Automatic ash-cleaning spiral dust collection pole electric dedusting machine

A self-cleaning, spiral-type technology, applied in the direction of electrode structure, electrostatic separation, electrode cleaning, etc., can solve problems such as prone to failure, complicated vibration equipment, and delay in production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

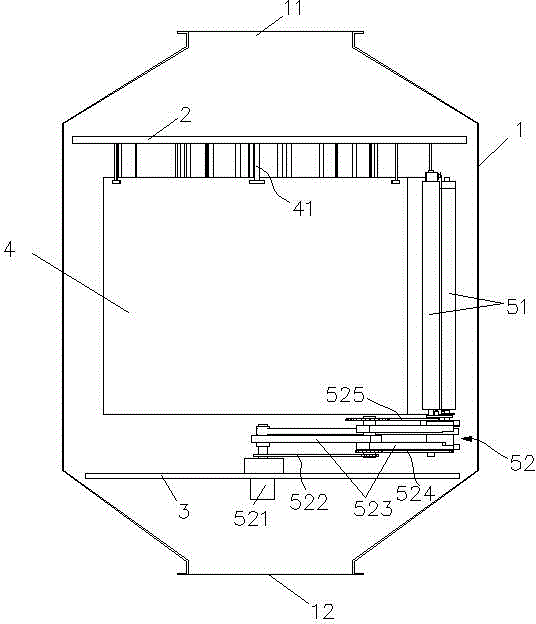

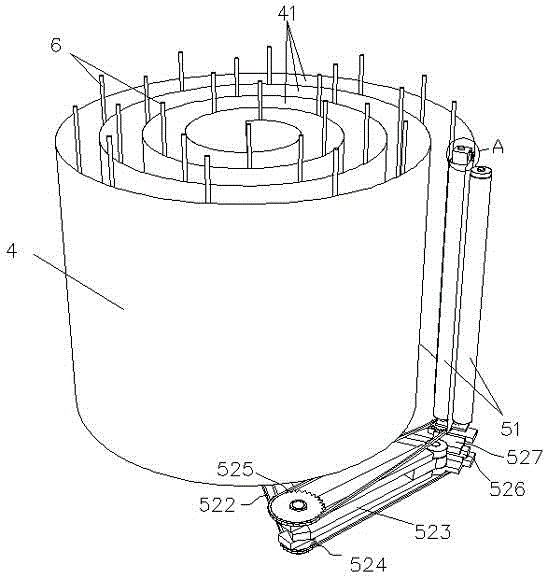

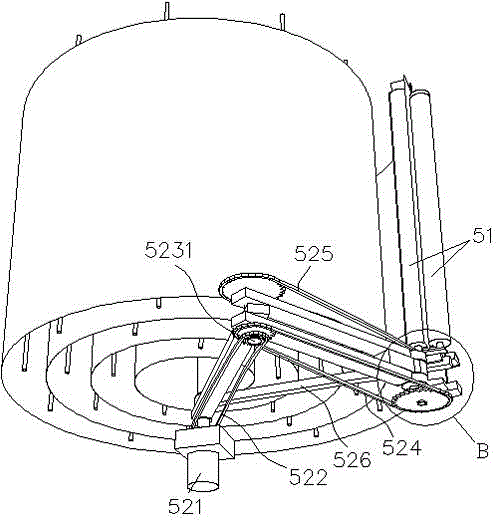

[0021] like Figure 1 to Figure 6 As shown, the present invention comprises shell 1, corona pole 6, dust collection pole 4, dust collection plate support 2 and corona pole support, high-voltage power supply device, cylindrical dust removal brush 51, dust removal brush driving device 52, and shell 1 up and down Respectively set as a conical constriction, the lower end is provided with an air inlet 12, and the upper end is provided with an air outlet 11, and the dust collection pole is arranged inside the shell, which is a vertically arranged equidistant spiral dust collection pole plate 4, etc. Distance refers to the equal spacing between two adjacent spiral plates, the linear shape formed by its cross section (horizontal section) is a plane spiral, the height of the dust collection plate is the same, and the corresponding position of the inner and outer sides of the spiral dust collection plate There is a pair of cylindrical dust removal brushes 51 that are in contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com