Method for forming magnetic tunnel junction through patterning quad-layer mask

A magnetic tunnel junction and mask pattern technology, applied in the manufacture/processing of electromagnetic devices, etc., can solve the problems of unclear outline masks, affecting MTJ patterns, and difficulty in forming clear and sharp side walls, so as to eliminate consumption and improve Effect of patterns and contours, reducing the risk of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

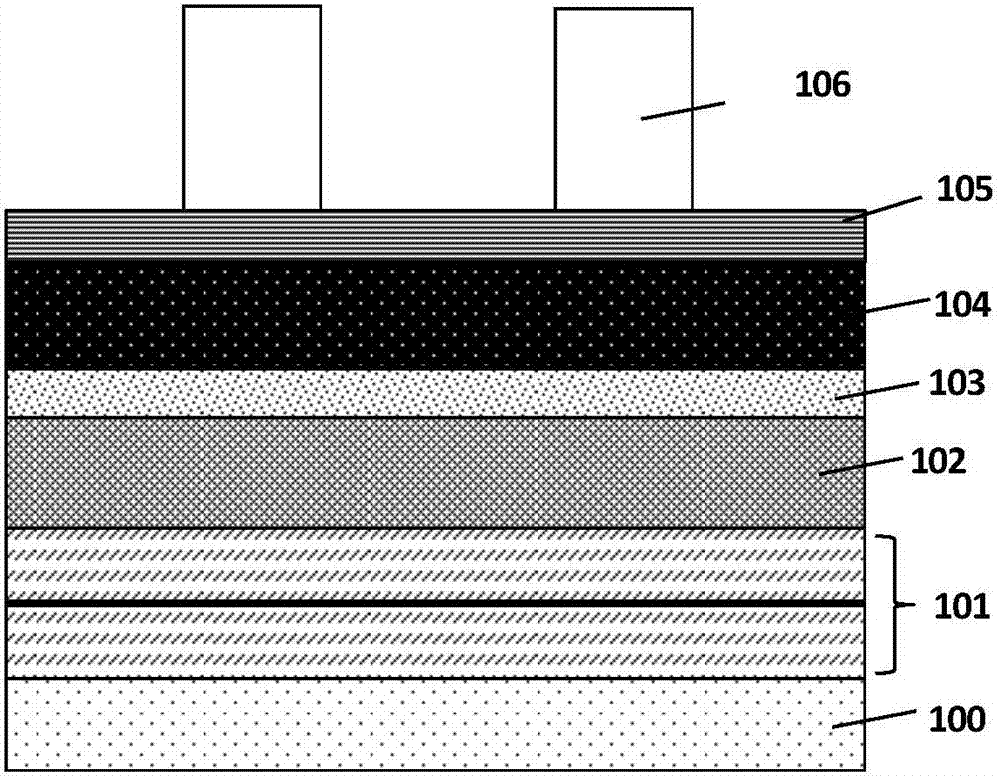

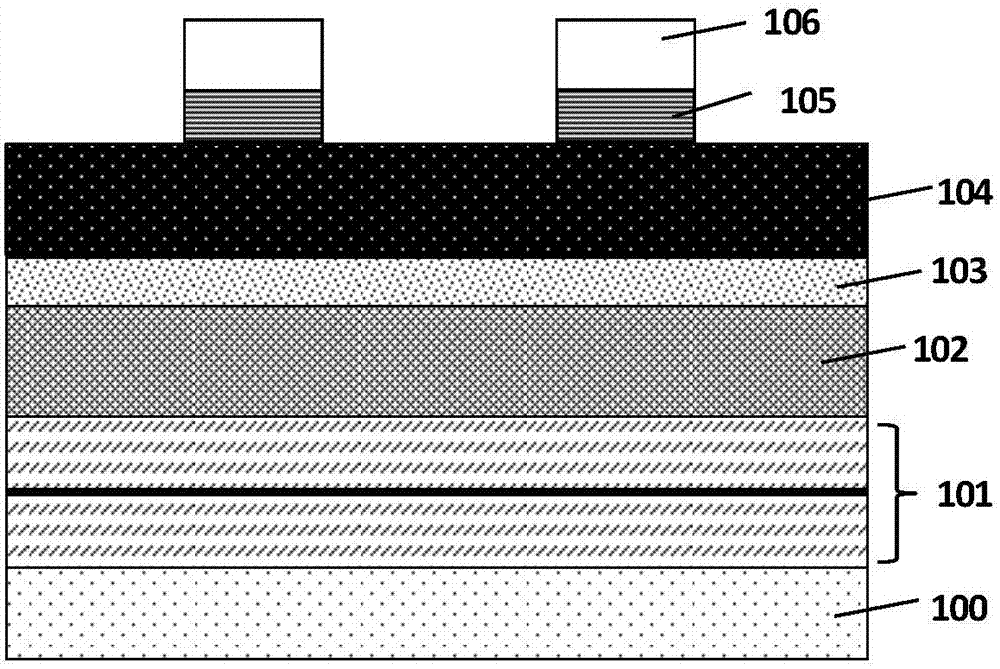

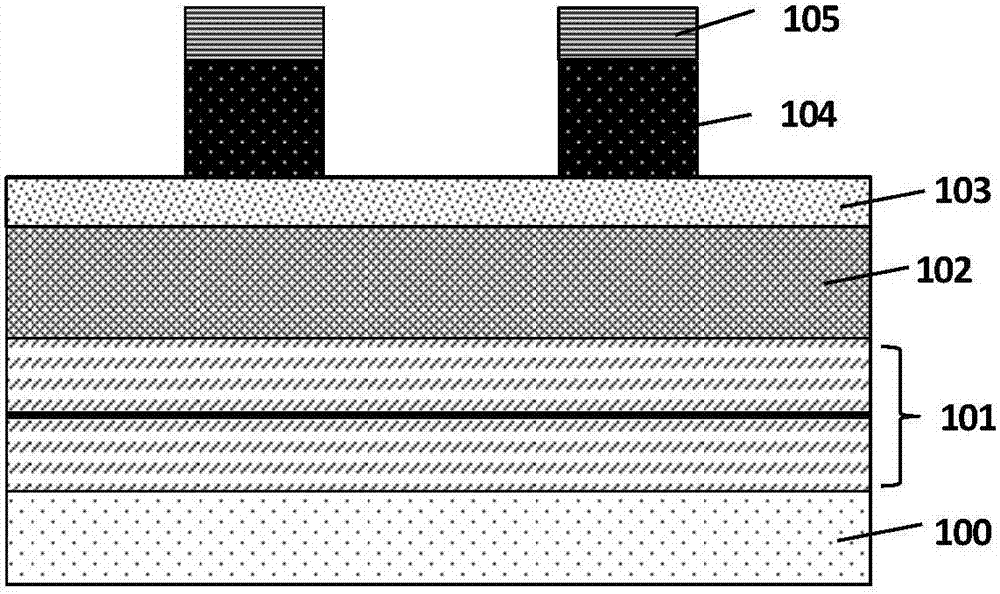

[0051] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the drawings of the present invention all adopt a simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

[0052] A four-layer mask patterning method for MTJ, including but not limited to the preparation of magnetic random access memory (MRAM), nor any process sequence or flow, as long as the prepared product or device is prepared with the following preferred process sequence or flow Same or similar. The method includes:

[0053] Step 1: Form MTJ film layer unit on the substrate;

[0054] Step two, forming a QLM film unit on the MTJ film unit;

[0055] Step 3: Form a photoresist (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com