Fuselage section having an integral pressure bulkhead formed from composite fibre material, as well as a fuselage shell having a fuselage section such as this

一种机身外壳、合成材料的技术,应用在机身、飞机地板、飞机配件等方向,能够解决结构重量高、零件数量多、生产成本高等问题,达到降低生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

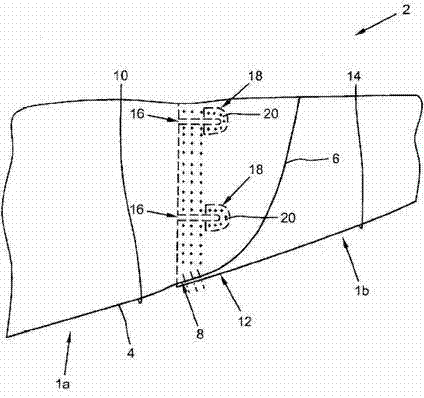

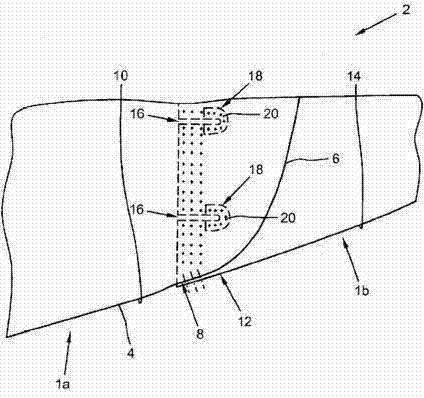

[0018] The figure shows a detail of a fuselage skin 2 formed from several suitable fuselage sections 1a, 1b for the pressure-resistant fuselage of an aircraft, including an approximately conical tapering tail. According to the invention, the fuselage section 1 a comprises a fuselage shell structure 4 made of fiber composite material and a pressure bulkhead 6 formed integrally with the fuselage shell structure 4 . The approximately spherical pressure bulkhead 6 (spherical pressure cap) is curved and protruded toward the tail of the fuselage, and forms a tail end of a pressure-resistant ventilation area of the aircraft fuselage. The transition zone from the fuselage shell structure 4 to the pressure bulkhead 6 extends continuously without sharp bends that would distort the fiber orientation, and the transition zone is fairly flat in such a way as to avoid Unfavorable right angles. Since the pressure bulkhead 6 is integrally formed with the fuselage section 1a, a weight-optimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com