Rock wall slope drilling device

A drilling device and slope technology, which is applied to supporting devices, drilling equipment and methods, drill pipes, etc., can solve the problems of rock slopes that cannot be mechanically operated, low efficiency, personal injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

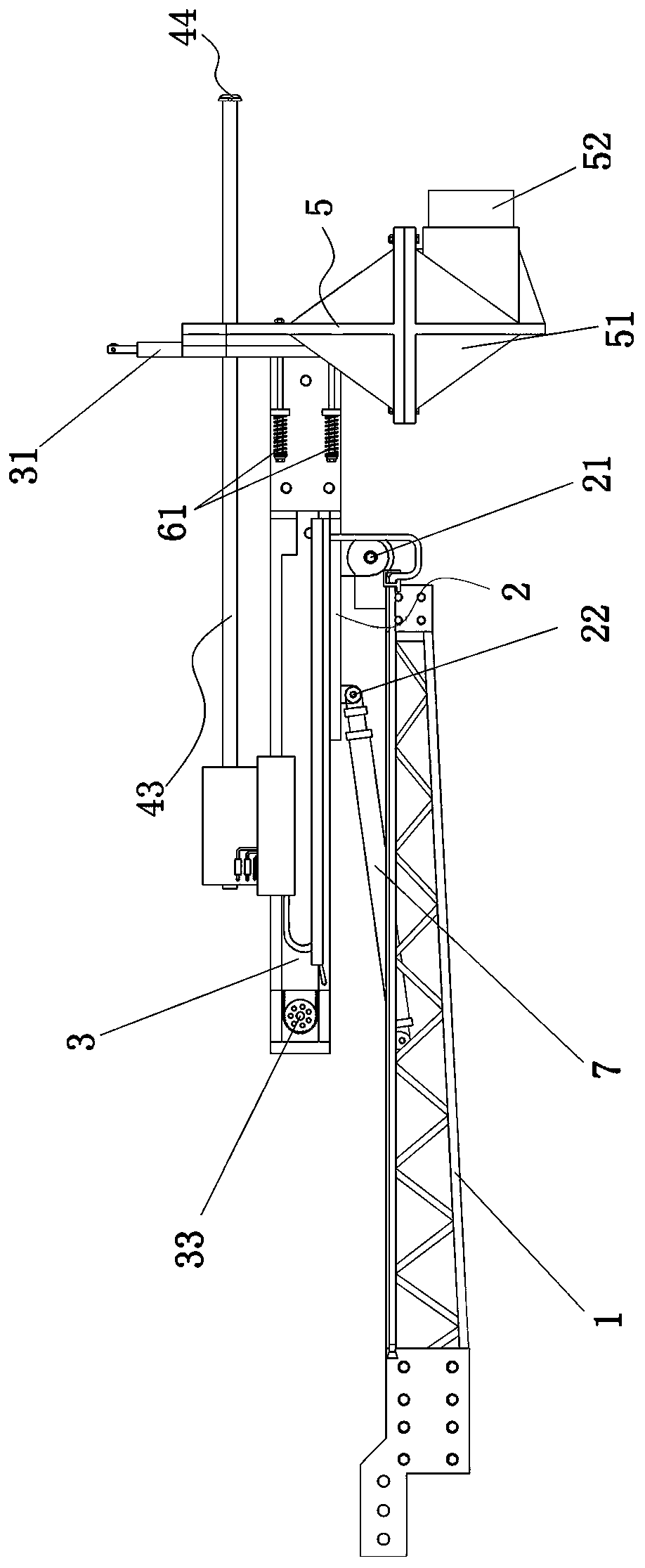

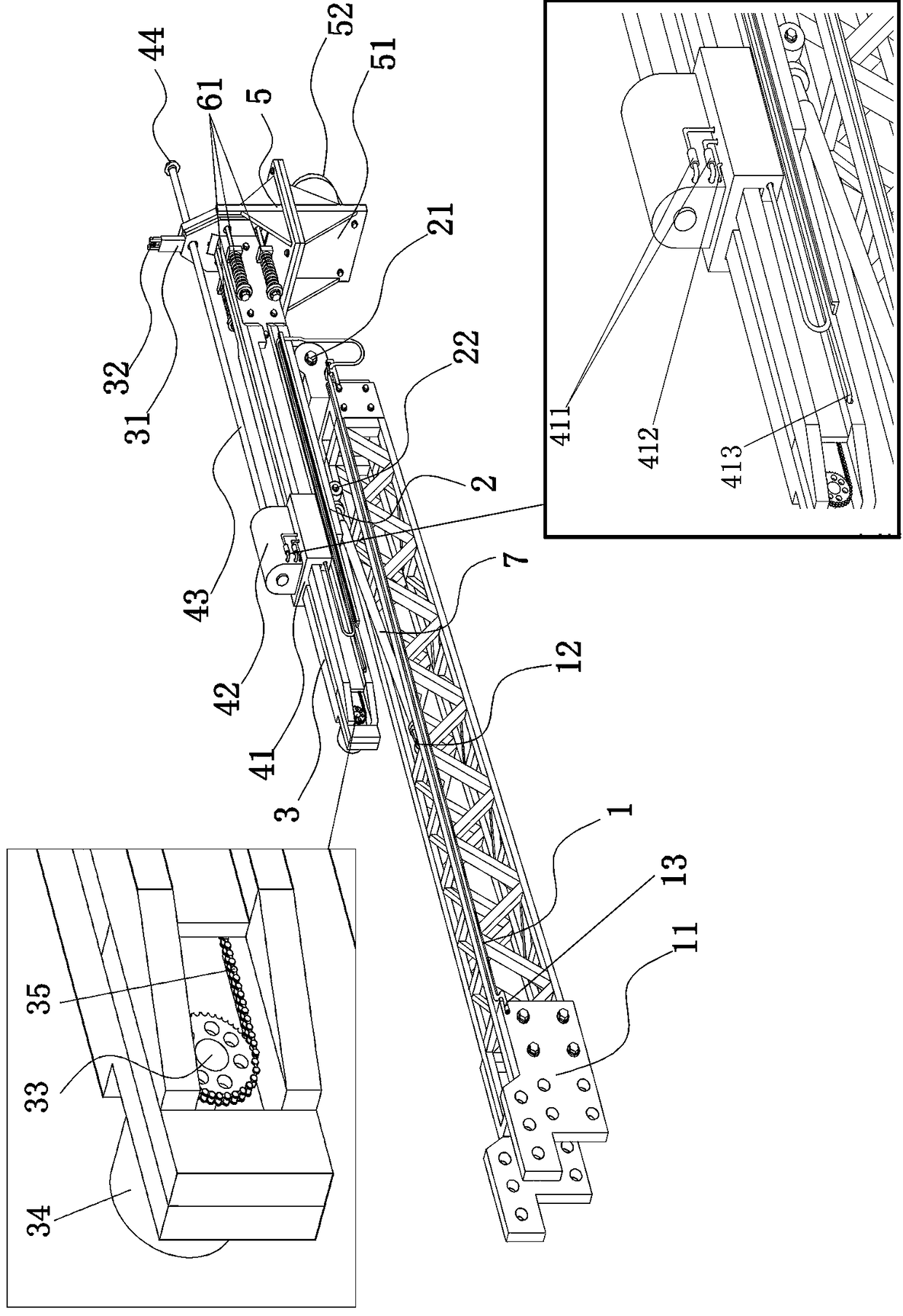

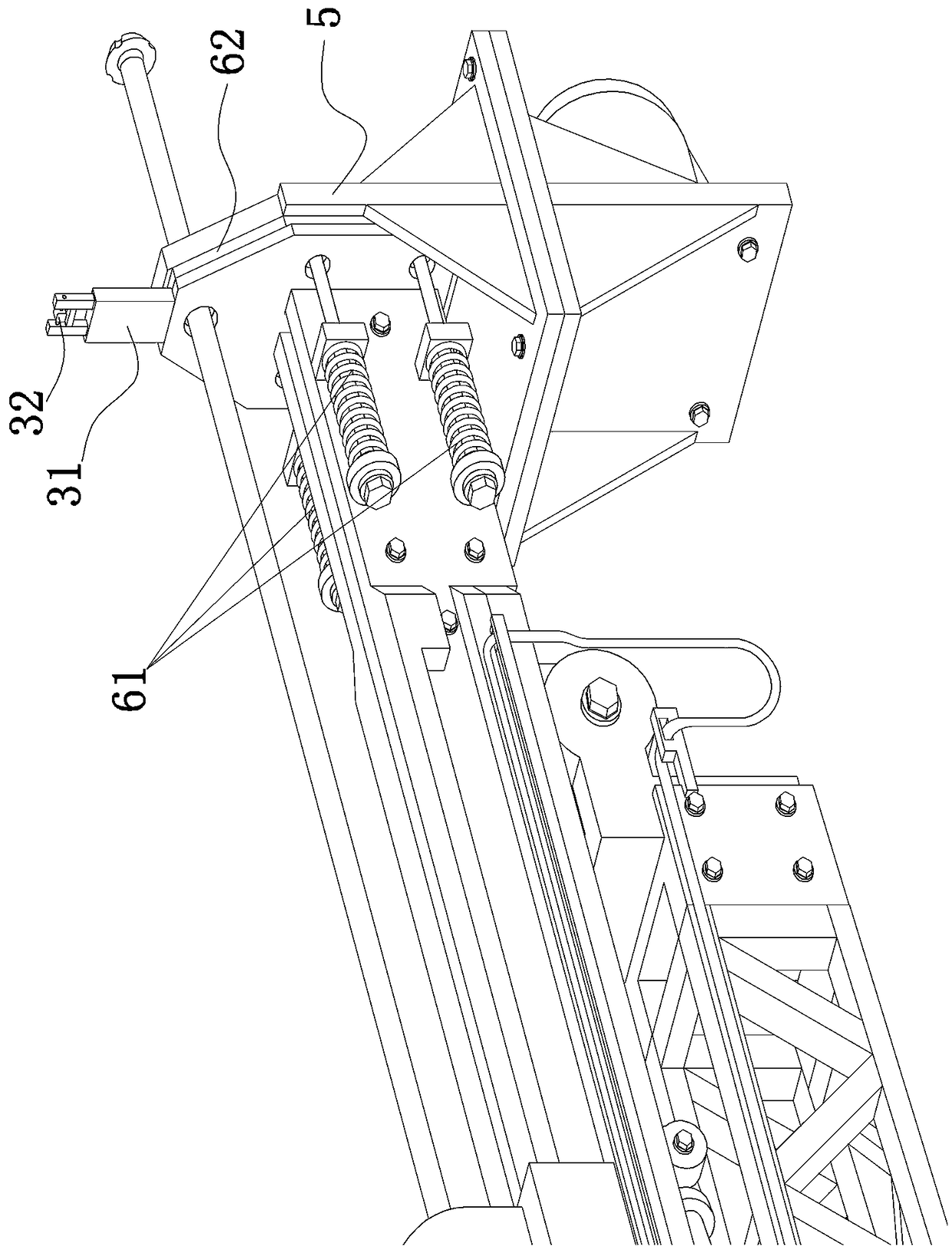

[0028] Such as Figure 1-6 As shown, a rock wall slope drilling device includes: a crane or a crane, a truss 1, a girder pitching mechanism 2, a girder frame 3, a rock drill, a girder stabilizing seat 5, a monitoring system, a buffer device, a delivery pipe 13, legs 52;

[0029] The truss 1 is fixed on the telescopic arm of the crane or the crane through the truss fixing seat 11; the beam frame 3 is connected to the truss 1; the pitching motion is performed under the control of the pitching mechanism 2;

[0030] The beam frame pitching mechanism 2 includes: a hydraulic cylinder 7, a fixed rotating shaft 12 of the oil cylinder, a pitching rotating shaft 21, and a rotating shaft 22 of the oil cylinder; catch;

[0031] The beam frame 3 is provided with a rock drill base 41, a rock drill base track, a sprocket 33, a hydraulic motor 34, and a chain 35. The rock drilling pump 42 of the rock drill is fixed on the rock drill base 41, and the hydraulic motor 34 drives the sprocket 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com