Patents

Literature

89results about How to "Close fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

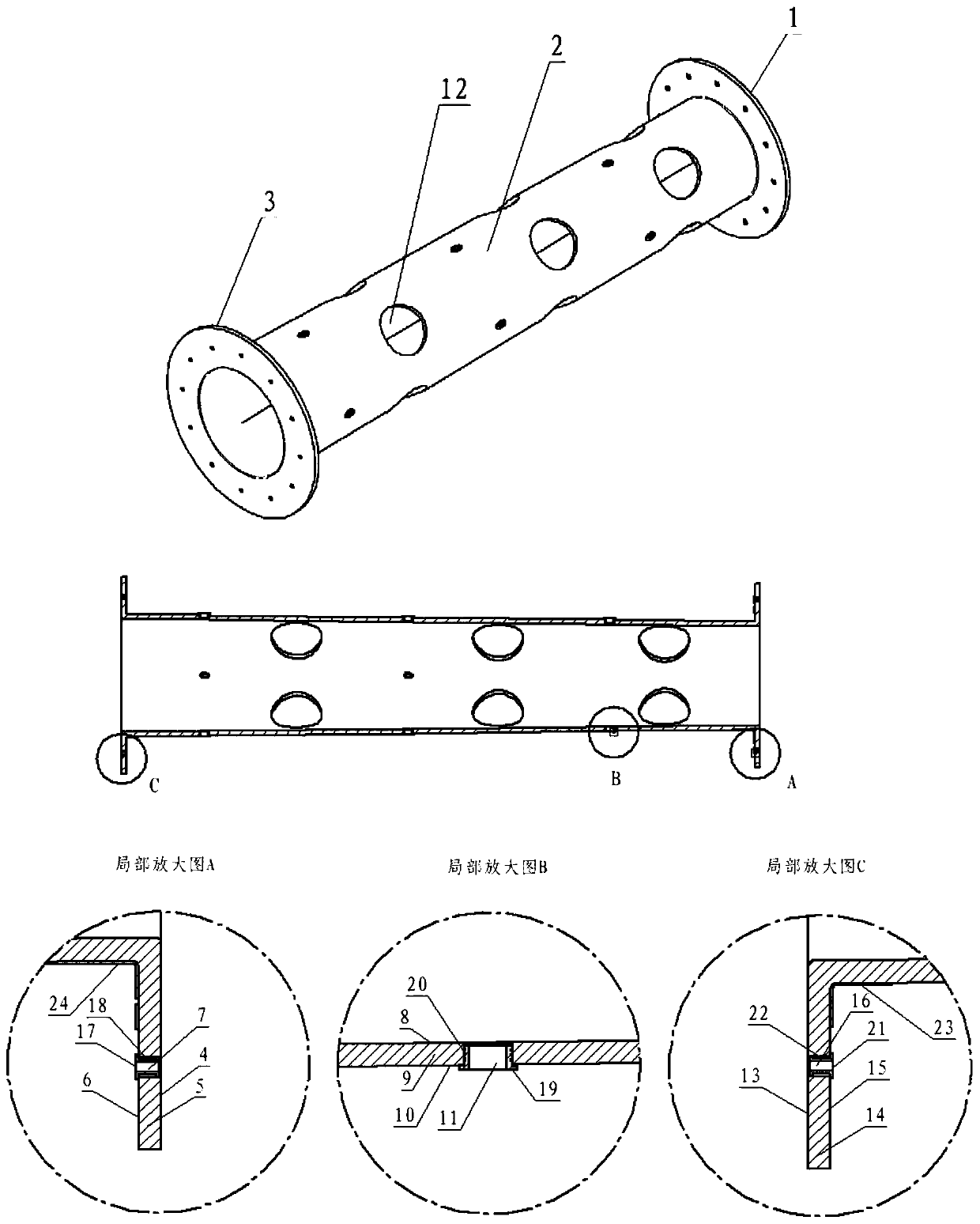

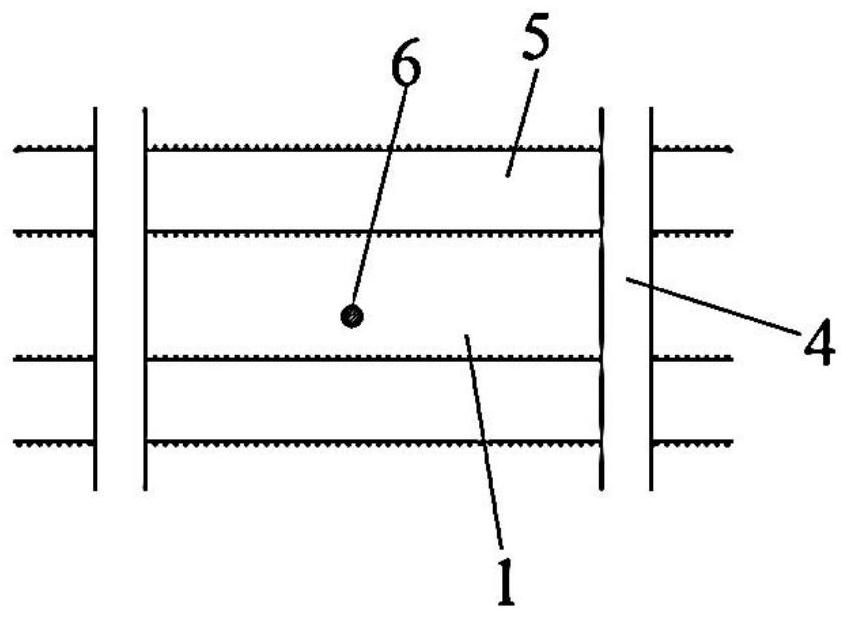

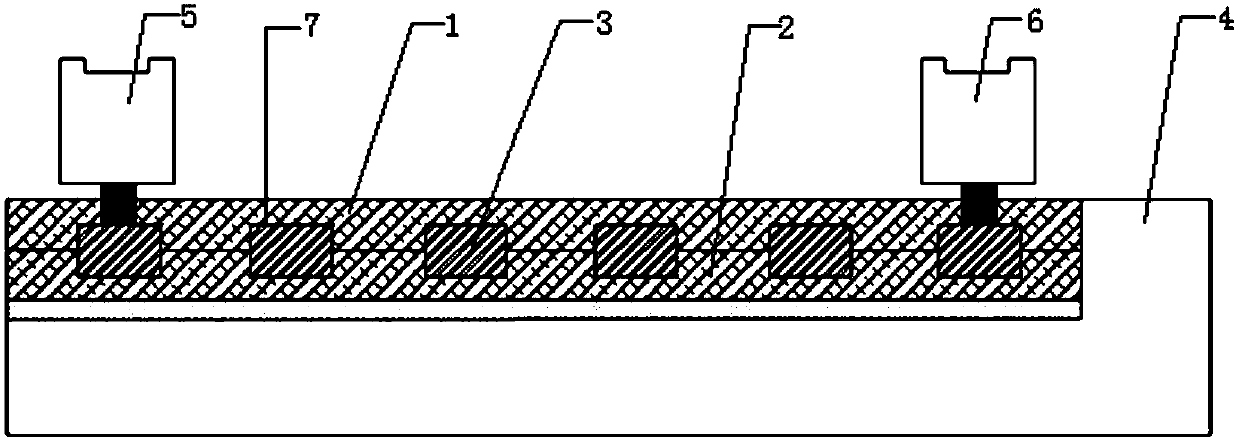

Lattice reinforced foam sandwich preform, and production method and application thereof

ActiveCN106494022AImprove anti-scourabilityWill not deformSynthetic resin layered productsGlass/slag layered productsYarnFiber

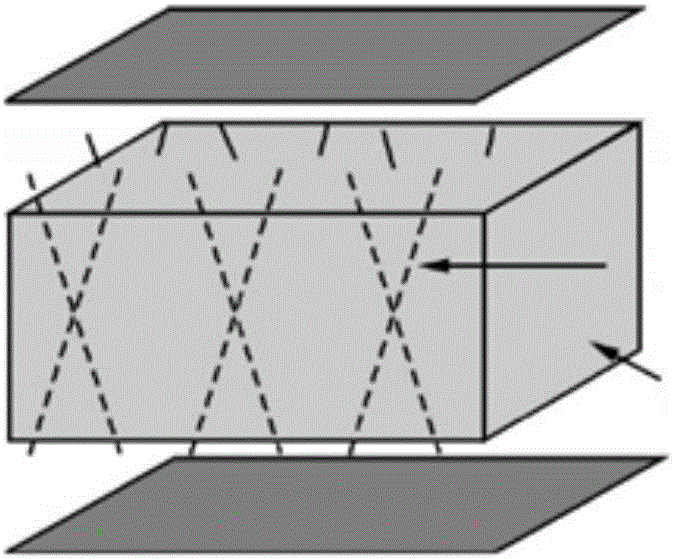

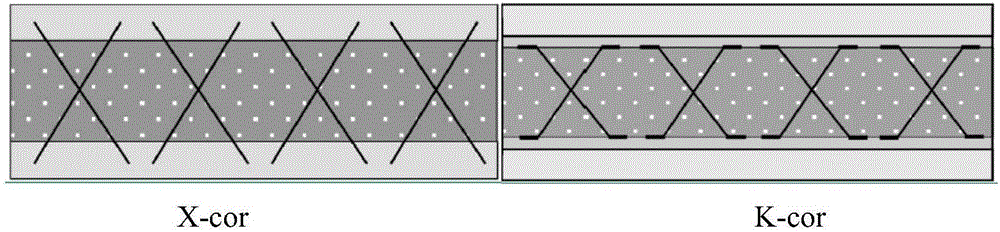

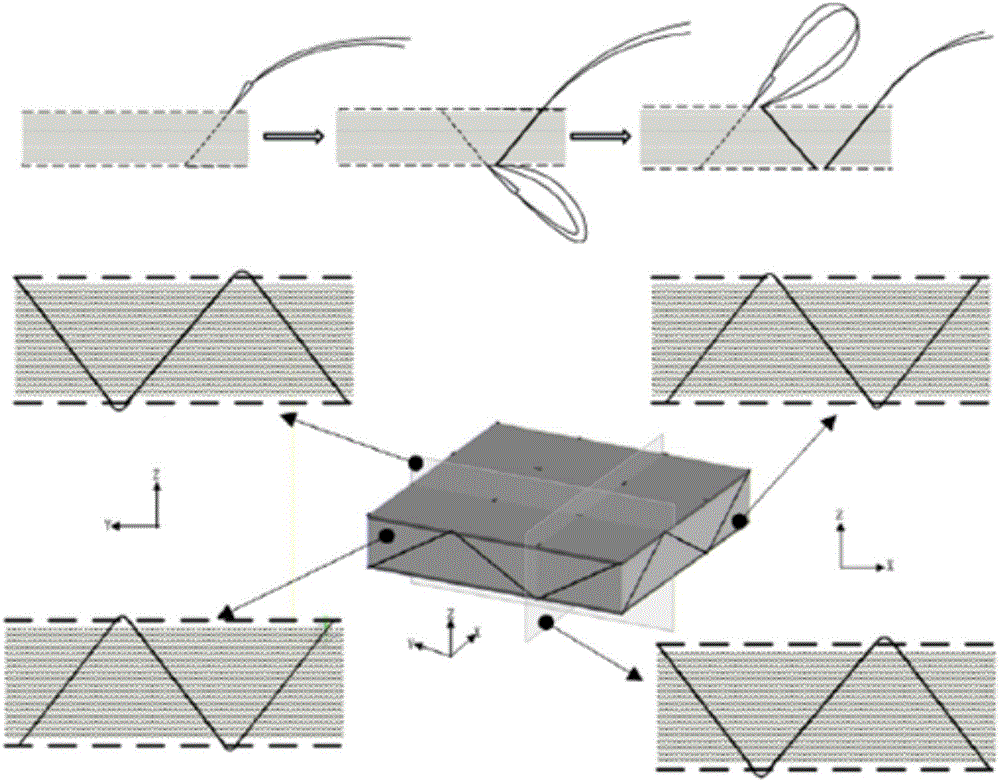

The invention discloses a lattice reinforced foam sandwich preform, and a production method and an application thereof. The lattice reinforced foam sandwich preform comprises an upper fiber fabric, a foam core material, a lower fiber fabric and yarns; and the upper fiber fabric, the foam core material and the lower fiber fabric are sequentially superposed, and are stitched through the yarns. The production method comprises the following steps: cutting a fiber cloth and the foam core material with the same dimension, respectively covering the upper surface and the lower surface of the foam core material with the cut fiber cloth, and carrying out glue spraying and pasting to form a sandwich structure; and stitching the sandwich structure by using the yarns to obtain the lattice reinforced foam sandwich preform. The lattice reinforced foam sandwich preform has the advantages of good scour resistance, and close interlayer lamination of the fiber fabrics, and can be applied to production of stable composite materials with good mechanical performances, used for tank rotation baseboards.

Owner:NAT UNIV OF DEFENSE TECH

Pre-embedded and prefabricated magnetic attraction end guiding type building crack repairing device and method based on magnetic force

InactiveCN113250483AHas the effect of anti-oxidationWill not harmBuilding repairsTinningMagnetic tension force

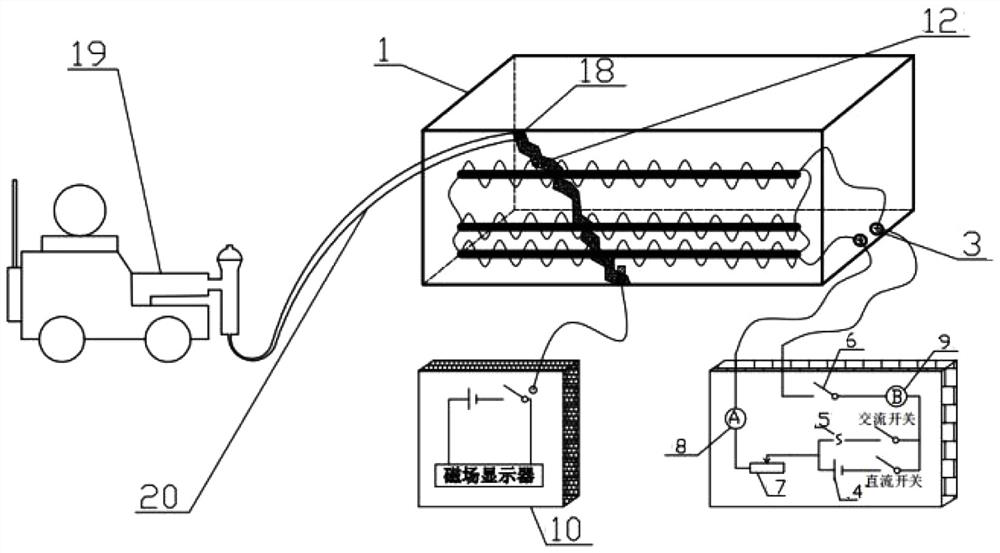

The invention provides a pre-embedded and prefabricated magnetic attraction end guiding type building crack repairing device and a method based on magnetic force. The device comprises a steel bar pre-embedded in a reinforced concrete beam body; the steel bar is wound with a tinned copper wire; the tinned copper wire penetrates through a reserved wire interface pre-formed in the reinforced concrete beam body; the tinned copper wire is connected with an electromagnetic induction device used for providing current; a guide hole is formed in the position, where a crack easily occurs, of the reinforced concrete beam body; and the guide hole is connected with a high-pressure jet grouting machine through a grouting pipe, and then magnetic mortar is injected into the crack. The magnetic mortar is injected into a required position under the guide adsorption of different magnetic attraction ends, so that the sufficient grouting effect is achieved, and the crack repairing and filling rate is increased. According to the pre-embedded and prefabricated magnetic attraction end guiding type building crack repairing device and the method based on the magnetic force, the needed materials are simple, the assembly cost is low, and the device has prefabrication performance, is fast to operate, and is high in crack repair guiding effect and long in duration time.

Owner:CHINA THREE GORGES UNIV

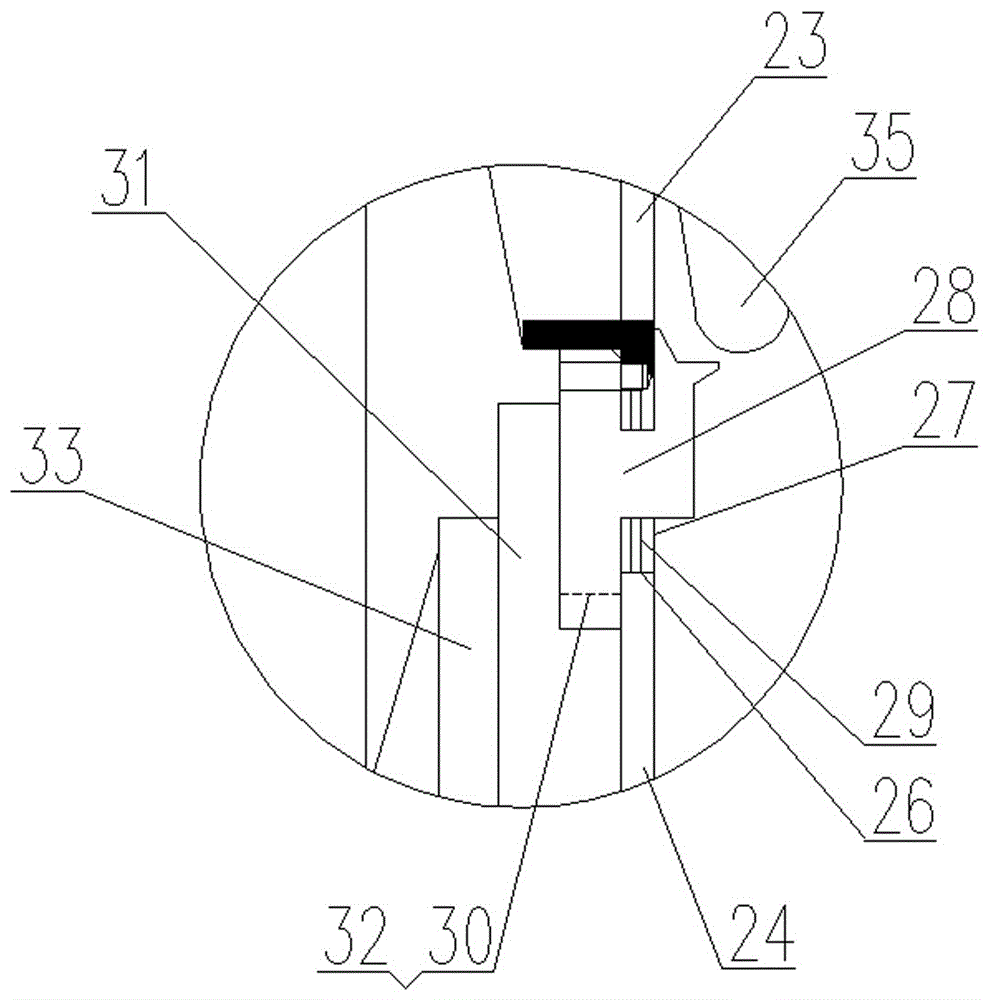

Tool for detecting airtightness of engine cylinder cover

ActiveCN108151970AAir tightness detection is accurateNot easy to shiftFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

Owner:宁波强盛机械模具有限公司

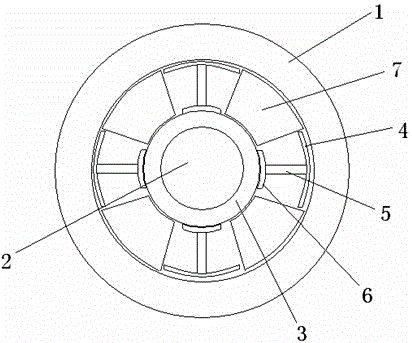

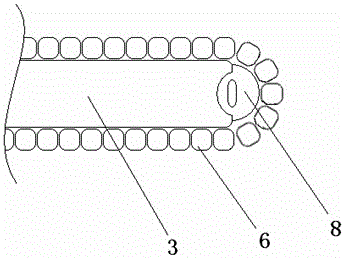

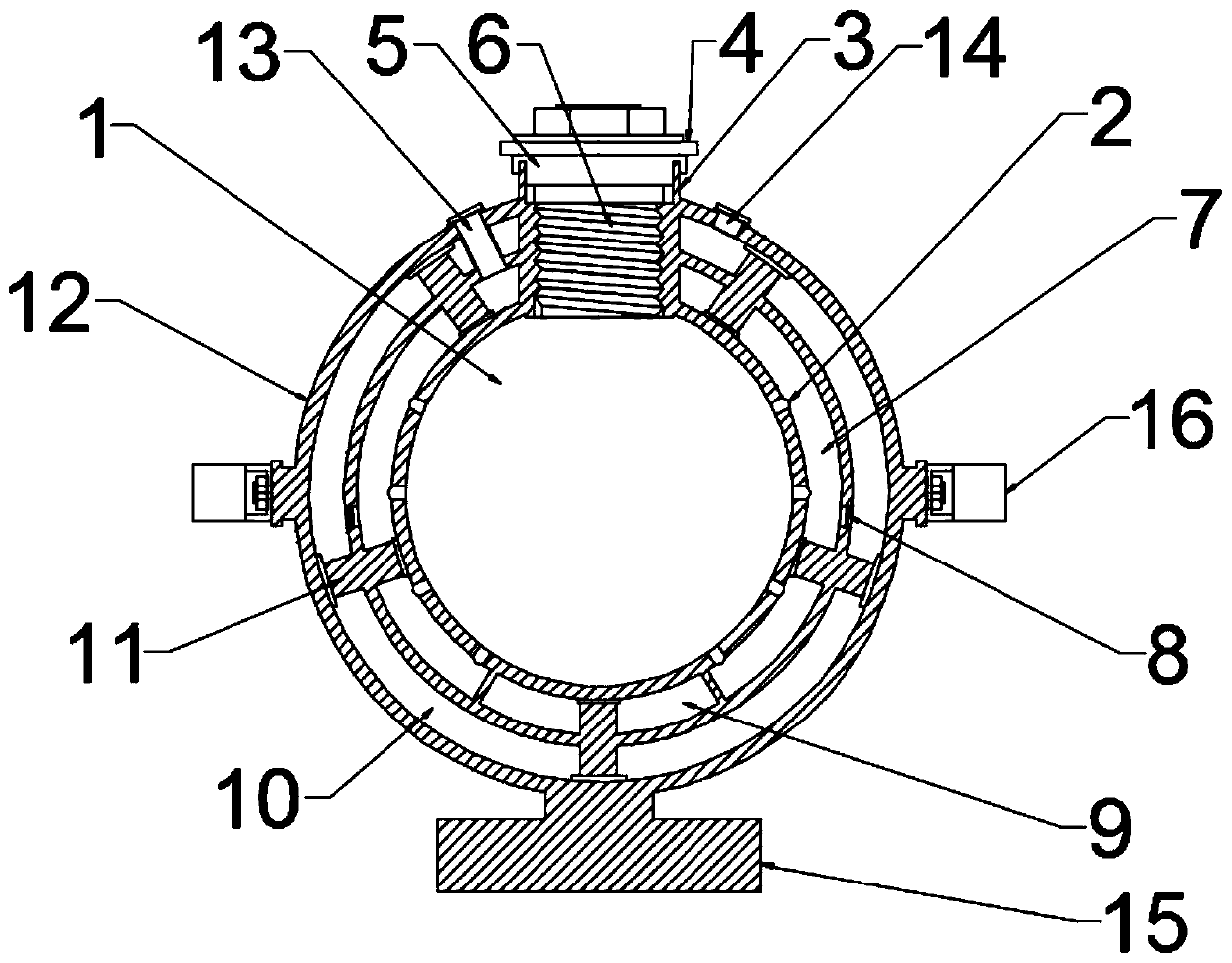

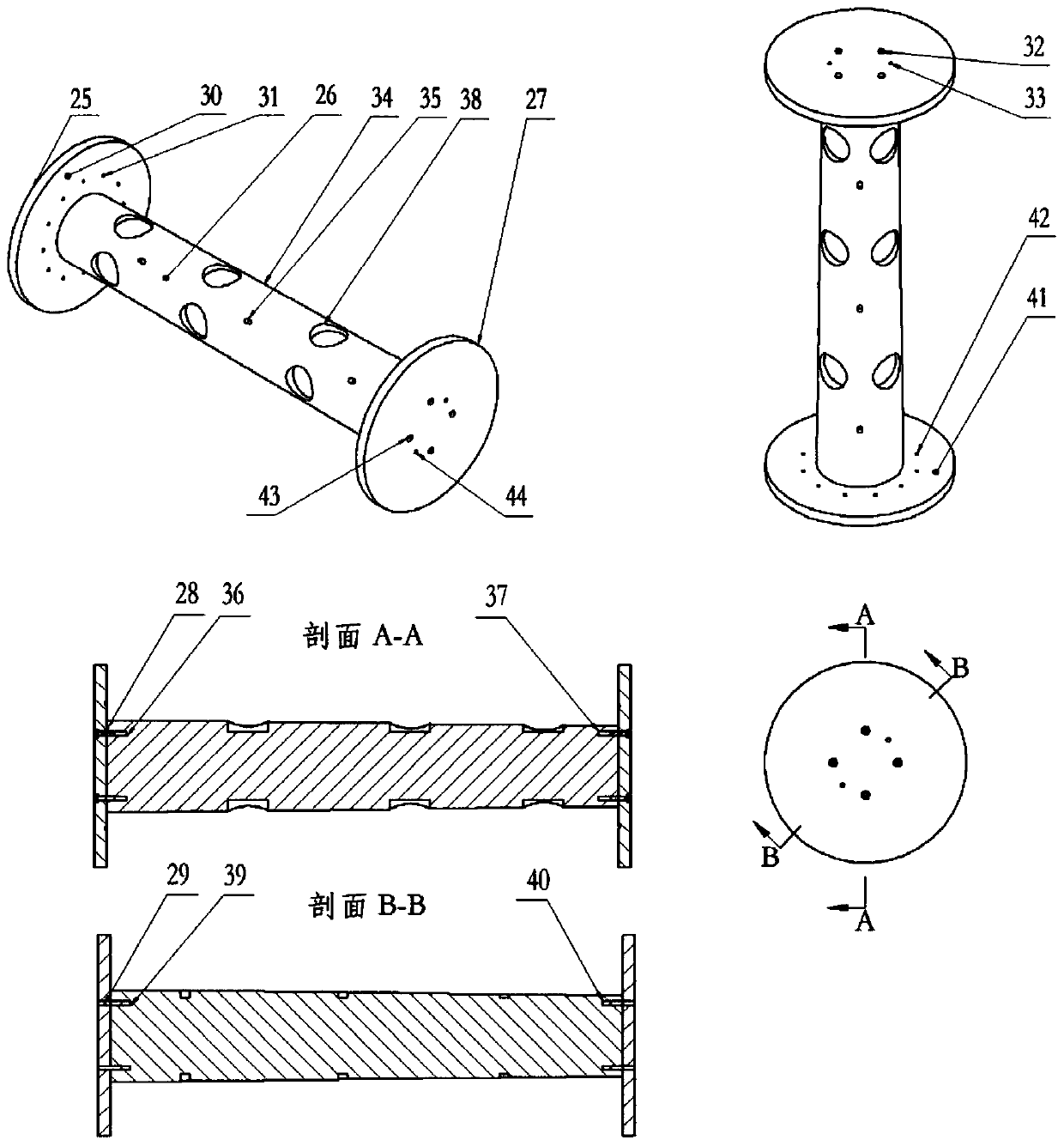

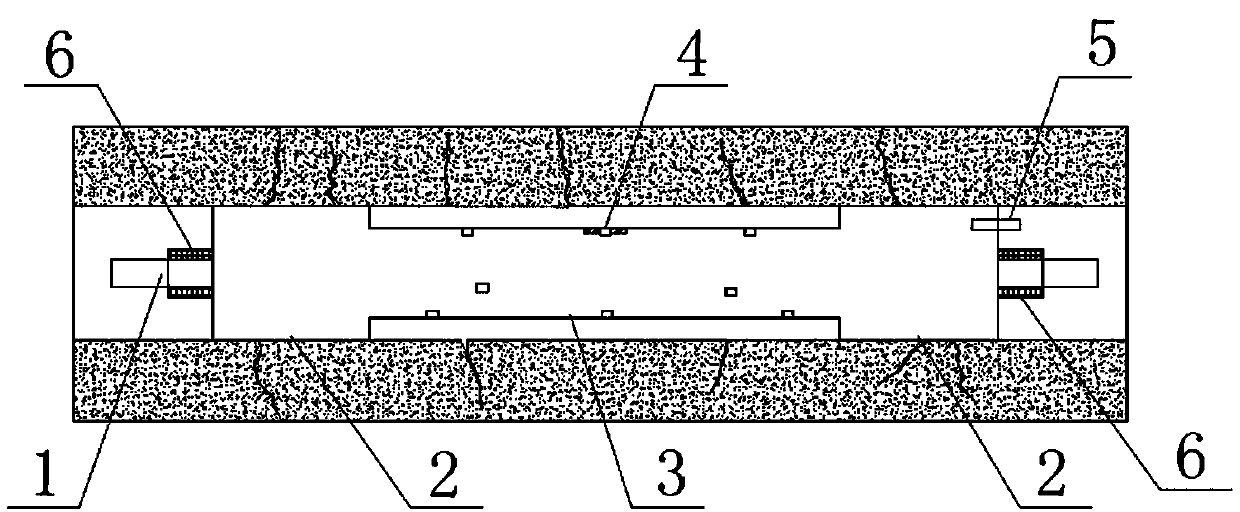

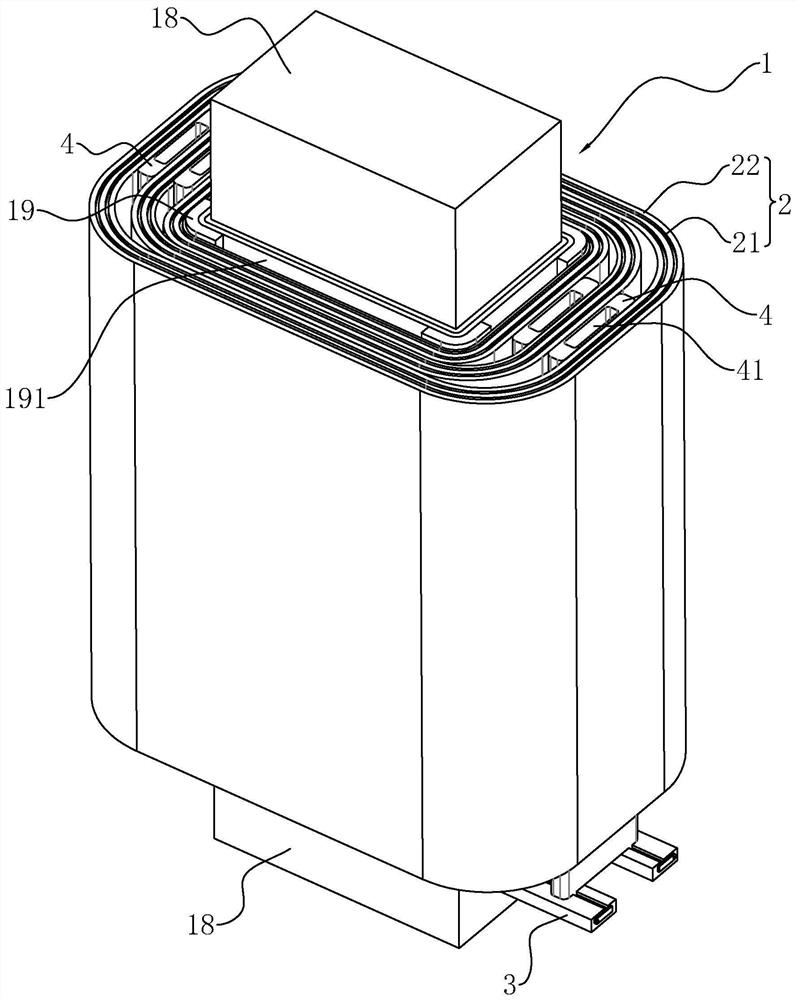

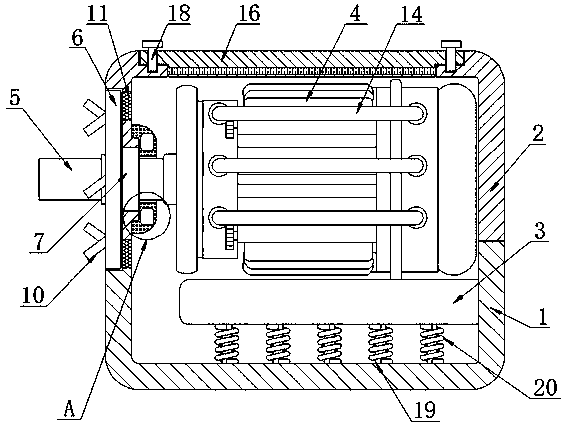

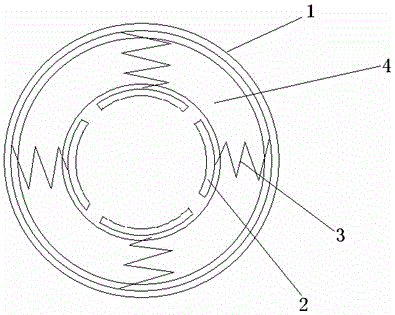

Inner and outer winding coil layered heat dissipation apparatus

ActiveCN106057415AWide gap structureNo creepageTransformers/inductances coolingTransformers/inductances coils/windings/connectionsState of artChain structure

The invention discloses an inner and outer winding coil layered heat dissipation apparatus. The layered heat dissipation apparatus comprises a rolling apparatus, an inner heat dissipation apparatus and an outer heat dissipation apparatus, wherein the rolling apparatus comprises an inner cylinder; four supporting parts are arranged on the outer surface of the inner cylinder and adopt T-shaped structures; the inner heat dissipation apparatus comprises a heat dissipation strip mechanism; the heat dissipation strip mechanism adopts a chain structure formed by mutually hinging a plurality of heat dissipation blocks one by one; the outer heat dissipation apparatus comprises an outer cylinder; a plurality of coamings are arranged in the outer cylinder; and an annular cooling bag is arranged between the coamings and the inner surface of the outer cylinder. Compared with the prior art, the inner and outer winding coil layered heat dissipation apparatus has a relatively wide gap structure, so that the creepage between high and low level voltage coils is avoided; a rolling movement can be continuously performed in a formed gap by utilizing the heat dissipation strip mechanism to continuously take away inner heat; and a cooling liquid is added in the annular cooling bag of the outer heat dissipation apparatus to form water circulation so as to continuously take away heat on an outer high-voltage coil.

Owner:JIANG SU ZHONGRONG TECH

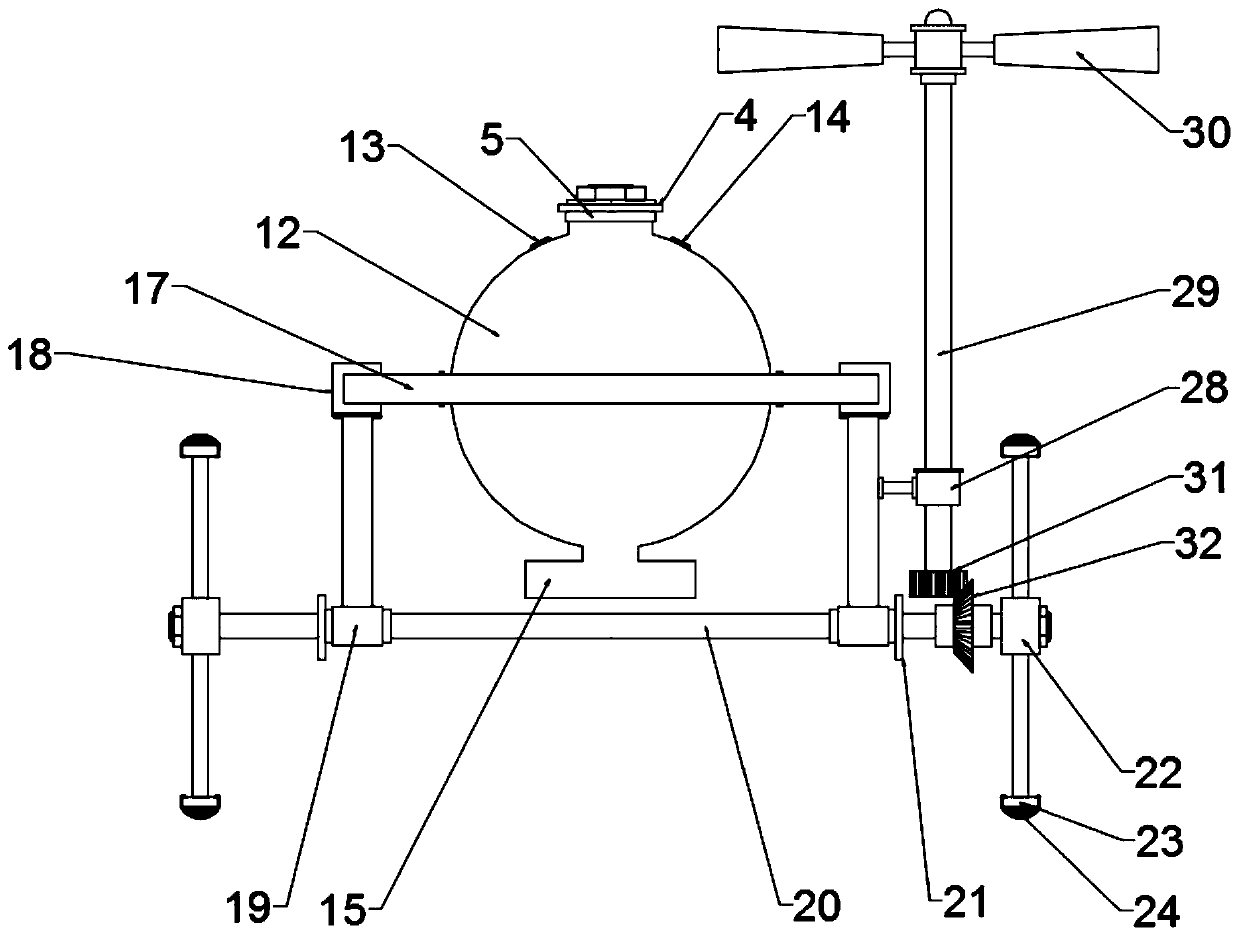

Novel environment-friendly portable catalyst packaging device

The invention discloses novel environment-friendly portable catalyst packaging device. The packaging device comprises a storage device, a stabilizing device, a travelling device and a power device; the storage device can adjust the temperature of an organic tin catalyst storage environment; the stabilizing device comprises first rotating rings, a second rotating ring and a weighting block and enables the storage device to be always in a stable state; the travelling device comprises first sleeves, second sleeves, a transverse shaft, limiting plates, hubs, rims, rubber rings and supporting rodsand enables the packaging device to move, so that the carrying cost is reduced; and the power device comprises a third sleeve, a rotating shaft, a power windmill and an umbrella-shaped transmission structure. According to the packaging device, the packaging device is driven to move through clean energy, so that the pollution to the environment is reduced; and the temperature and the stability ofthe internal environment for storing an organic tin catalyst can be effectively improved, so that the storage effect on the organic tin catalyst is guaranteed.

Owner:DEYANG JIANAN MACHINERY MFG

Fabricated building wallboard installing and positioning device

InactiveCN111472559APrecise positioningEasy to moveBuilding material handlingWall plateArchitectural engineering

Owner:CHONGQING UNIV OF ARTS & SCI

Aramid skin-paper honeycomb sandwich cylinder shell structure, preparation method thereof and application thereof

ActiveCN110299598ASimple designReduce in quantityLamination ancillary operationsSynthetic resin layered productsEpoxyNomex

The invention relates to an aramid skin-paper honeycomb sandwich cylinder shell structure, a preparation method thereof and application thereof and particularly relates to a Kevlar49 aramid fiber woven fabric reinforced epoxy resin based composite material skin-Nomex perforated paper honeycomb sandwich cylinder shell structure applied to a spacecraft antenna sub-system support structure and a preparation method thereof, belonging to field of spacecraft composite material structures and the forming technology.

Owner:BEIJING SATELLITE MFG FACTORY

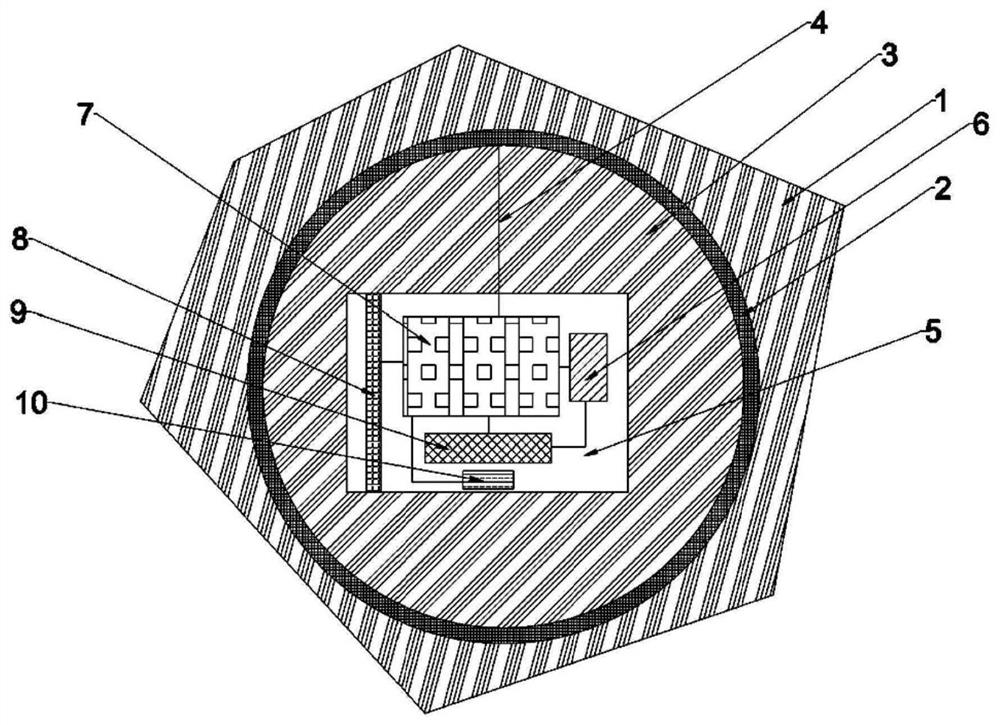

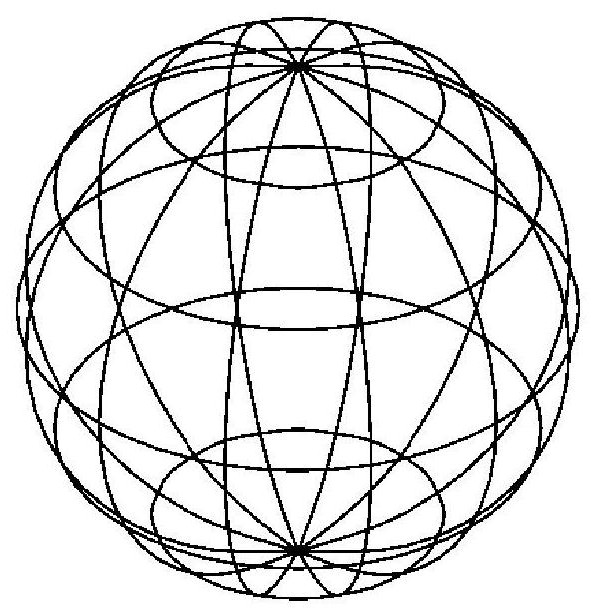

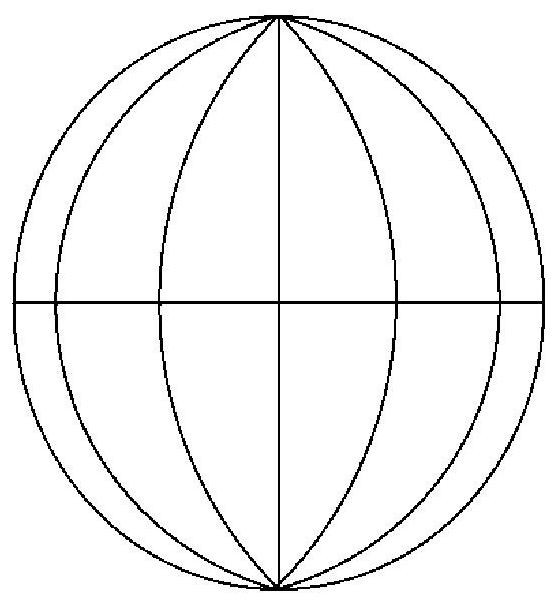

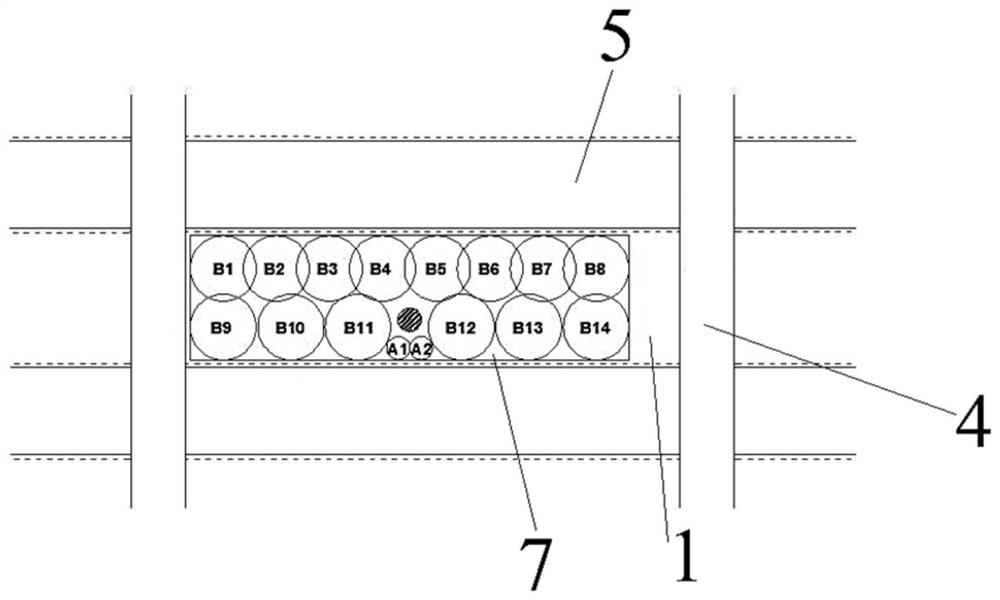

High-sensitivity stress sensing aggregate suitable for intelligent pavement

PendingCN111636326AAccurately grasp the generationAccurate grasp of scalabilityIn situ pavingsTransmission systemsRoad surfaceStress mode

The invention discloses a high-sensitivity stress sensing aggregate suitable for an intelligent pavement. The high-sensitivity stress sensing aggregate comprise an outer shell, a spherical stress sensing layer is arranged in the outer shell in a matched mode. A plurality of piezoelectric patches coded according to spatial positions are uniformly distributed and arrayed on the outer surface of thespherical stress sensing layer; an inner protective shell is arranged in the spherical stress sensing layer in a matching manner; a functional packaging body is arranged in the inner protective shell;a central processing unit, a signal transmission module and a power supply module are arranged in the functional packaging body; wherein each piezoelectric patch is electrically connected with the central processing unit, the central processing unit is electrically connected with the signal transmission module, the power supply module is electrically connected with the central processing unit andthe signal transmission module, the central processing unit is used for converting electric signals of the piezoelectric patches into stress information, and the signal transmission module is used for sending the stress information to an external information receiving device. According to the invention, the contact effect between aggregate particles can be accurately distinguished, and the particle stress mode and the stress propagation rule can be accurately analyzed.

Owner:CHANGAN UNIV

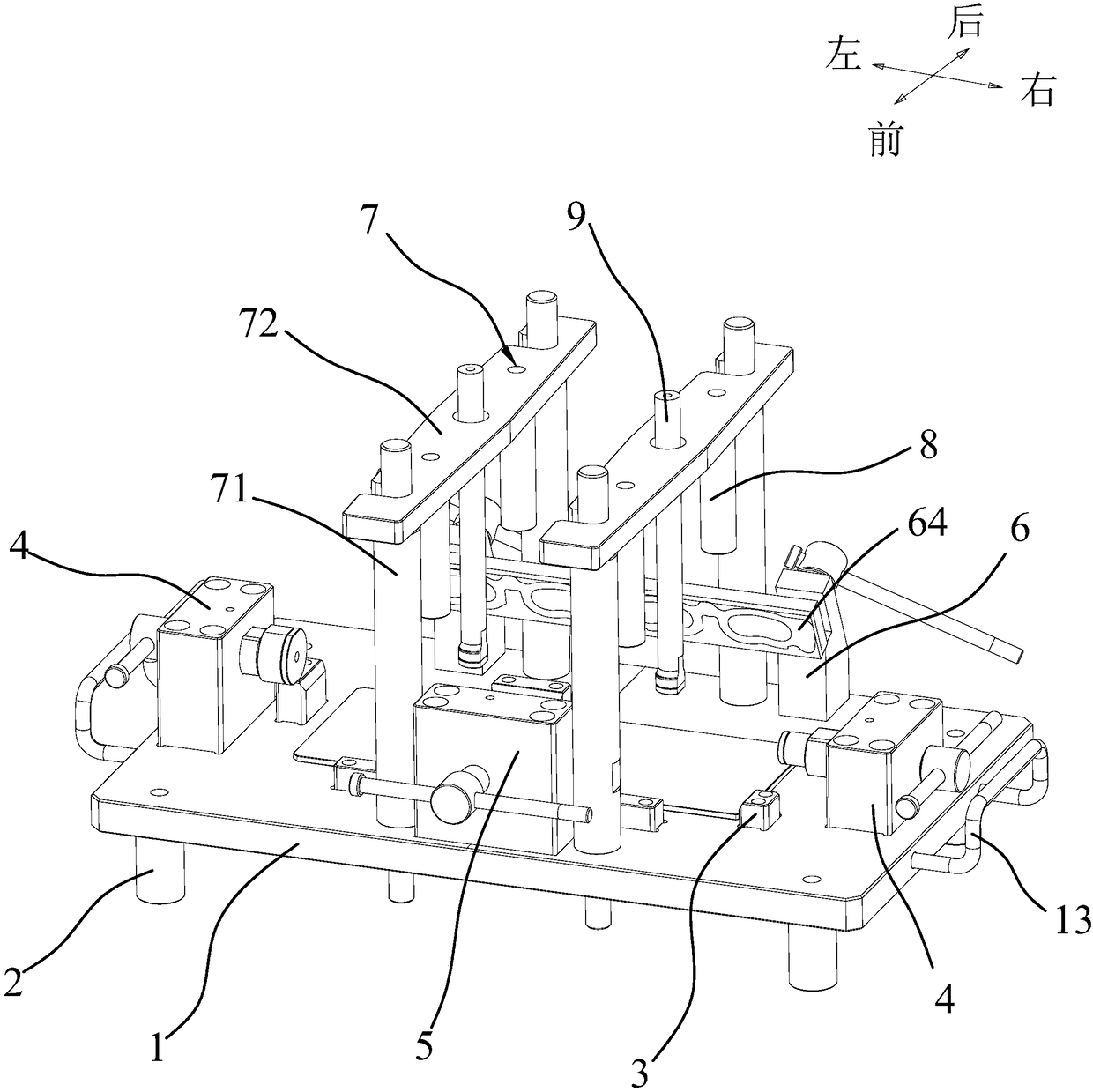

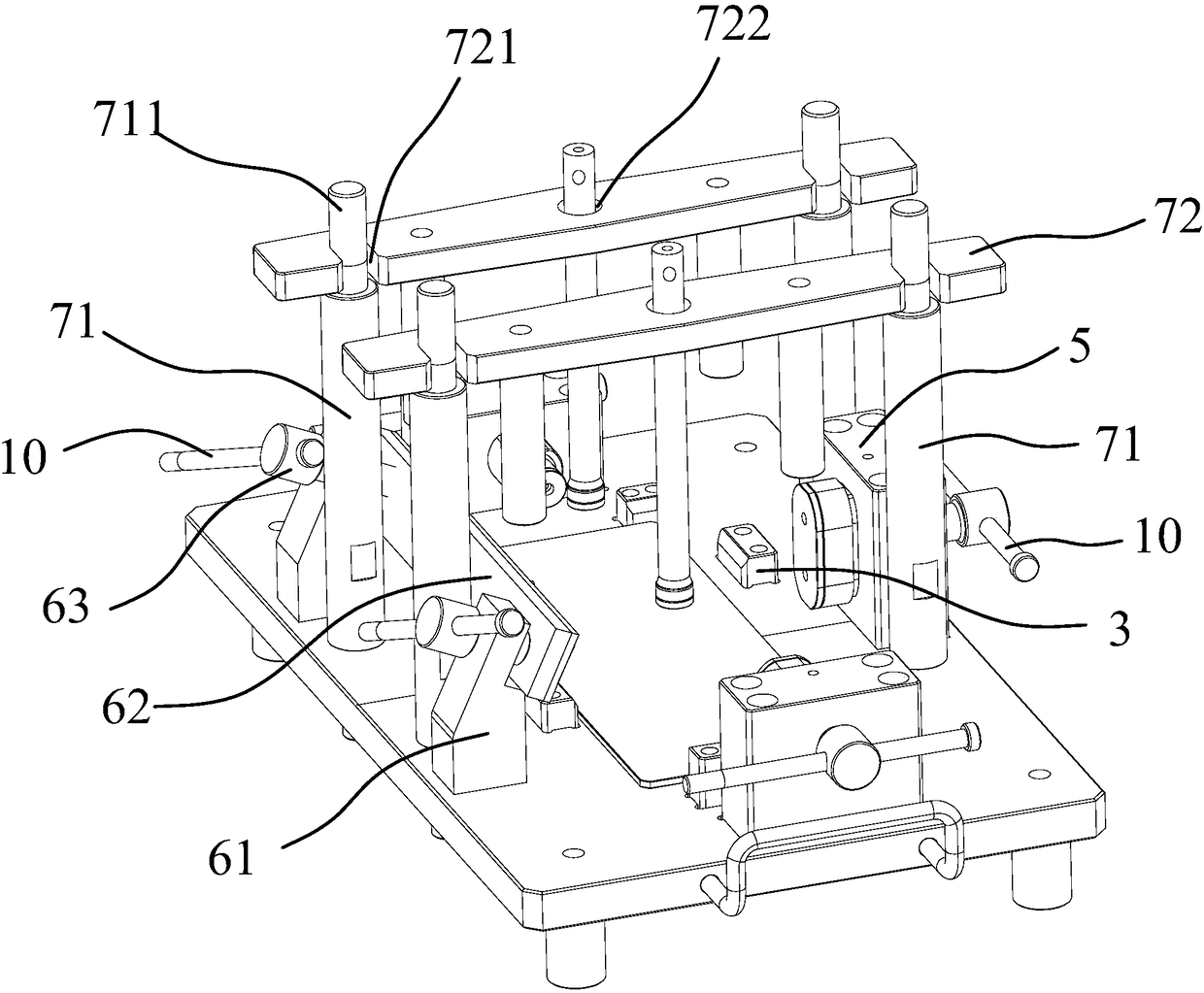

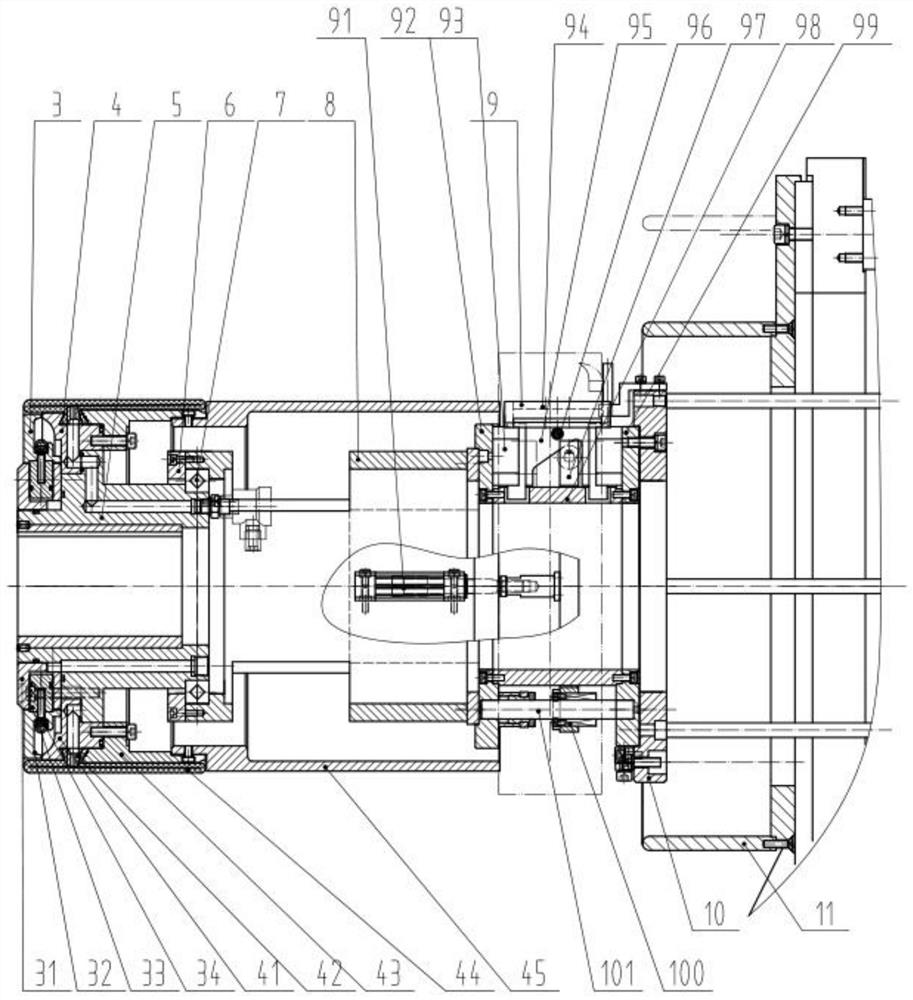

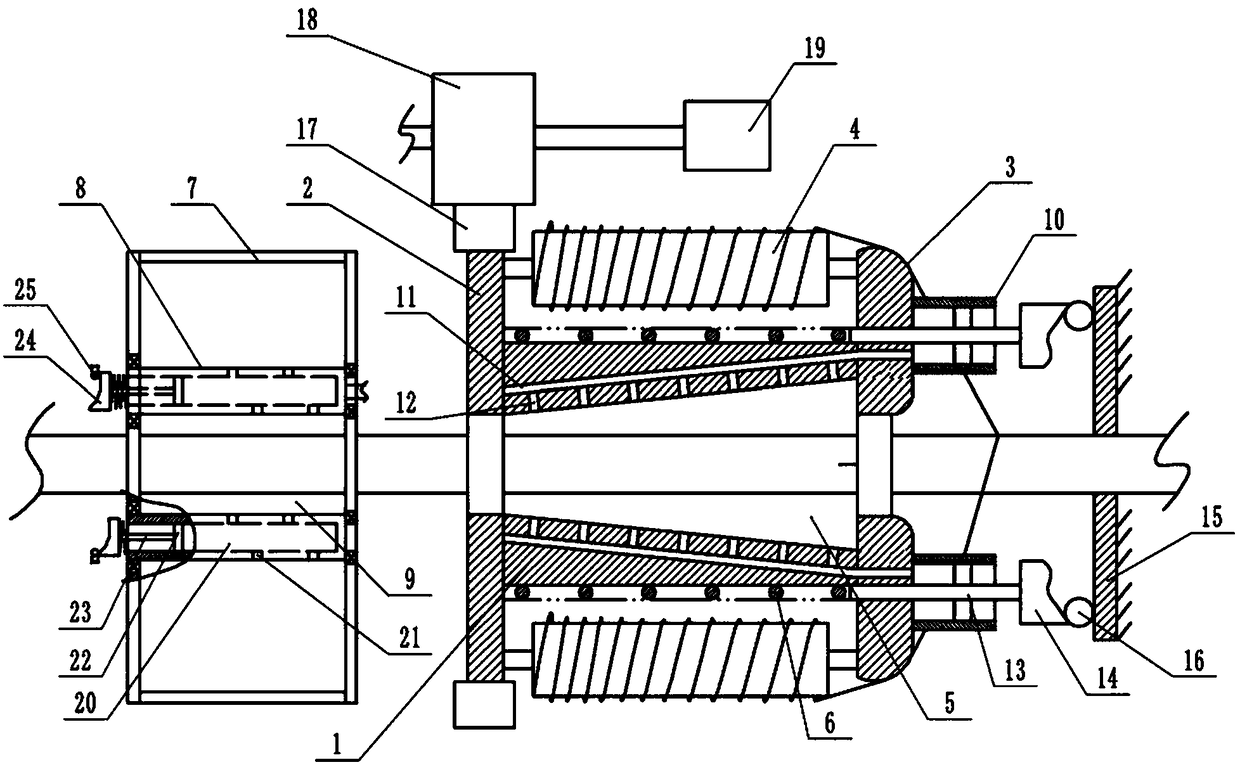

Automatic attaching machine for steel-rubber rim of engineering tire

The invention relates to an automatic attaching machine for a steel-rubber rim of an engineering tire. The automatic attaching machine comprises a base, a left rack, a right rack, a right rack advancing and retreating cylinder, a rubber ring overturning and attaching device and a steel rim rotating and attachment supporting device, wherein the left rack and the right rack are arranged on the left side and the right side of the base oppositely respectively, the steel rim rotating and attachment supporting device is arranged on the left rack; and the rubber ring overturning and attaching device is arranged on the right rack, is driven by the right rack advancing and retreating cylinder to advance towards and retreat from the steel rim rotating and attachment supporting device on the left rack and overturn to attach a rubber ring to a steel rim on the steel rim rotating and attachment supporting device. The automatic attaching machine has the advantages that the structure is compact, the operation is convenient, time and labor are saved, the labor intensity of workers is low, the productivity is high, the attachment is tight, the quality is good and the applicability is high.

Owner:TAIXING SHUANGYANG LEATHER RUBBER MACHINERY FACTORY

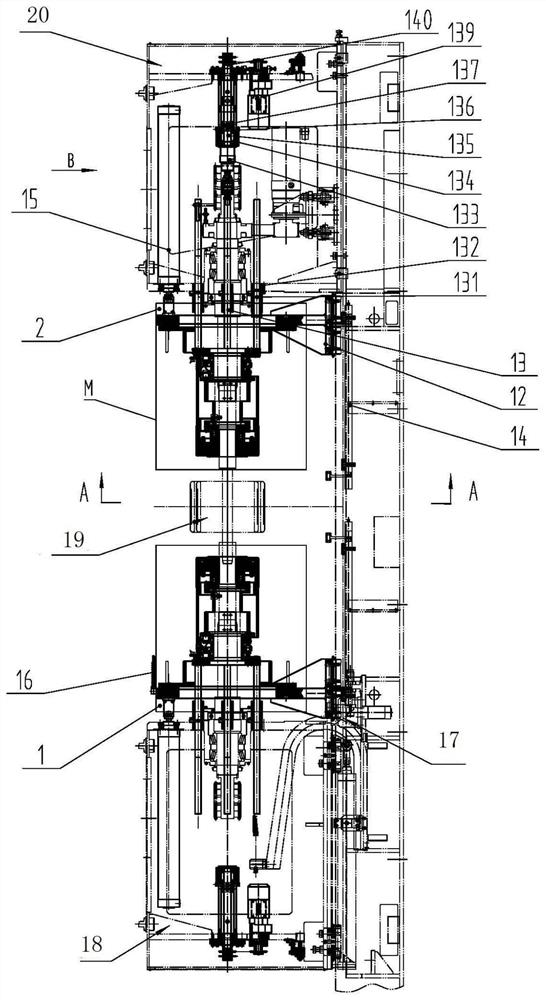

Two-stage flat drum laminating first-stage molding machine for semi-steel radial tires

The invention discloses a two-stage flat drum laminating first-stage molding machine for semi-steel radial tires. The molding machine comprises a left buckle ring forward and reverse wrapping device arranged on a tailstock main shaft and a right buckle ring forward and reverse wrapping device arranged on a main machine main shaft, wherein the left buckle ring forward and reverse wrapping device isof the same structure as the right buckle ring forward and reverse wrapping device, and each comprise a capsule support block assembly, a reverse wrapping capsule assembly, a sliding sleeve, a pressure ring, a bearing, a transition sleeve, a tire ring centering device, a fixed disc, a push disc, a supporting seat, a magnetic ruler and a reverse wrapping assembly specification adjusting device. The capsule support block assemblies and the reverse wrapping capsule assemblies are both matched with and fixed on the sliding sleeves, the sliding sleeves are in key joint with the main machine main shaft and the tailstock main shaft, and the left buckle ring forward and reverse wrapping device slides along the tailstock main shaft. The right buckle ring forward and reverse wrapping device slidesalong the main machine main shaft. Motors on the reverse wrapping assembly specification adjusting devices drive the reverse wrapping capsule assemblies to complete automatic size adjustment of the tires.

Owner:北京敬业机械设备有限公司

Gas extraction device and method for preventing coal and gas outburst

The invention discloses a gas extraction device and method for preventing coal and gas outburst. The gas extraction device comprises a device main body and a collecting tank, wherein an extraction outer pipe is arranged in the device main body, a hollow pipe is arranged in the extraction outer pipe, ventilation meshes are formed in the hollow pipe, a drilling rig is installed in the hollow pipe, a drilling bit is installed at the lower end of the drilling rig, a dust screen is installed outside the drilling bit, a leakage-proof silica gel pad is connected to the upper end of the extraction outer pipe, and a hose supporting ring is arranged in the leakage-proof silica gel pad. According to the gas extraction device and method for preventing coal and gas outburst, the leakage-proof silica gel pad can be attached to a hole through the outward acting force of a supporting spring, so that gas is always extracted in the extraction outer pipe during extraction; and meanwhile, the leakage-proof silica gel pad can be tightly attached to a discharging pipe through the upper end of the airflow acting force, so that gas leakage is avoided.

Owner:CHONGQING VOCATIONAL INST OF ENG

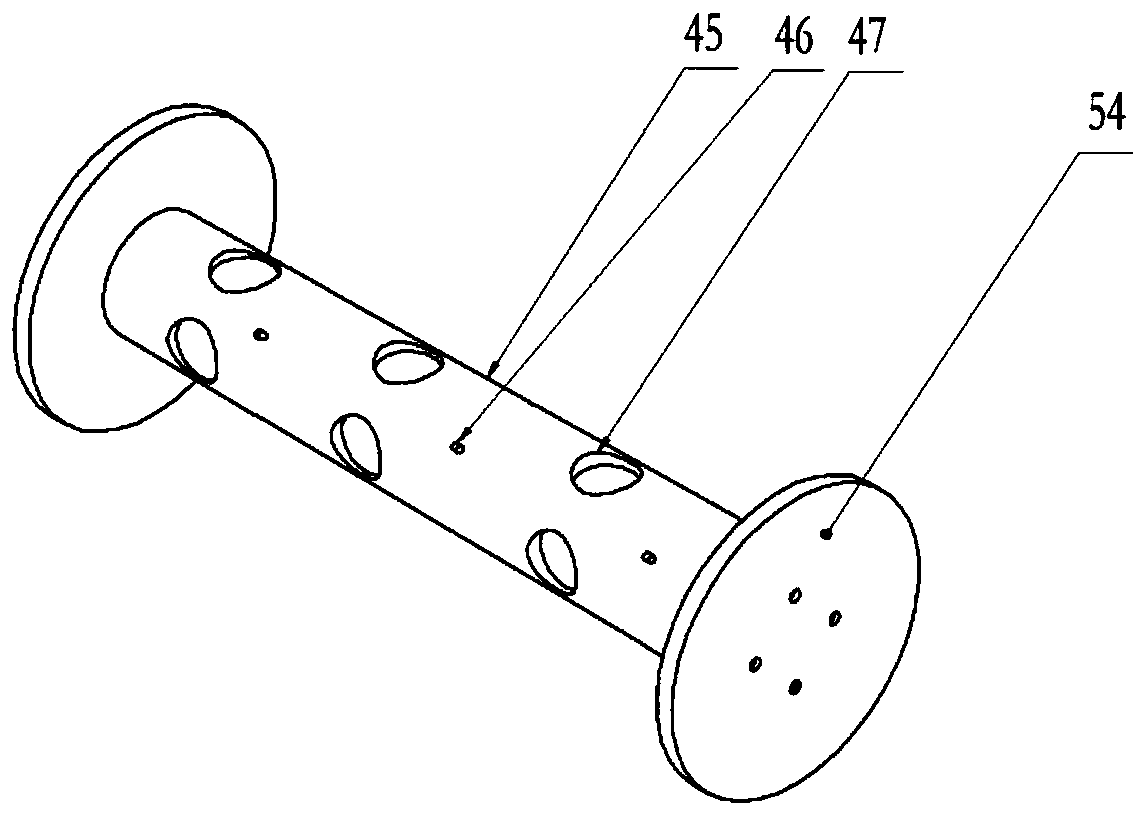

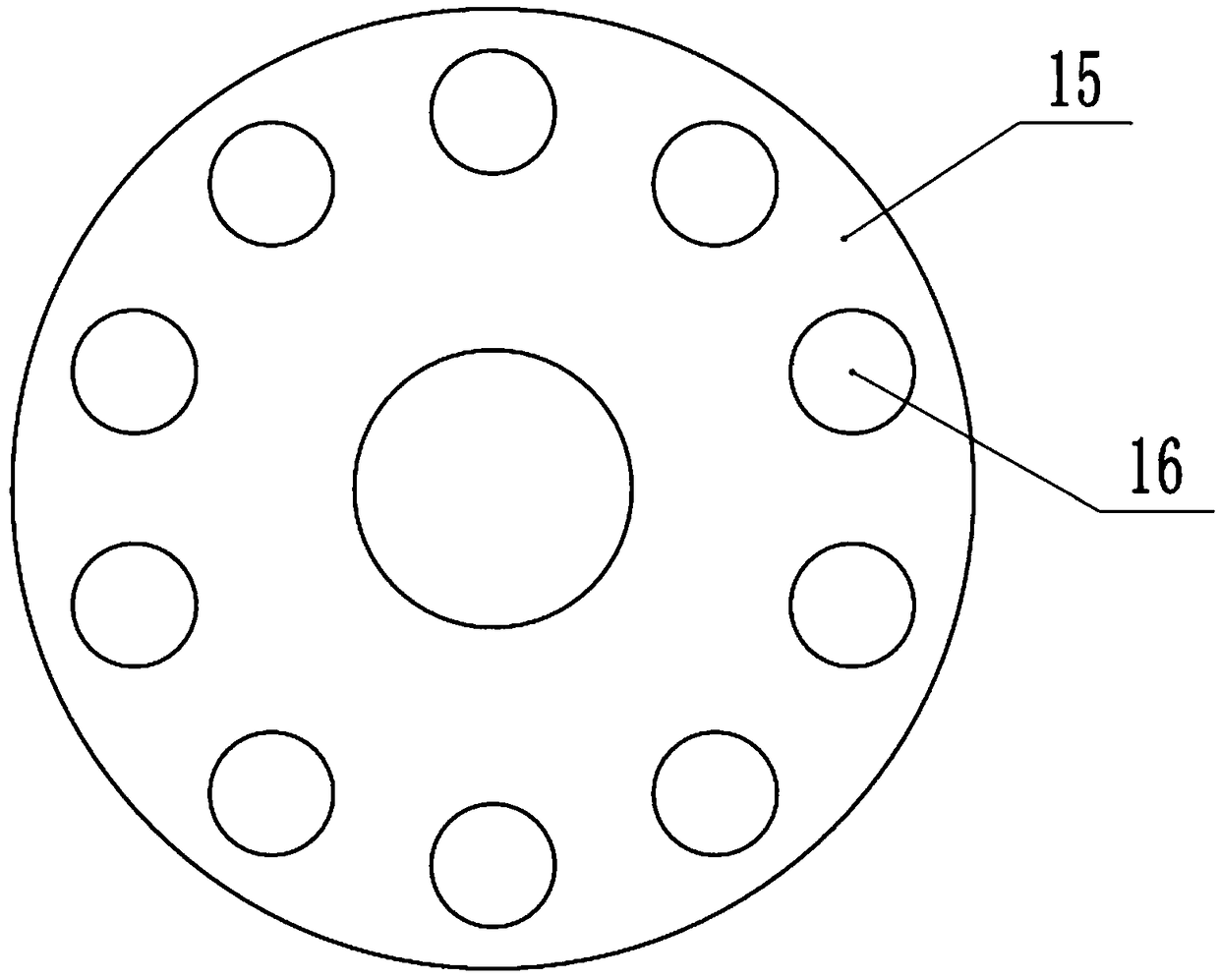

A core wire covering device for electric wires and cables

ActiveCN109065280AHigh coating uniformityThere will be no phenomenon that the thickness is not easyInsulating conductors/cablesEngineeringFixed position

The invention relates to the technical field of wire and cable processing, A core covering device for electric wire and cable is disclosed, including the rack, characterized in that: the actuate mechanism is also included, A traction collection roll is sequentially arranged on that machine frame, A cable cooling mechanism and a cable covering mechanism, The cable covering mechanism comprises a rotating roller rotatably connected to the machine frame, a driving plate driven by a driving mechanism fixedly connected to one end of the rotating roller and a wire plate fixedly connected to the otherend of the rotating plate, a plurality of winding rollers are rotatably connected between the wire plate and the driving plate along the circumferential direction of the rotating roller, and a tapered hole for the cable to pass through is formed in the middle of the rotating roller. As that rotation of the rotate roller is match with the traveling speed of the core wire, the coating material is kept in a relatively fixed position to coat the core wire, the coating uniformity is high, and the phenomenon that the thickness is not consistent will not be occur.

Owner:广东华东新电缆有限公司

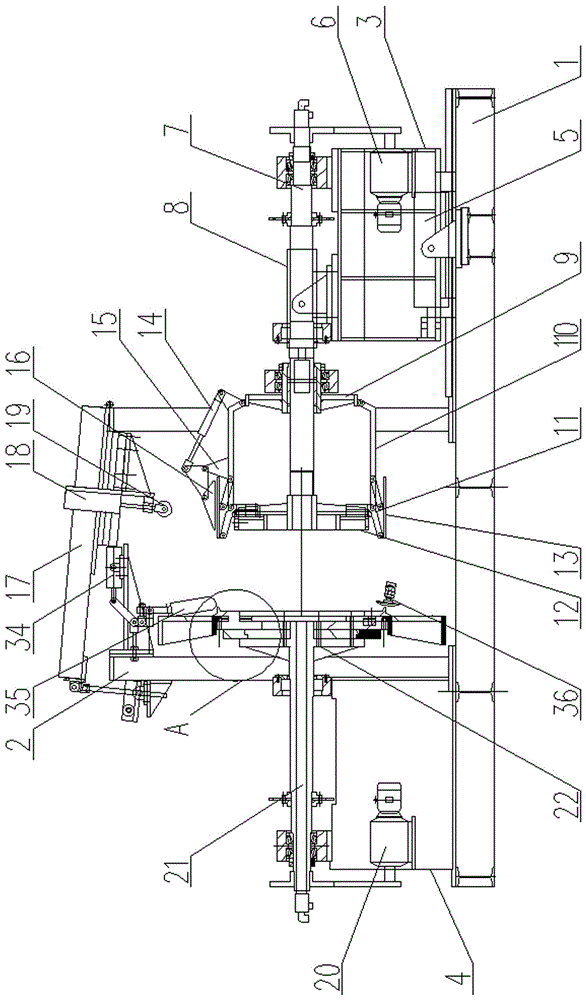

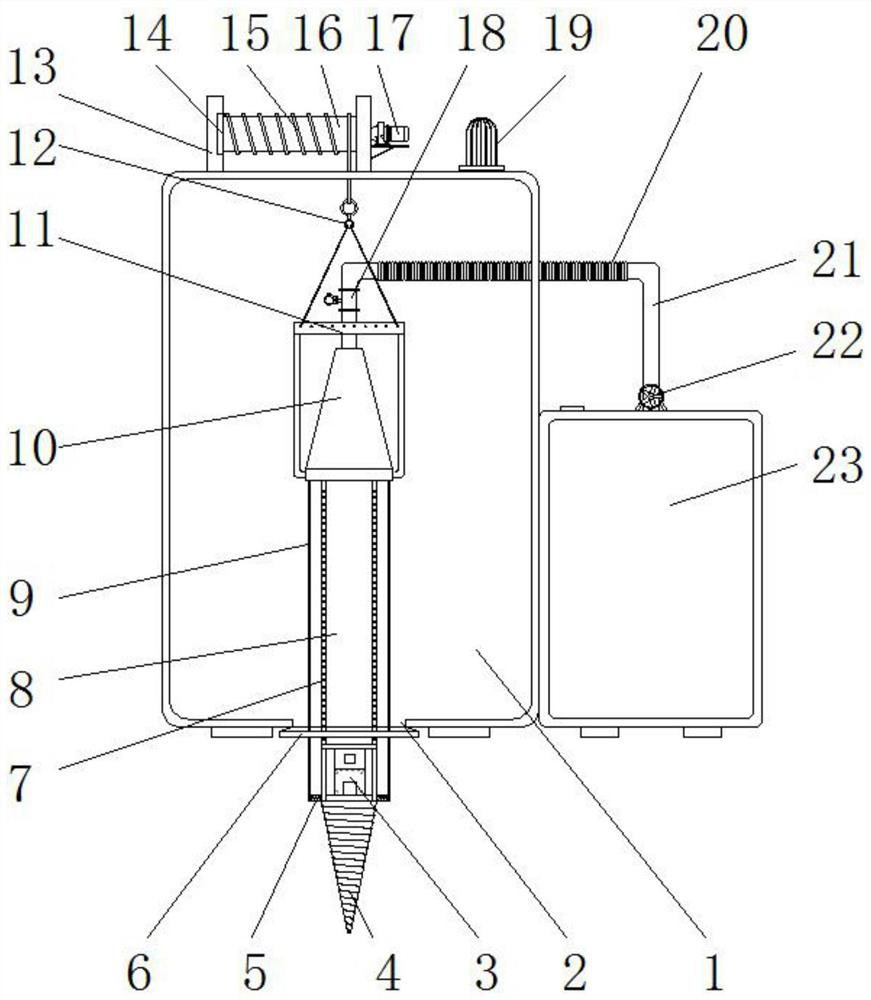

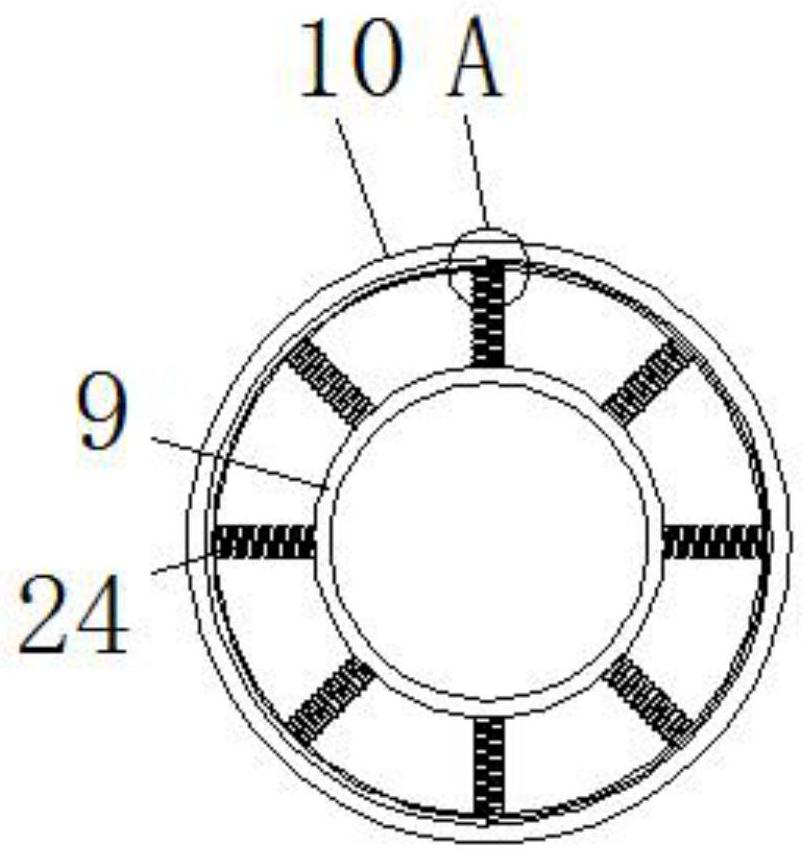

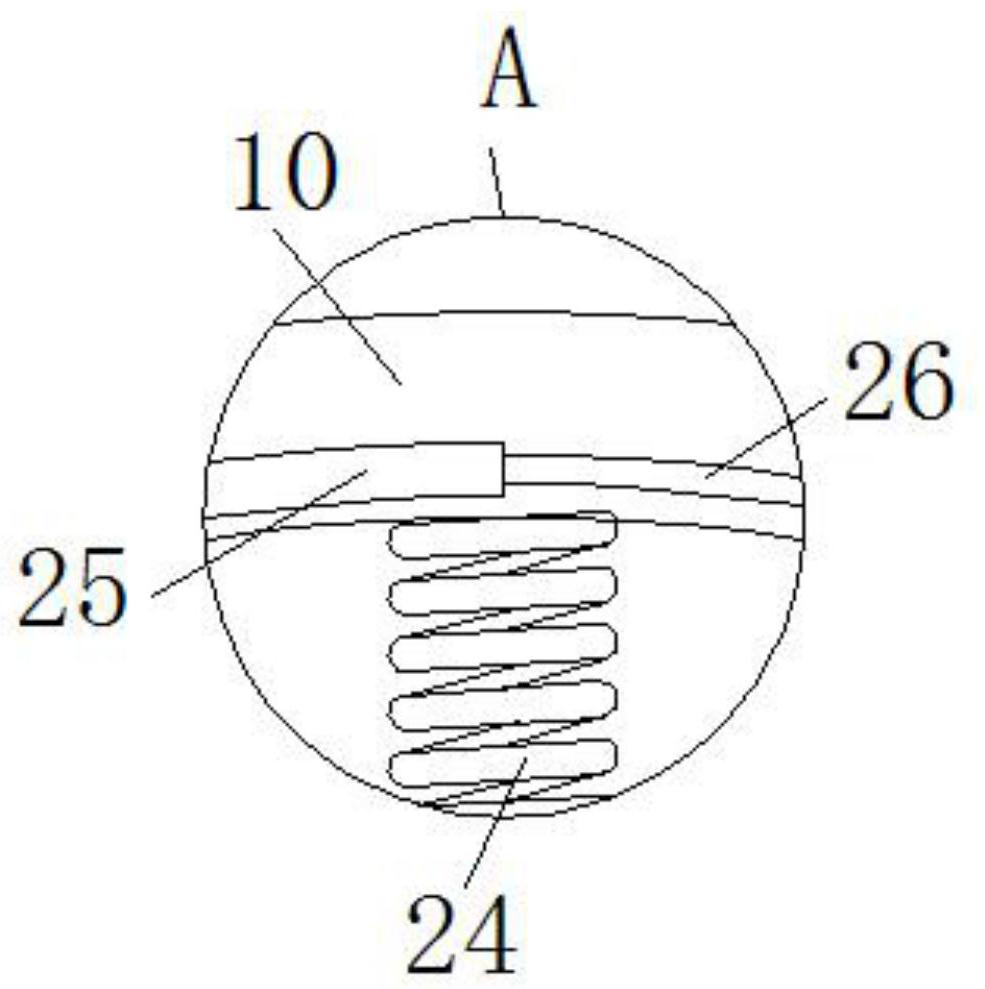

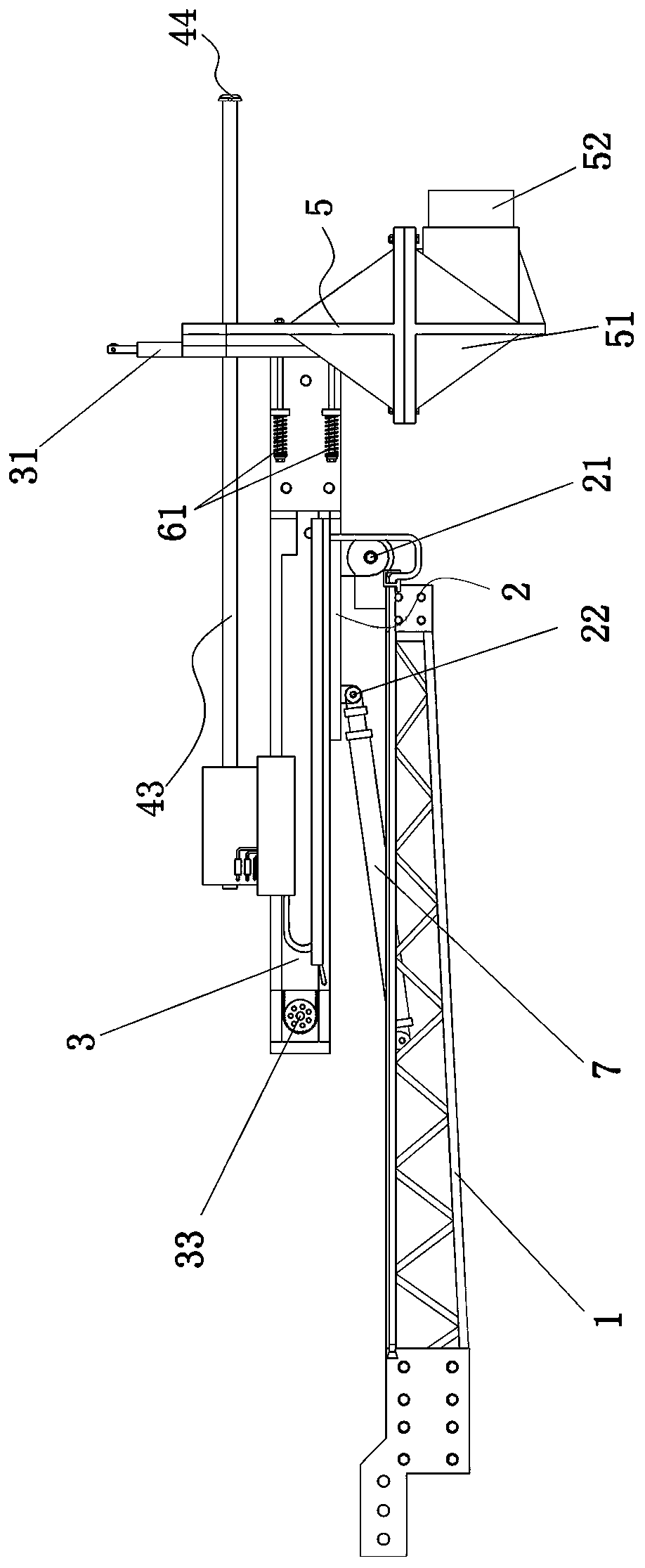

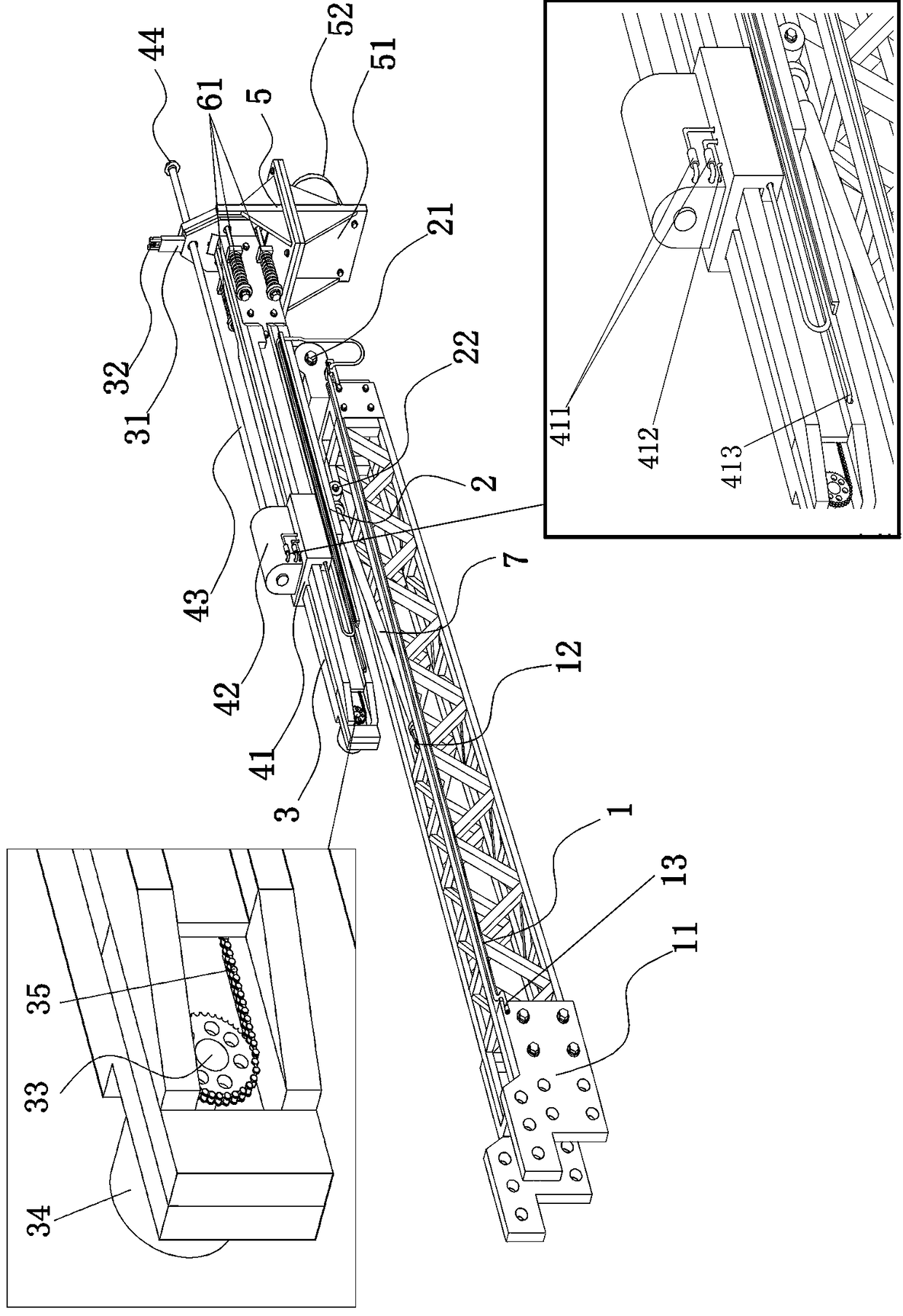

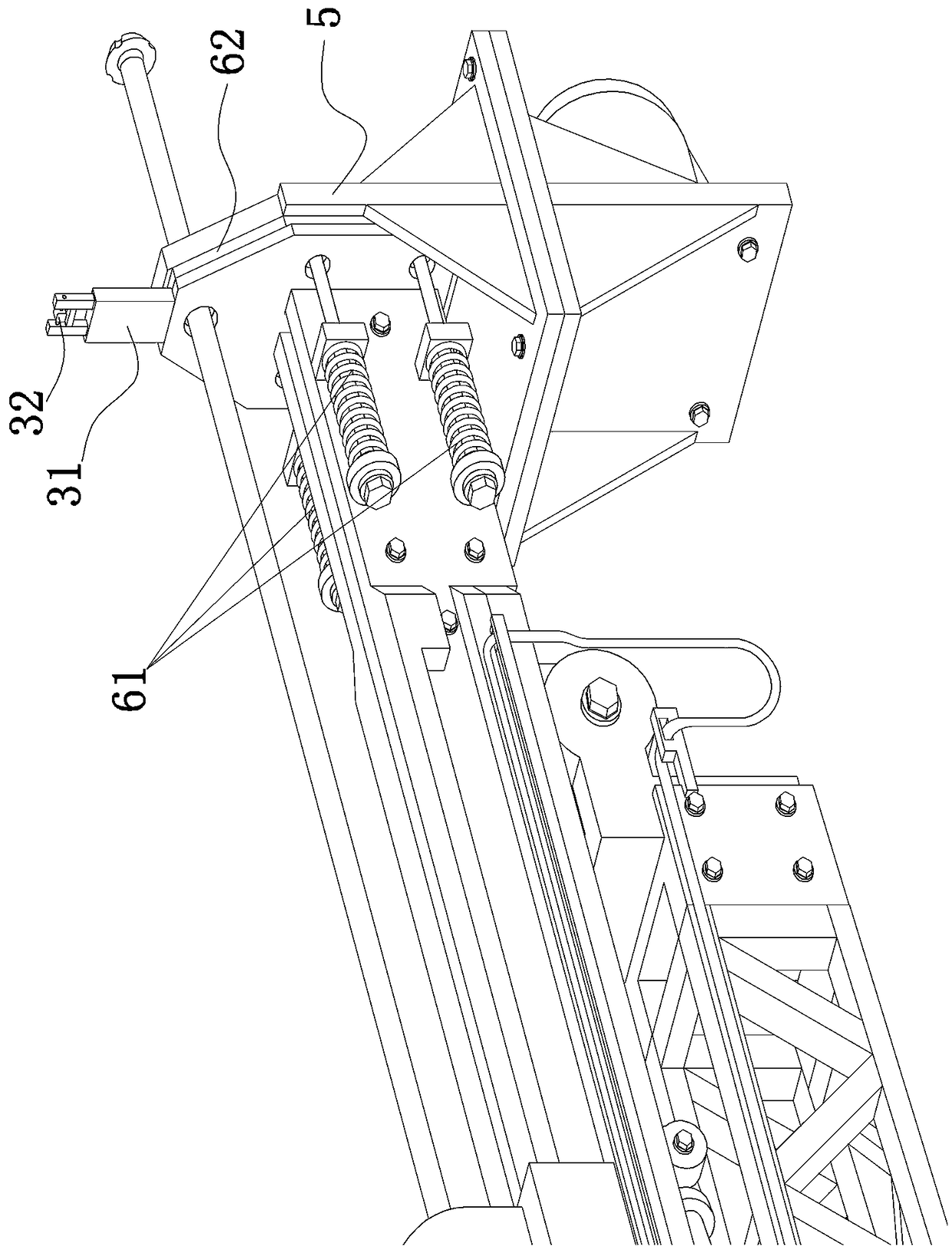

Rock wall slope drilling device

PendingCN108756742ASolve the problem that mechanical drilling cannot be usedClose fitDrilling rodsConstructionsAdhesion forceReciprocating motion

The invention provides a rock wall slope drilling device which comprises a crane or a hoist, a truss, a beam frame pitching mechanism, a beam frame, a rock drilling machine, a rock drilling machine stepping mechanism and a frame beam stabilizing seat. The rock drilling machine makes reciprocating movement on the beam frame, the frame beam stabilizing seat is fixed to the top end of the beam frame,and a drill rod penetrates through the upper portion of the frame beam stabilizing seat. The crane, a crane boom, the beam frame and the frame beam stabilizing seat form the stable structure by taking the ground and the rock wall as supporting points; the rock drilling machine moves forwards and backwards on a rock drilling machine base track; rubber supporting feet of the frame beam stabilizingseat are multi-point supporting feet, after the multi-point supporting feet jack rock, due to the fact that force applied to each point is different, springs in point-shaped supporting foot sleeves generate different elastic deformation, thus the effects that the supporting feet are closely attached to the surface of the rock to obtain higher adhesion force, and contact stability is improved are achieved, and meanwhile, the vibration reduction effect is also achieved; and the problem that the rock slope with large fall cannot adopt mechanical drilling is solved.

Owner:吉林省信旺地质工程有限公司

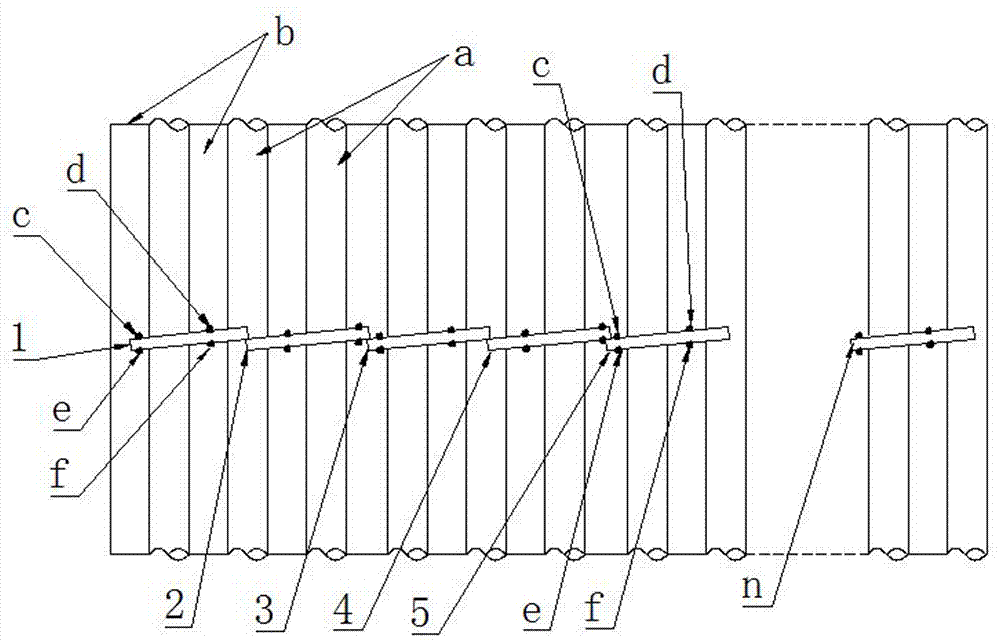

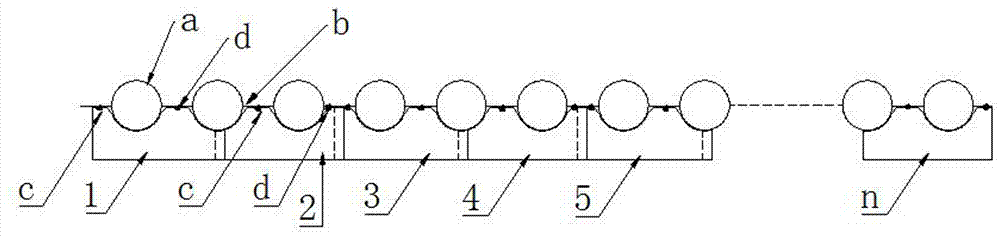

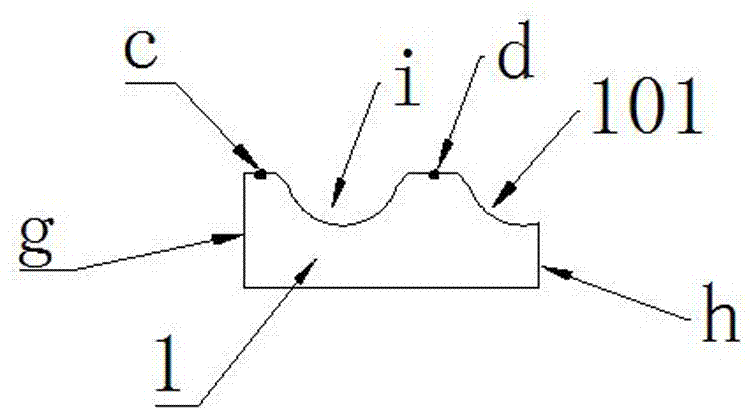

Water wall abrasionproof scale type welding method

ActiveCN106944760AWill not cause sheddingPrecise positioningOther workshop equipmentWelding apparatusEngineeringWater cooling

The invention relates to a water wall abrasionproof scale type welding method. Abrasionproof plates are adopted to carry out abrasion prevention on water cooled pipes in a sequential scale type overlapped manner. One side of each abrasionproof plate is provided with circular arc matched with the outer wall of the corresponding water cooled pipe, wherein the two sides of the circular arc are provided with an X welding point and a Y welding point, and the two welding points are arranged on the two sides of the abrasionproof plate. A horizontal line is drawn for the water cooled pipes which are arranged side by side, and the abrasionproof plates intersect with the horizontal line. Frstly, the X welding points of the first abrasionproof plates are subjected to spot welding, then, the X welding points of the second abrasionproof plates are subjected to spot welding sequentially, the multiple abrasionproof plates are sequentially subjected to spot welding, the abrasionproof plates intersect with the horizontal lines and are mutually and partially overlapped, the X welding points of each abrasionproof plate are welded, and then the Y welding points of each abrasionproof plate are welded; or the X welding points and the Y welding points of each abrasionproof plate are sequentially welded. The method using the scheme has the beneficial effects that overlapping gaps of the abrasionproof plates are tight, the welding quality is high, the abrasionproof plates are not prone to disengaging, and the abrasionproof effect is good.

Owner:ZHENGZHOU SANZHONG WEAR TECH

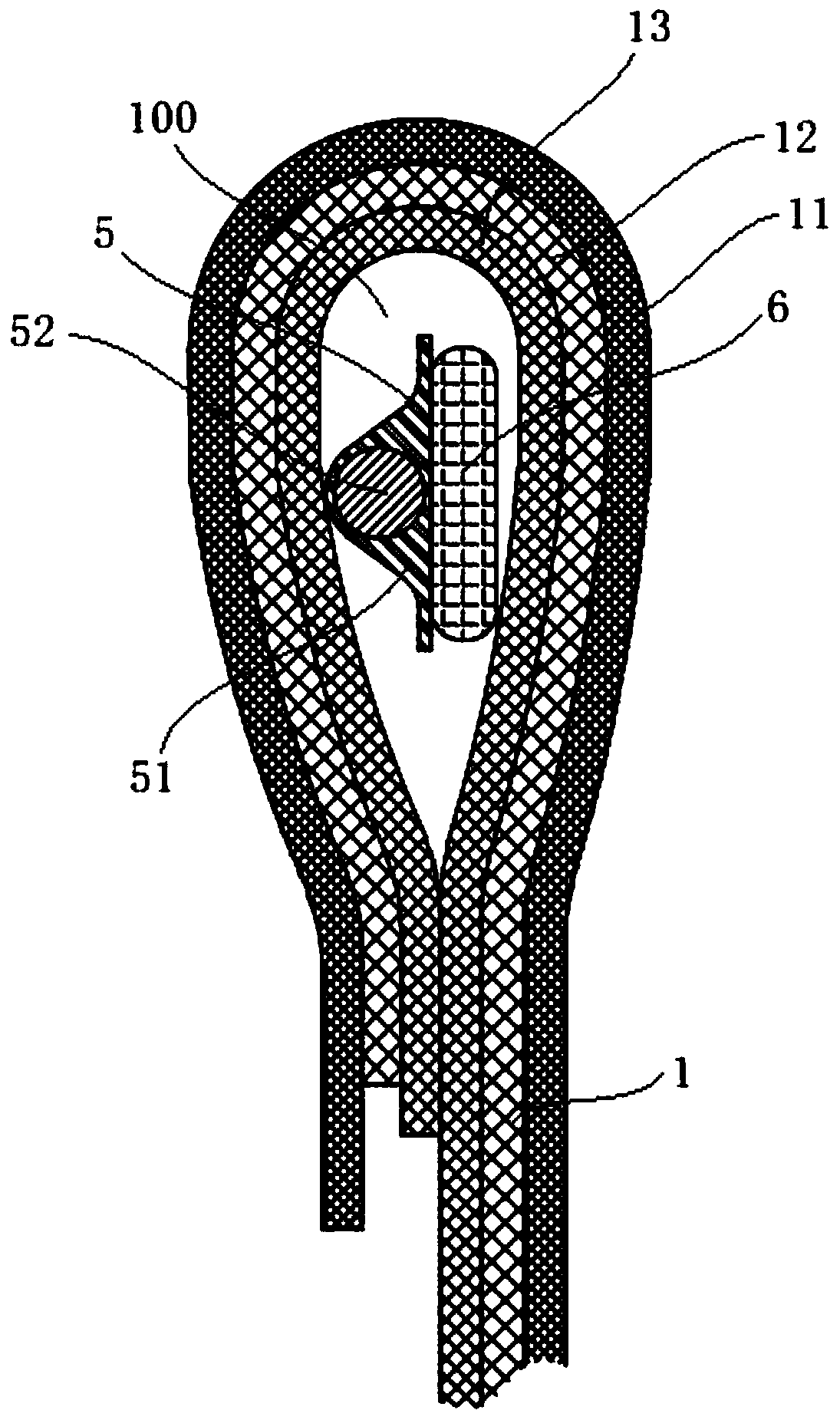

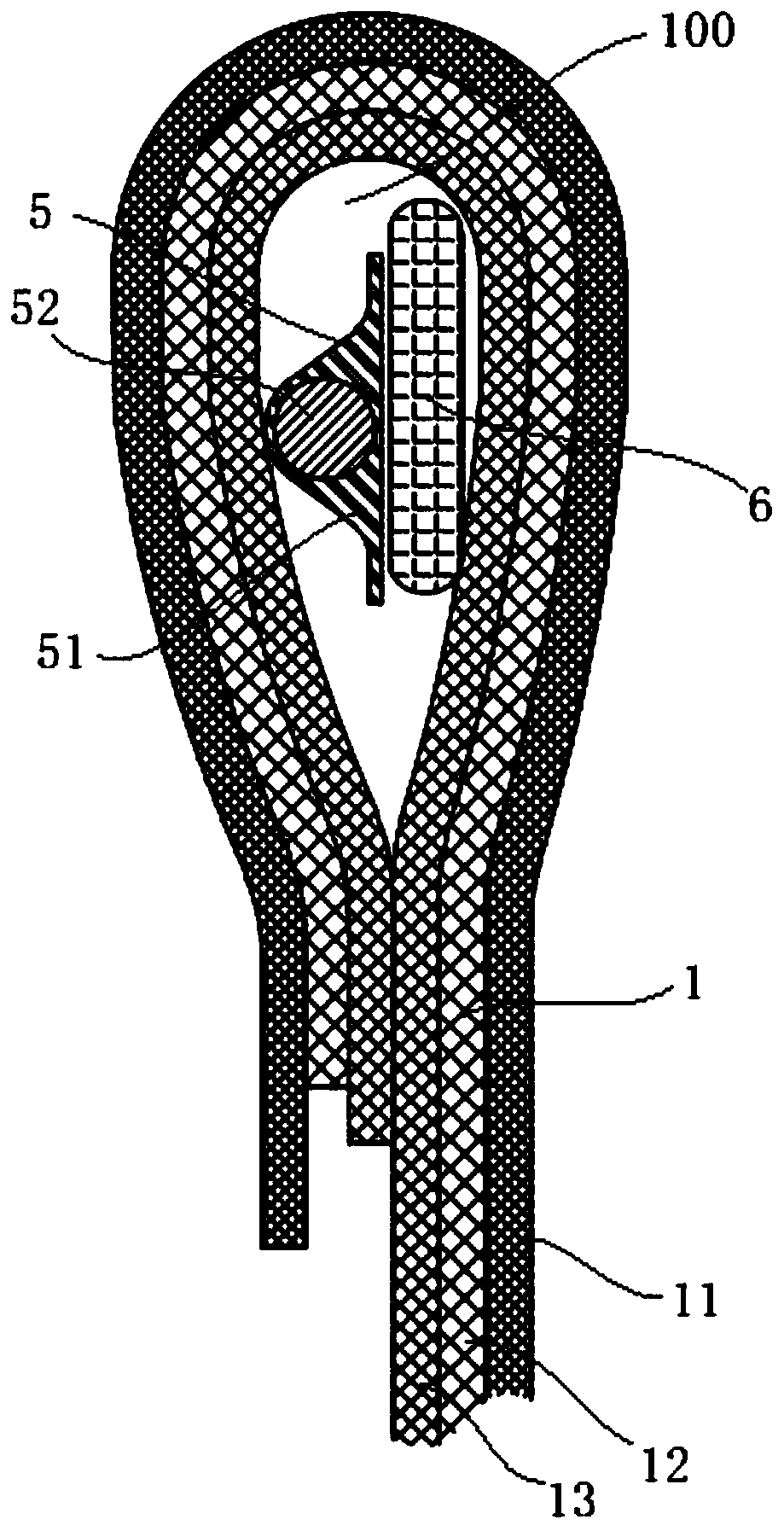

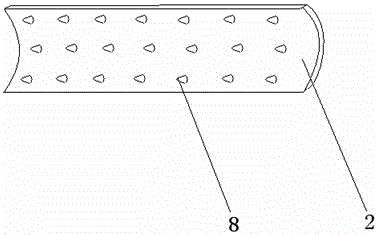

Bag type gas extraction hole plugging device

The invention relates to a hole plugging device used for plugging a coal gas extraction hole, in particular to a bag type gas extraction hole plugging device which is suitable for all kinds of drill holes, is good in plugging effect and can adjust the depth of plugging the hole. The pocket type gas extraction hole plugging device comprises a bag body which is made of fabric with breathable and water seepage properties and a slurry injecting connector which is arranged on one end of the bag body which is of a hollow barrel structure; the bag body is sleeved outside a gas extraction pipe and comprises plugging sections and a slurry injecting section; the plugging sections are located at the two ends of the bag body; the slurry injecting section is arranged between the plugging sections; the outer diameter of the plugging sections is larger than the diameter of the gas extraction drill hole to be plugged; the outer diameter of the slurry injecting section is smaller than the diameter of the gas extraction drill hole to be plugged; slurry outlet holes are formed radially in the slurry injecting section; a hoop is sleeved on the opening of each end of the bag body; the inner diameter of the slurry injecting connector is 12mm; the number of the slurry outlet holes is ten; and the pore diameter of each slurry outlet hole is 2-3mm. The bag type gas extraction hole plugging device has the advantages that the structure is simple, the operation is convenient, the depth of plugging the hole is adjustable, the bag body is tightly fitted with a coal bed, and the plugging is tight.

Owner:JIAOZUO CHANGHAI MACHINERY TECH

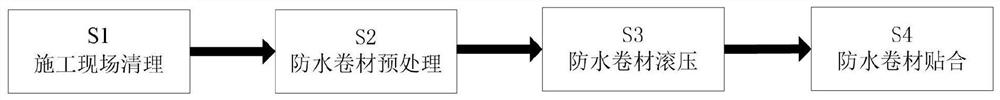

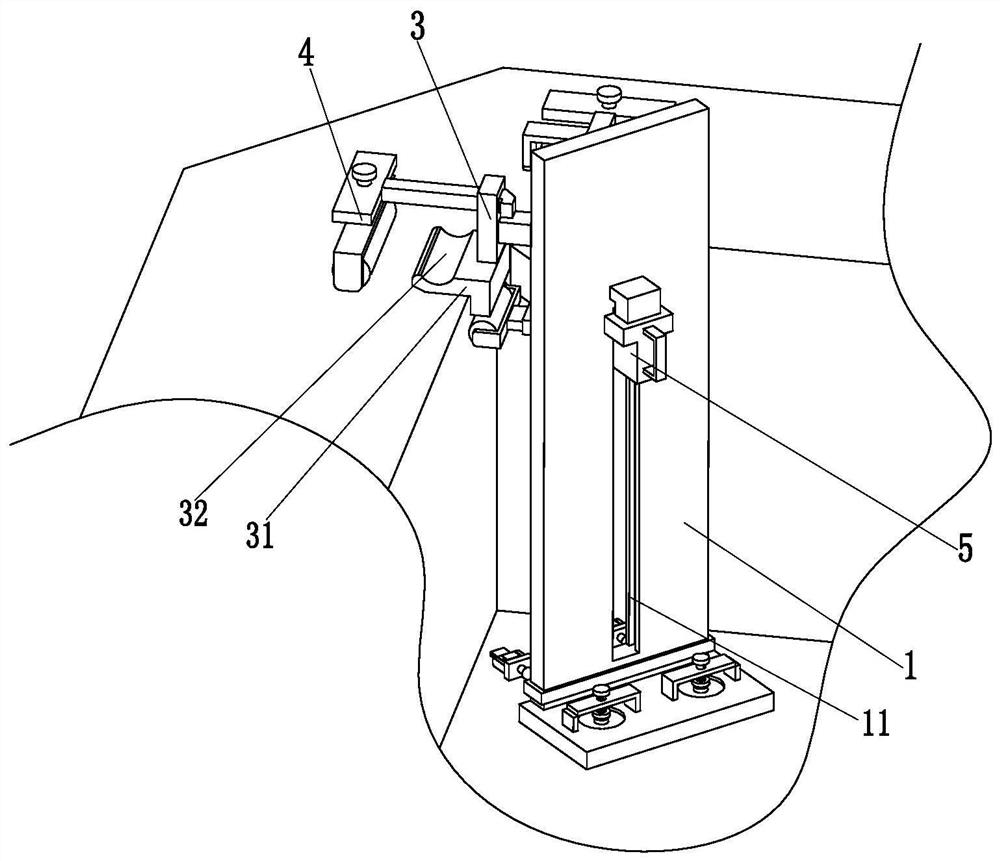

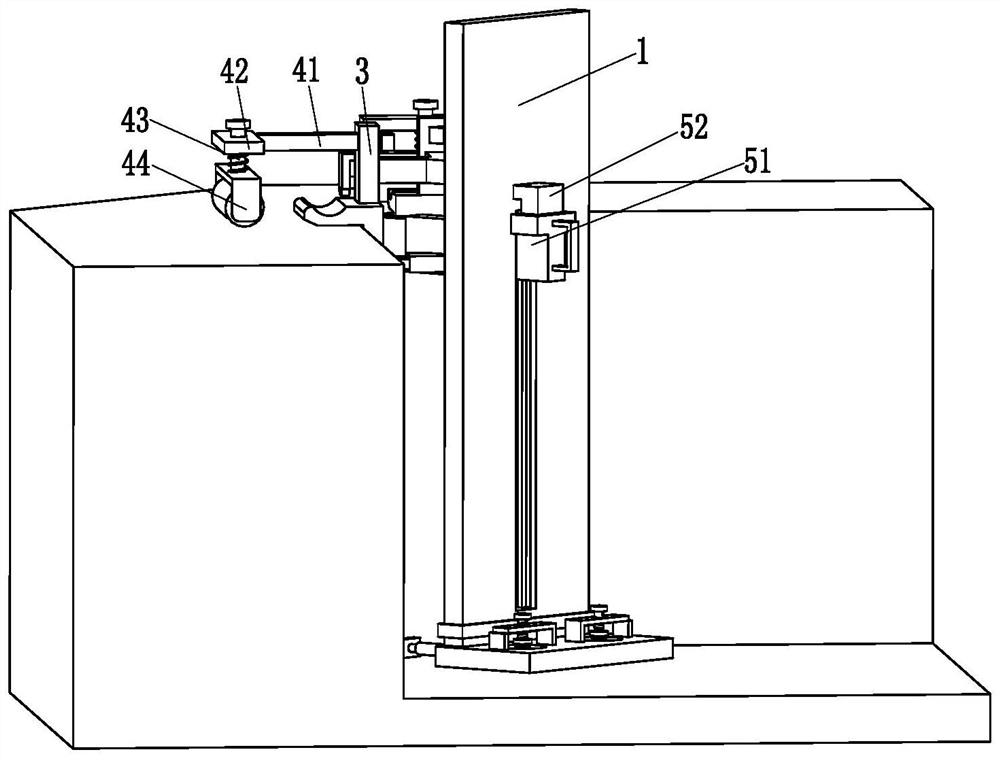

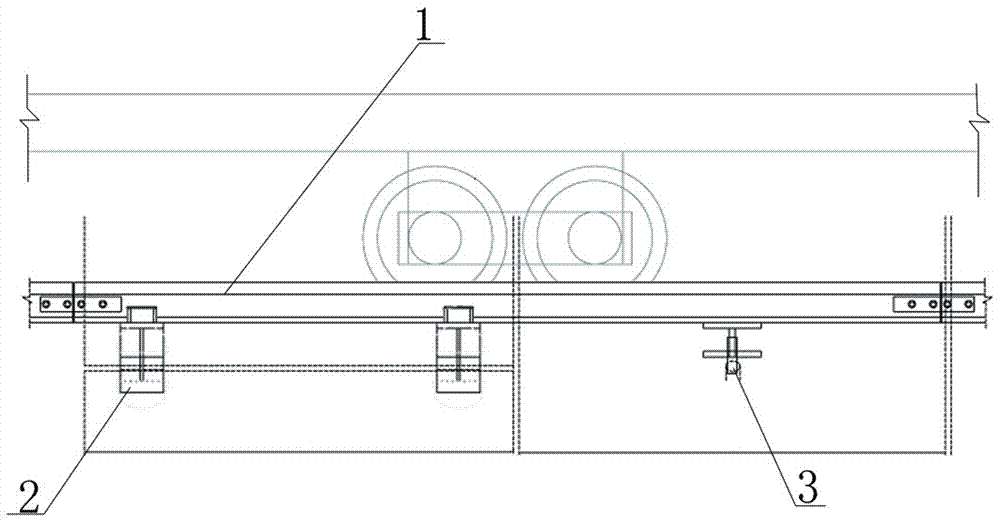

Polyethylene polypropylene fiber composite waterproof roll laying construction method

InactiveCN112681398AEasy to lap and layIncrease laying straightnessProtective foundationConstruction engineeringMaterials science

The invention relates to a polyethylene polypropylene fiber composite waterproof roll laying construction method. The polyethylene polypropylene fiber composite waterproof roll laying construction method adopts the following waterproof roll laying device, and the waterproof roll laying device comprises a vertical frame, a support frame, a clamping and pressing plate, a pressing mechanism and a rolling mechanism; and the polyethylene polypropylene fiber composite waterproof roll laying construction method adopting the waterproof roll laying device comprises the following steps: S1, cleaning a construction site; S2, pretreating waterproof rolls; S3, rolling the waterproof rolls; and S4, laminating the waterproof rolls. According to the construction method, the following problems existing when waterproof rolls are manually laid in the prior art that the laying difficulty of the side edges of the waterproof rolls is high, the waterproof rolls at the upper end and the side surfaces of a square pit need to be manually flattened and compacted respectively, the waterproof rolls can be displaced and deflected when being laid, consequently the laying effect of the waterproof rolls is poor, the waterproof rolls are prone to wrinkling during laying, and the waterproof performance of the waterproof rolls in the later period is affected can be solved.

Owner:竺从力

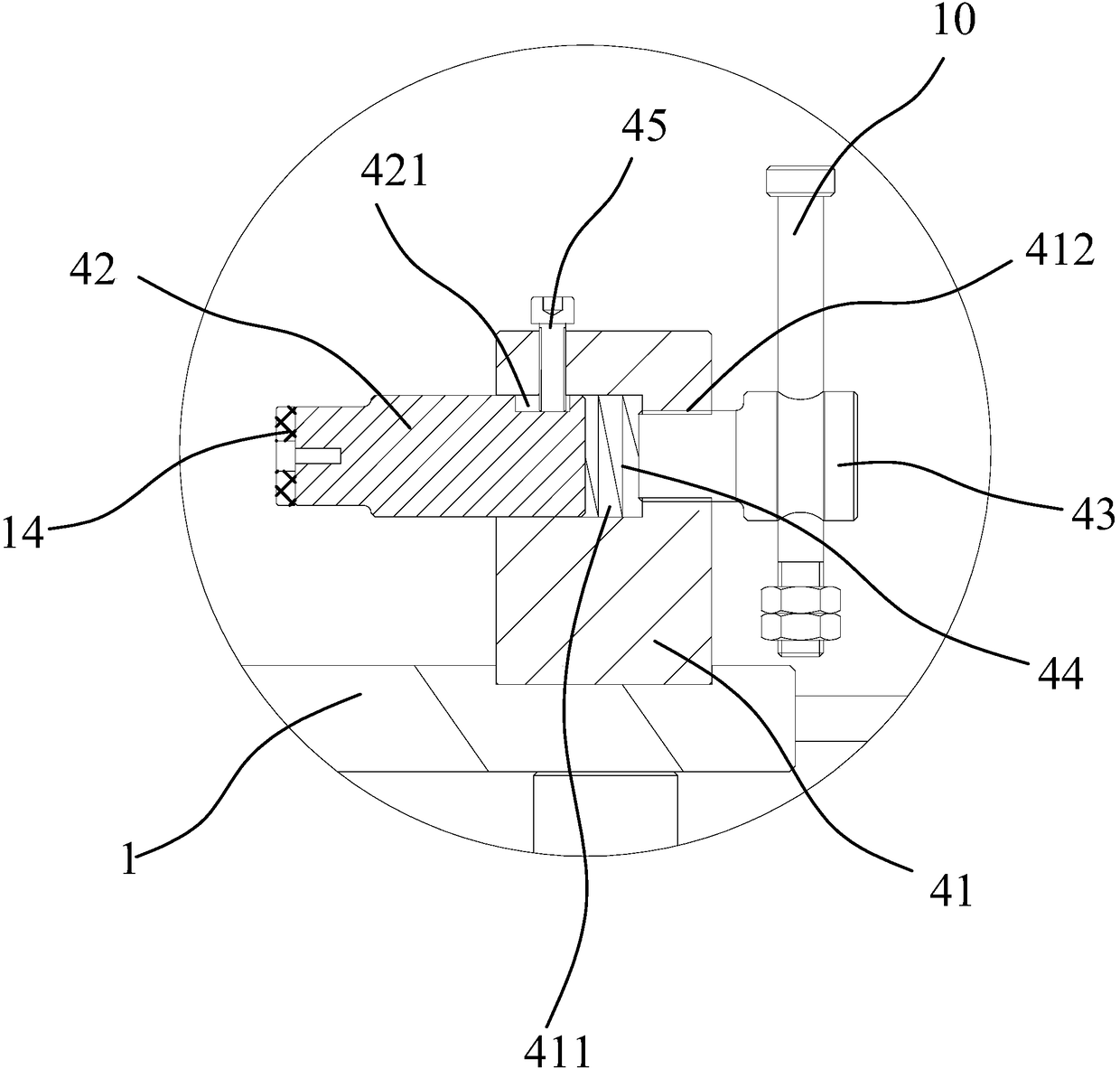

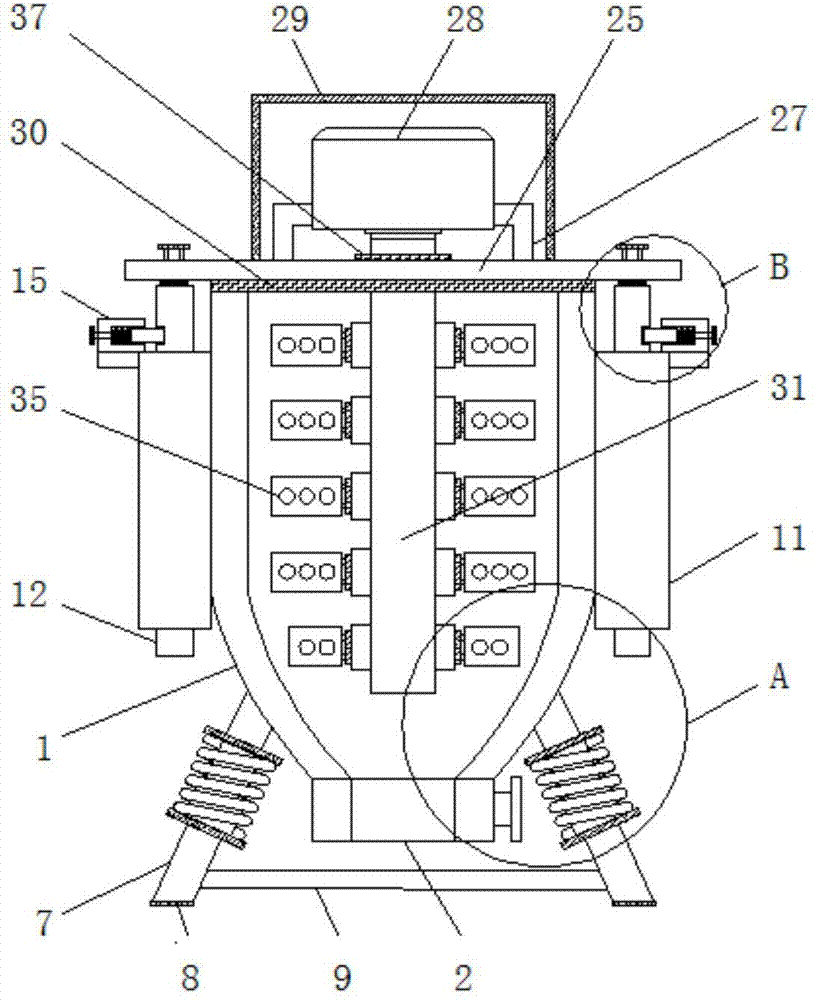

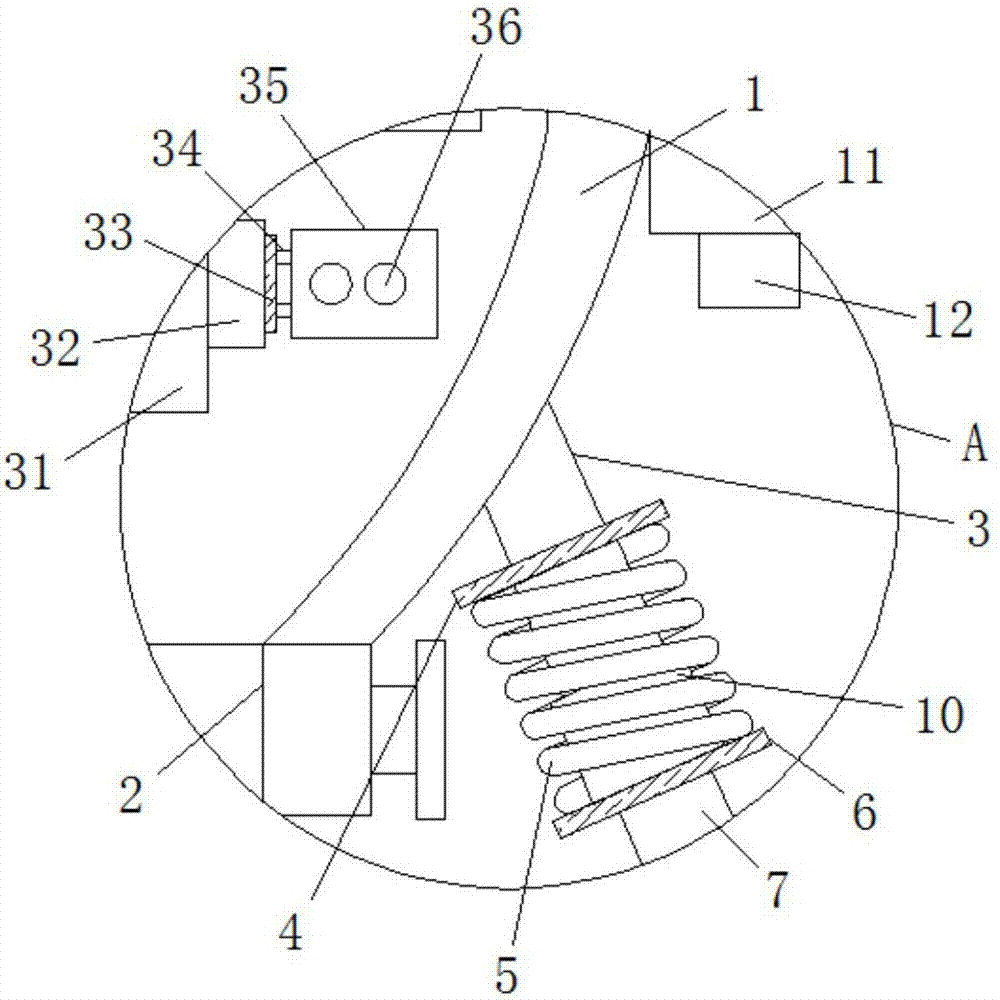

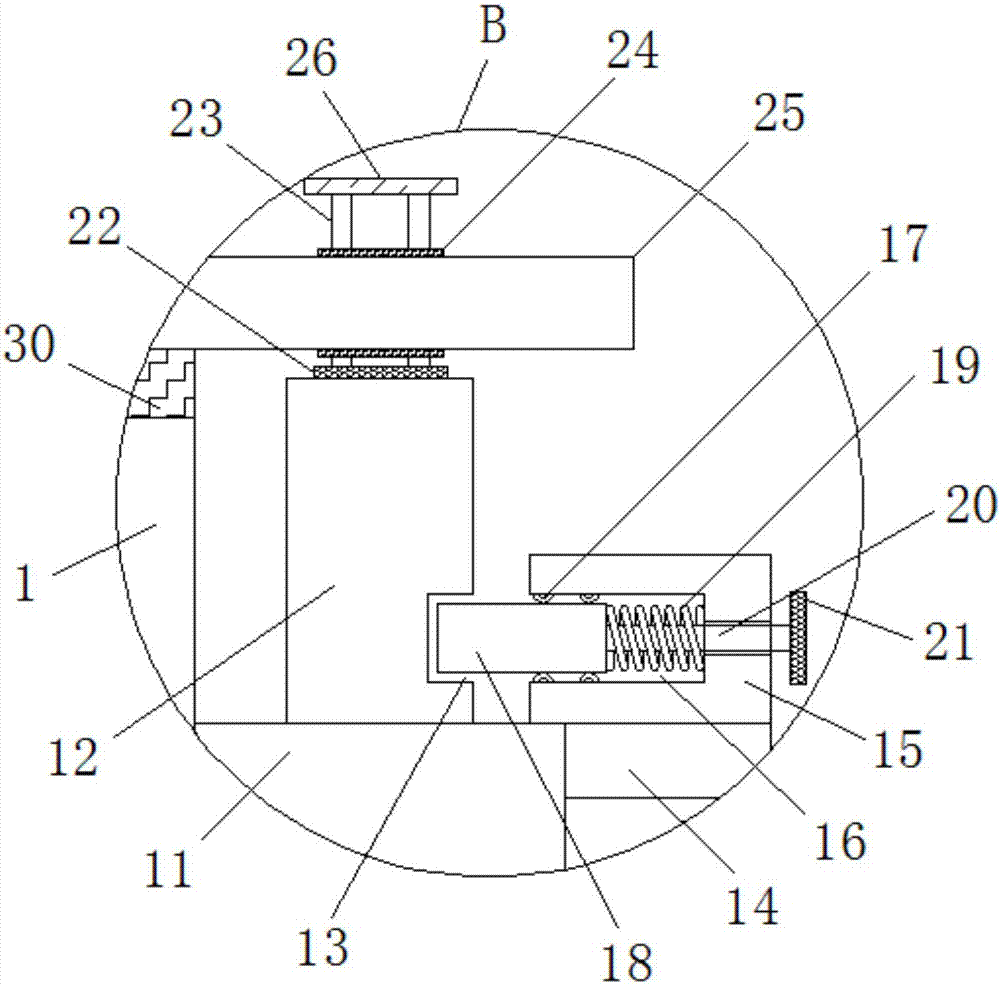

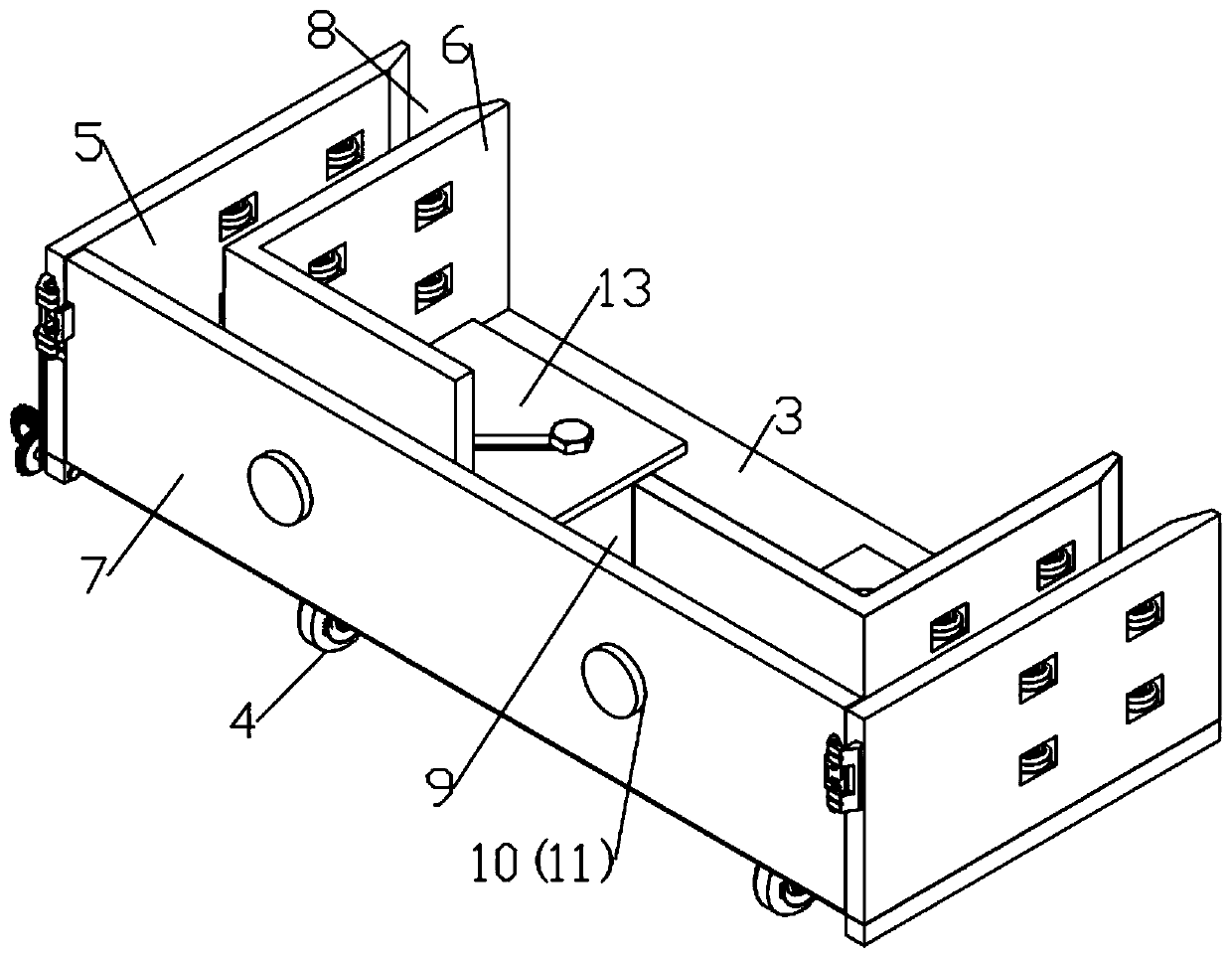

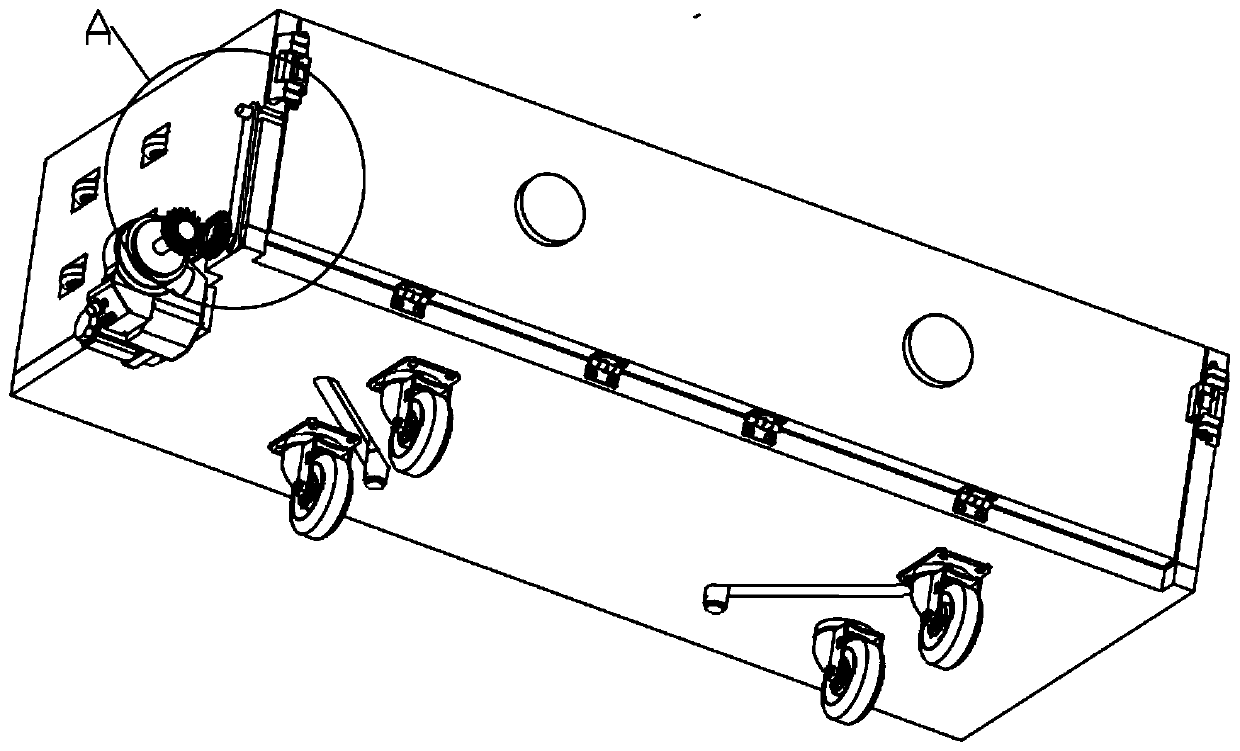

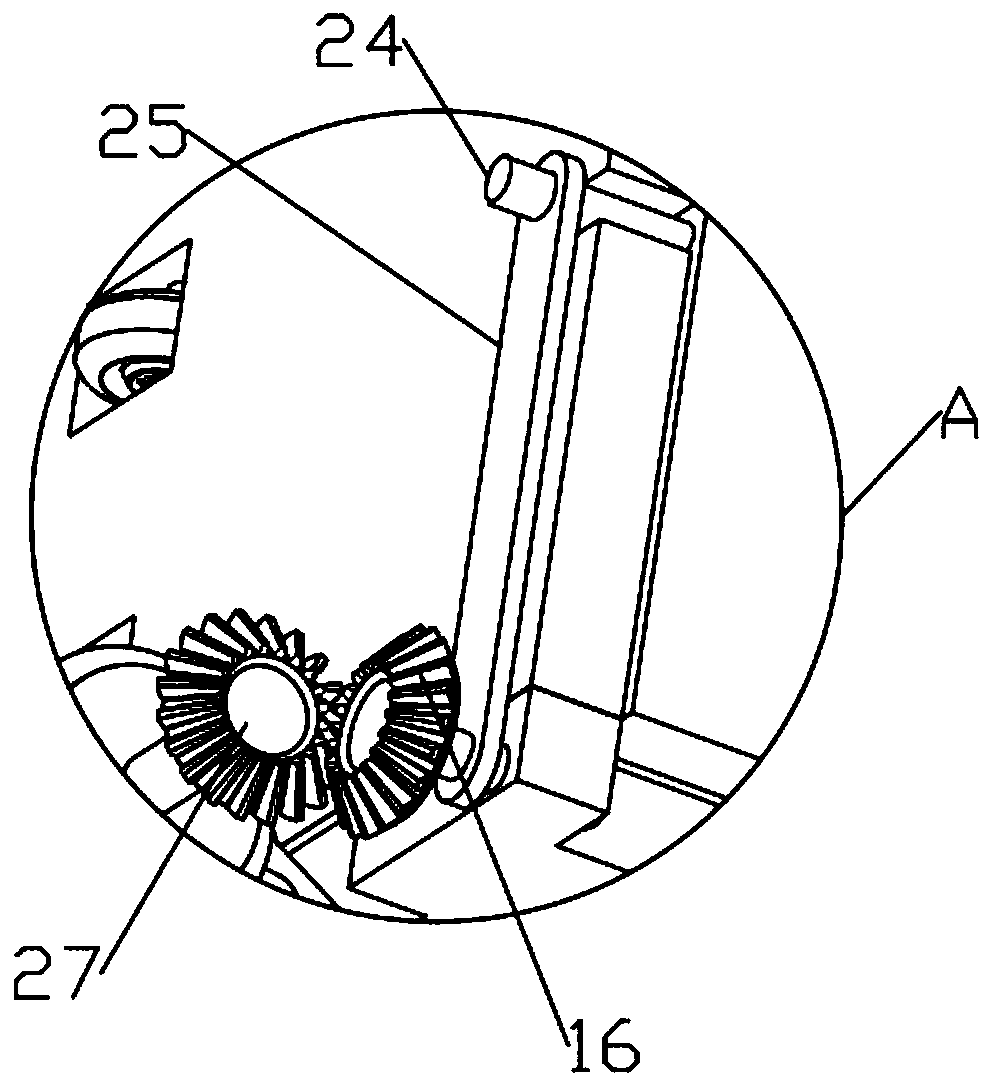

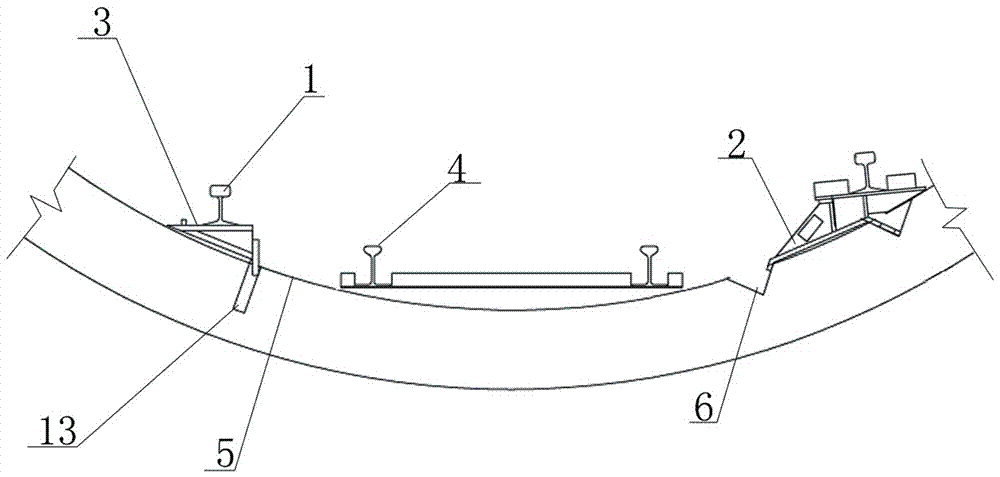

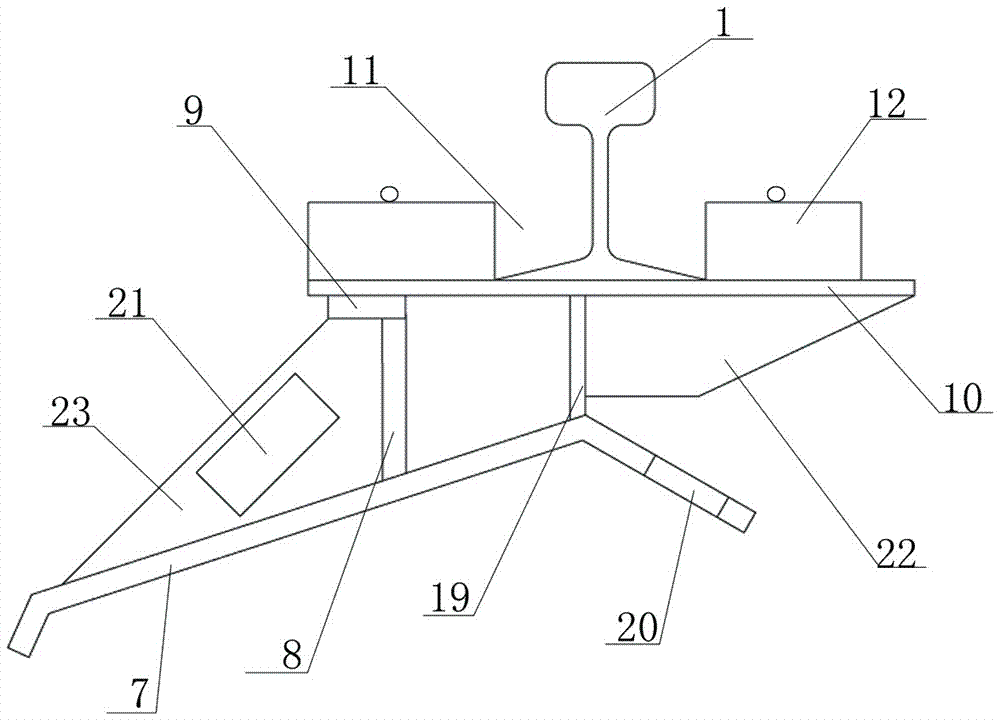

Convenient-mounted type shield trolley combined rail bearings and utilization method thereof

The invention provides convenient-mounted type shield trolley combined rail bearings and a utilization method thereof. The convenient-mounted type shield trolley combined rail bearings comprise two kinds of trolley rail bearings fixed to the bottoms of trolley rails, the two trolley rails are arranged on the two sides of an electromobile rail, and the positions below the trolley rails and the electromobile rail are both provided with pipe pieces. Each pipe piece is of a shield tunnel circular second lining structure, and laid on a pipe piece foundation with the section being in an arc shape. The trolley rails are fixed to the pipe pieces through the two kinds of trolley rail bearings which are used by cooperation, and the two kinds of trolley rail bearings are the limiting trolley rail bearings and the loading trolley rail bearings which are arranged below the trolley rail alternately in a 2:1 mode. The two ends of each limiting trolley rail bearing are connected with hand holes on thecorresponding pipe piece, one end of each bearing trolley rail bearing is arranged blow the trolley rails, and the other end is connected with an assembly hole. The convenient-mounted type shield trolley combined bearings have the characteristics of being safe, applicative and the like, have good popularization and practical value, and can generate good economic benefits after being widely applied and popularized.

Owner:北京城建中南土木工程集团有限公司

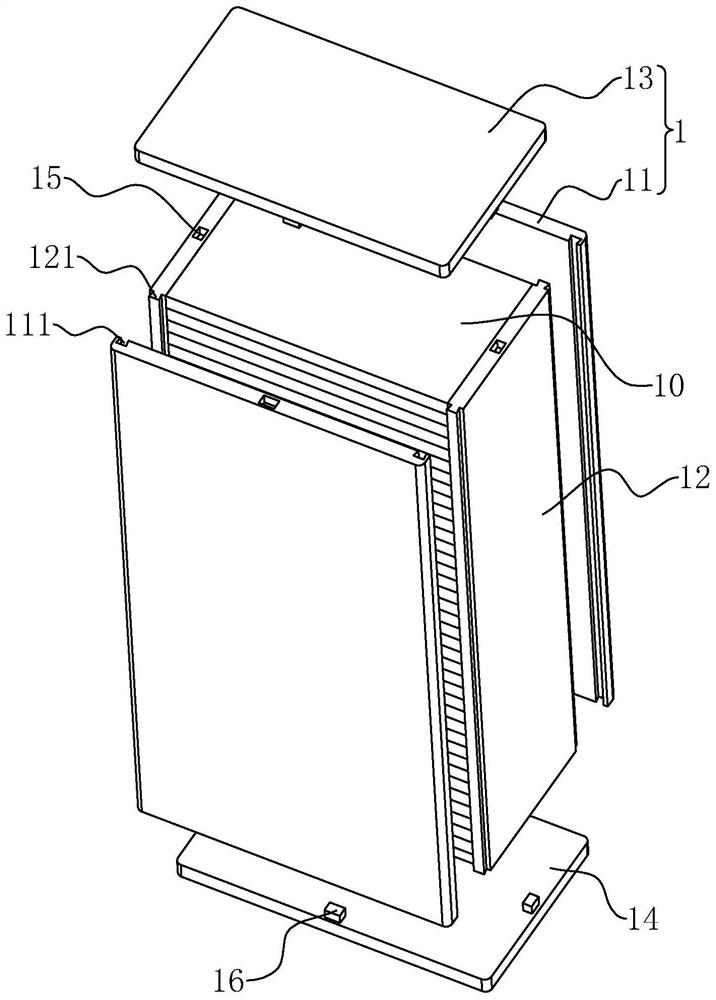

Electric reactor iron core structure, and manufacturing equipment and manufacturing method thereof

ActiveCN113130180AConvenience to workImprove cooling effectTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEpoxyAluminum foil

The invention relates to an electric reactor iron core structure. The structure comprises a magnetic core cake and a winding wound on the magnetic core cake, the winding comprises an insulation paper layer and an aluminum foil tape layer which are mutually staggered and stacked, the outer side wall of the magnetic core cake is coated with an epoxy resin layer, division bars are fixed to the four vertex angles of the magnetic core cake in a protruding mode, and the division bars are fixedly connected to the epoxy resin layer. The length direction of the division bars is parallel to the length direction of the magnetic core cake, the winding is wound on the division bar, and a first heat dissipation air channel is formed between the inner wall of the winding and the outer wall of the magnetic core cake; and mounting plates are arranged on the two opposite outer side walls of the magnetic core cake in a protruding mode, a plurality of partition plates are arranged on the mounting plates, the length direction of the partition plates is parallel to the length direction of the magnetic core cake, winding cavities allowing windings to penetrate through and be wound are formed between the partition plates and the partition strips and between every two adjacent partition plates on the same mounting plate, and second heat dissipation air channels are formed in the end faces of the partition plates in a penetrating mode. The structure has the advantage that the heat dissipation effect of the reactor is improved.

Owner:上海波亮电器制造有限公司

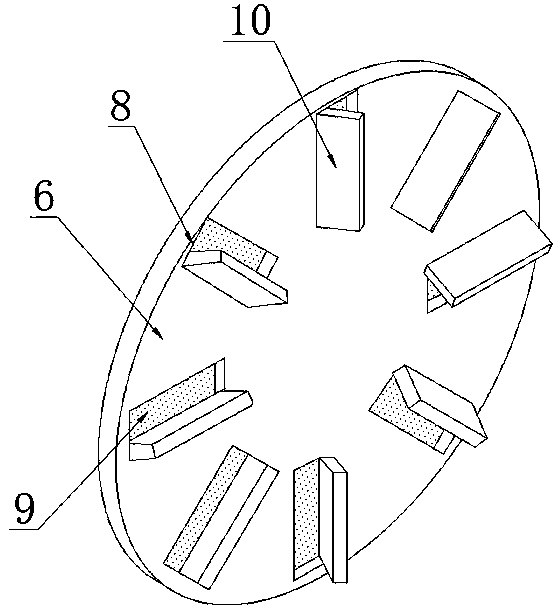

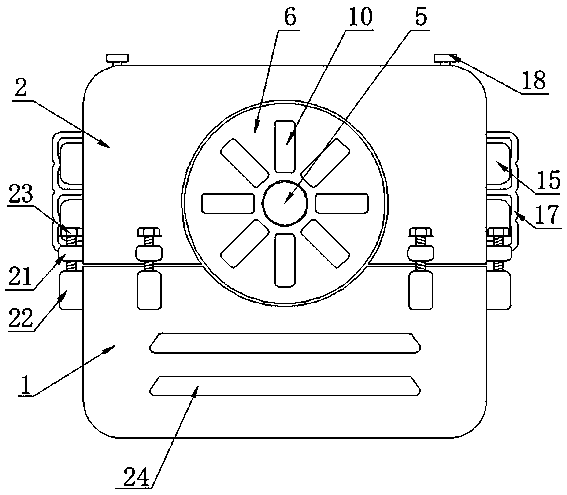

Permanent magnet motor for new energy automobile

ActiveCN111525740AMaintain temperatureMaintain balanceCooling/ventillation arrangementSupports/enclosures/casingsCircular discNew energy

The invention discloses a permanent magnet motor for a new energy automobile. The permanent magnet motor comprises a lower box body and an upper box body, wherein the bottom of the upper box body is movably connected with the top of the lower box body, the inner cavity of the lower box body is fixedly connected with a bearing plate, the surface of the bearing plate is fixedly connected with a motor body, and the inner cavity of the motor body is rotatably connected with an output shaft. The invention relates to the technical field of permanent magnet motors. According to the invention, duringwork, the output shaft rotates and drives the disc to rotate at the same time, the disc drives the air suction groove and the flow guiding plate to rotate so as to form vortex flow, external air is pumped into the air suction groove along the air suction groove and is filtered by the first filter screen, the filtered air is introduced into the lower box body and the upper box body along the annular groove, the hot air in the upper box body and the lower box body is exhausted along the air inlet groove, and air exchange is performed, so that air exchange treatment can be performed while working, the balance between the temperature in the box bodies and the outside can be kept, the motor body is prevented from working at high temperature for a long time, and the motor body does not need to be driven by an additional power source.

Owner:重庆市小电天体新能源汽车有限公司

Zinc-coated steel wire for 1960MPa-level marine engineering and production method thereof

ActiveCN111763899AGuaranteed suitabilityEnsure safetyHot-dipping/immersion processesEngineeringStructural engineering

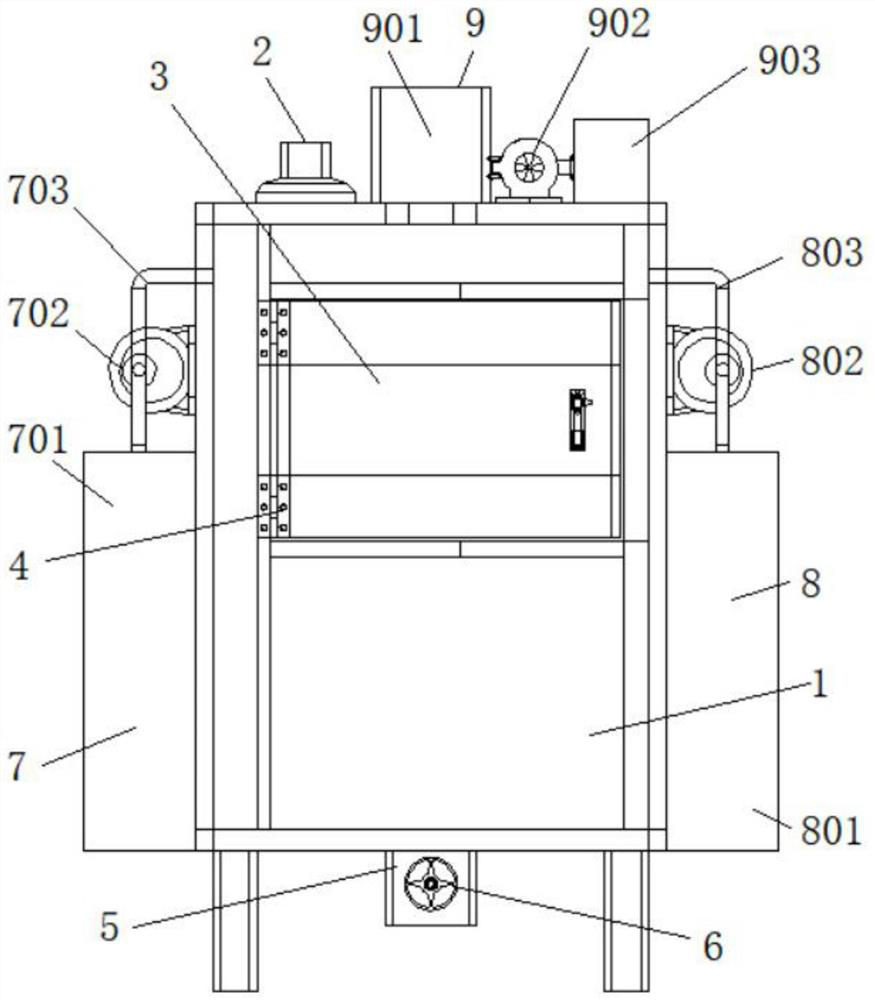

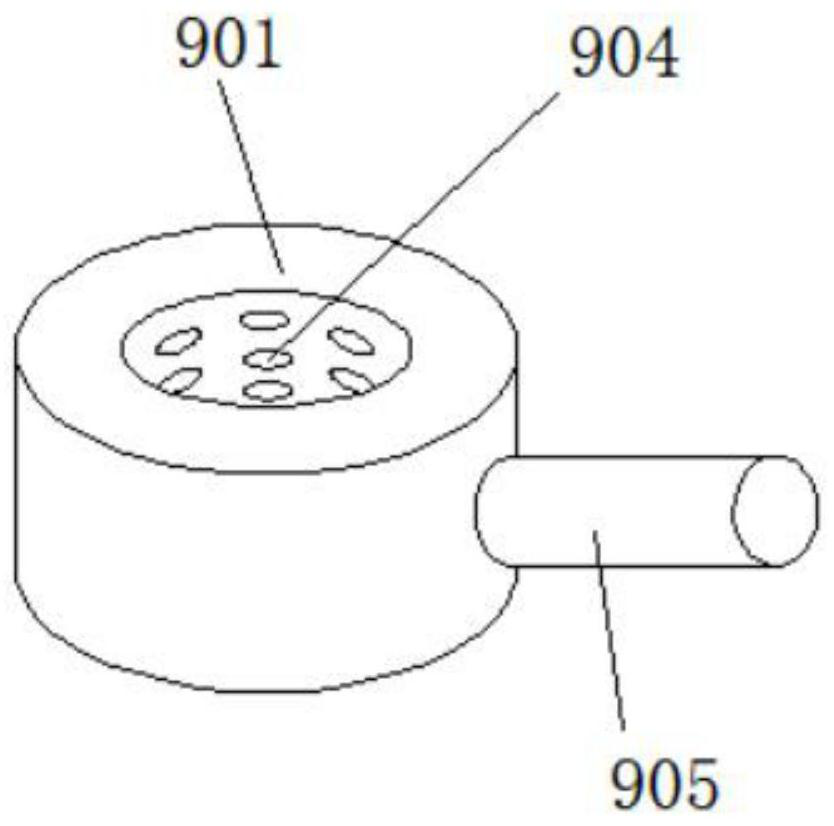

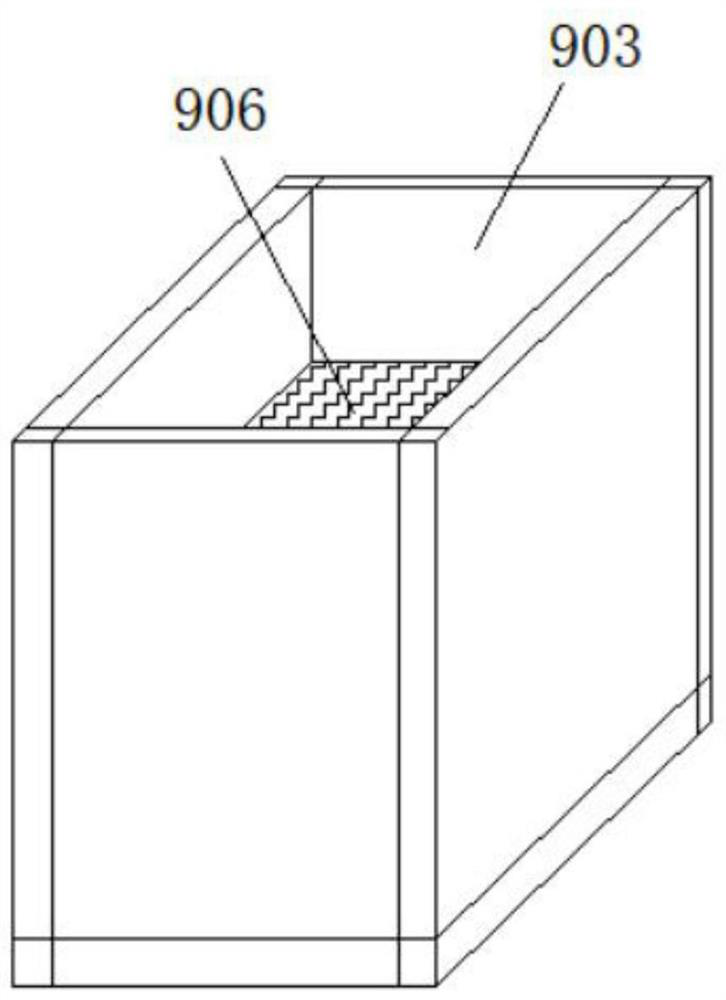

The invention discloses a zinc-coated steel wire for 1960MPa-level marine engineering and a production method thereof. The zinc-coated steel wire for 1960MPa-level marine engineering comprises a zinc-coated box body, an acid pickling conveying structure, a plating solution conveying structure and a plating solution air-drying structure, wherein a water inlet is formed in the left upper end of thezinc-coated box body; the front end surface of the zinc-coated box body is provided with a sealing door plate; one side of the sealing door plate is connected to a connecting hinge; the acid picklingconveying structure is mounted at the left side of the zinc-coated box body; the plating solution conveying structure is arranged at the right side of the zinc-coated box body; the plating solution air-drying structure is arranged at the upper end of the zinc-coated box body; the rear side of the zinc-coated box body is provided with a repair and grinding structure, and a zinc-coated steel wire rolling structure; and the repair and grinding structure is positioned above the zinc-coated steel wire rolling structure. The integrated structure of the zinc-coated box body can be arranged to accomplish processes such as acid pickling, washing, plating assisting solution adding and drying, so that integral floor space of the device can be reduced, a great deal of space is saved, and production efficiency of steel wire zinc-coating is improved.

Owner:南通市华星钢丝制品有限公司

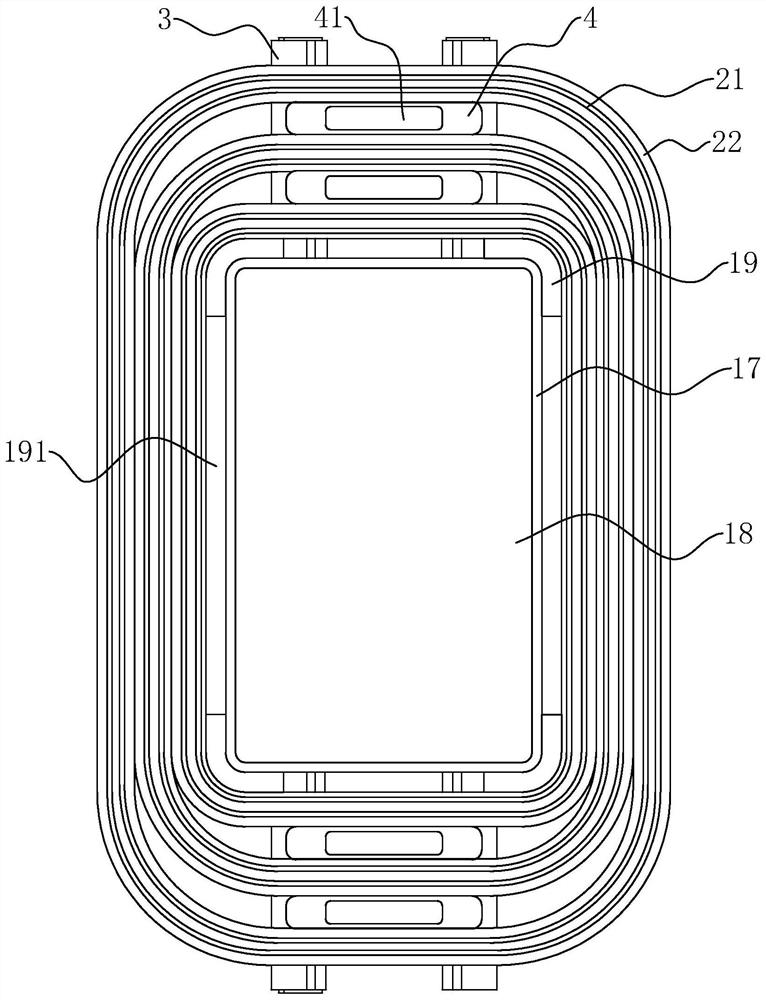

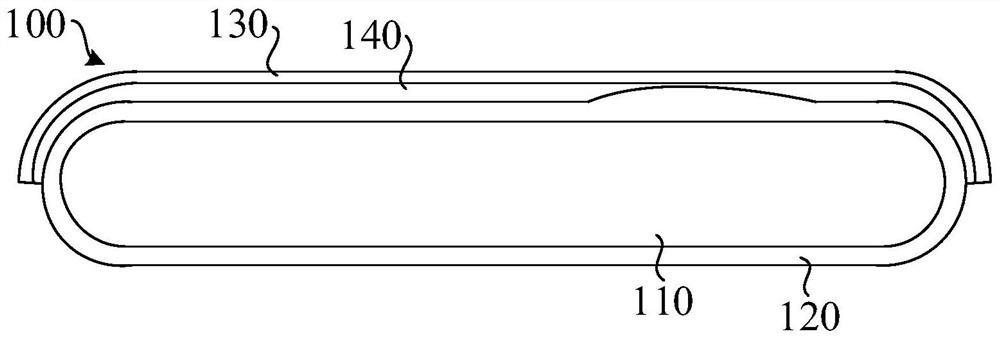

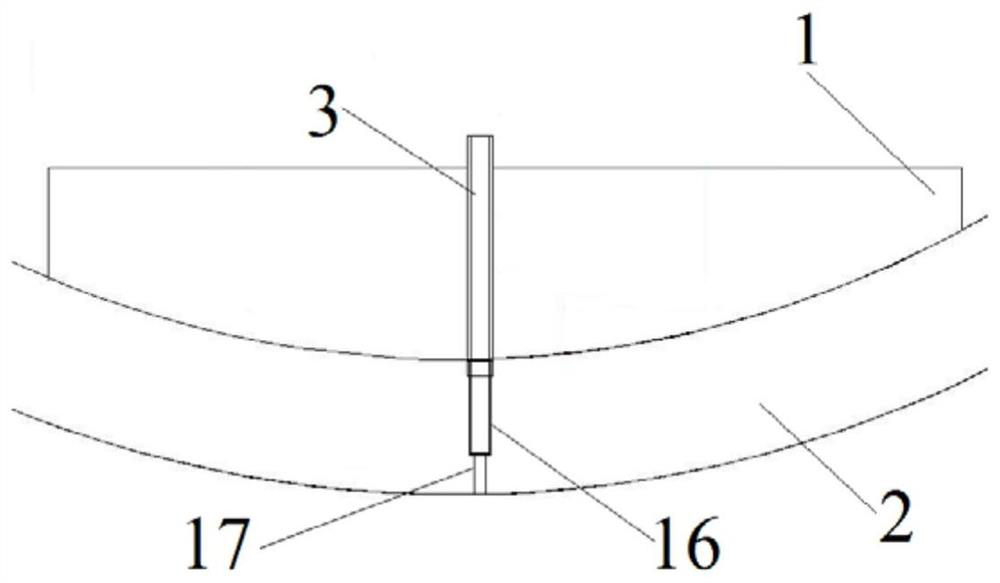

Terminal device and assembling method thereof, and fitting compensation method of curved screen and cover plate

ActiveCN112637383AImprove pass rateEffective fitTelephone set constructionsTerminal equipmentStructural engineering

The invention provides a terminal device and an assembling method thereof, and a fitting compensation method of a curved screen and a cover plate. The terminal equipment comprises a machine body, a curved screen and a cover plate. The curved screen is arranged on the outer surface of the body; the cover plate is attached to the outer surface of the curved screen, a transparent compensation layer is arranged between the cover plate and the curved screen, and the compensation layer compensates for the gap between the curved screen and the cover plate in a matched mode. The transparent compensation layer is arranged between the cover plate and the curved screen, so that the non-uniform gap between the curved screen and the cover plate is compensated in a matched manner, the cover plate and the curved screen can be effectively and compactly attached, the problems of tilting, bubbles and the like are avoided, the cover plate and the curved screen are integrated, and the product percent of pass of the terminal equipment is increased.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

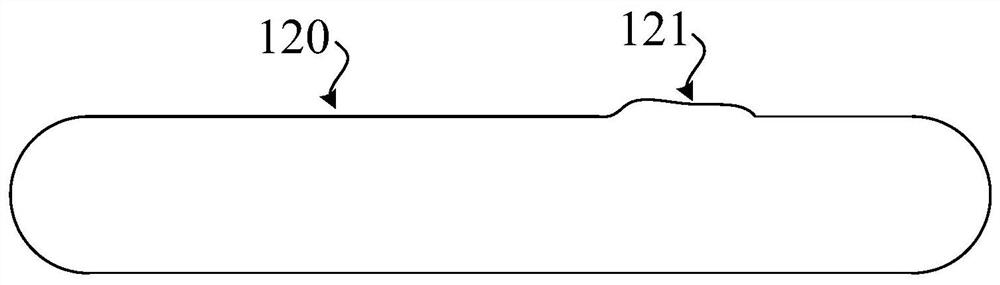

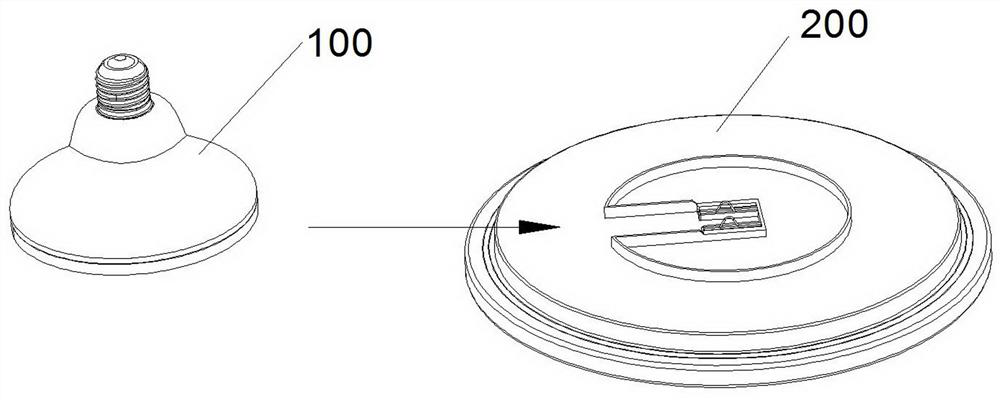

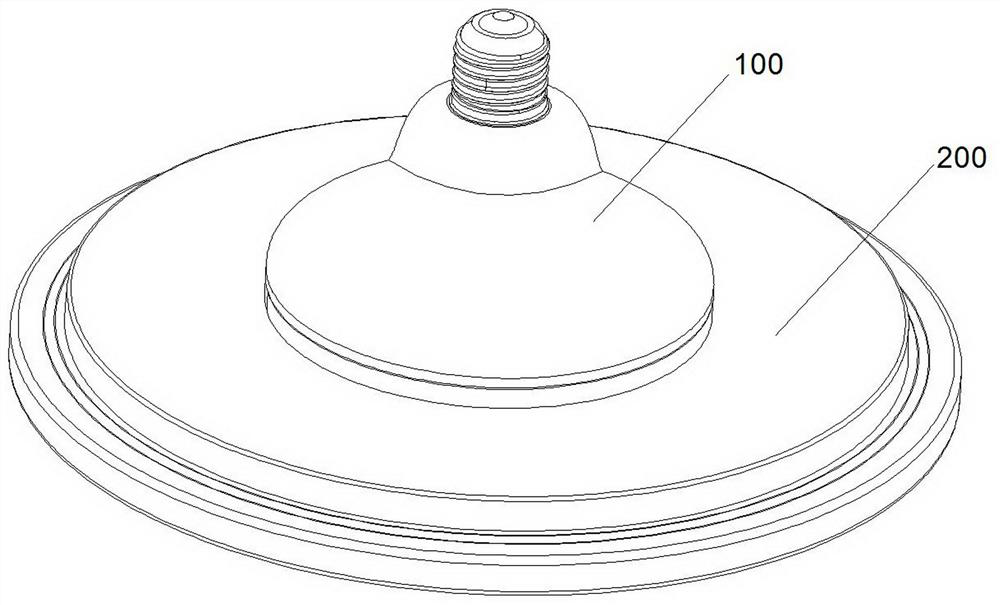

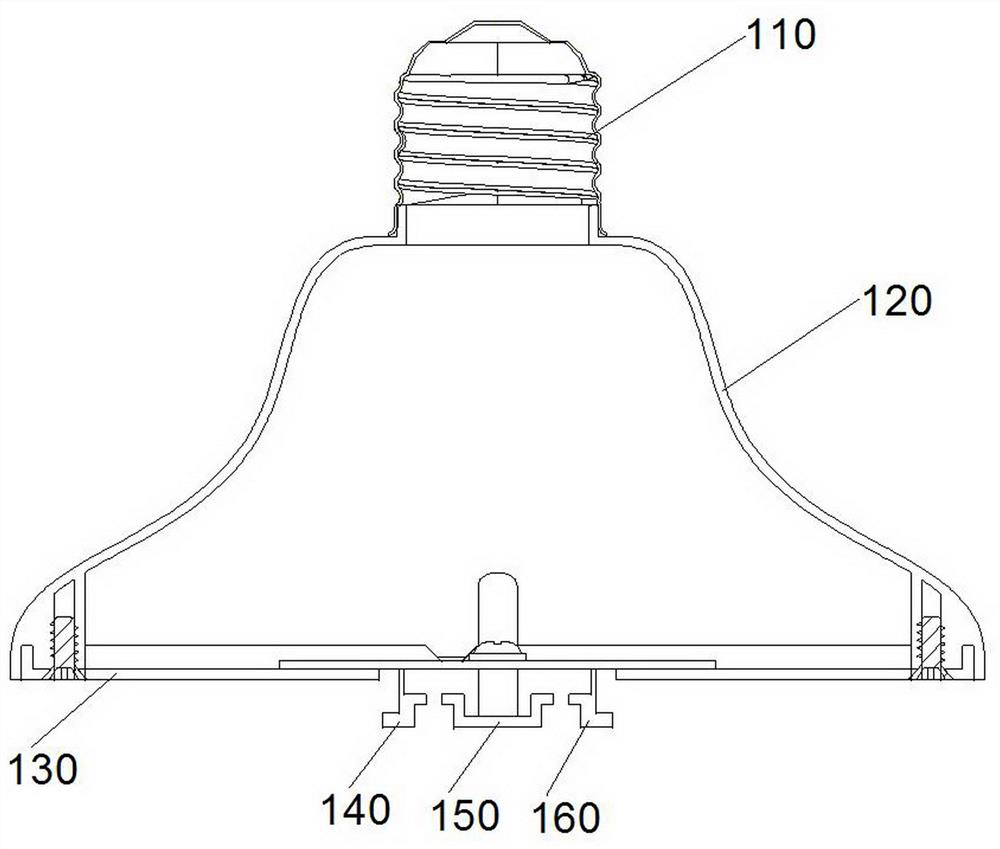

Clamping groove type flying saucer lamp

InactiveCN112728457AStrong sense of experienceEasy to install and disassembleElectric circuit arrangementsLight fasteningsStructural engineeringMechanical engineering

The invention discloses a clamping groove type flying saucer lamp, which comprises a driving assembly 100 and a lamp body assembly 200, wherein a plurality of sliding pieces are arranged at the bottom end of the driving assembly 100, a boss 230 is arranged at the top end of the lamp body assembly 200, a sliding piece guide groove 231 is formed in the boss 230, the sliding piece guide groove 231 is used for sliding guide of the multiple sliding pieces, the tail end of the sliding piece guide groove 231 is provided with a plurality of sliding grooves, each sliding piece is used in cooperation with the corresponding sliding groove in a sliding mode, and the plurality of sliding pieces and the sliding grooves slide relative to each other and are used for mounting and dismounting of the driving assembly 100 and the lamp body assembly 200. The clamping groove type flying saucer lamp is guided by the sliding piece guide groove 231, moves close to or away from along the mounting axis to achieve mounting and dismounting, and the flying saucer lamp has the advantages of convenient mounting and dismounting, simple operation, compact clamping, disassemble lamp design, reliable and safe electrification, high user experience and the like.

Owner:广东铖熙照明有限公司

Subway tunnel ballast bed segment post-wall grouting method

ActiveCN111878119AGuaranteed denseImprove securityUnderground chambersTunnel liningStructural engineeringCement Material

The invention relates to a subway tunnel ballast bed segment post-wall grouting method. The subway tunnel ballast bed segment post-wall grouting method comprises a grouting step and a sealing step. The grouting step specifically comprises the steps that a grouting hole is formed in a ballast bed, a grouting pipe is inserted into the grouting hole, and grouting is performed in the grouting pipe. The sealing step specifically comprises the steps of cutting a ballast bed around a grouting hole to a segment below the ballast bed, cutting off one part located on the outer side of the segment, of the grouting pipe, filling one part located in the segment, of the grouting pipe with double-fast cement or inserting a sealing plug, forming an annular third groove in the periphery of the grouting hole in the segment, placing an annular elastic sealing ring in the third groove; arranging a sealing plate on the elastic sealing ring, fixing the sealing plate to the segment through chemical bolts, and filling and leveling up the cut part on the ballast bed with a filler. Compared with the prior art, the subway tunnel ballast bed segment post-wall grouting method has the advantages of being betterin sealing performance and the like.

Owner:SHANGHAI RAIL TRANSIT MAINTENANCE SUPPORT

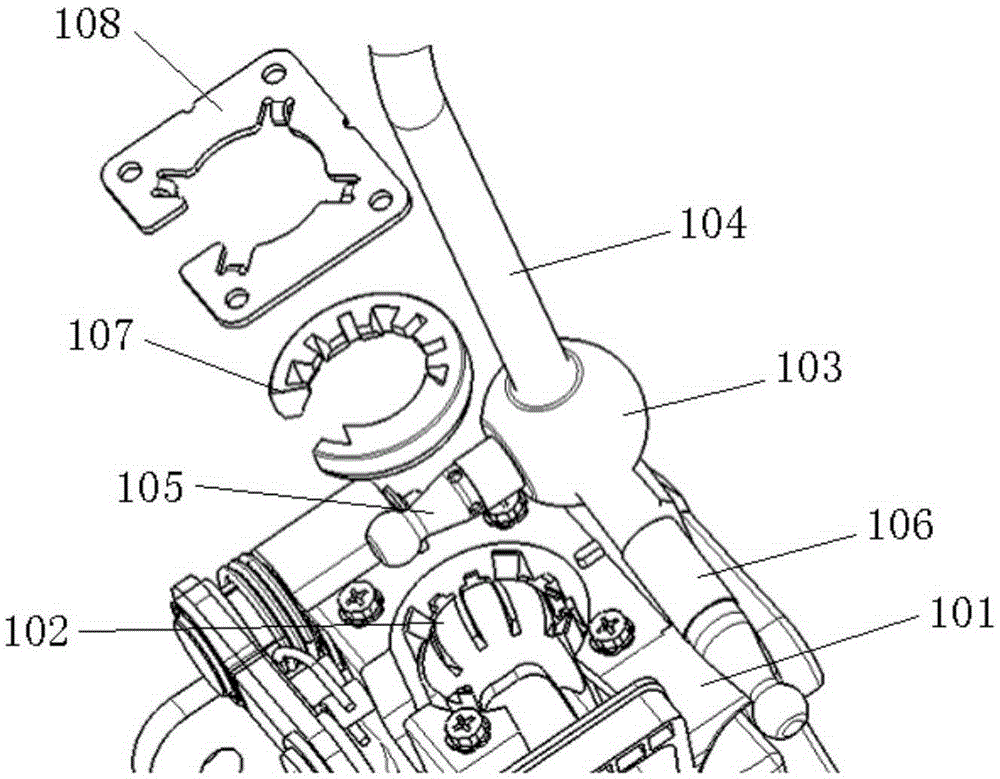

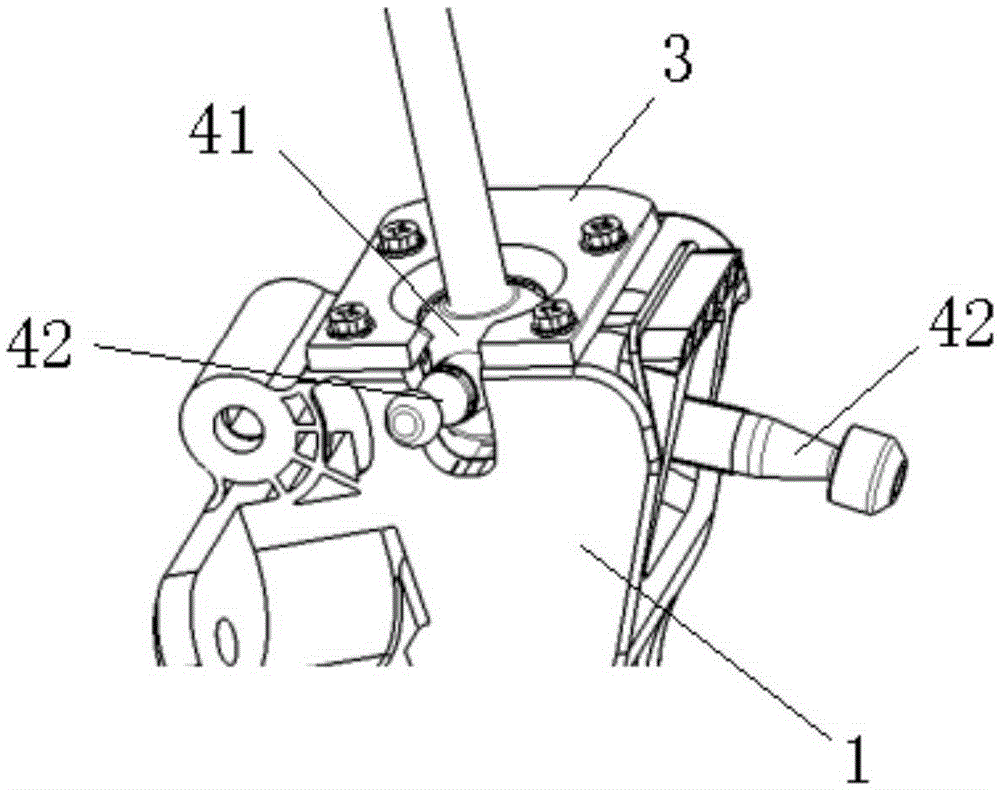

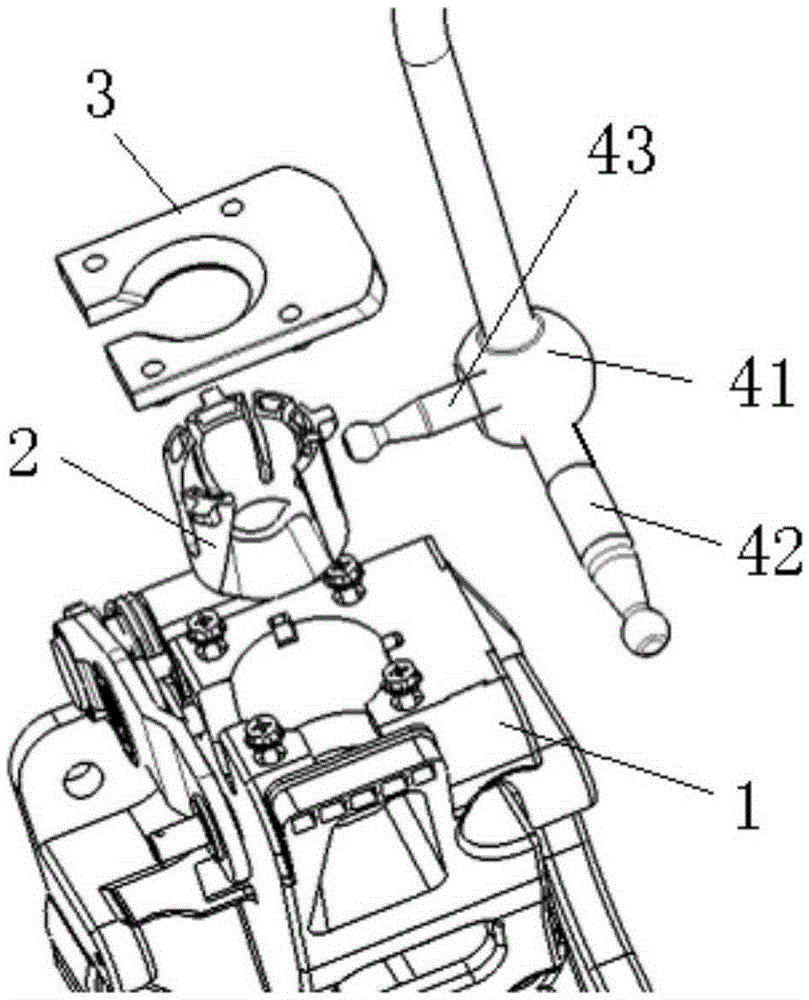

Automobile and gear shifter thereof

InactiveCN105276157AReduce mold costReduce processing costsGearing controlEngineeringMechanical engineering

The invention discloses an automobile and a gear shifter thereof. The gear shifter comprises a base, a neck bush and a gear shifting rotation assembly. The base is provided with a cylinder groove, a gear selecting arm via hole and a gear shifting arm via hole. The neck bush is inlaid into the cylinder groove and detachably connected with the base through a connection piece. The side wall of the neck bush is attached to the groove wall of the cylinder groove. The upper end of the neck bush is tightly pressed in the cylinder groove. The neck bush is provided with a ball-shaped hole, a gear selecting arm avoiding hole and a gear shifting arm avoiding hole. A ball head of the gear shifting rotation assembly is rotationally installed in the ball-shaped hole. In this way, the base and the neck bush are of a split type structure and connected detachably through the connection piece so that the base and the neck bush can be assembled after being machined separately, and the mold-making cost of the base is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

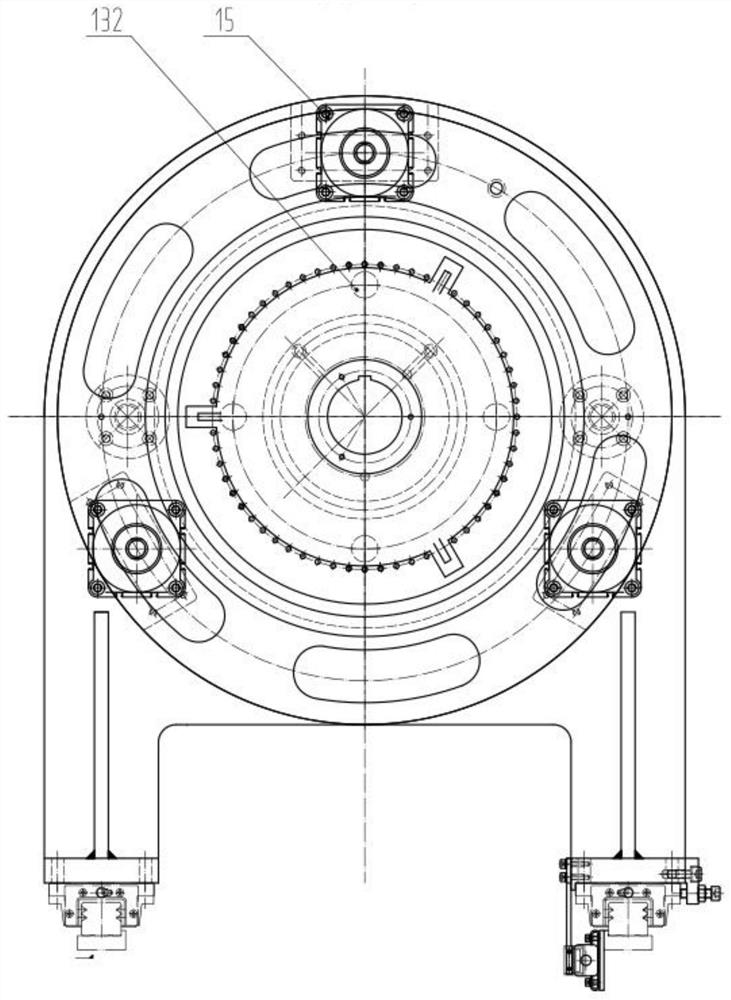

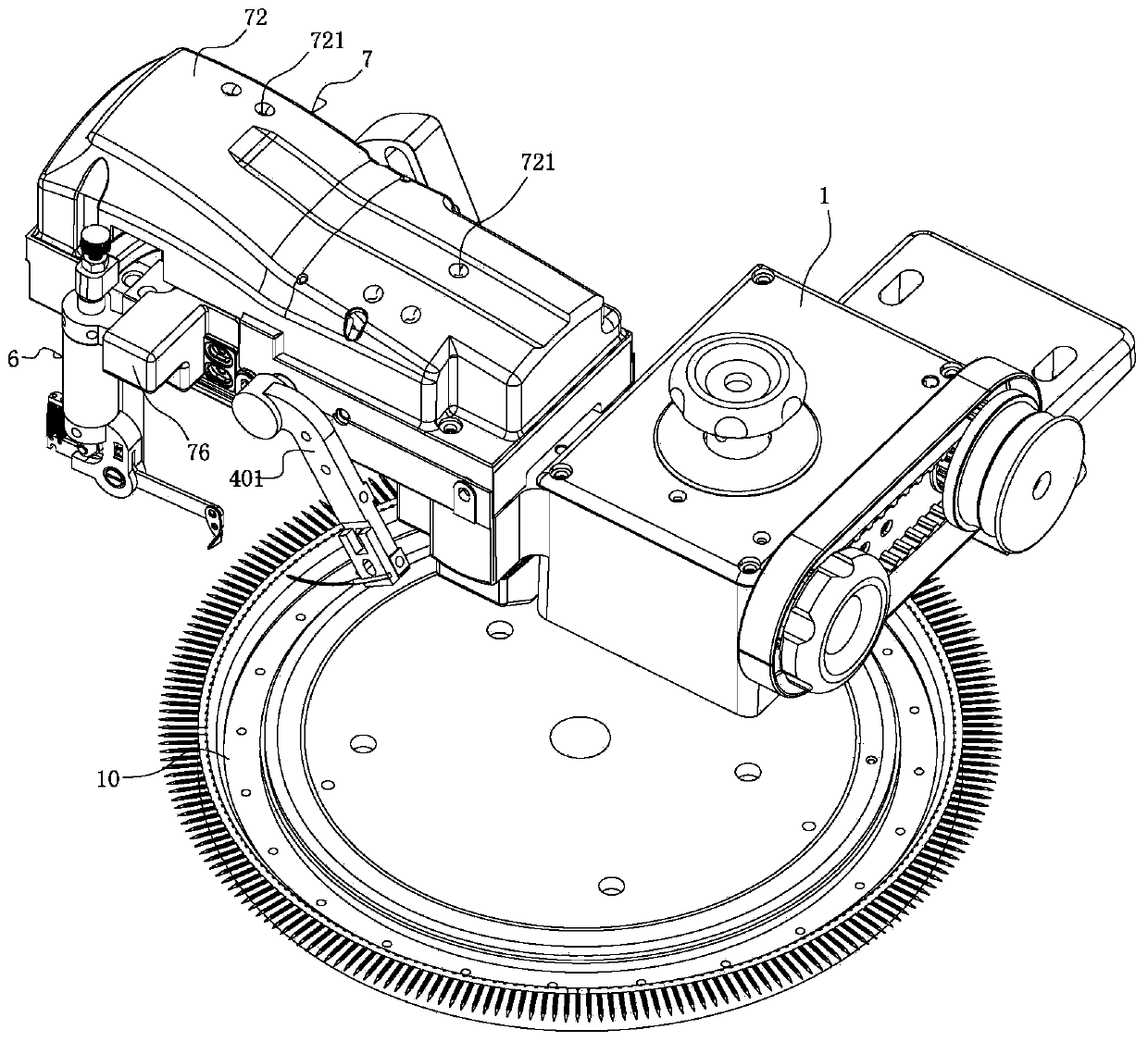

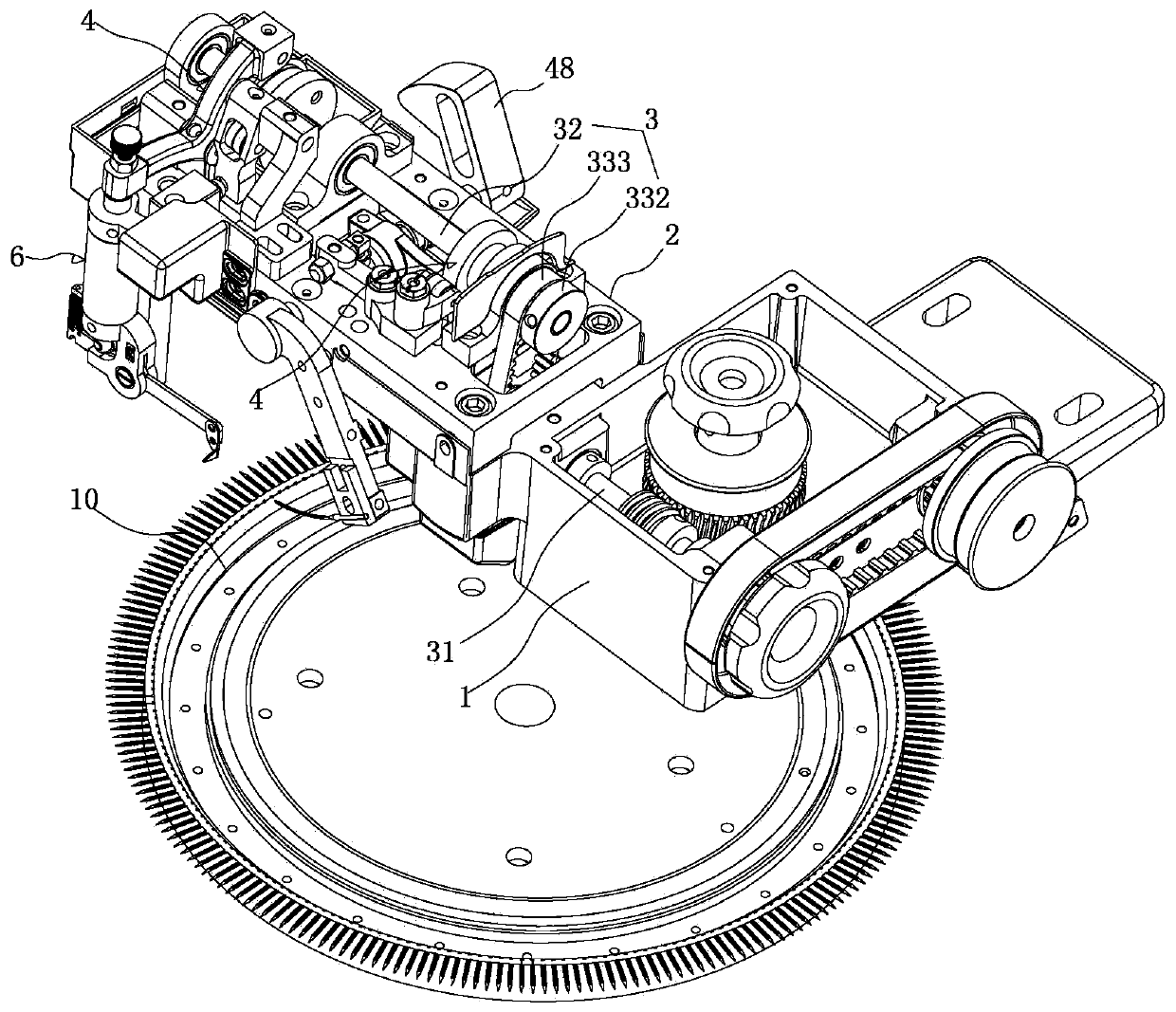

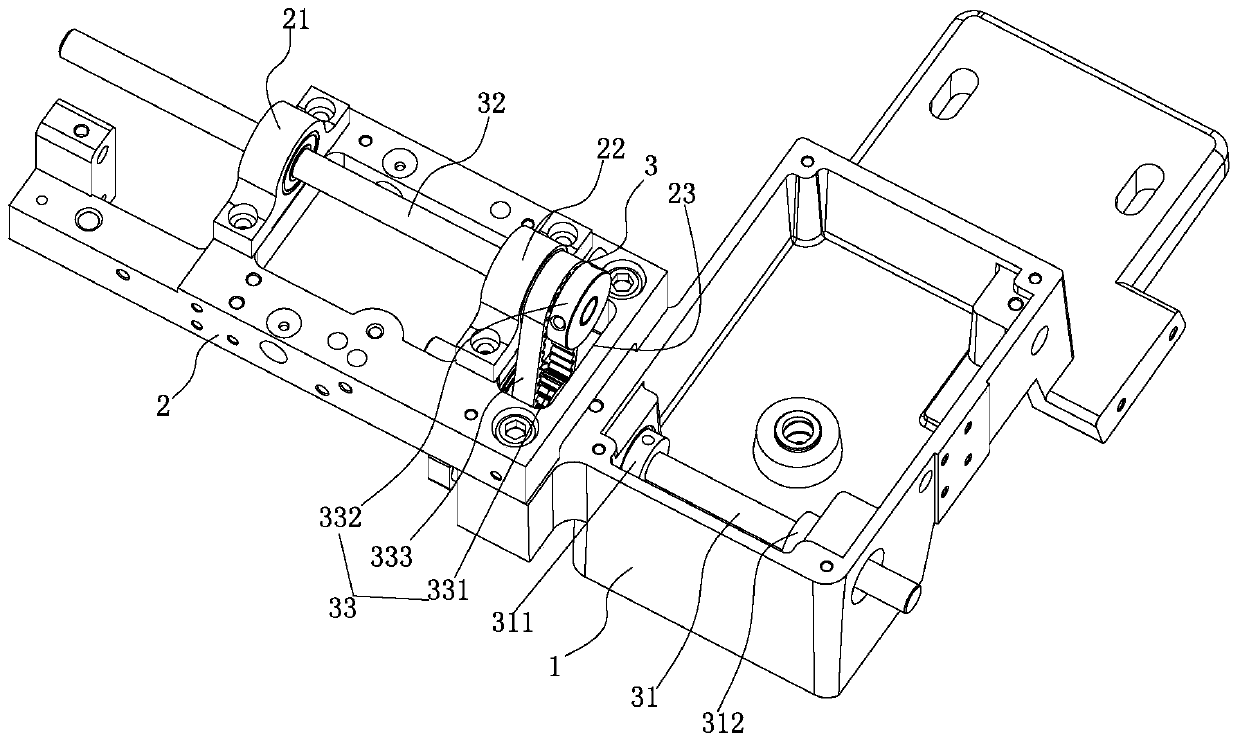

High-speed synchronous-belt dial linking machine

ActiveCN110644146AImprove installation strengthGuaranteed sewing qualityLubrication/cooling devicesSewing-machine control devicesControl engineeringMachine

The invention discloses a high-speed synchronous-belt dial linking machine, comprising a bed, a support mounted on the bed, a dial mounted at the lower end of the support, a synchronous belt drive structure mounted on the bed and the support, a needle swinging drive structure mounted on the support, a cantilever and a needle both mounted on the needle swinging drive structure, a thread take-up drive mechanism mounted on the support, a thread take-up device connected with the thread take-up drive mechanism, and an oil-storage lubricating structure mounted on the periphery of the support. The synchronous-belt drive structure comprises a main shaft mounted on the bed, an auxiliary shaft mounted on the support, and a synchronous belt assembly mounted between the main shaft and the auxiliary shaft; the synchronous belt assembly comprises a first synchronous wheel mounted at the end of the main shaft, a second synchronous wheel mounted at the end of the auxiliary shaft, and a synchronous belt mounted between the first synchronous wheel and the second synchronous wheel; the support is mounted at the edge of the upper end face of the bed, and a longitudinal space is formed between the support and the bed; a reinforced bearing pedestal for supporting the end of the main shaft is arranged on the lateral side of the bed.

Owner:东莞市缝神机械设备有限公司

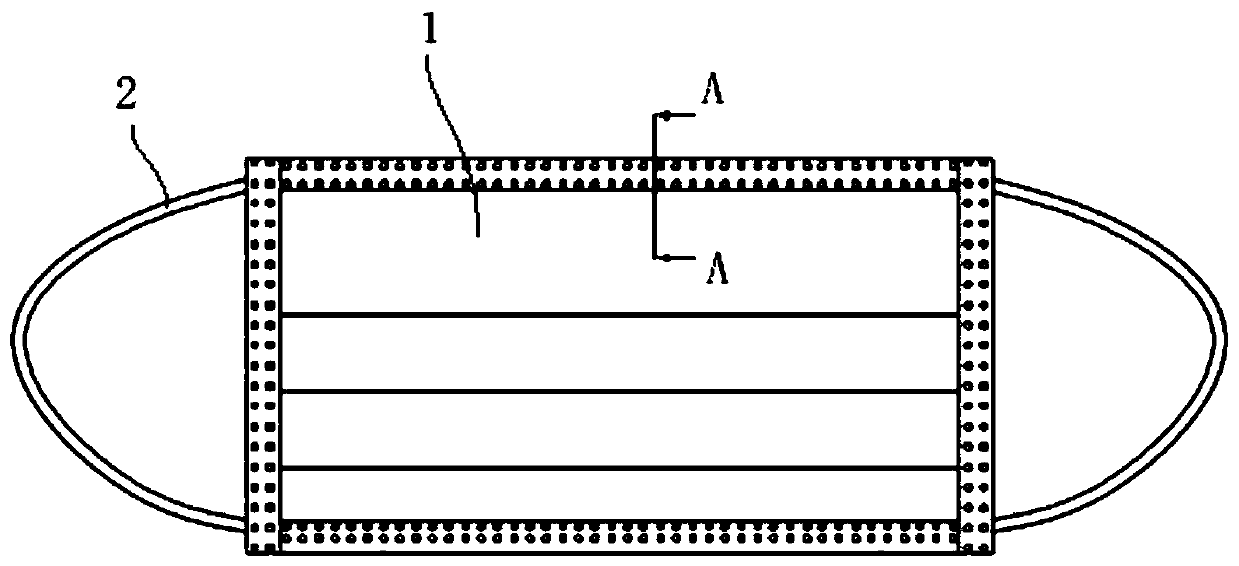

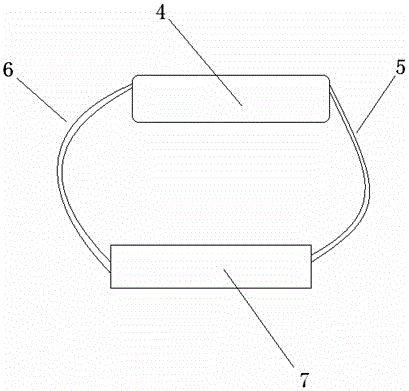

Planar mask

PendingCN111345528AGuaranteed normal and convenient useFitting effect is more convenient and fasterGarment suspendersProtective garmentEngineeringMechanical engineering

A planar mask comprises a mask body and ear bands connected to the left side and the right side of the mask body, and the mask body comprises an inner layer, a middle layer and an outer layer; connecting parts are further arranged between the mask body and the ear bands, one side of each connecting part is connected with the side end of the mask body through three or more first connecting parts, and the other side of each connecting part is connected with the two end portions of the ear band on the side where the connecting part is located through second connecting parts. Through the arrangement of the connecting parts, the tension of the ear bands received by the mask body is improved from upper and lower two-point stress to more balanced stress, so that the left side and the right side of the mask are enabled to be more closely attached to the face of a user, and the attaching effect of the user is more convenient and quicker.

Owner:张涵文

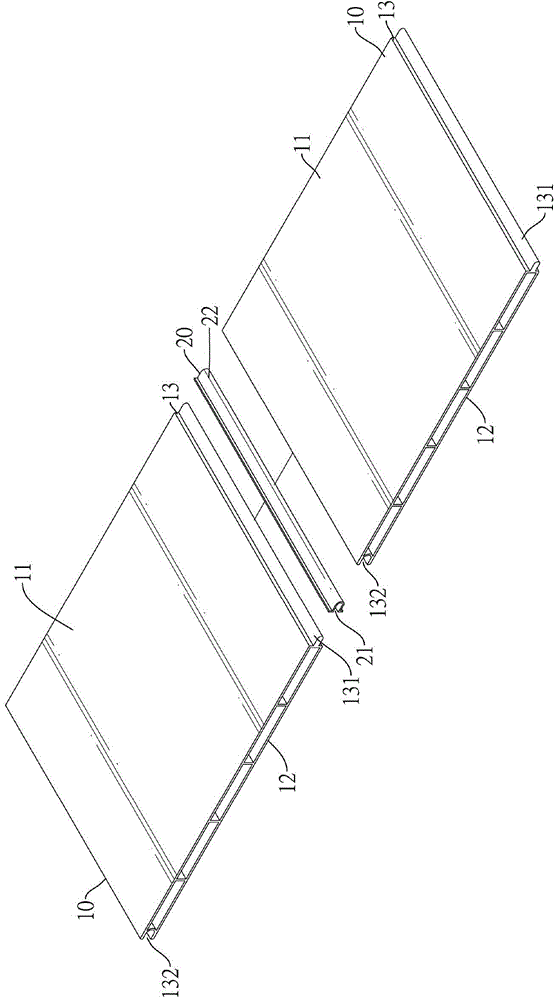

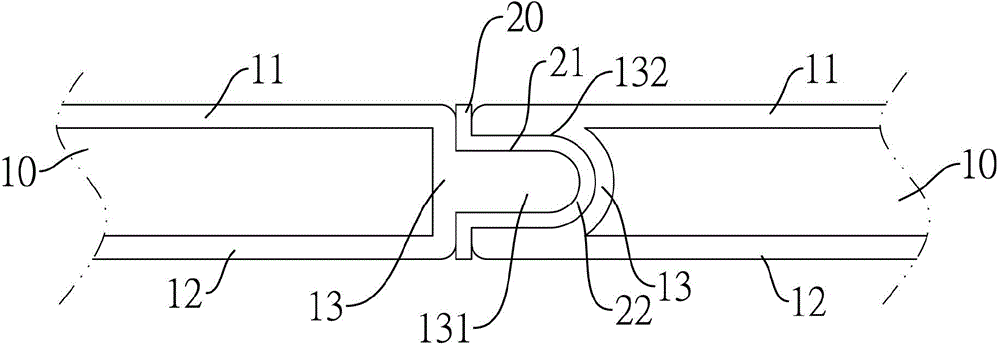

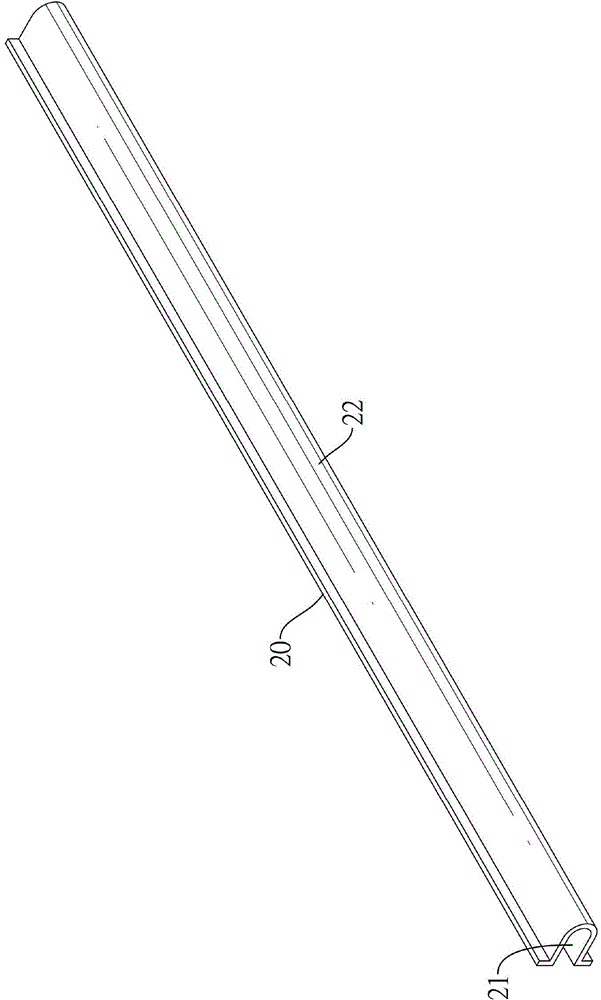

Sheet material assembly structure and combination method thereof

InactiveCN105840603AClose fitIncreased sturdiness and durabilitySheet joiningEngineeringHigh pressure

The board assembly structure and its combination method provided by the present invention utilize the flange structure and the groove structure provided on the ring side of the board, and the fillet arrangement between the flange structure and the groove structure adjacent to the two boards, Make the plate and the plate more closely, and use the relative melting point characteristics of the material of the molding and the material of the board. After the assembly of the board and the molding is completed, apply high pressure and high temperature to make the molding into a molten state, and the flange The surface of the structure and the groove structure is completely covered, and then the adjacent panels are bonded and fixed. With the setting of the combined structure and the use of its combination method, multiple panels are repeatedly connected to form a strong and durable floor, cabinet or light. compartment.

Owner:CING STAR

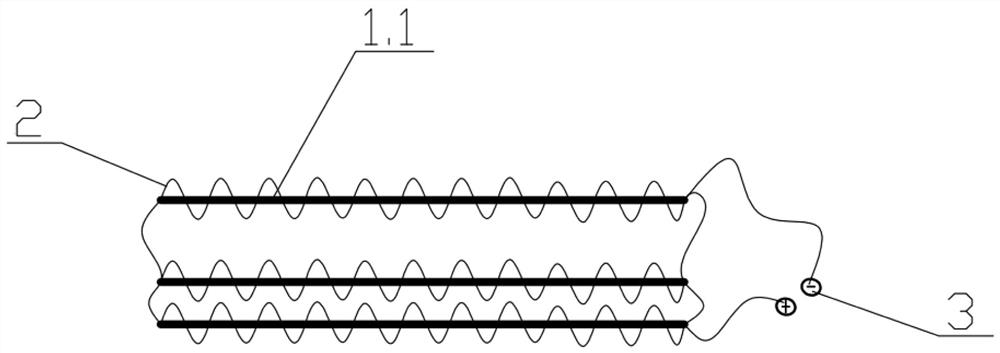

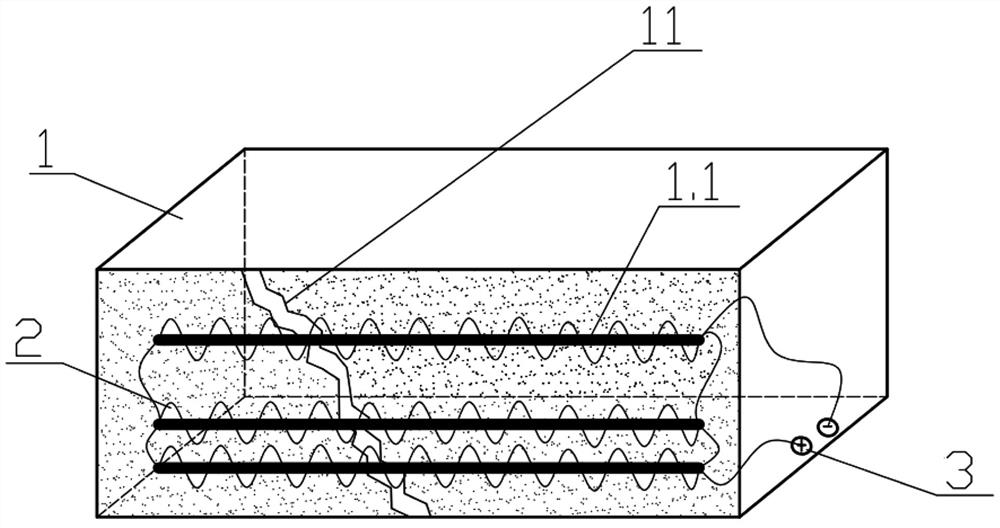

Electrically heated unfreezing sheet

InactiveCN104202849AFlexibleClose fitHeating element materialsElectrical resistance and conductanceElectricity

The invention discloses an electrically heated unfreezing sheet. The electrically heated unfreezing sheet comprises an upper insulating medium layer, a lower insulating medium layer, a heating resistor, a power source positive electrode connector and a power source negative electrode connector, wherein the upper insulating medium layer and the lower insulating medium layer are stuck vertically in a sealing manner; at least two heating resistors are embedded in the stuck vertically and integrally stuck upper insulating medium layer and the lower insulating medium layer; the heating resistors are electrically connected in sequence; the heating resistors located on the two ends are respectively connected with the power source positive electrode connector and the power source negative electrode connector. The electrically heated unfreezing sheet has flexibility, can be bent at will, and accordingly can be assembled on curved and special-shaped devices. The electrically heated unfreezing sheet is high in mechanical intensity, vibration-resistant, strong in heat-resistant impact capability, and convenient to assemble.

Owner:ANHUI ACT BLUE ENVIRONMENTAL PROTECTION CO LTD

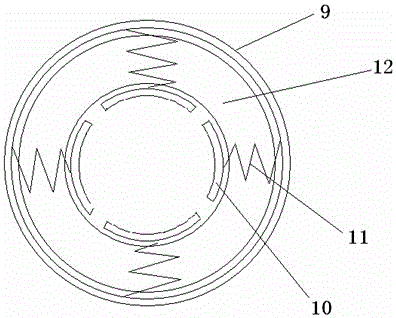

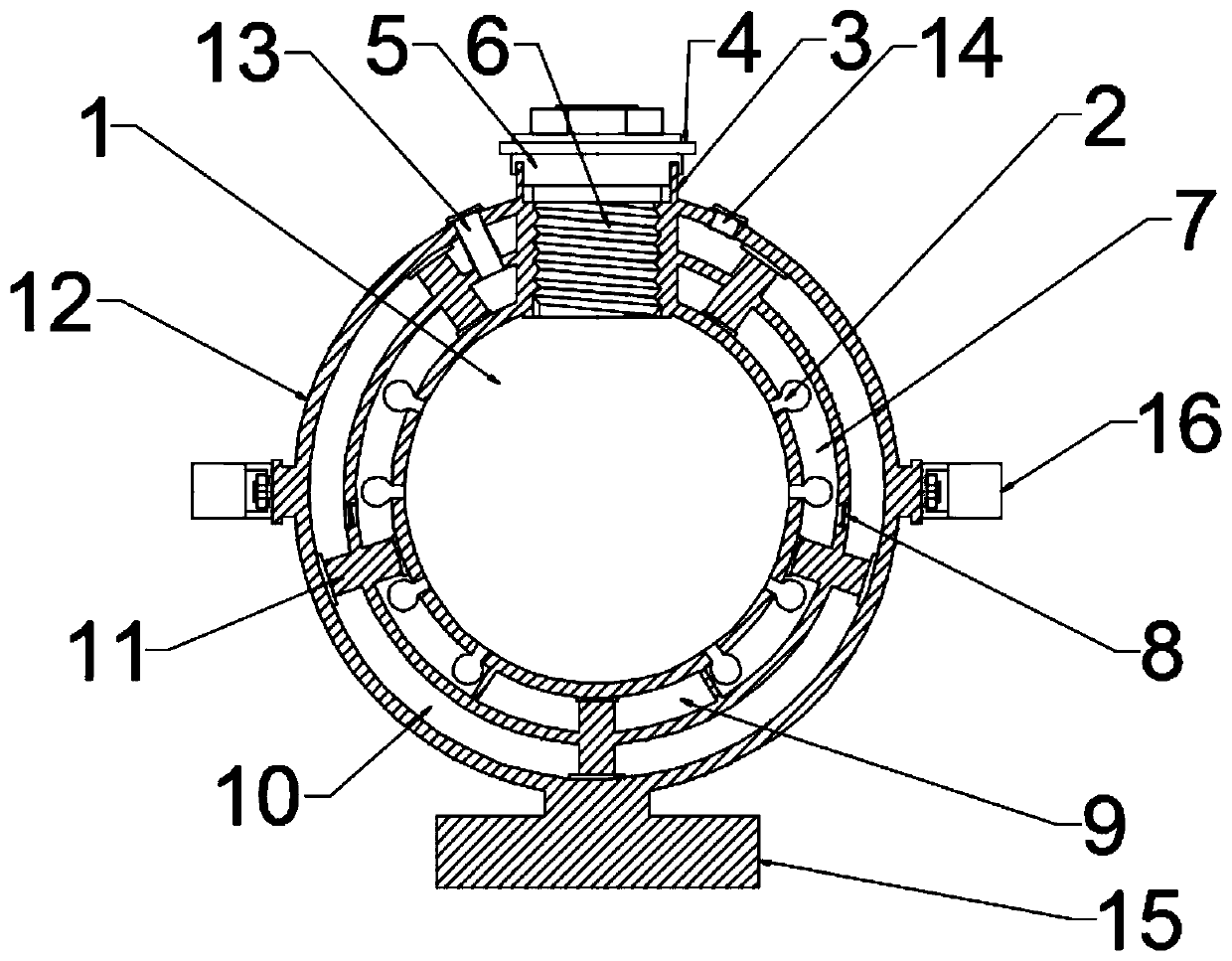

External cooling device of high-voltage coil

ActiveCN105788827AImprove cooling effectImprove applicabilityTransformers/inductances coolingTransformers/inductances coils/windings/connectionsBarrel ShapedElectric control

The invention discloses an external cooling device of a high-voltage coil. The external cooling device comprises an outer barrel, wherein a plurality of coamings are arranged in the outer barrel; the plurality of coamings synchronously move toward the circle center of the section of the outer barrel and can be connected with one another to form a barrel-shaped structure; the high-voltage coil is located in the barrel-shaped structure; spring dragging devices are arranged among the coamings and the inner surface of the outer barrel; annular cooling bags are further arranged among the coamings and the inner surface of the outer barrel; and the annular cooling bags are internally filled with cooling liquid. Compared with the prior art, the cooling liquid is added into the annular cooling bags to form a water cycle, and heat on the high-voltage coil is continuously brought away; the coamings retractably move so that the diameter of the formed barrel-shaped structure can be adjusted, and the barrel-shaped structure can be adaptive to the specifications of coils with different sizes; and the external cooling device of the high-voltage coil is commonly used for heat dissipation of the coils in an electric control cabinet, has strong applicability and has a good heat dissipation effect on the external high-voltage coil.

Owner:JIANG SU ZHONGRONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com