Processing equipment for wood

A kind of processing equipment and wood technology, which is applied in wood processing equipment, manufacturing tools, mortising machines, etc., can solve the problem that the slotting machine cannot satisfy the opening of spiral grooves, and achieve the effect of avoiding movement and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

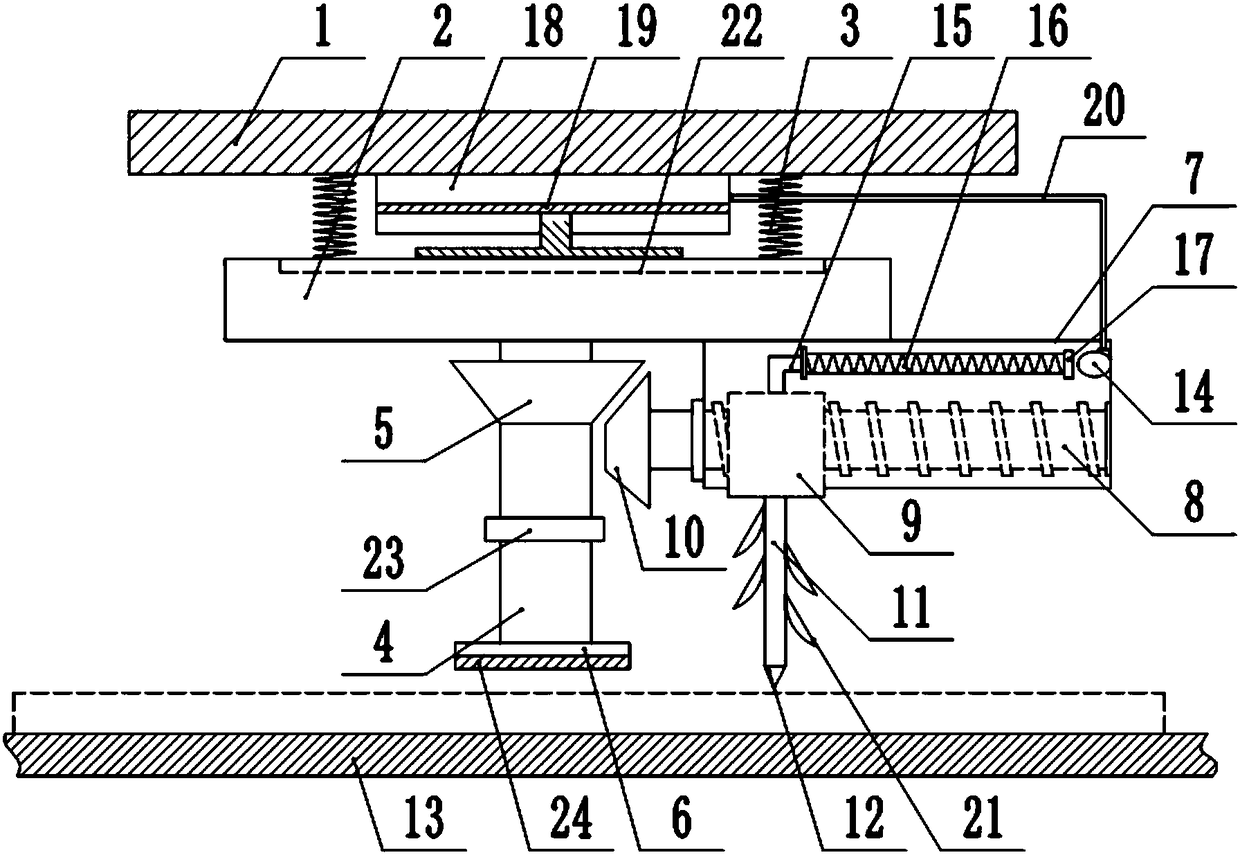

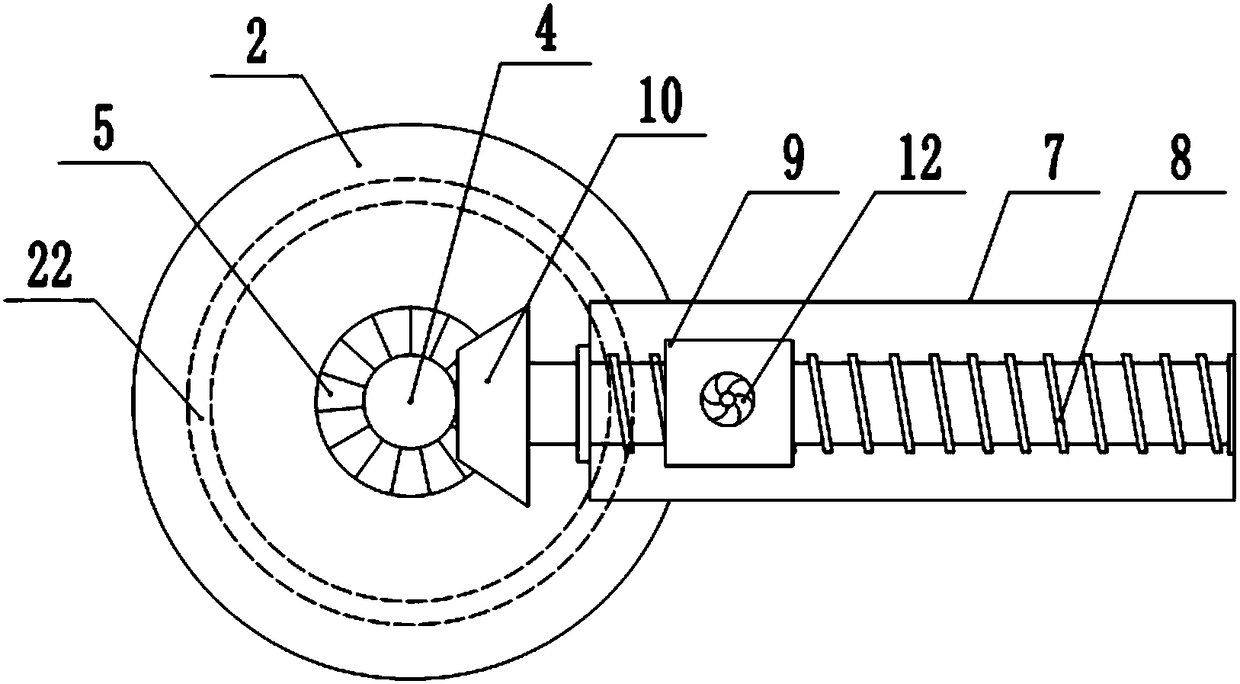

[0020] The reference signs in the accompanying drawings of the description include: fixed plate 1, drive plate 2, support spring 3, drive shaft 4, first bevel gear 5, pressing plate 6, fixed box 7, screw mandrel 8, nut 9, second Bevel gear 10, drill rod 11, drill bit 12, conveyor belt 13, air bag 14, support rod 15, telescopic spring 16, extrusion plate 17, cylinder 18, piston 19, air duct 20, rotating blade 21, circular chute 22, Collar 23, rubber pad 24.

[0021] The embodiment is basically as attached figure 1 Shown: wood processing equipment, including a frame, a fixed plate 1 and a driving mechanism, the fixed plate 1 is fixedly connected to the frame, the bottom of the fixed plate 1 is fixedly connected with a cylinder 18, and the inside of the cylinder 18 is sealed and slidably connected with a piston 19, The piston 19 is fixedly connected with a piston rod, and the free end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com