Electric reactor iron core structure, and manufacturing equipment and manufacturing method thereof

A technology of iron core structure and reactor, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic core manufacturing, transformer/inductor core, etc., which can solve the problems of reactor damage, high reactor heat, and poor heat dissipation. To achieve the effect of improving the service life and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-9 The application is described in further detail.

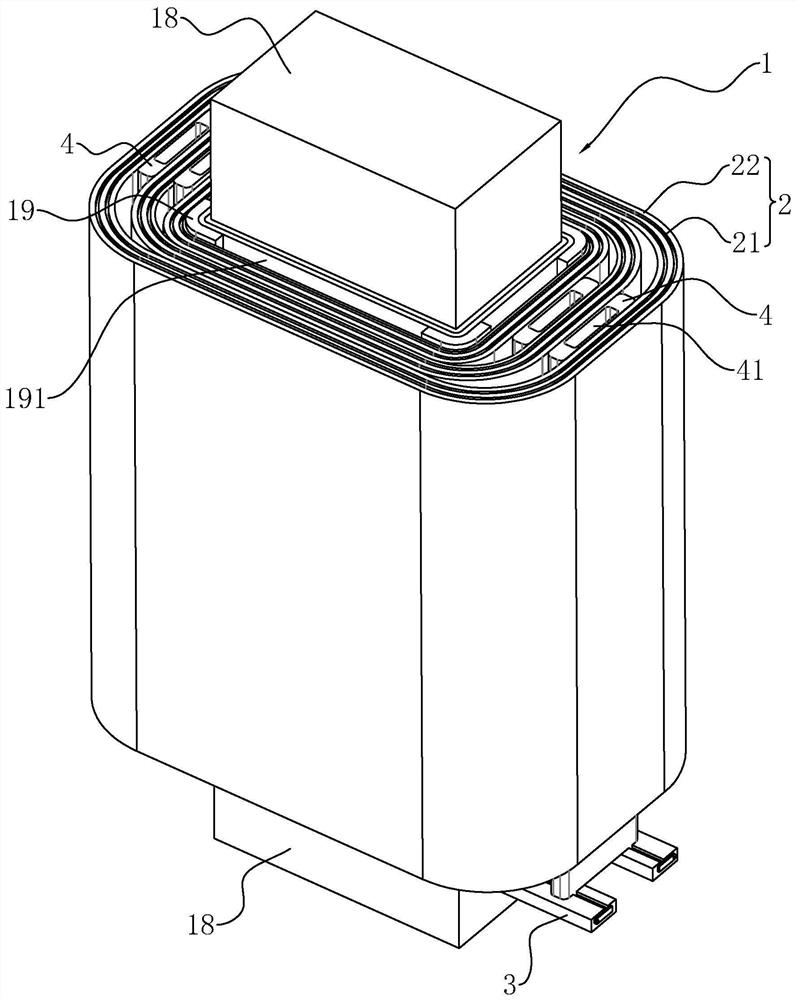

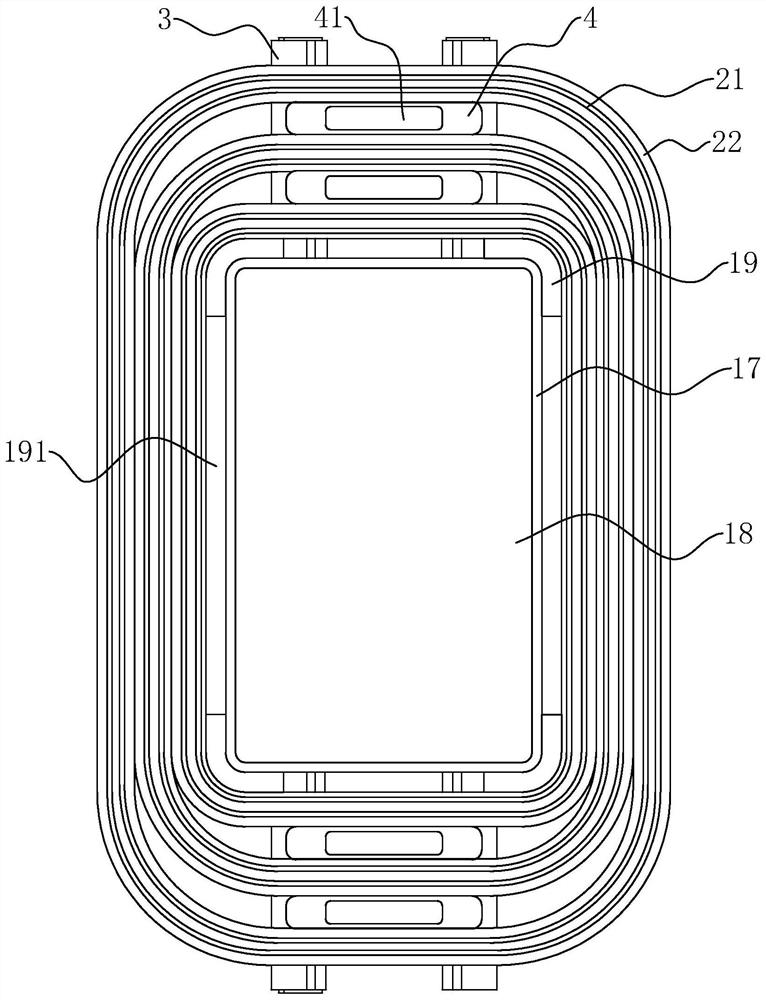

[0048] The embodiment of this application discloses a reactor core structure, refer to figure 1 , including a magnetic core cake 1 and a winding 2 wound on the magnetic core cake 1 , the wire group includes insulating paper layers 21 and aluminum foil tape layers 22 stacked alternately.

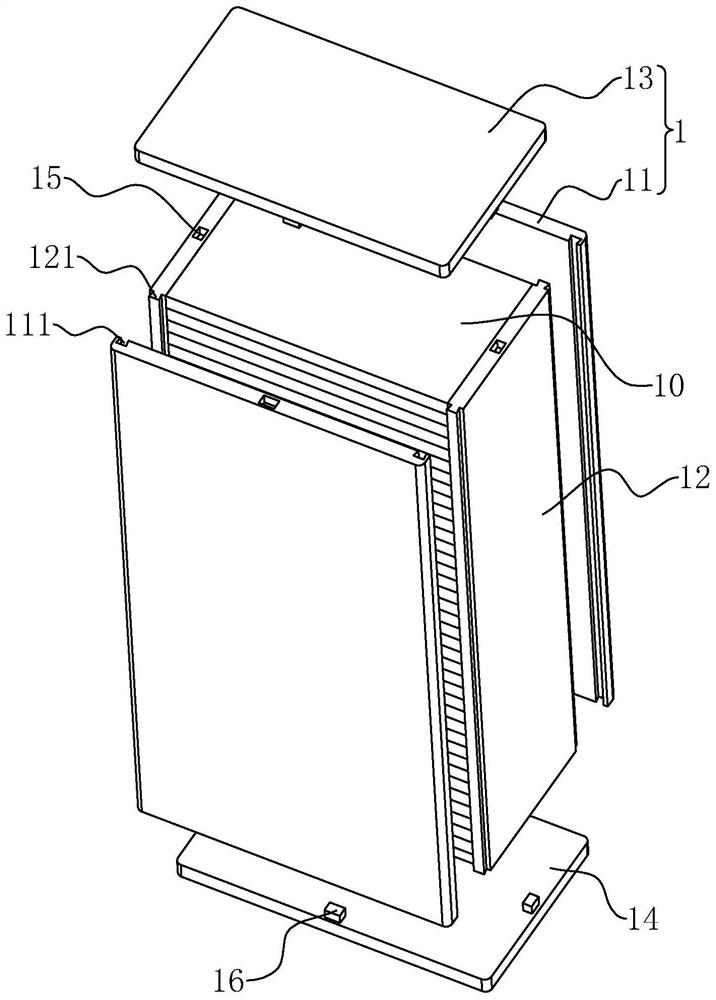

[0049] refer to figure 1 , figure 2 The magnetic core cake 1 includes two first side plates 11 arranged parallel to each other, two second side plates 12 arranged parallel to each other, an upper sealing plate 13 and a lower sealing plate 14, the first side plate 11, the second side plate 12. The upper sealing plate 13 and the lower sealing plate 14 form a cube, and the magnetic core cake 1 is provided with a plurality of chips 10 arranged horizontally and stacked on top of each other. The chip 10 is parallel to the upper sealing plate 13 and the lower sealing plate 14 , and the chip 10 is perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com