Automatic attaching machine for steel-rubber rim of engineering tire

A technology for engineering tires and laminating machines, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of time-consuming and laborious manual operation, affecting the quality of tire production, and improving the quality of steel rubber rings, so as to achieve reliable fit and appearance. Smooth and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

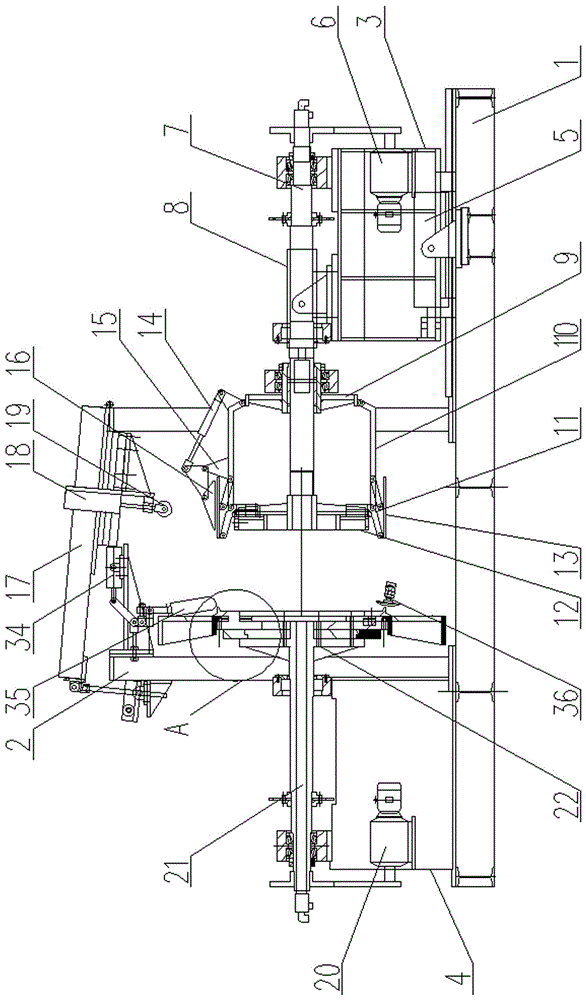

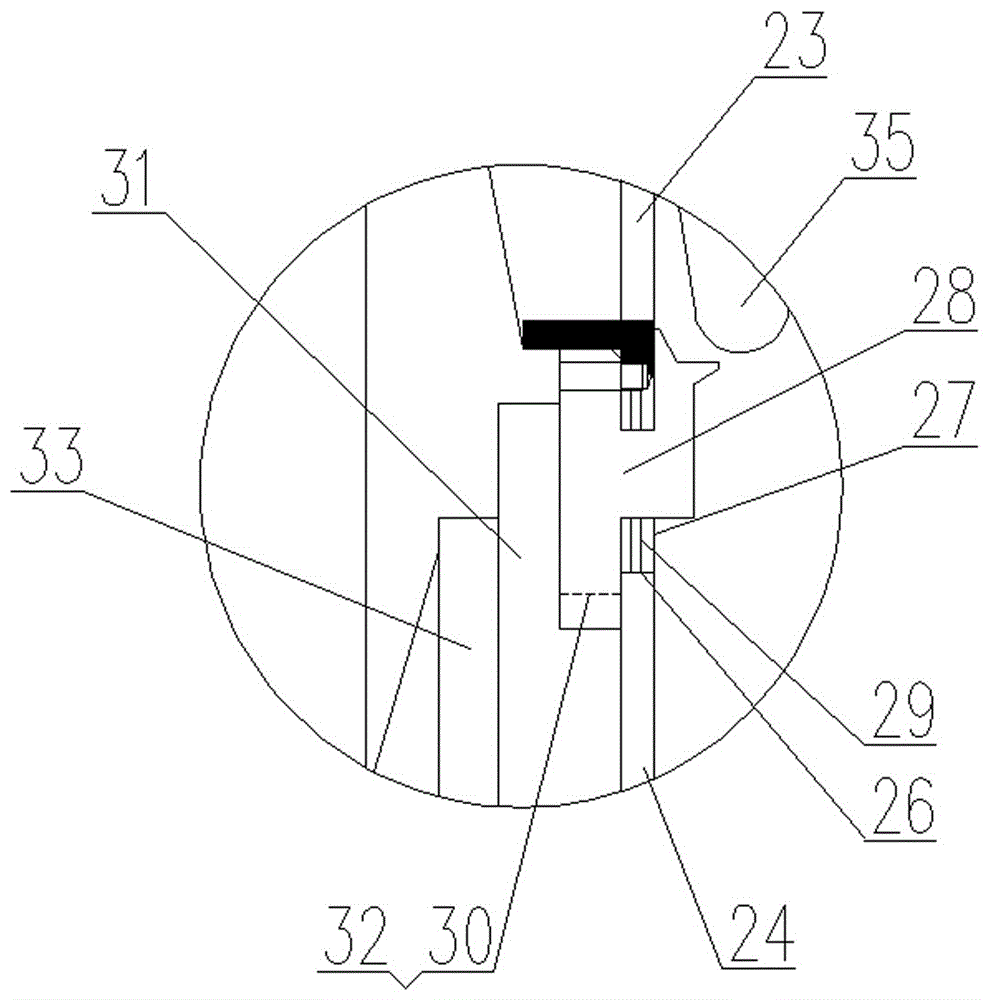

[0016] figure 1 , 2 Shown: Engineering tire steel apron automatic bonding machine, including base 1, left frame 4, right frame 3, right frame advance and retreat cylinder 5, apron turning and bonding device and steel ring rotating support device, left, The right frame 4 and 3 are respectively arranged on the left and right sides of the base 1, the steel ring rotating supporting device is arranged on the left frame 4, the apron turning and bonding device is arranged on the right frame 3 through the right frame advancing and retreating cylinder 5. Drive the apron flip-fitting device to advance and retreat towards the steel ring of the left frame, turn it over and attach the apron to the steel ring, rotate the support and affix the steel ring. The apron turning and bonding device includes a right main shaft 7, a turning cylinder 8, a push girder 9, a turning push rod 10, a parallelogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com