Plate edge grinding device for machining

A technology for machining and sheet metal, applied in the field of sheet edging devices for machining, can solve the problem that the edging device cannot adjust the position and angle of grinding, and achieve the effects of improving convenience, increasing bearing capacity and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

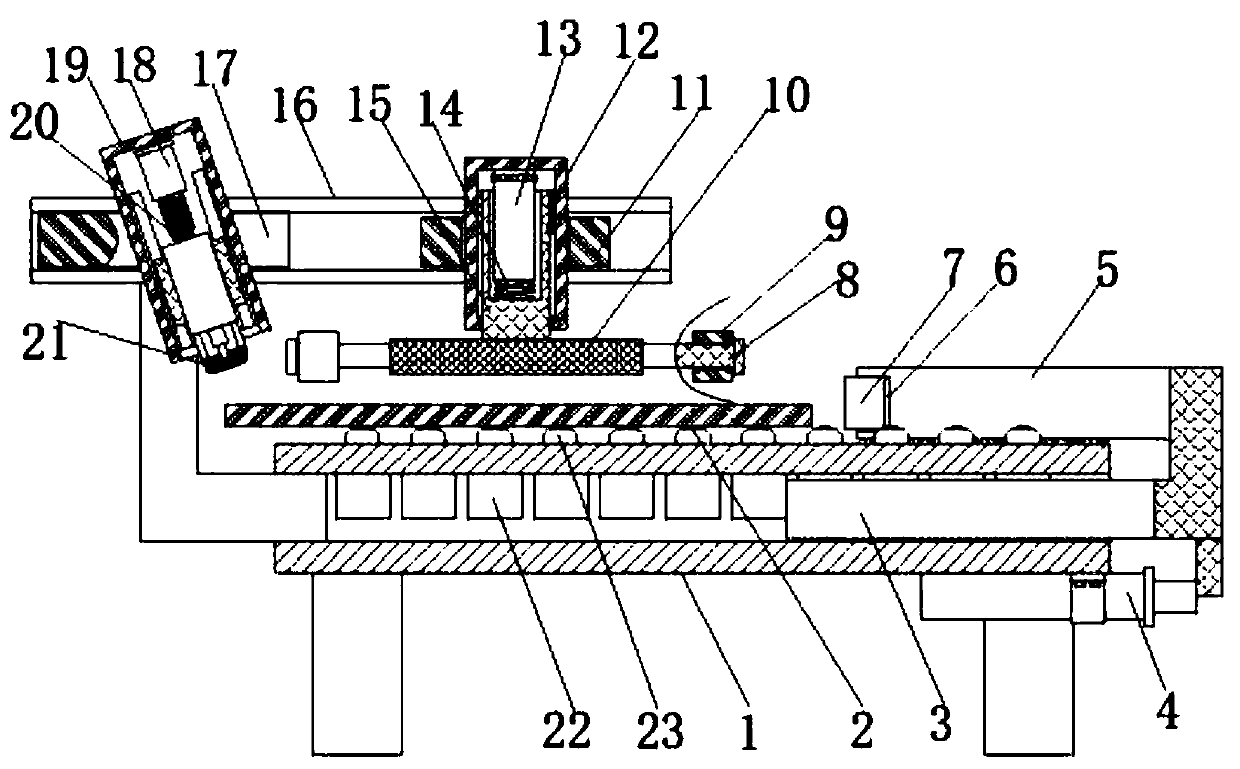

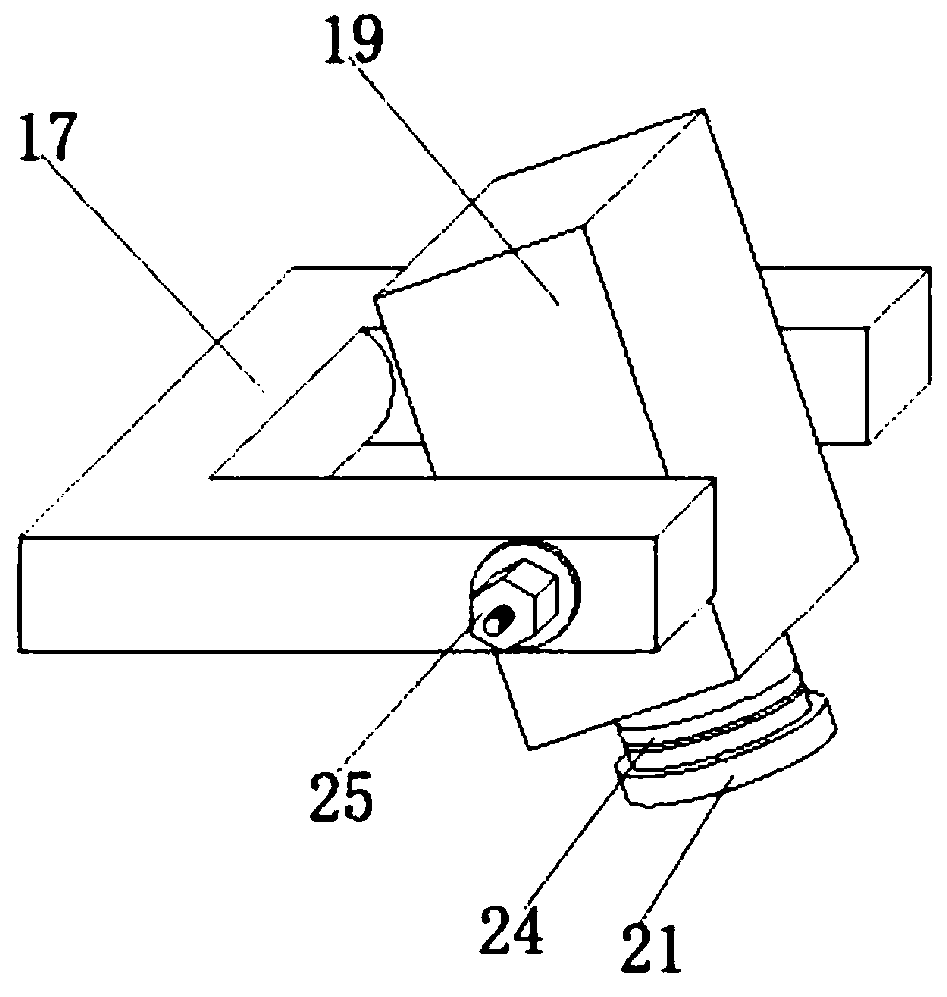

[0029] refer to Figure 1-5 , a plate edging device for mechanical processing, including a base 1 with a cavity in a flat square tube structure, one end of the base 1 is inserted with two mutually symmetrical L-shaped support frames, and the two L-shaped support frames Two channel-steel crossbeams 16 with opposite openings and parallel to each other are fixed on the top of the top, and C-shaped clamping blocks 17 and rectangular fixed frames 11 are respectively clamped between the two channel-steel beams 16 near the two ends. The middle of the C-shaped clamping block 17 A motor box 19 with an opening downward is clamped, and coaxially distributed elongated studs are respectively fixed on the opposite side outer walls of the motor box 19, and the outer walls of the studs are screwed with fastening bolts. When the angle of the motor box 19 is adjusted Can be screwed fastening bolt afterwards and motor case 19 is clamped, to fix the inclination angle of motor case 19, the inside ...

Embodiment 2

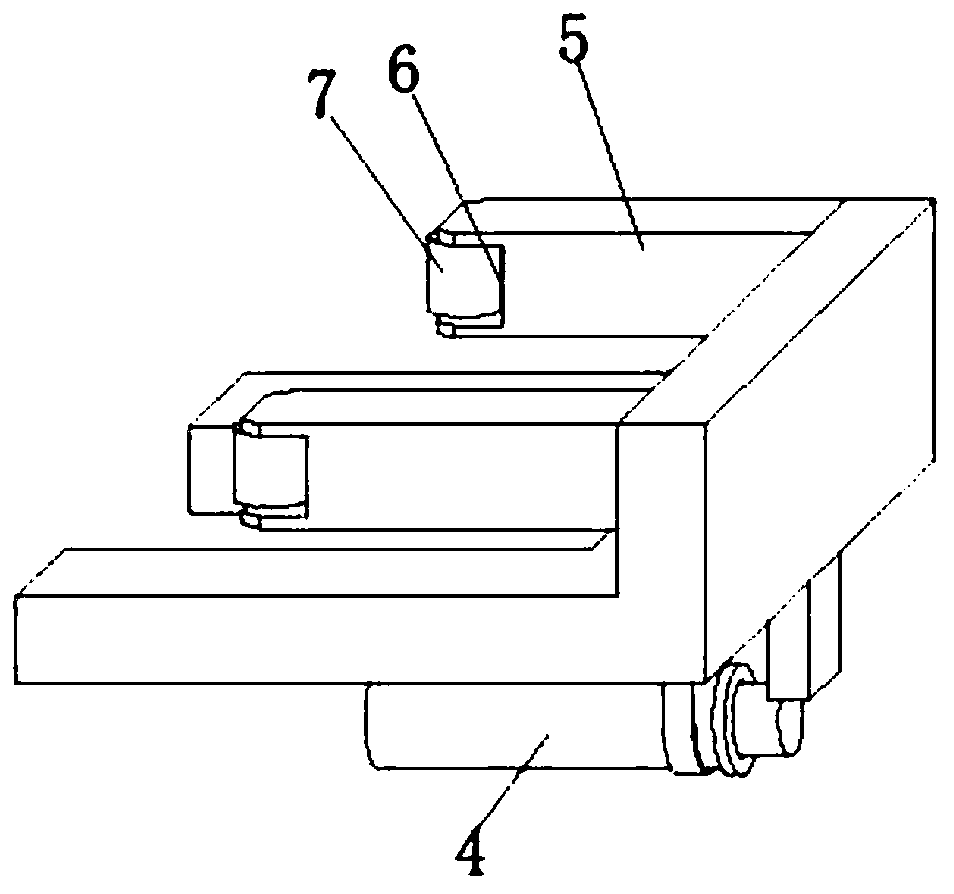

[0037] refer to figure 1 with image 3 , a plate edging device for mechanical processing. Compared with Embodiment 1, this embodiment also includes that the end of the bottom end of the base 1 away from the L-shaped support frame is fixed with a telescopic rod 4 by bolts, and the extension rod of the telescopic rod 4 is The end is fixed with a push block.

[0038] Wherein, one end of the base 1 close to the telescopic rod 4 is slidably connected with an L-shaped sliding plate 3 , and the side of the vertical plate of the L-shaped sliding plate 3 near the middle of the base 1 is fixed with two resisting rods 5 .

[0039] Wherein, gaps 6 are formed at the ends of the two resisting rods 5 away from the L-shaped sliding plate 3 , and rollers 7 are arranged in the gaps 6 .

[0040] Working principle: When in use, it can hold the edge of the plate body away from the grinding side tightly, and change the sliding friction into rolling friction, which plays a good guiding role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com