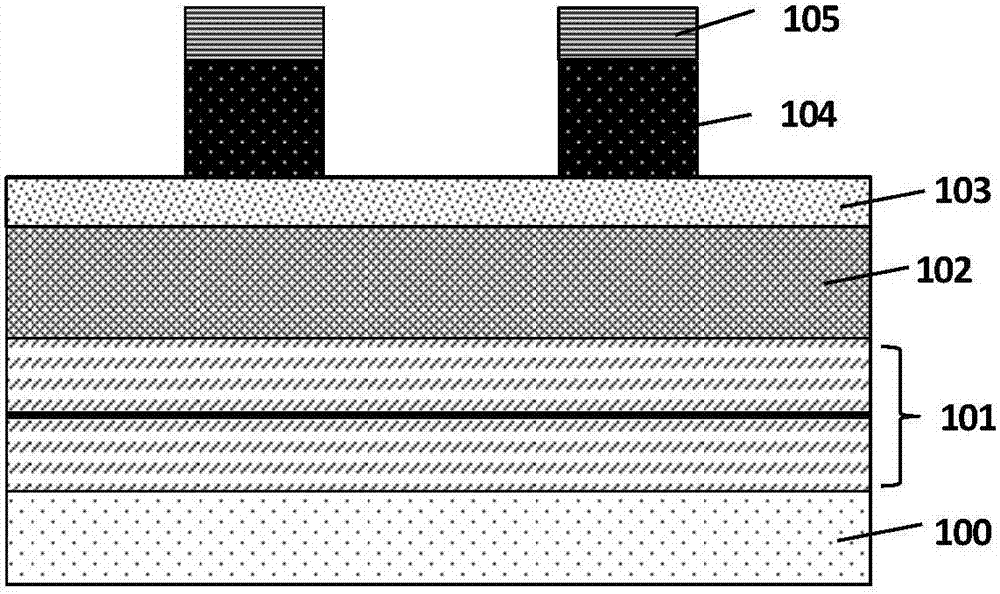

Method for forming magnetic tunnel junction through patterning quad-layer mask

ActiveCN107331770AWon't distortImprove patternGalvano-magnetic device manufacture/treatmentEtchingLithographic artist

The invention provides a method for forming a magnetic tunnel junction through patterning a quad-layer mask. The method comprises the following steps of 1, forming a magnetic tunnel junction film layer unit on a substrate; 2, forming a quad-layer mask film layer unit on the magnetic tunnel junction film layer unit; 3, forming a photoresist unit on the quad-layer mask film layer unit; 4, patterning the photoresist unit through lithography; 5, patterning the quad-layer mask film layer unit; 6, patterning the magnetic tunnel junction film layer unit; 7, trimming the side wall of the damaged patterned magnetic tunnel junction film layer unit by means of ion beam etching; and 8, coating the patterned magnetic tunnel junction film layer unit by means of a silicon nitride layer. The method has advantages of effectively improving a pattern and a contour after tantalum mask etching, eliminating consumption of tantalum mask before magnetic tunnel junction etching, and reducing shortcircuit risk of a magnetic random memory circuit bit wire and a magnetic tunnel junction unit.

Owner:SHANGHAI CIYU INFORMATION TECH

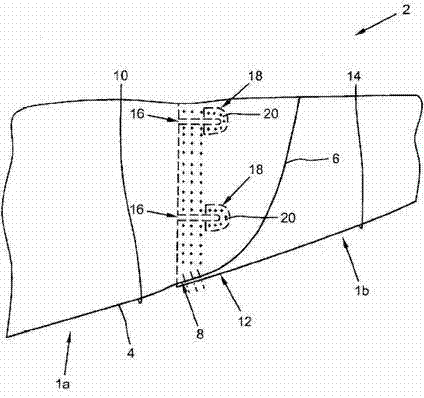

Fuselage section having an integral pressure bulkhead formed from composite fibre material, as well as a fuselage shell having a fuselage section such as this

InactiveCN102164817AReduce manufacturing costOptimized high-strength structureEfficient propulsion technologiesWeight reductionFlight vehicleMechanical engineering

A fuselage section (1a) is disclosed for the pressure fuselage of an aircraft having a fuselage shell structure (4) and at least one pressure bulkhead (6) composed of a composite fibre material, wherein the pressure bulkhead (6) is formed integrally with the fuselage shell structure (4). A fuselage shell (2) having at least one such fuselage section (1a) is also disclosed.

Owner:AIRBUS OPERATIONS GMBH

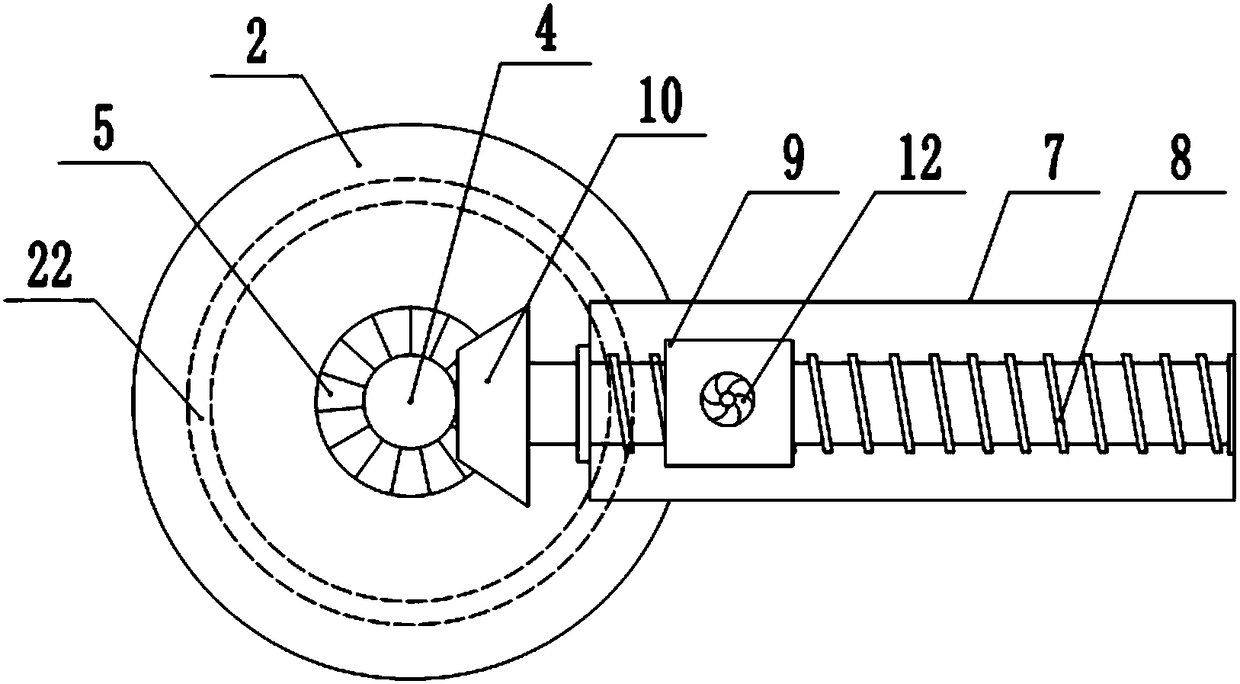

Wood board slotting equipment

InactiveCN107053383ASimple wayWon't distortWood mortising machinesWood slotting machinesEngineeringWood plank

The invention relates to the technical field of wood plate machining, in particular to wood board slotting equipment. The wood board slotting equipment comprises a rack, a locating device, a slotting device and a level device, wherein the locating device is mounted on one side of the rack; the locating device is provided with controllable cylinders and clamps; the controllable cylinders are arranged on the rack; the clamps are arranged at the left and right short ends of the rack; the slotting device is arranged on the other side of the rack; the slotting device comprises a supporting seat and a cutting wheel motor; the cutting wheel motor is placed above the supporting seat; a sliding rail is arranged below a supporting table; and a pressure sensor is arranged on the level device. The wood board slotting equipment can quickly locate a wood board and enable the wood board to be horizontally placed and also can guarantee stable slotting for the wood board.

Owner:CHONGQING YIJU DOOR

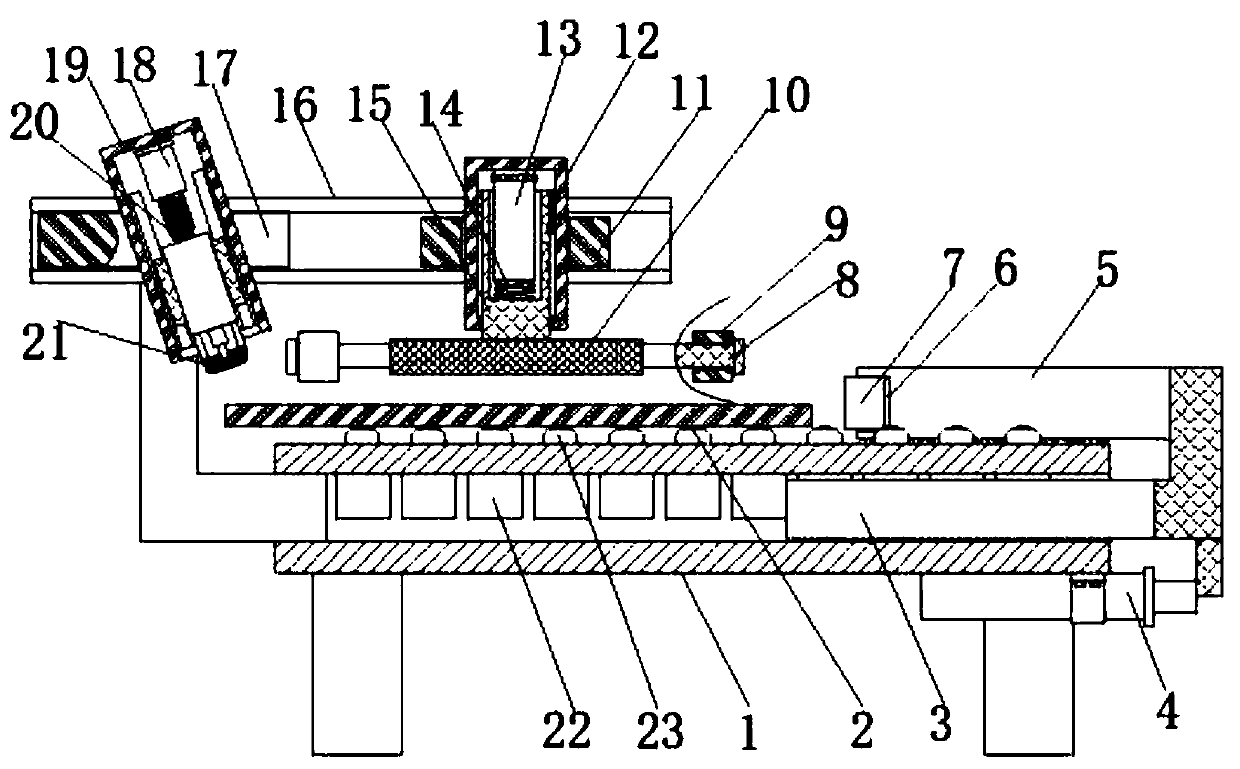

Plate edge grinding device for machining

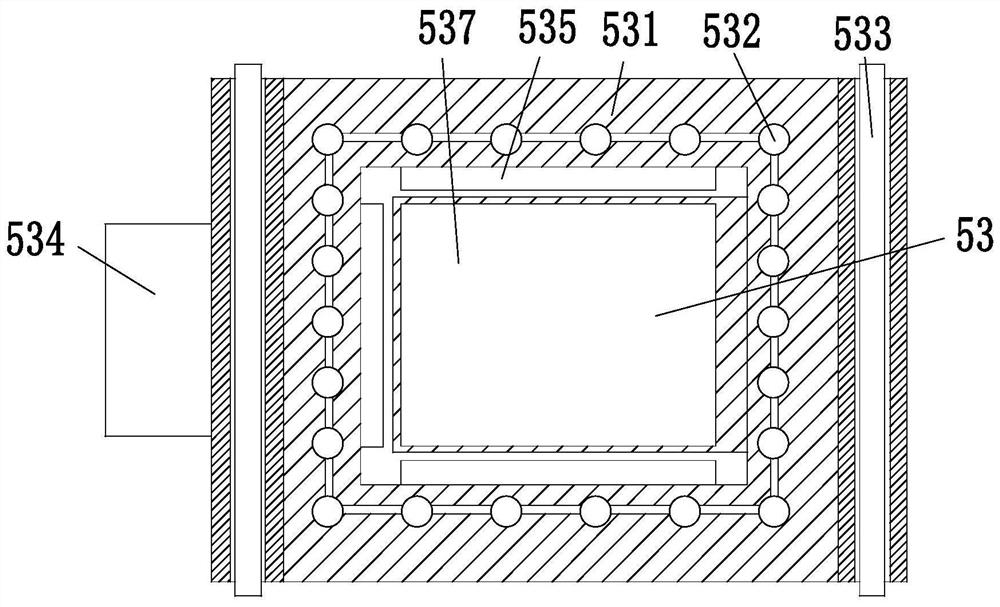

InactiveCN111482860AImprove convenienceAvoid radial forceEdge grinding machinesGrinding work supportsEngineeringMachining

The invention belongs to the technical field of grinding devices, particularly relates to a plate edge grinding device for machining, and provides the following scheme for solving the problem that anexisting edge grinding device cannot adjust a grinding position and angle in time according to actual conditions. The plate edge grinding device comprises a base in which a cavity is of a flat squaretube structure; two symmetrical L-shaped supporting frames are inserted into one end of the base, two parallel channel steel cross beams with opposite openings are fixed to top ends of the two L-shaped supporting frames, and a C-shaped clamping block and a rectangular fixing frame are clamped to the positions, close to the two ends, between the two channel steel cross beams correspondingly; and amotor box with a downward opening is clamped in the middle of the C-shaped clamping block. According to the plate edge grinding device disclosed by the invention, when the edge of a plate needs to beground in the using process, the edge of the plate only needs to be moved to the position above the edge of the base, then the pressing plate is controlled to descend so as to rapidly press the plate,and meanwhile, the plate can be pushed to advance while being ground, and the grinding convenience is improved.

Owner:程宏剑

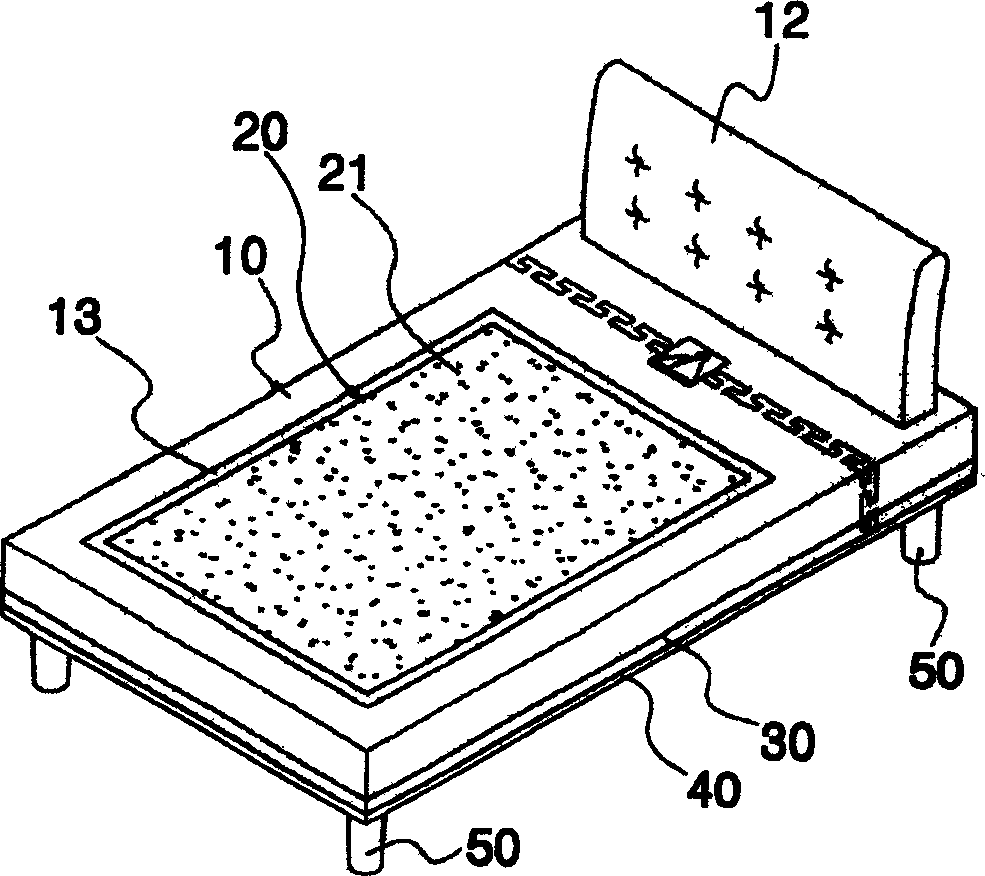

Mattress integrated stone bed

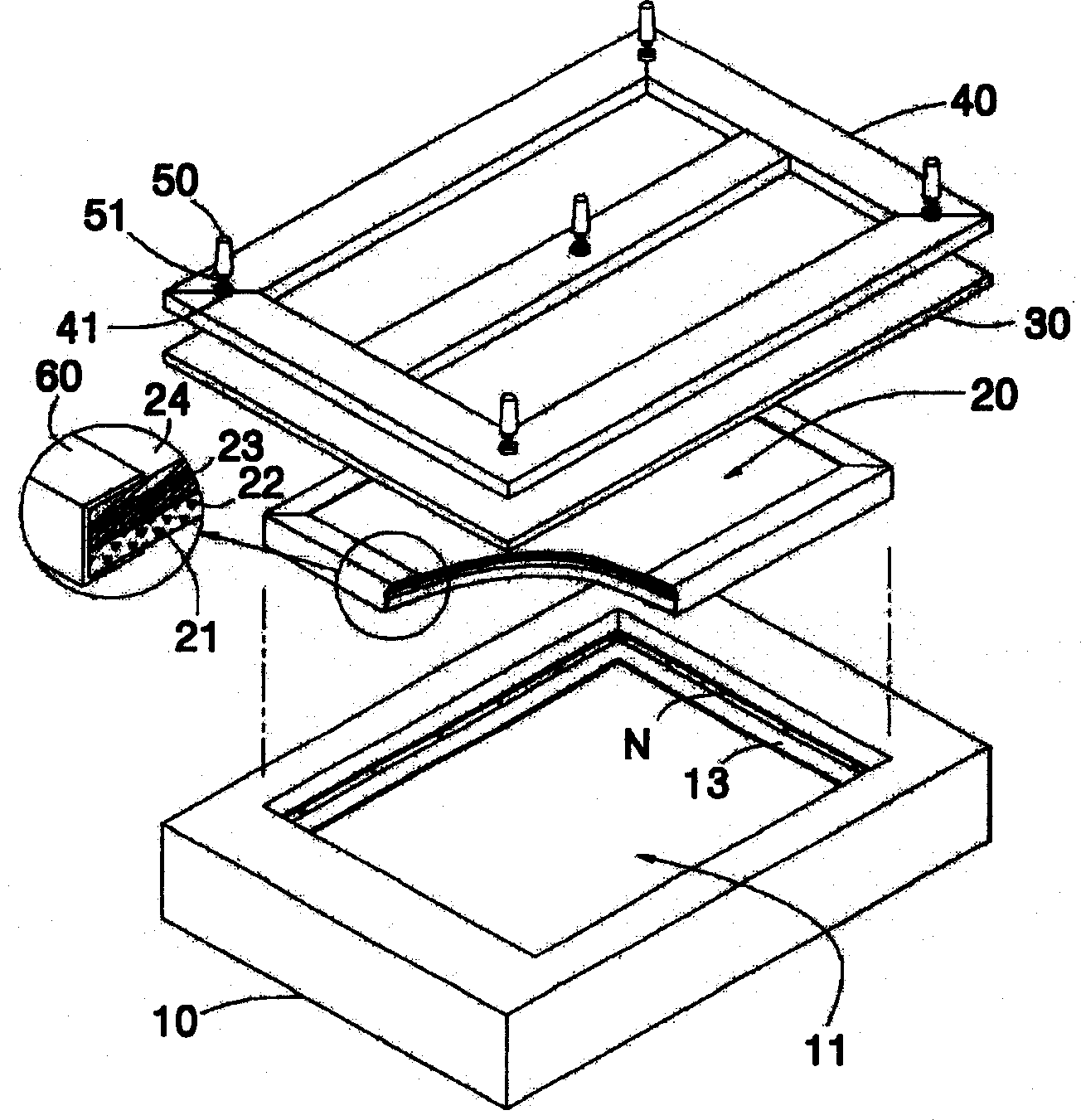

A connector for a synthetic resin pipe is provided to easily and stably connect the synthetic resin pipes by heating fused members with a high-frequency molding machine. Grooves(3,3') and protrusions(4,4') are formed at the outside of connecting bodies(2,2'). Coupling holes(6,6') are formed at both sides of the connecting bodies. Fused members(9,9') are disposed at the inner faces of the connecting bodies. A high-frequency molding machine is connected to a connecting ring(21) and a press plate(22) enclosing the connecting bodies, and heats the fused members.

Owner:曹茂铉

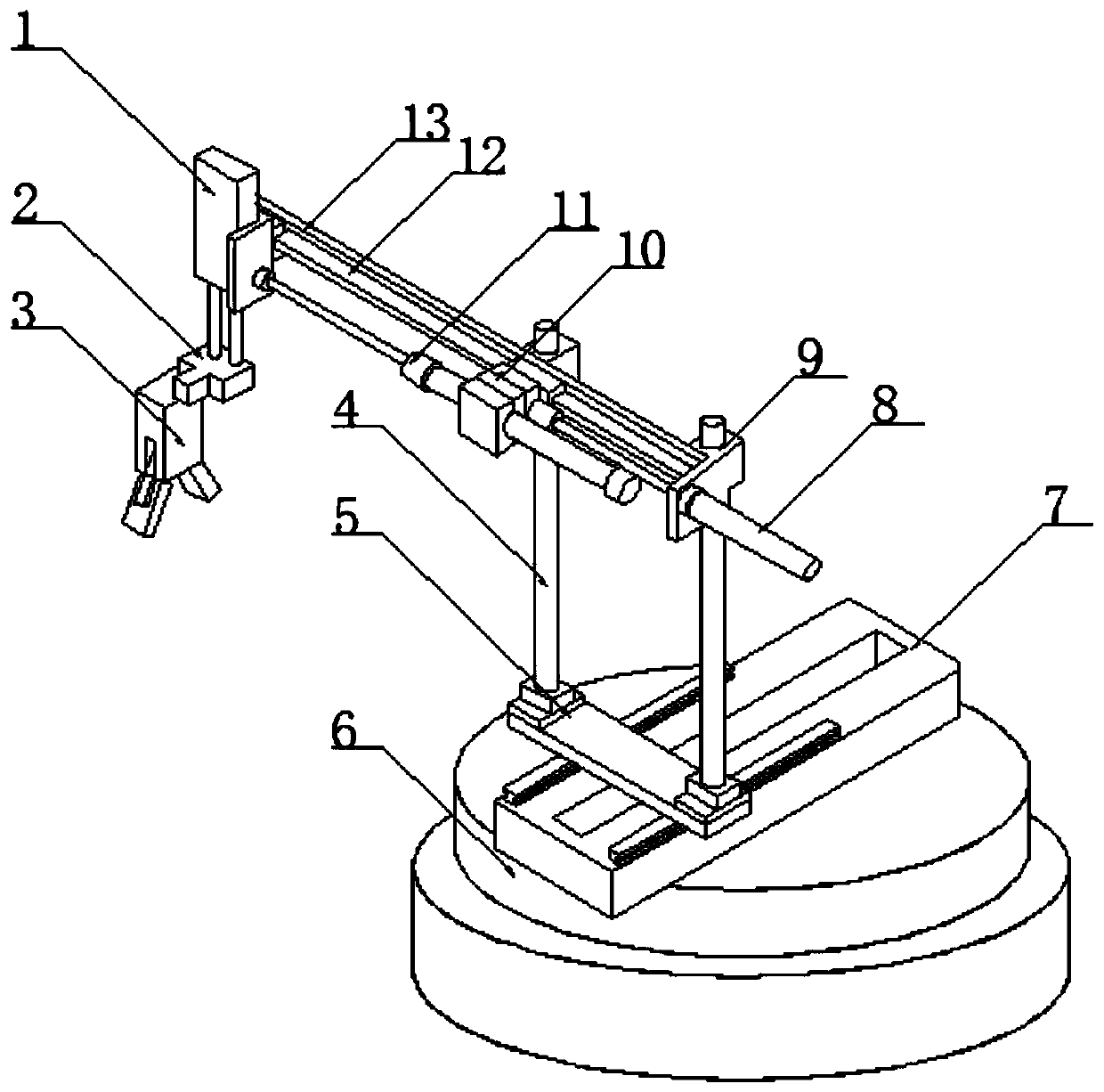

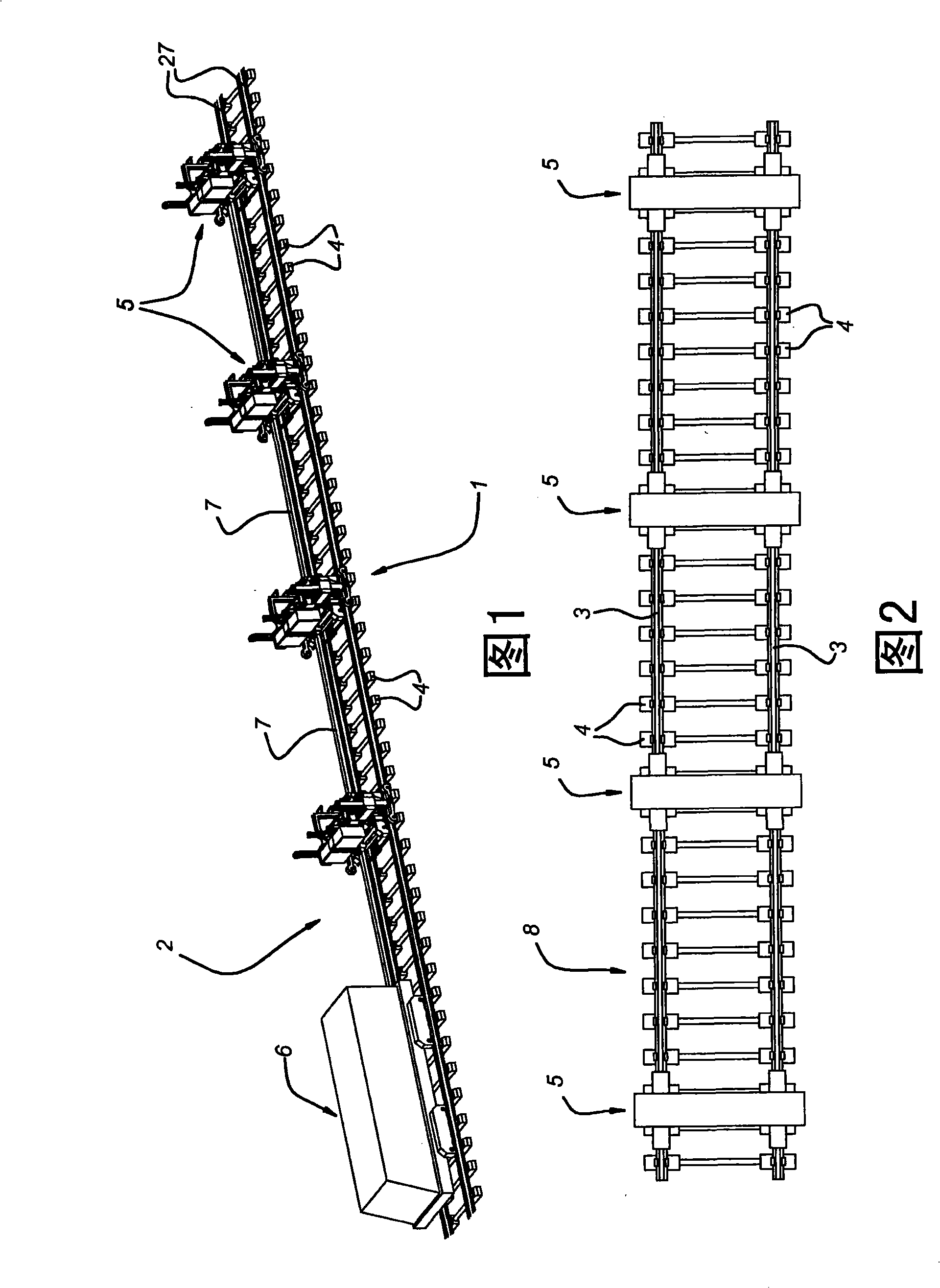

Method and adjusting installation for producing a stretch of railway

InactiveCN101321917AWon't distortBallastwayRailway track constructionTrackwayArchitectural engineering

A method of laying a section of railway track comprising a railway track as well as foundations on which the railway track is supported, comprises the following stages: the creation of the foundations - the creation of a system of a series of sleepers as well as rails by means of which the sleepers are held in parallel and at a distance from each other, - the creation of a adjusting installation, the laying of the system by way of the adjusting installation, - the supporting with regard to the foundations, by way of secondary support means, such as spindles, of the system in the position set out by the adjusting installation, - the removal of the adjusting installation, the pouring of a hardenable concrete between the series of sleepers of the system and the foundations, - the hardening of the hardenable concrete in order to create a connection between the sleepers of the system and the foundations, - implementing the pouring and hardening of the hardenable concrete while the sleepers interact with the rails and after the adjusting installation has been removed. An accurate end result can be achieved by the stages of: - removing the rails from the series of sleepers of the system after the concrete has hardened, - thereafter applying continuous rails to the series of sleepers of the system.

Owner:皇家BAM集团公司 +1

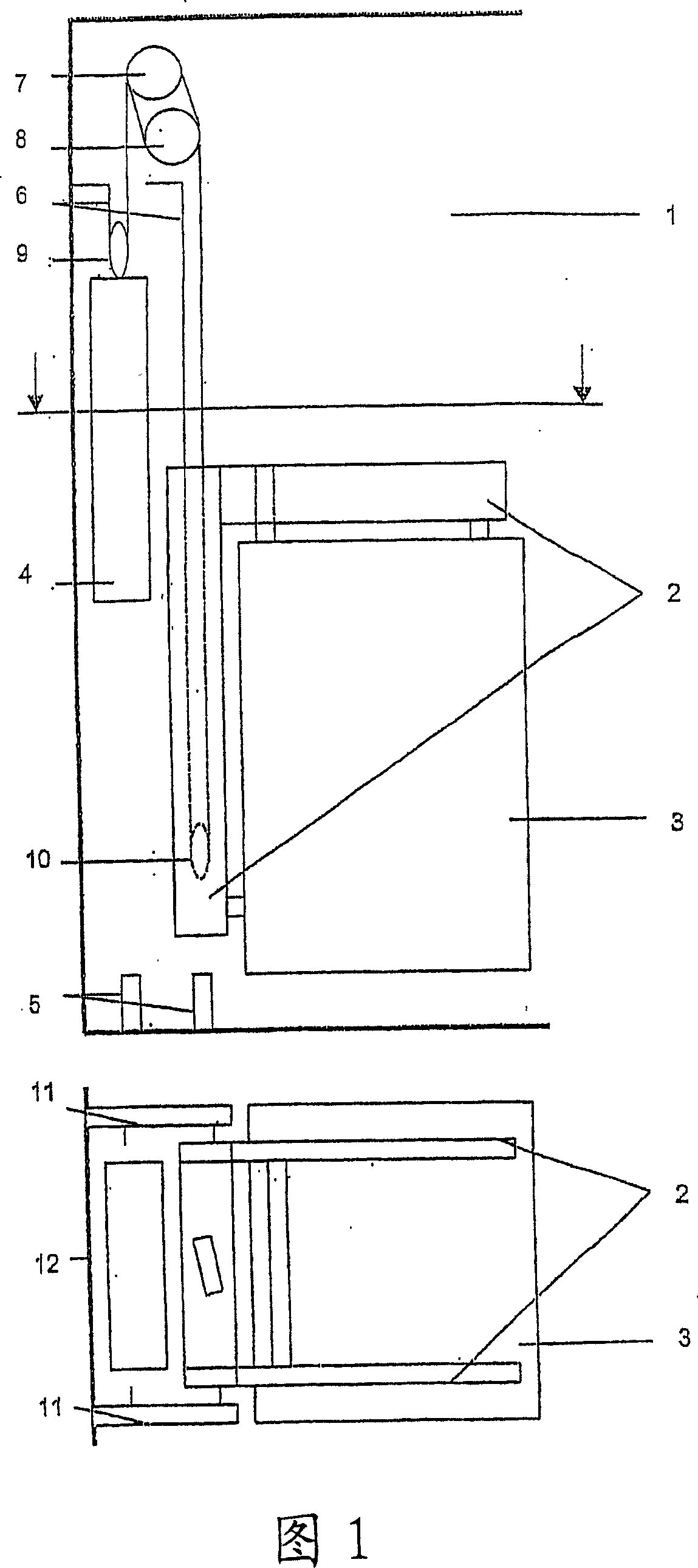

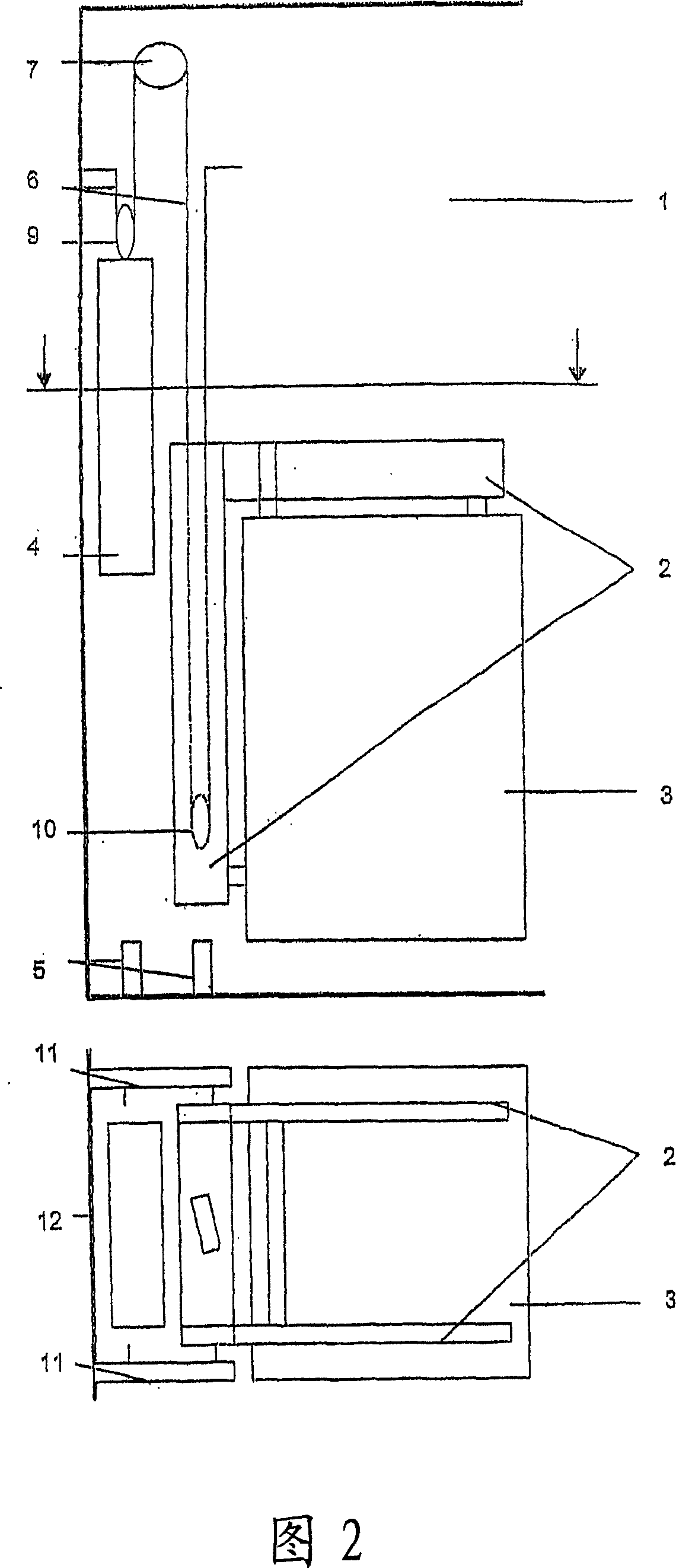

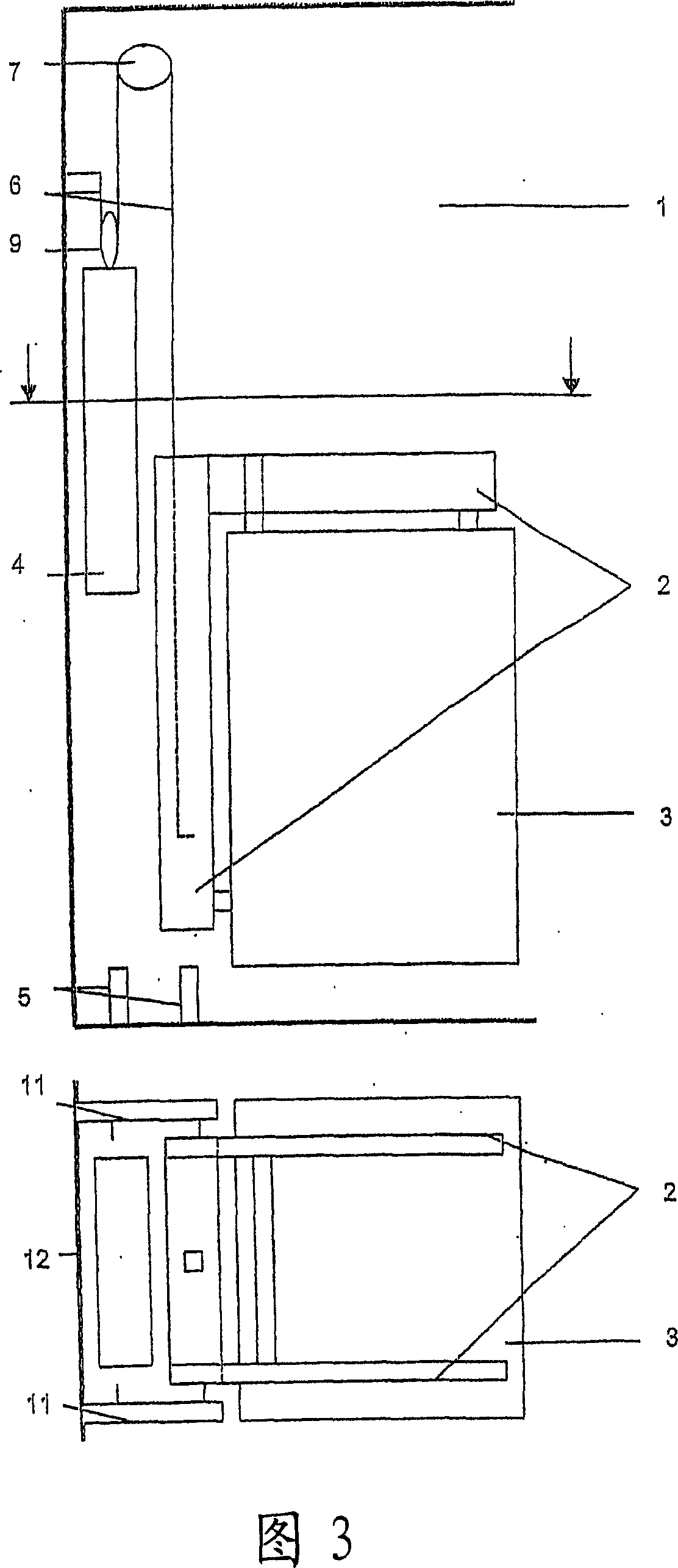

Elevator ('rucksack'-elevator comprising a car suspended on the car frame)

The cabin (3) as well as the counterweight (4) are suspended in a two to one relation and moved by a belt (6) and pulley drive (7,8,9). The carrying frame (2) is assembled of a vertical and a horizontal part, the horizontal part positioned on the roof of the cabin (3). A return pulley (10) attached to the lower end of the vertical part which ends at a distance from the bottom of the cabin (3) saves space underneath the unit. Two shock absorbers (5) are positioned between the bottom of the shaft (1) and the bottom of the cabin (3) when lowered down.

Owner:WITTUR

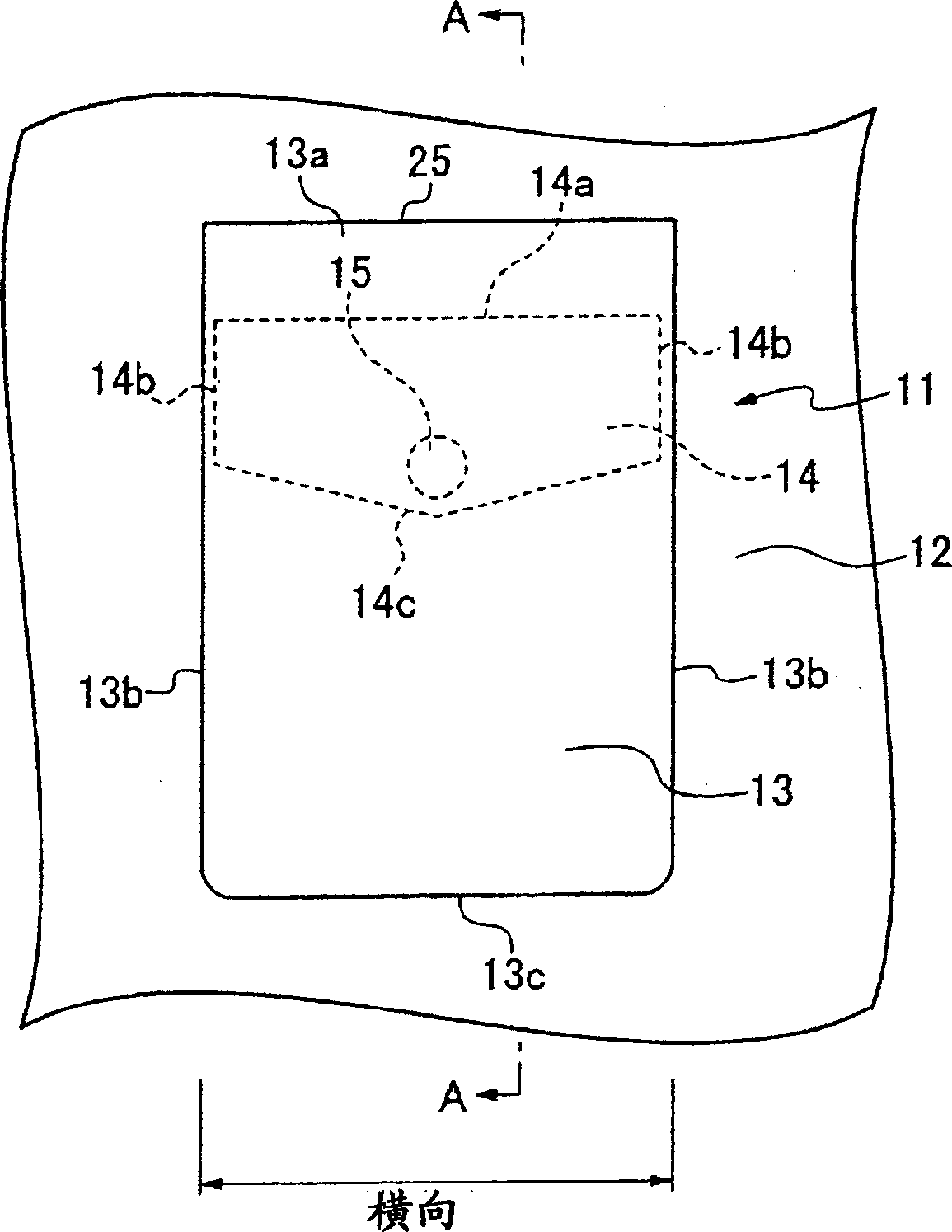

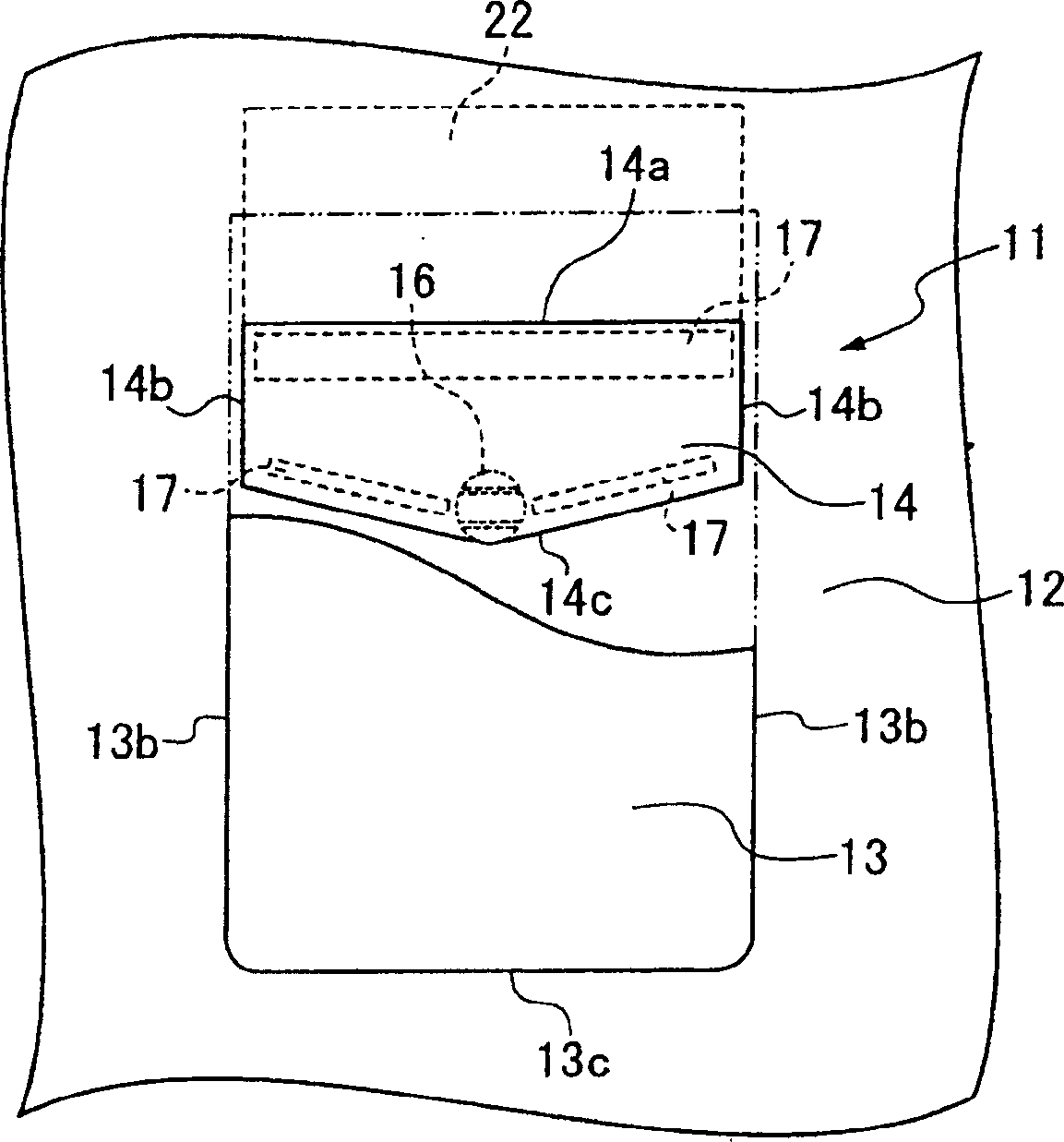

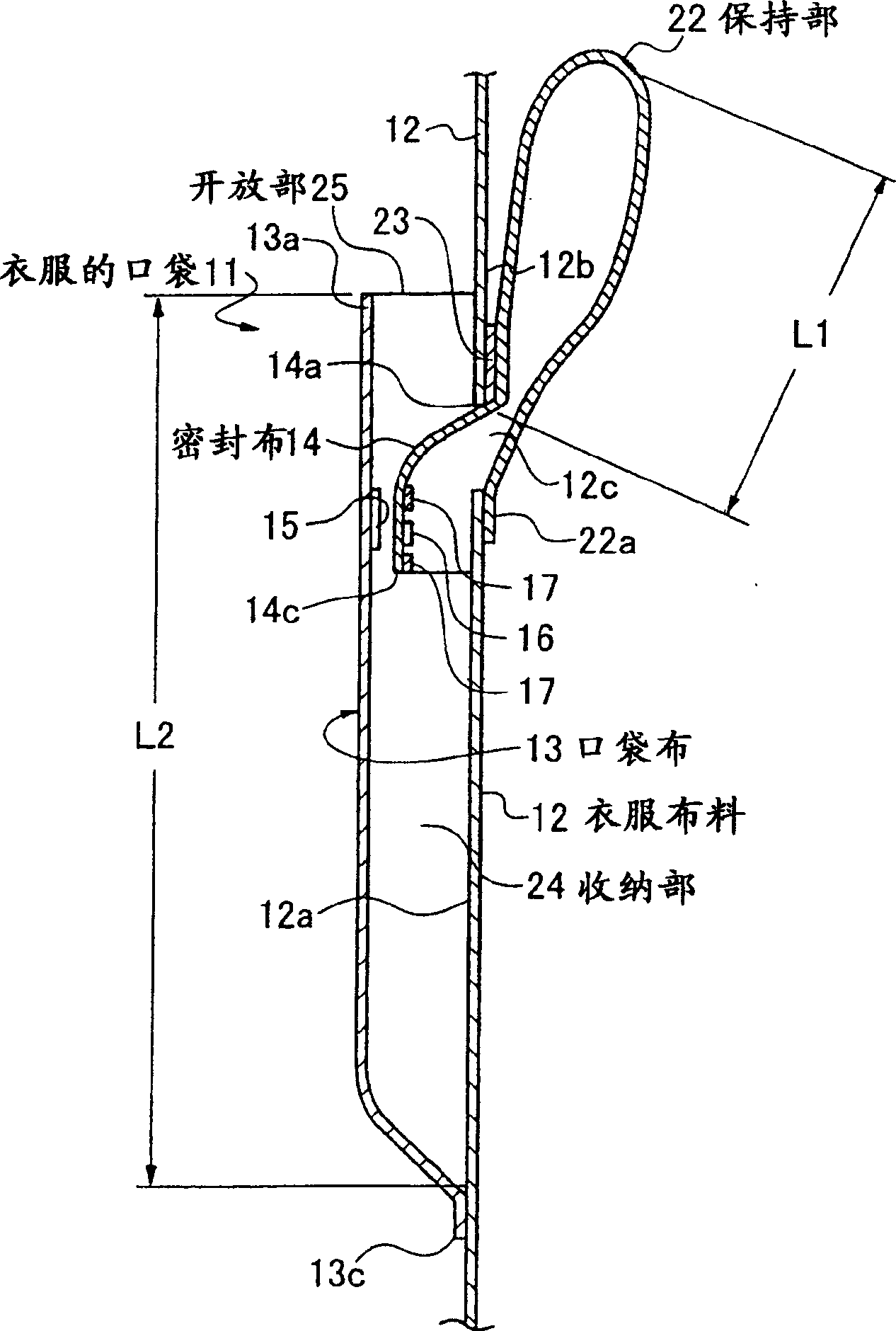

Pocket of clothes

InactiveCN1498559ATake out and put in smoothlyAdsorption is easyGarmentsEngineeringMechanical engineering

Owner:海老原 健三

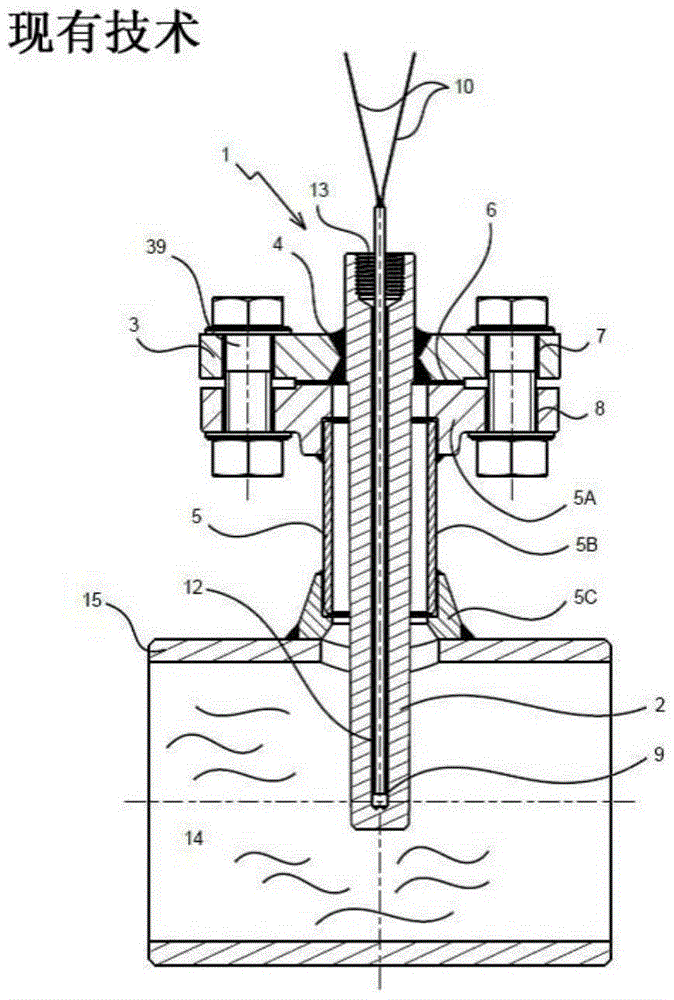

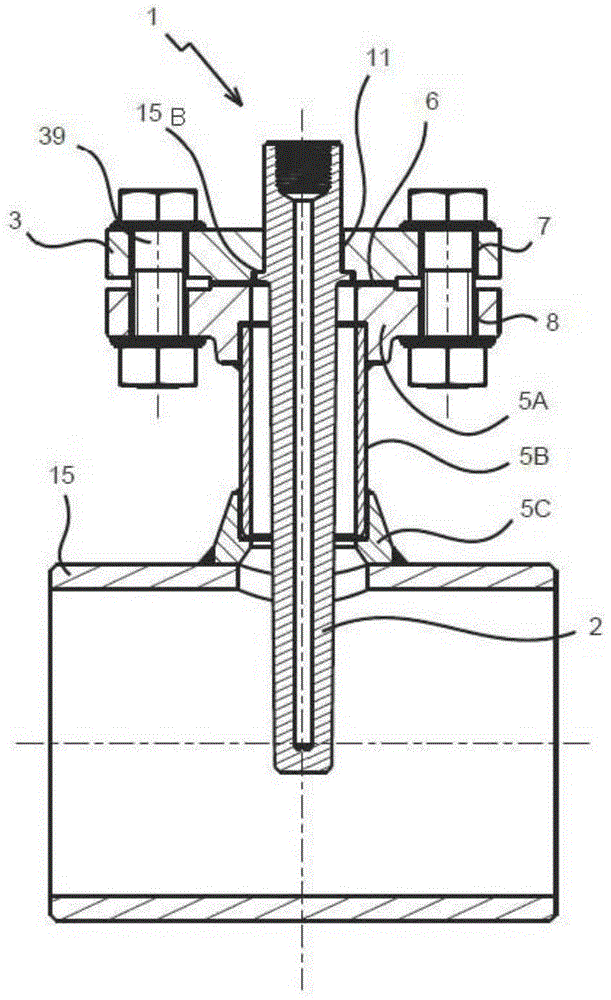

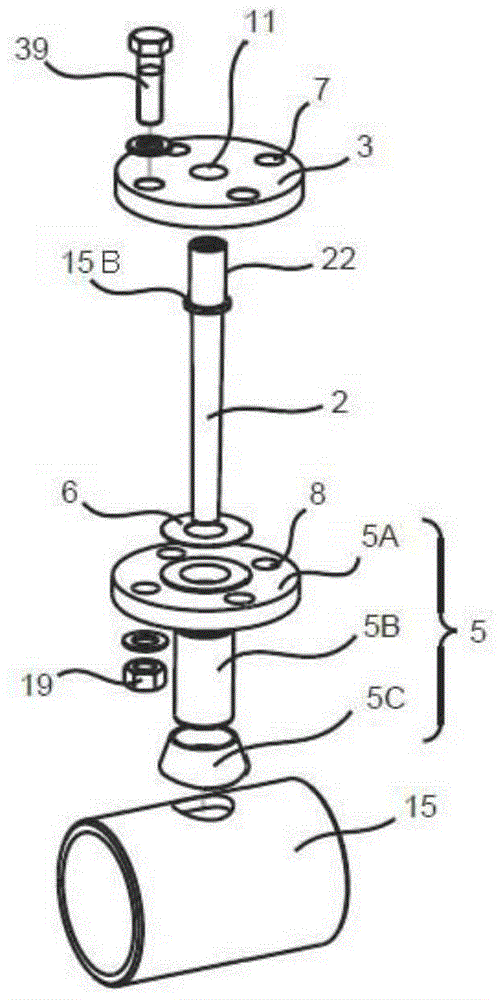

Adapter for measuring a physical variable

InactiveCN105300424AWon't distortReduce complexityThermometer detailsMeasurement apparatus componentsState variableEngineering

An adapter (1) is proposed for measuring a physical state variable of a medium in a system (15) by means of a sensor. The adapter (1) has a descender tube closed towards the medium (2) which can be inserted into the medium through an opening (5) and contains the sensor and a flange plate (3) having a central recess and that can be sealingly connected with a connecting flange (5A). The descender tube (2) is sealingly fitted in the flange plate (3). The sealing fitting of the descender tube (2) in the flange plate (3) results from a temperature difference being established between the descender tube (2) and the flange plate (3), wherein the descender tube (2) is inserted into the flange plate (3), and then temperature equilibrium established between the descender tube (2) and the flange plate (3) in order to obtain a sealing press-fit connection between the descender tube (2) and the flange plate (3). The production of such an adapter is less complex and faster than with welding. Almost any material combinations are possible. Since no welding occurs, the welding procedure test and subsequent post-processing may be dispensed with.

Owner:WIKA ALEXANDER WIEGAND SEANDCO KG

Processing equipment for wood

PendingCN108515591AMeet the needs of machining spiral groovesMeet needsWood mortising machinesBark-zones/chip/dust/waste removalProcess equipmentDrive shaft

The invention relates to processing equipment for wood. The processing equipment comprises a rack, a fixing plate and a driving disc. An air cylinder is fixedly connected to the bottom of the fixing plate, and the driving disc is located below the fixing plate. A piston rod of the air cylinder abuts against the driving disc, and the top of the driving disc is movably connected with a supporting spring. The free end of the supporting spring is fixedly connected to the bottom of the fixing plate, and the driving disc is fixedly connected with a driving shaft coaxially. A first bevel gear is fixedly connected to the driving shaft coaxially, and the eccentric position of the driving disc is connected with a fixing box. An air bag is fixedly connected to the inner wall of the fixing box and communicates with an air guiding pipe. The other end of the air guiding pipe communicates with the air cylinder, and a lead screw is rotationally connected into the fixing box. One end of the lead screwpenetrates through the fixing box and is fixedly connected with a second bevel gear engaged with the first bevel gear coaxially. The lead screw is connected with a nut in a threaded mode, and the bottom of the nut is fixedly connected with a drill bit. A supporting rod is fixedly connected to the top end of the nut, and a telescopic spring is fixedly connected to the supporting rod. The other endof the telescopic spring is fixedly connected with an extruding plate abutting against the air bag. According to the processing equipment, a spiral groove can be formed in the wood.

Owner:重庆木头木脑文化创意有限公司

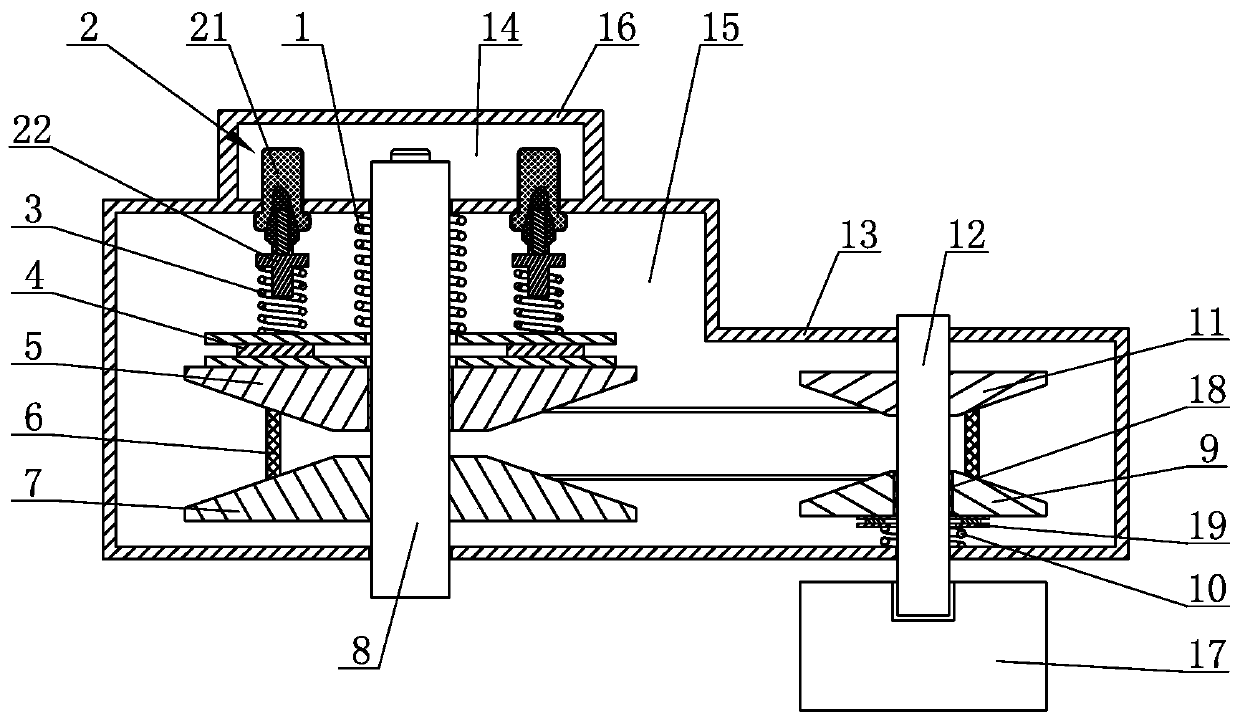

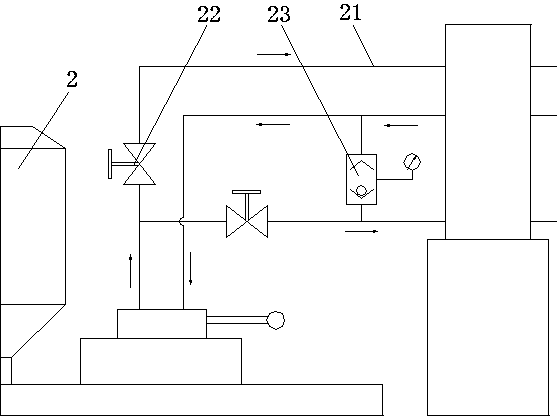

Water pump speed regulating mechanism capable of achieving temperature control over flow

ActiveCN110566336AHeating up fastMeet different working conditionsCoolant flow controlPump controlTemperature controlDrive shaft

The invention discloses a water pump speed regulating mechanism capable of achieving temperature control over flow. The water pump speed regulating mechanism comprises a temperature control chamber and an executing chamber. The temperature control chamber is provided with a temperature executing mechanism. The temperature control chamber is provided with a water inlet, and the executing chamber isprovided with a variable speed executing mechanism. The variable speed executing mechanism is provided with a drive shaft and a driven shaft stretching out of the executing chamber. The drive shaft is a power input shaft, and the driven shaft is a power output shaft. The temperature control executing mechanism stretches into the executing chamber and is connected with the variable speed executingmechanism. The temperature control executing mechanism adjusts the transmission ratio of the variable speed executing mechanism according to the water temperature of the temperature control chamber.When the water return temperature of an engine is low, under the adjustment of the temperature control executing mechanism, the transmission ratio of the variable speed executing mechanism becomes small, flow of a water pump is reduced, the temperature of the engine is increased rapidly, and the water pump can meet different work conditions of the engine.

Owner:WEICHAI HEAVY MACHINERY

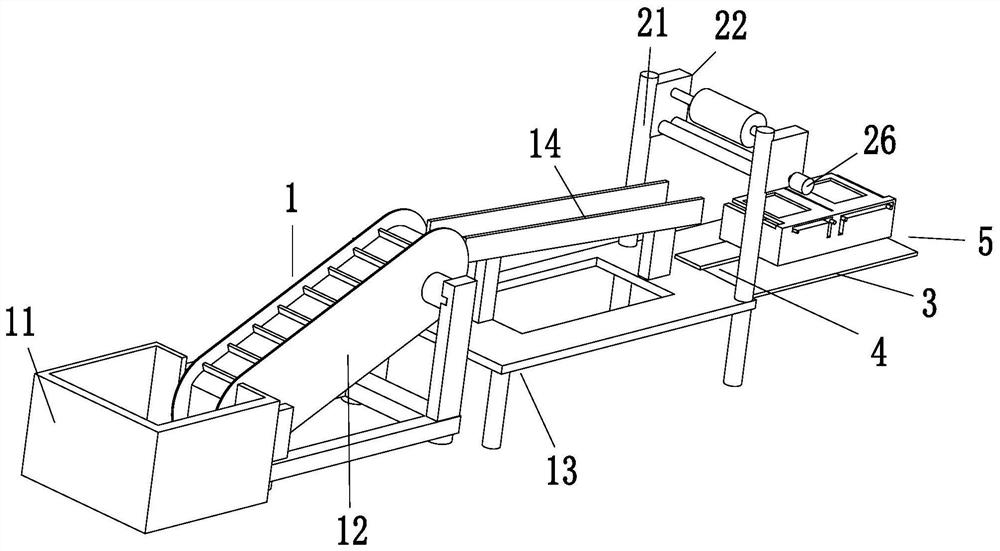

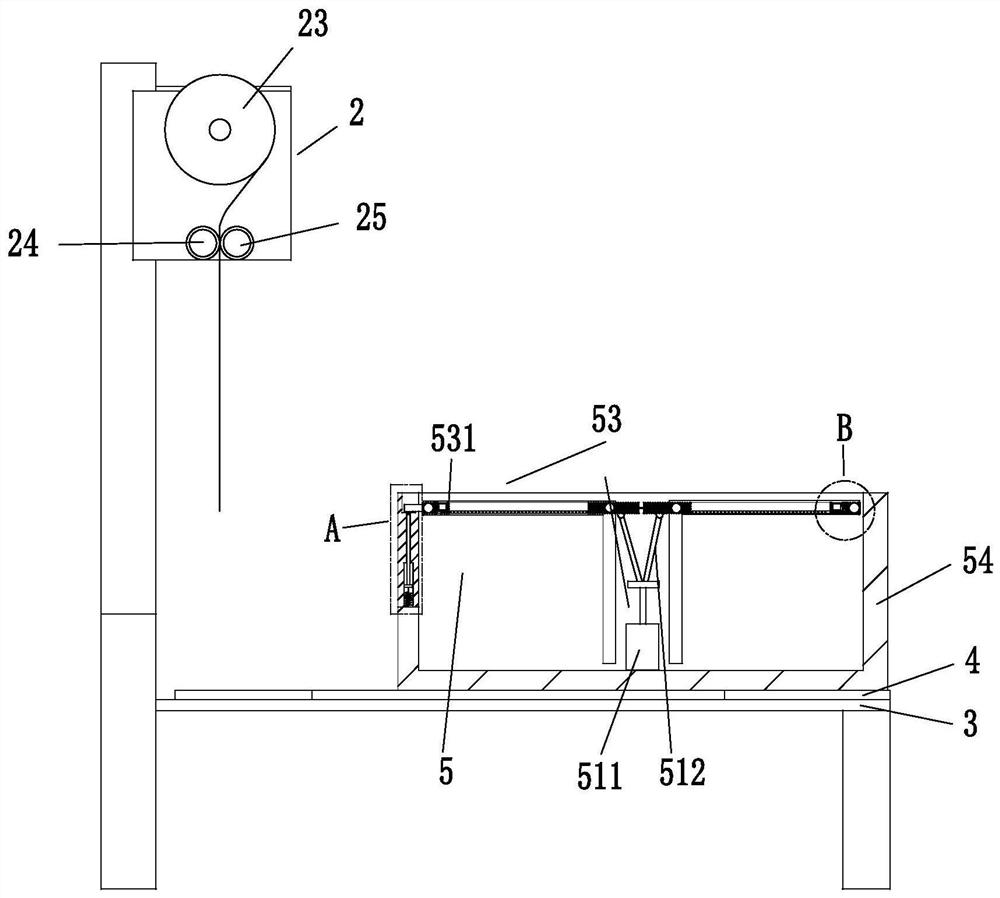

Fruit bagging machine

ActiveCN111703614AReduce breakage rateImprove efficiencyWrapping material feeding apparatusWrapper twisting/gatheringManufacturing engineeringMechanical engineering

The invention relates to a fruit bagging machine. The fruit bagging machine includes a conveying device, a winding device, a supporting plate, an electric sliding block and a packaging device; the winding device is installed at the upper right end of the conveying device; the supporting plate is installed at the right end of the conveying device; the electric sliding block is installed on the supporting plate; and the packaging device is installed on the electric sliding block. When a fruit bagging machine in the prior art is used for packaging, the bag is required to be manually opened in advance for preparation, and when the fruit falls into the bag, manual sealing is required, and the tightness of the seal cannot be guaranteed, which is very time-consuming and labor-consuming; and whenthe fruit bagging machine in the prior art is used for packaging, the packaging bag can be broken due to the impact of the fruit falling into the bag, which results in low packaging efficiency, thereby resulting in certain economic losses; and the invention solves the above problems.

Owner:徐州市威尔玛科技有限公司

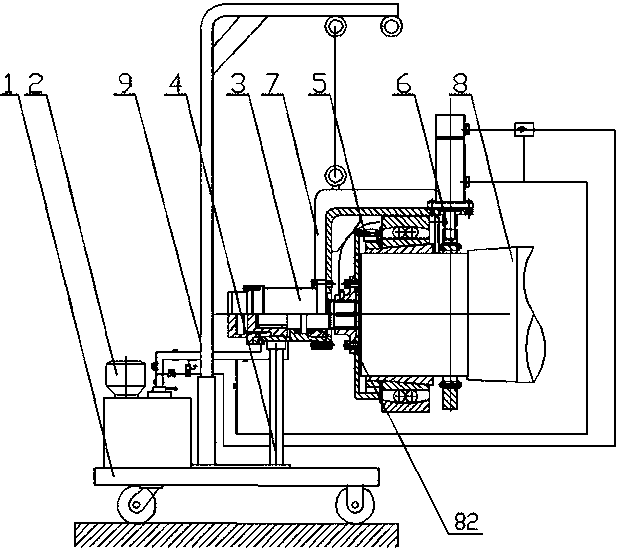

Bearing assembly dismounting and mounting tool

The invention relates to the field of large equipment maintenance, in particular to a bearing assembly dismounting tool. A bearing assembly dismounting and mounting tool comprises a movable platform,a power source, a driving device, a bracket assembly, a chuck connection assembly and a shaft neck clamping assembly; and a structural frame is fixedly mounted on a shell of the driving device and provided with a first positioning face and a second positioning face, the chuck connection assembly is mounted on the first positioning face, the shaft neck clamping assembly is mounted on the second positioning face, thus when the shaft neck clamping assembly clamps a main shaft of a bearing assembly, the axis of the chuck connection assembly is parallel with the axis of the main shaft. According tothe bearing assembly dismounting tool, even force bearing can be achieved in the dismounting and mounting processes of a bearing, it can be ensured that the bearing is not damaged during adjusting and an adapter sleeve is not distorted during mounting and dismounting, the pre-tightening force of a pressure system can further be controlled precisely, the quality precision of mounting and dismounting of the bearing assembly can be ensured and improved to the maximum extent, and the bearing assembly dismounting tool has the advantages that potential safety hazards are eliminated, the overhaulingtime is shortened, the overhauling quality is ensured, and the working efficiency is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

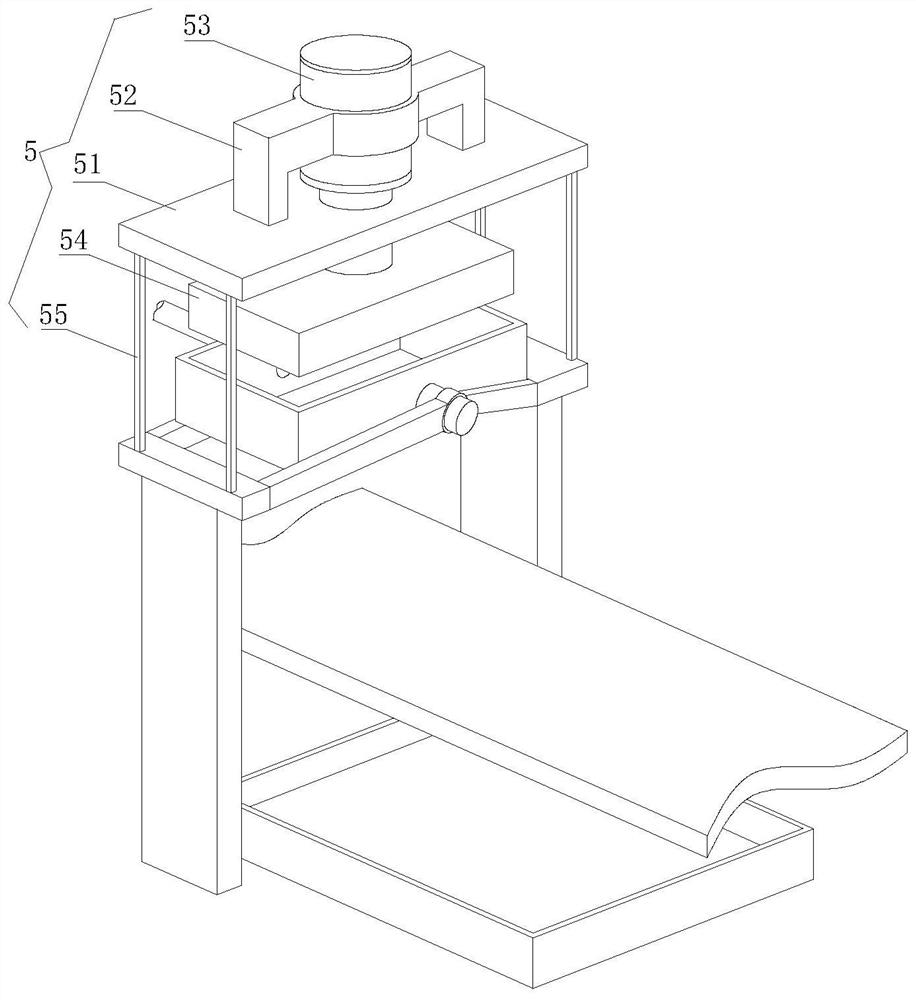

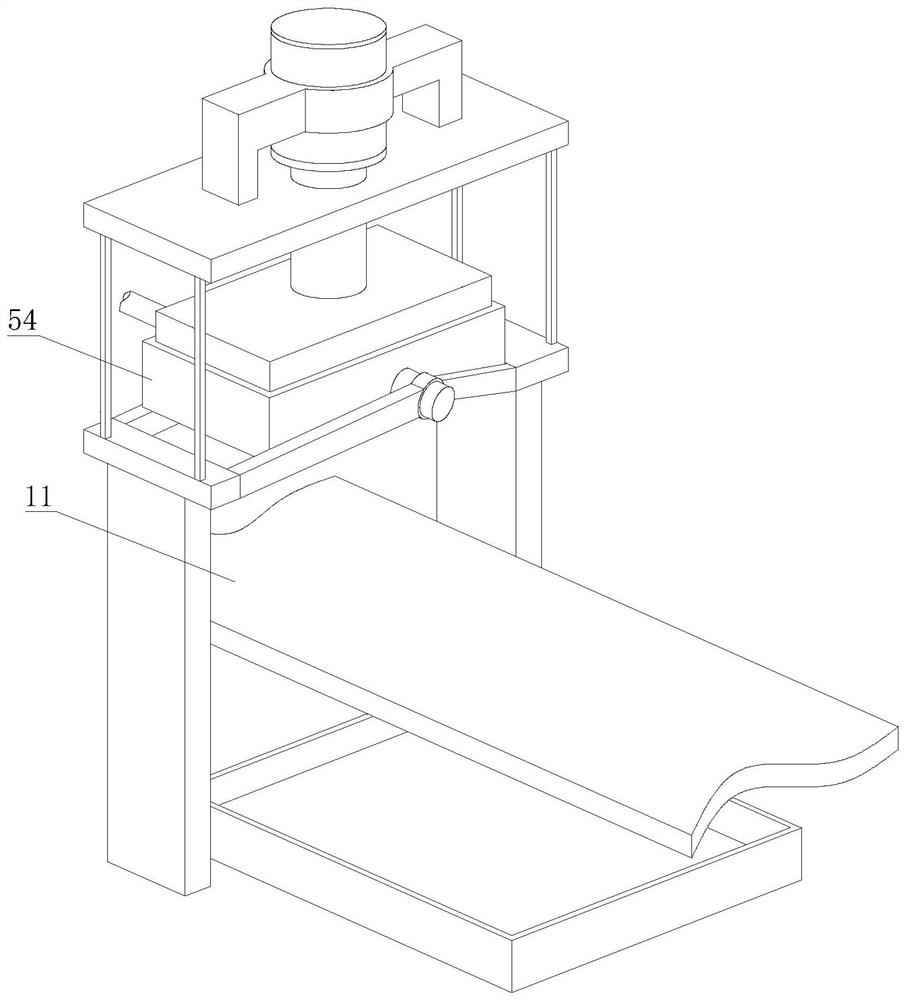

Adobe block rapid forming device for vegetable breeding and implementation method of adobe block rapid forming device

The invention discloses an adobe block rapid forming device for vegetable breeding and an implementation method of the adobe block rapid forming device, and belongs to the technical field of adobe block forming. The adobe block rapid forming device comprises a conveying frame, a sucking pump for sucking mud-water mixtures and a box body for storing mud and water. A conveying belt connected to theconveying frame transversely penetrates through a rack, a forming mechanism, a rotary discharging mechanism and a feeding mechanism are mounted on the rack, the feeding mechanism is connected with therotary discharging mechanism, and the mud-water mixtures sucked by the sucking pump through negative pressure are discharged into the rotary discharging mechanism. According to the adobe block rapidforming device for vegetable breeding and the implementation method of the adobe block rapid forming device, the forming mechanism is arranged above the rotary discharging mechanism and telescopicallyextrudes the mud-water mixtures to form adobe blocks, the rotary discharging mechanism is movably connected with the rack, the rotary discharging mechanism is driven by an external motor to rotate, the adobe blocks fall onto the conveying belt to be transferred, mud and water are extruded through the forming mechanism, the adobe blocks are discharged through cooperation with the rotary discharging mechanism, and finally the adobe blocks are conveyed away by the conveying belt to complete overall rapid forming.

Owner:HEXIAN DESHENG AGRI DEV CO LTD

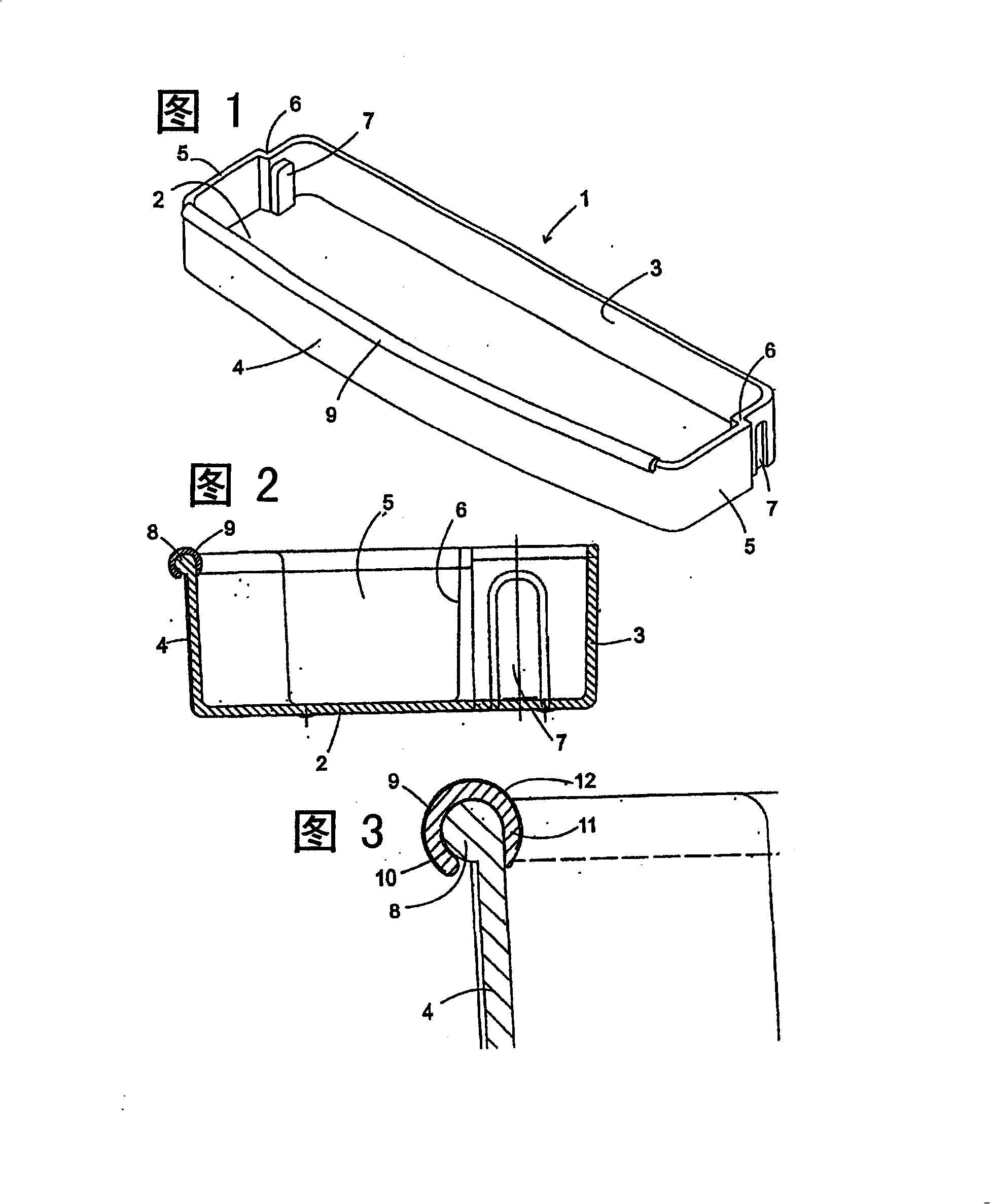

Refrigerator having a compartment for accommodating articles that are to be cooled

ActiveCN100432596CProtection from damageWon't distortLighting and heating apparatusCooling fluid circulationMechanical engineeringRefrigerated temperature

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Thermal compounded steel-aluminum compounded conductive rail and manufacturing method

The invention relates to a heat-composite steel-aluminum composite conductive rail and a manufacturing method thereof, belonging to equipment for supplying power to the third rail of urban rail transit. It mainly adopts steel side knurling, and the inner side of the two lugs of the corresponding aluminum rail has wavy intersecting ribs and grooves. It is heated in the uniform temperature tube of the tunnel kiln, and multiple pairs are arranged in the middle of the steel-aluminum composite production line. After the special burner is used to control the aluminum lugs to be in a superplastic deformation state, 4 pairs of upper, lower, left, and right pressure wheels of the production line exert force to make the lugs rotate and move inward, and the protruding ribs of the lugs are squeezed into the knurls on the side of the stainless steel In the tank, the thermal compounding of steel and aluminum is completed, followed by T6 heat treatment and aging treatment, so that the steel-aluminum composite conductive rail has low resistance, high strength, small contact resistance, high-speed production and high yield.

Owner:李雷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com