Sheet material assembly structure and combination method thereof

A technology of assembly structure and combination method, applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of mildew and embrittlement, danger, chemical colloid coating is not careful enough, etc., to achieve tight clamping and increase firmness effect on durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

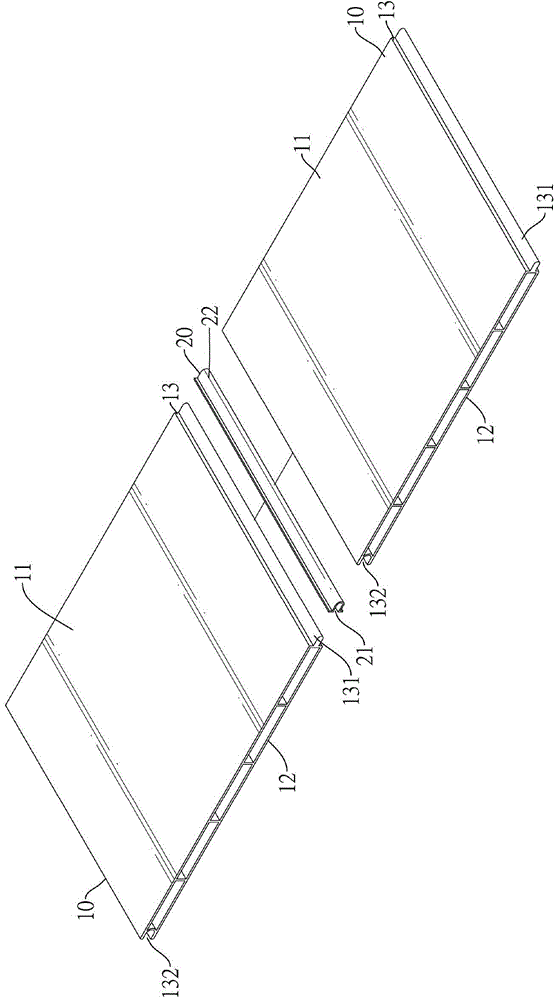

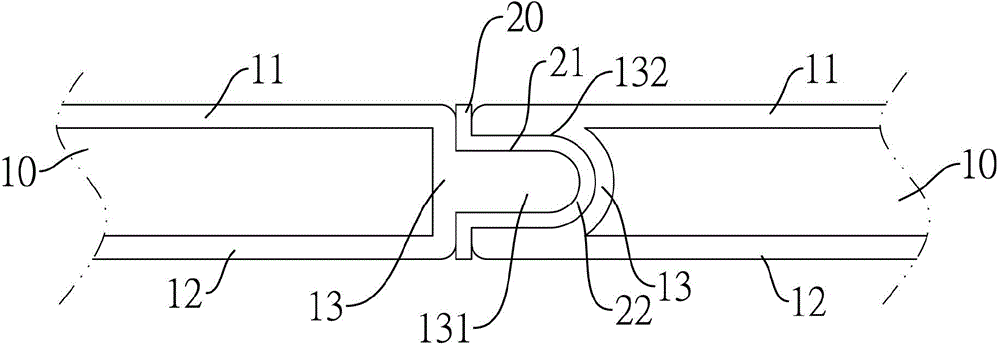

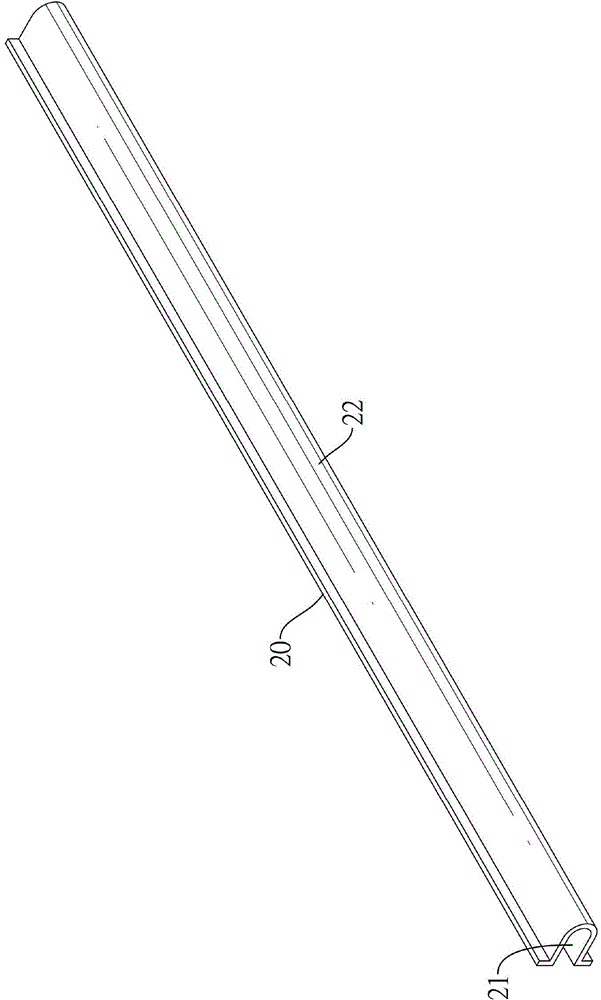

[0040] like figure 1 and figure 2 As shown, the plate assembly structure of the present invention includes: a plate 10 and a fillet 20 .

[0041] Wherein, each plate 10 is a rectangular block structure, which has a top surface 11, a bottom surface 12, and four ring sides 13 connecting the top surface 11 and the bottom surface 12, and is made of aluminum, tin, etc. Made of metal or alloy. One of the ring sides 13 of the four ring sides 13 has a flange structure 131, and the flange structure 131 extends outward from the ring side 13 toward the direction away from the plate 10, and on the four ring sides 13 There is a groove structure 132 corresponding to the flange structure 131 on the other ring side 13 opposite to the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com