Adobe block rapid forming device for vegetable breeding and implementation method of adobe block rapid forming device

A molding device and adobe technology, which is applied in the field of rapid prototyping devices for adobe blocks for vegetable breeding, can solve the problems of low work efficiency, irregular overall molding, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

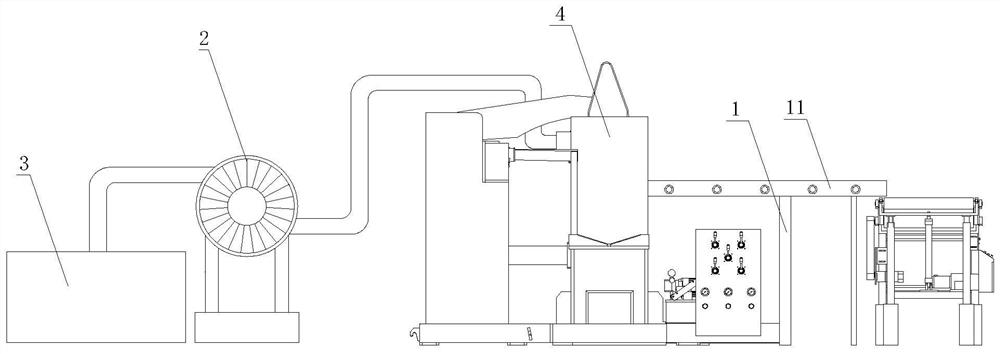

Method used

Image

Examples

Embodiment approach

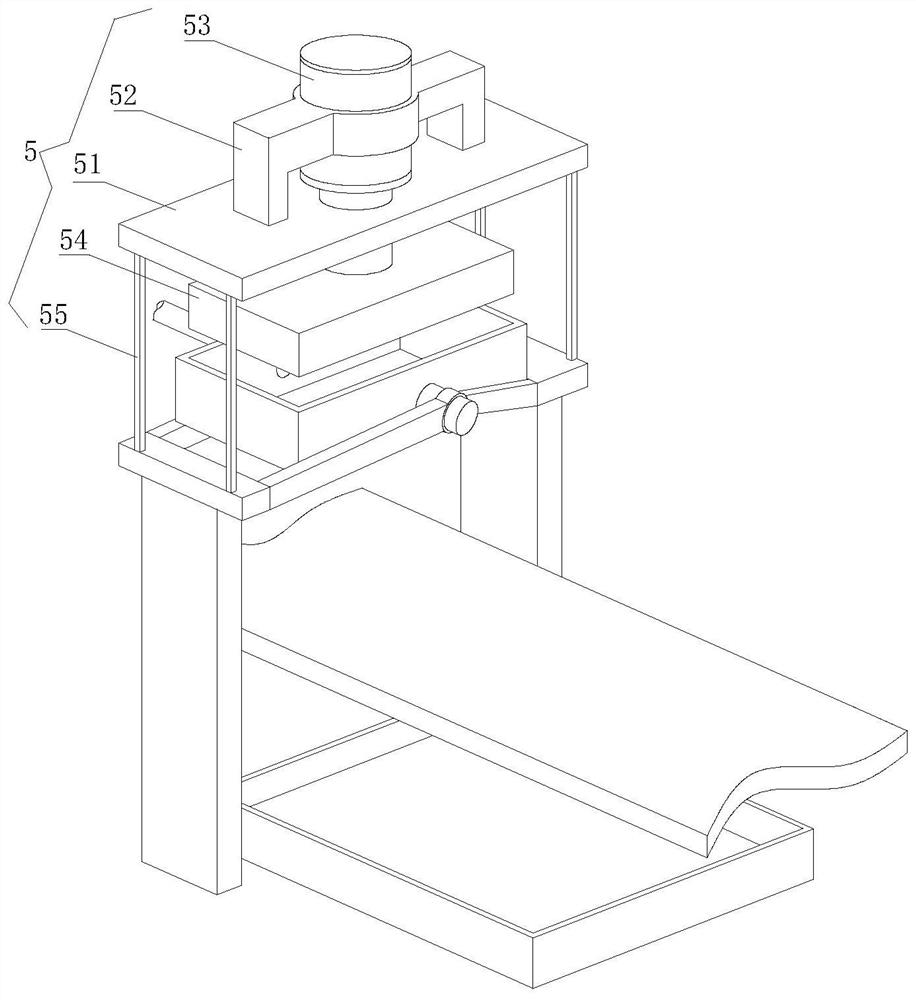

[0032] In order to better demonstrate the adobe block forming method, this implementation proposes an implementation method of the adobe block rapid prototyping device for vegetable breeding, including the following steps:

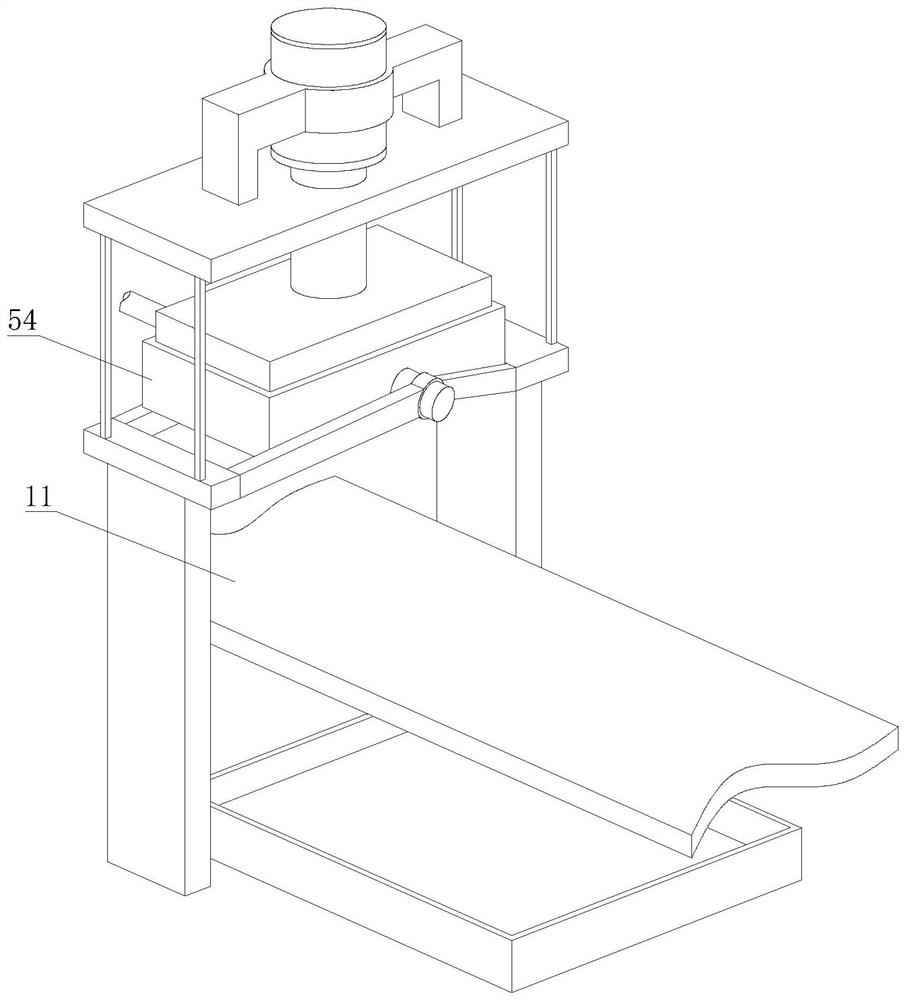

[0033] Step 1: The motor drives the lower shell 63 to rotate to a horizontal position, and the opening faces the pressure plate 54, and the pump 2 works to extract the muddy water mixture in the box body 3 and discharge it into the lower shell 63 through the sealing tube 72;

[0034] Step 2: The liquid level of the mud-water mixture in the lower shell 63 is not higher than that of the lower shell 63. The cylinder 53 drives the pressure plate 54 down and inserts it into the lower shell 63, and acts on the mud-water mixture to squeeze out the internal moisture and simultaneously squeeze it into a adobe block;

[0035] Step 3: After the extrusion is completed, the cylinder 53 drives the pressure plate 54 to separate from the lower shell 63 and rise to the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com