Water wall abrasionproof scale type welding method

A welding method and water-cooled wall technology, applied in welding equipment, metal processing equipment, workshop equipment, etc., can solve the problems of wear-resistant plate falling off, unqualified welding quality, poor anti-wear effect, etc. The effect of improving the anti-wear effect and enhancing the anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

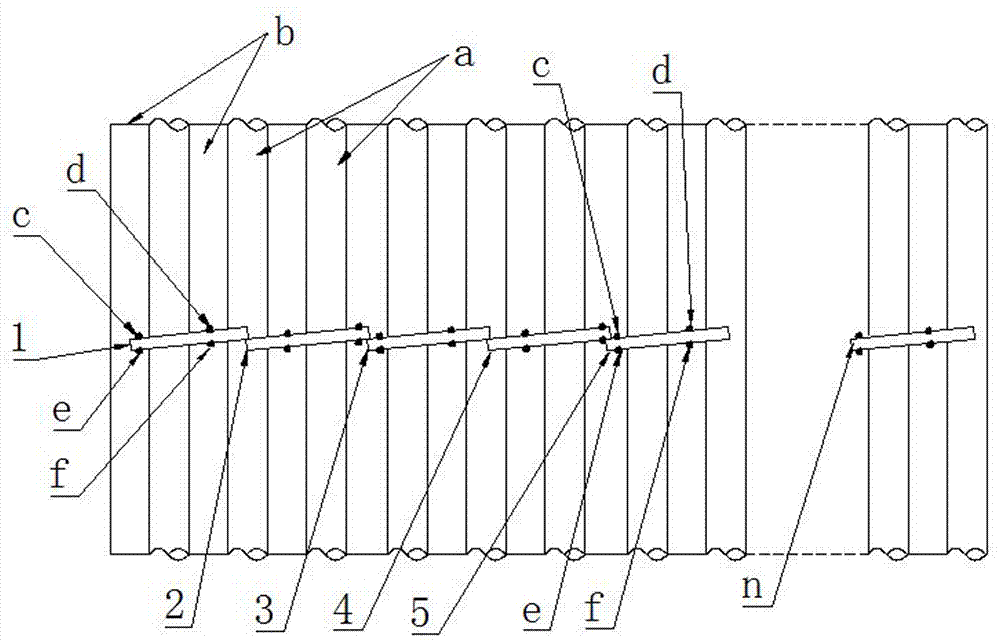

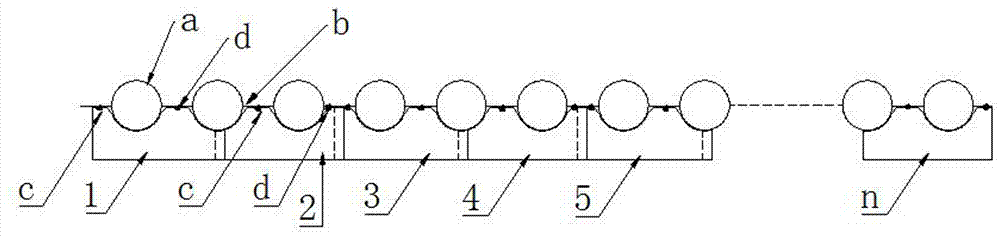

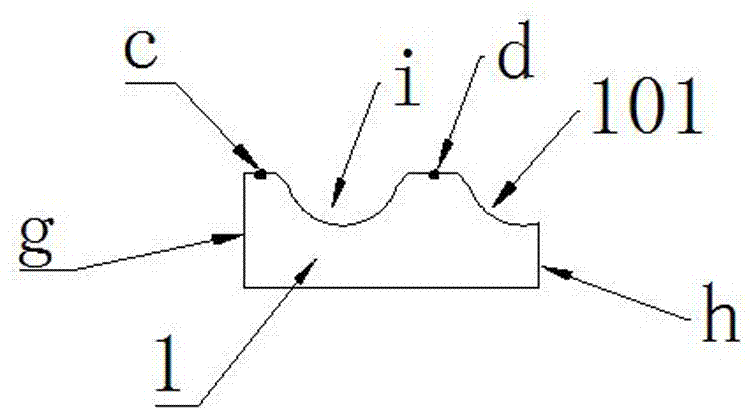

[0035] combined with figure 1 to attach Figure 8 , the water-cooled wall anti-wear fish scale welding method, the water-cooled pipe is anti-wear by using the anti-wear plate and the fish-scale overlapping method successively, including the anti-wear plate and the water-cooled tube a set up side by side, and the water-cooled tube a is a cylindrical tube, so The wear-resistant plate described above includes long strips at the A-end g and the B-end h, and one side of the wear-resistant plate between the A-end g and the B-end h contains an arc i that matches the outer wall of the water-cooled tube a, and the circle On both sides of arc i, end A g is X welding point c, end B h is Y welding point f, X welding point c is on the upper side of the side edge of the wear plate, and Y welding point f is on the side edge of the wear plate The lower side; the welding steps are as follows: step 1, use the ink fountain to level the water-cooled tube a set up side by side. The arc i of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com