Water pump speed regulating mechanism capable of achieving temperature control over flow

An automatic temperature control and speed regulating mechanism technology, which is applied in the control of coolant flow, engine components, machines/engines, etc., can solve the problems of large flow loss, small adjustment range, and fast flow speed, and achieve accurate control of return water temperature , high speed control precision, precise speed adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

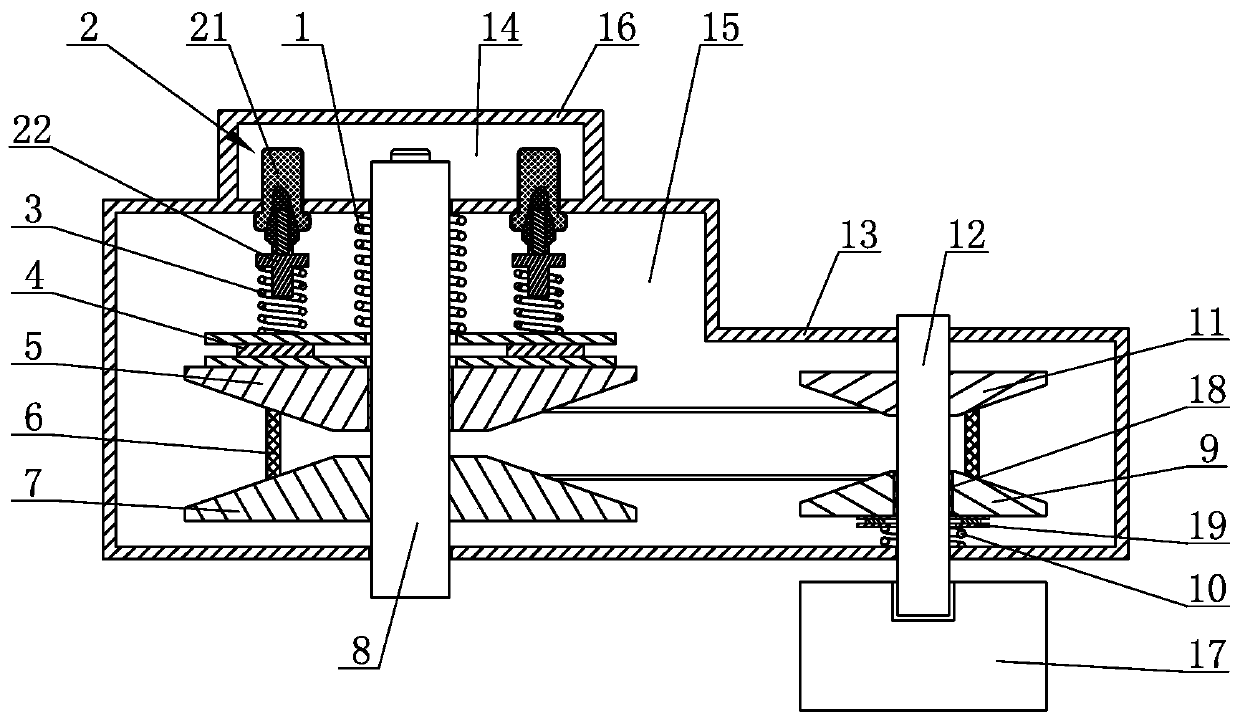

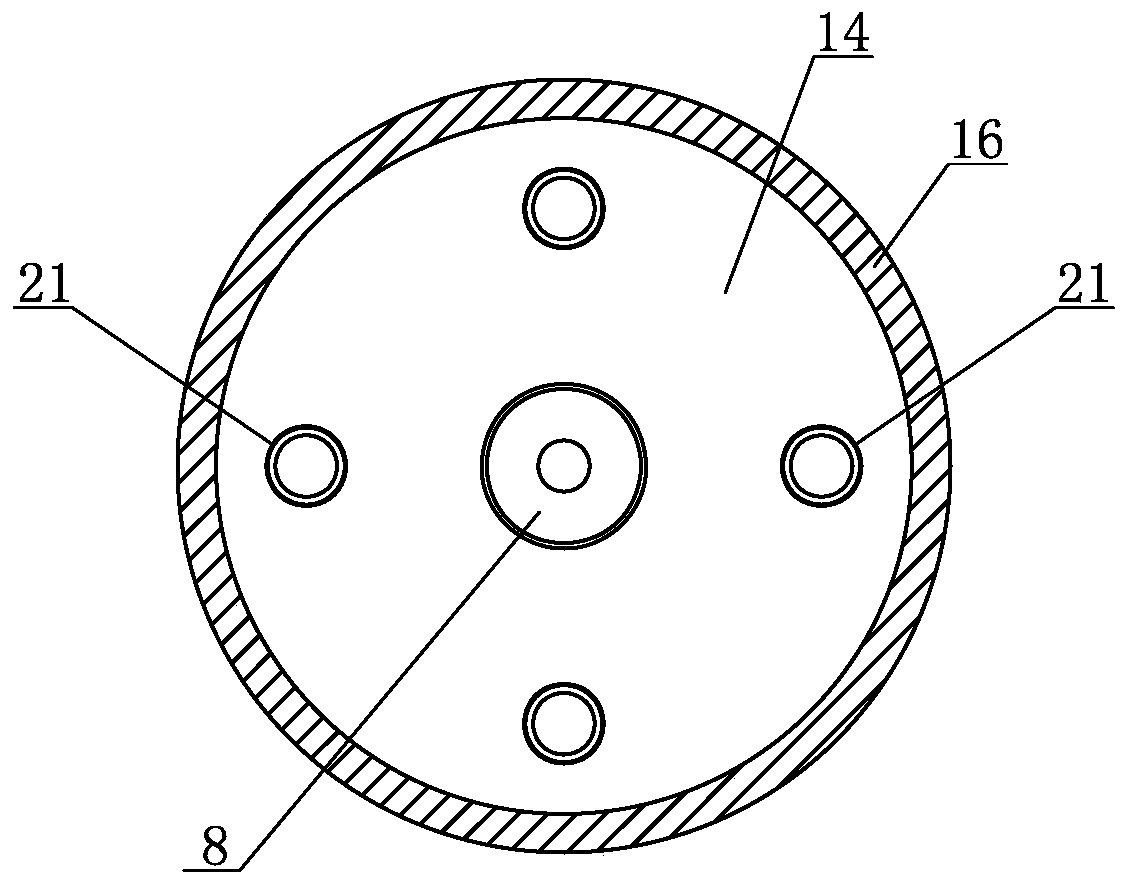

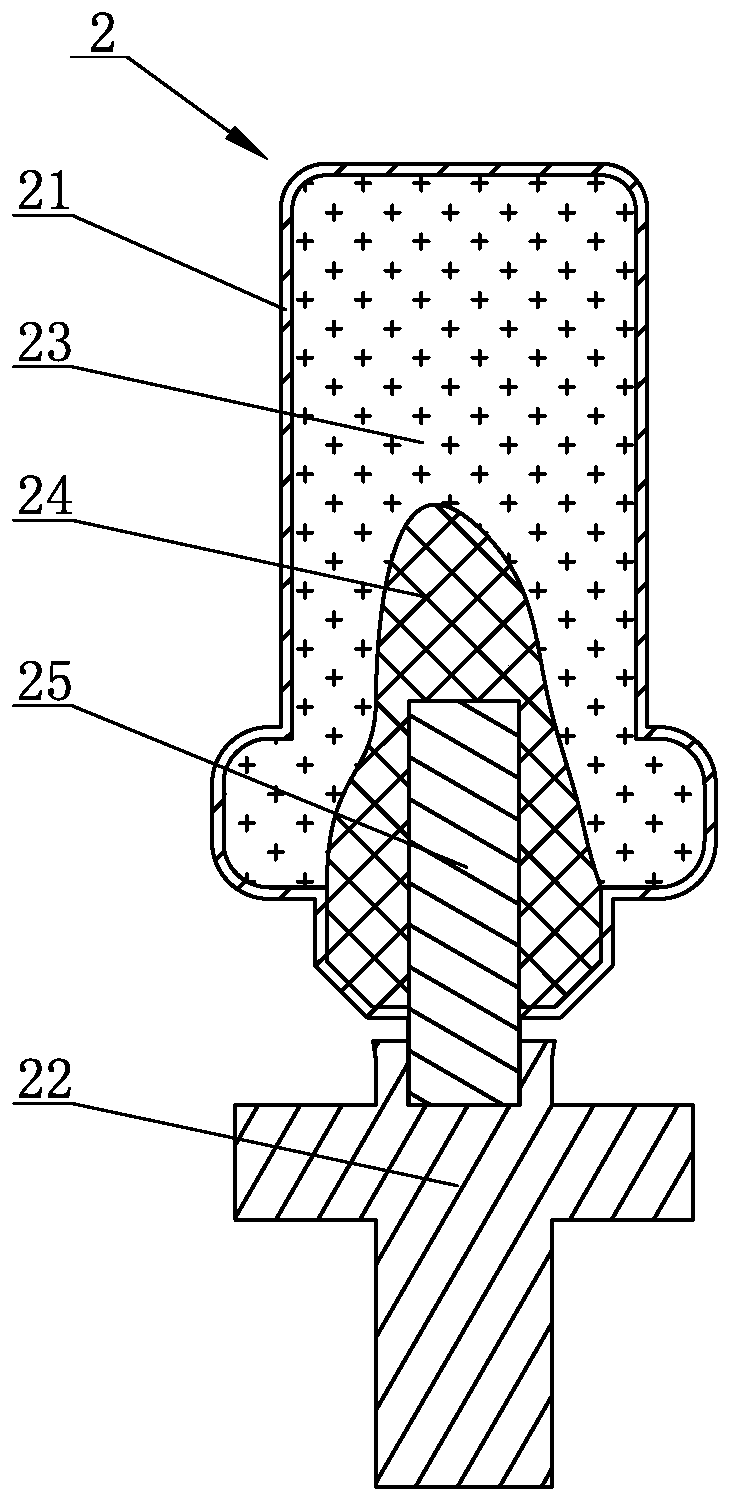

[0035] Such as figure 1 As shown, a water pump speed regulating mechanism with automatic temperature control flow includes: the execution chamber 15 surrounded by the execution chamber casing 13 and the temperature control chamber 14 surrounded by the temperature control chamber casing 16, the execution chamber casing 13 It is fixedly connected with the temperature control chamber housing 16, the temperature control chamber 14 is located on one side of the execution chamber 15, the temperature control chamber 14 is connected with the return water before the engine thermostat, and the water inlet of the temperature control chamber 14 is set in the temperature control chamber The housing 16 , or the driving shaft 8 is hollowly provided with a water inlet channel, and the water inlet channel communicates with the temperature control chamber 14 .

[0036] The execution room 15 is provided with a variable speed actuator, the variable speed actuator is a belt transmission mechanism ...

Embodiment 2

[0053] The structure of the second embodiment is basically the same as that of the first embodiment, the only difference is that the temperature control actuator 2 is arranged on one side of the driven moving cone 9, and a The active adjustment spring is not shown in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com