External cooling device of high-voltage coil

A high-voltage coil and external cooling technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, transformer/inductor parts, etc., can solve the problem of inability to get heat dissipation, increase contact, strengthen Cooling function, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

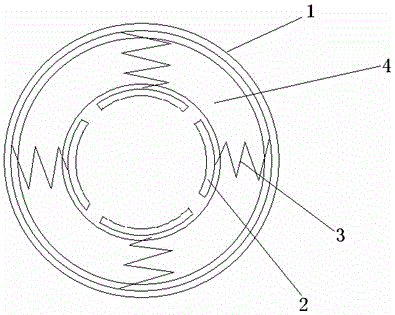

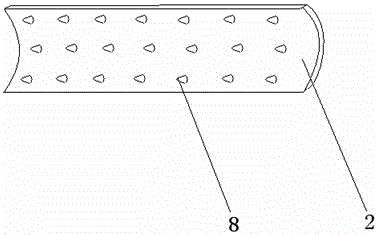

[0021] Such as figure 1 As shown, an external cooling device for a high-voltage coil of the present invention includes an outer cylinder 1. A plurality of enclosure plates 2 are arranged inside the outer cylinder 1. The enclosure plates 2 have an arc-shaped section, and the sections of the enclosure plates 2 face the outer cylinder 1. Synchronous movement of the center of the circle can be connected to each other to form a cylindrical structure, and the enclosure 2 is made of thermally conductive material;

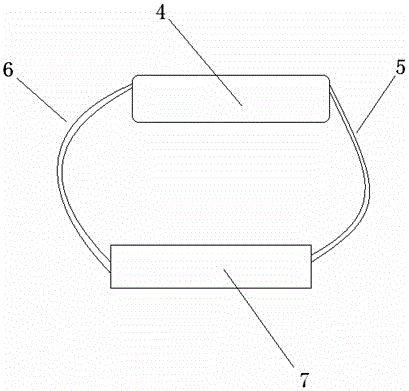

[0022] The high voltage coil is located in the cylindrical structure. A spring traction 3 is arranged between the enclosure plate 2 and the inner surface of the outer cylinder 1. One end of the spring traction 3 is connected to the outer cylinder 1, and the other end is connected to the enclosure plate 2. 2 and the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com