Mattress integrated stone bed

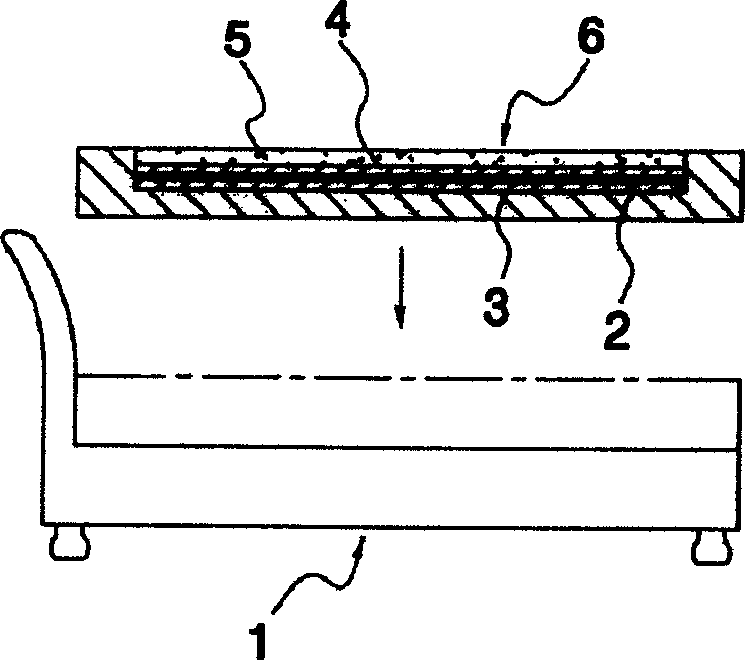

A one-piece, mattress technology, applied to beds, other seating furniture, sofas, etc., can solve the problems of increased thickness of decorative covering materials, lower bed quality, etc., and achieve reduced material consumption, high thermal conductivity, and low specific gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

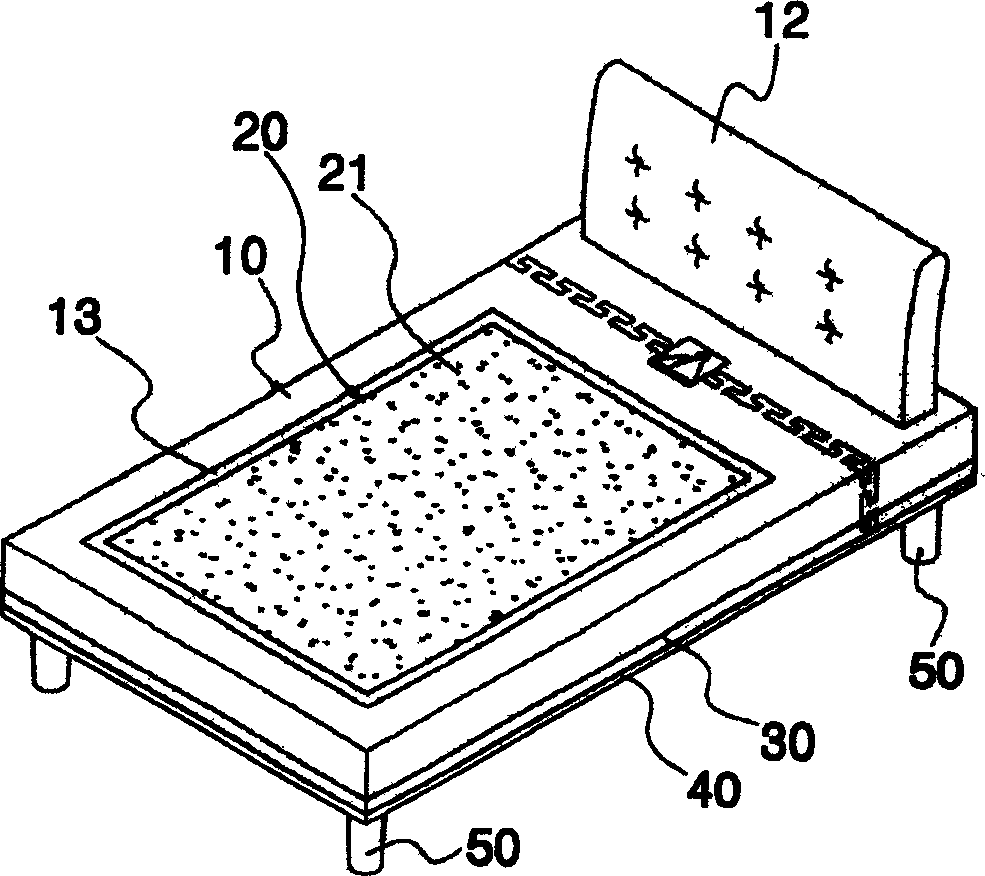

[0038] Such as figure 2 As shown, the integrated stone bed for mattresses according to the first embodiment of the present invention includes a mattress body 10 , a laminated assembly 20 , a tight support plate 30 , a bracket 40 and a plurality of legs 50 .

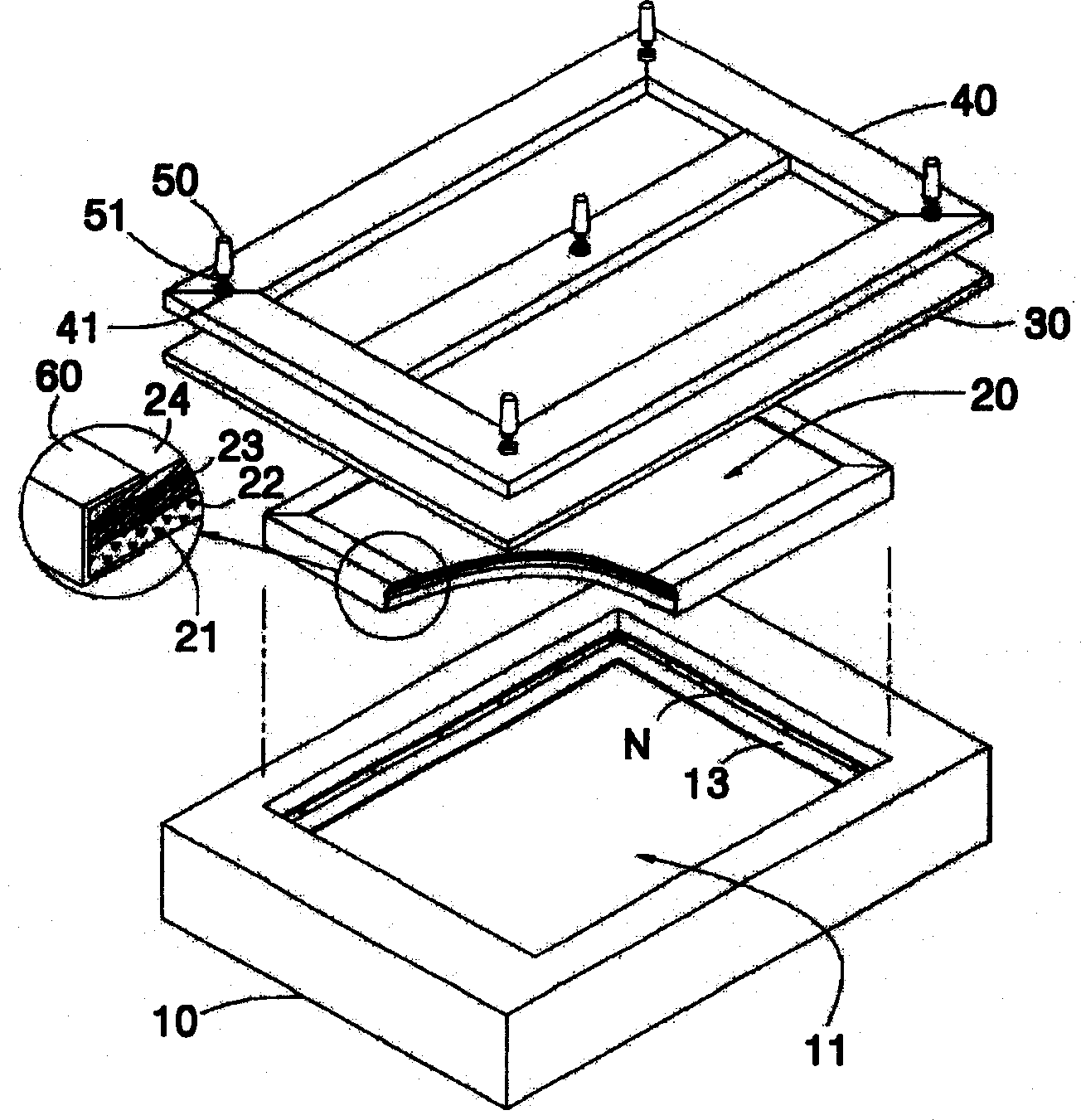

[0039] The mattress body 10 is a rectangular body with a predetermined thickness, and the support opening 11 is arranged in the middle of the mattress body 10, such as image 3 shown. A headboard 12 is provided on the upper surface of the end of the mattress body 10 . A plurality of locking screws N are used to arrange the clamping frame 13 with an L-shaped cross section along the inner surface of the support opening 11 of the mattress body 10, and the locking screws N are thus used to maintain the laminated assembly 20 in the mattress body 10. parts.

[0040] The stacked assembly 20 is placed in the support opening 11 of the mattress body 10, and has a stacked structure. The stone plate 21, the backing plate 22, the ...

no. 2 example

[0050] Such as Figure 5 As shown, the laminated assembly 200 according to the second embodiment can be used as a mattress for a mattress monolithic stone bed, or as a Boryo, which is laid flat on a flat support surface such as a floor. In the following description, the laminated assembly 200 for use with a mattress monolithic stone bed will be described.

[0051] refer to Figure 5 According to the second embodiment of the present invention, the integrated stone bed for mattresses includes a clamping frame 13 with an L-shaped cross section, and a plurality of locking screws are used to install the clamping frame 13 along the inner surface of the support opening 11 of the mattress body 10 , thereby retaining the laminated assembly 200 in the mattress body 10 in the same manner as in the first embodiment described above.

[0052] In addition, the mattress integrated stone bed according to the second embodiment of the present invention includes a headboard 12 and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com