Termination connection for superconductive cable

A superconducting cable and terminal connection technology, applied in the directions of superconducting devices, superconducting parts, superconducting elements, etc., can solve problems such as the performance degradation of superconducting cables 10, and prevent the generation of stress, peeling and damage. , the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0073] Hereinafter, a first embodiment of the present invention will be described in detail based on the drawings.

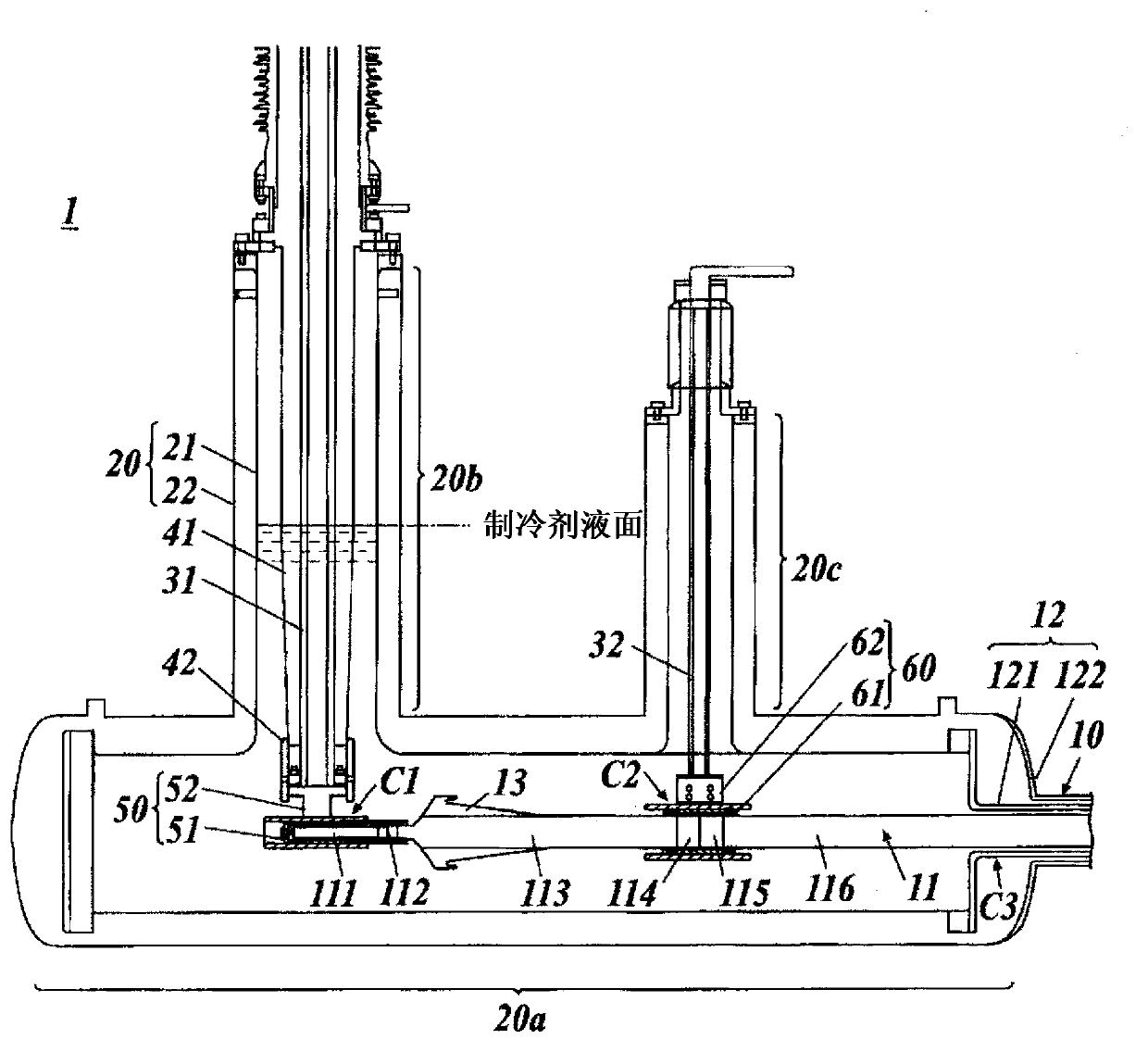

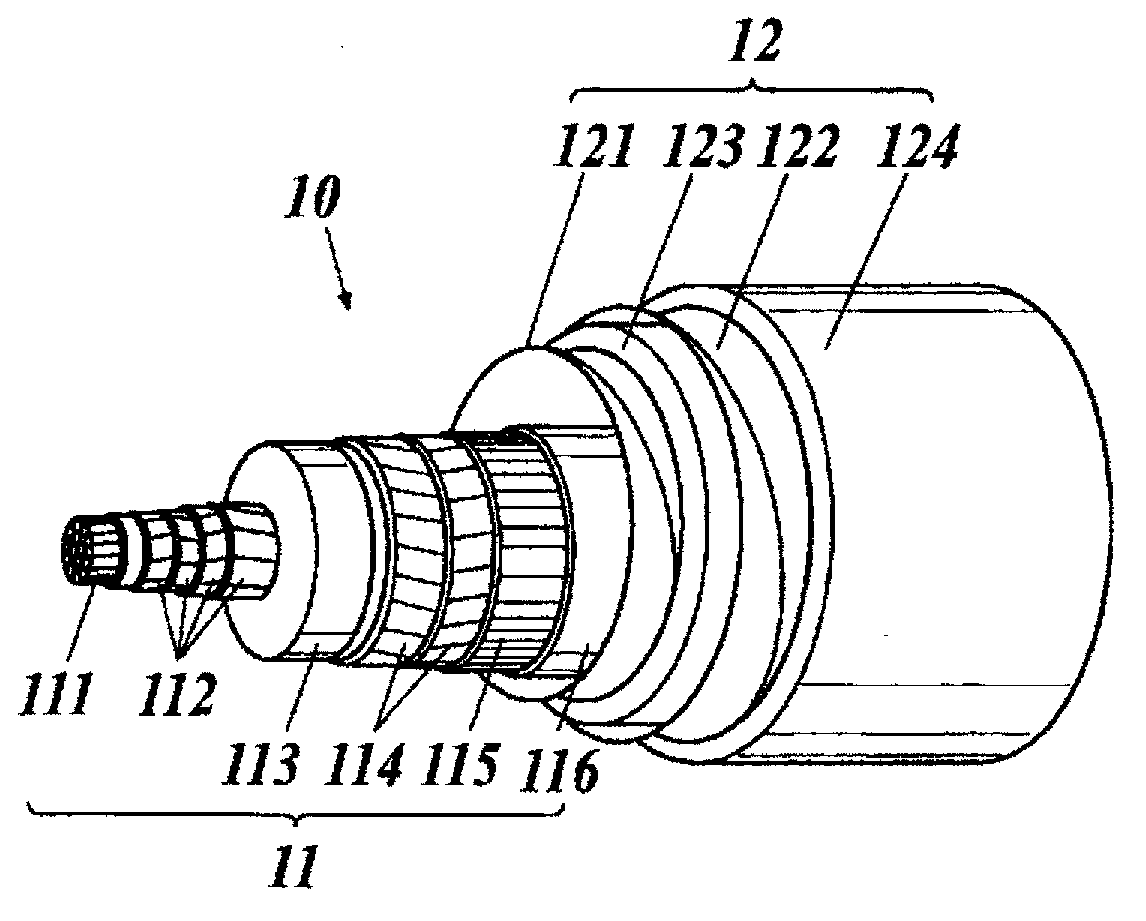

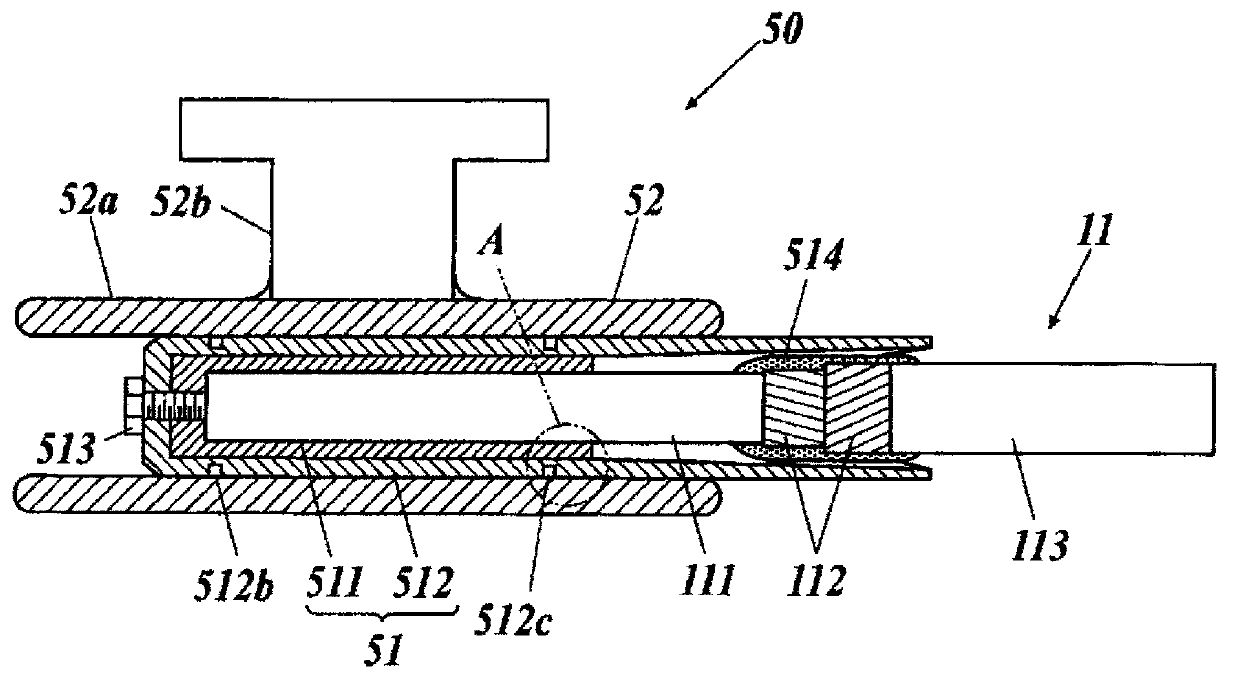

[0074] figure 1 It is a figure which shows the schematic structure of the terminal connection part of the superconducting cable of 1st Embodiment, figure 2 It is a figure which shows an example of the superconducting cable which should equip the terminal connection part.

[0075] figure 2 The shown superconducting cable 10 is a single-core superconducting cable in which a cable core 11 of one core is accommodated in a heat insulating tube 12 . The cable core 11 is composed of a skeleton (forma) 111 , a superconducting conductor layer 112 , an electrical insulating layer 113 , a superconducting shielding layer 114 , a common conductive shielding layer 115 , and a protective layer 116 .

[0076] The skeleton 111 is a winding core for forming the cable core 11 , and is formed, for example, by twisting common conductive wires such as copper wires. The skeleton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com