Intelligent grabbing device for automobile part production

A technology for grabbing devices and auto parts, applied in the direction of claw arms, manipulators, program-controlled manipulators, etc., can solve the problems of poor flexibility of the grabbing mechanism and small grabbing range, and expand the grabbing range and force-bearing point area Large, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

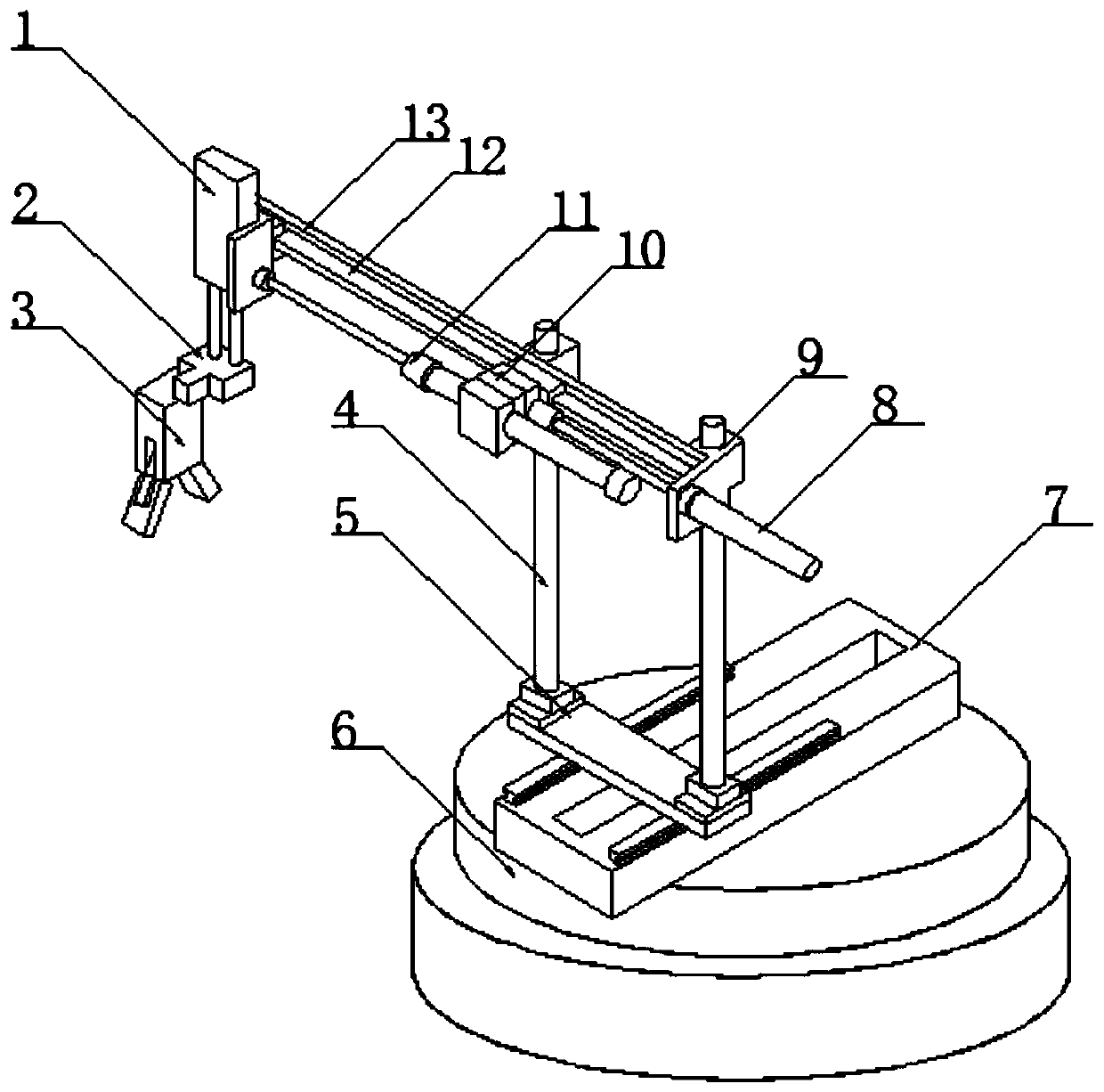

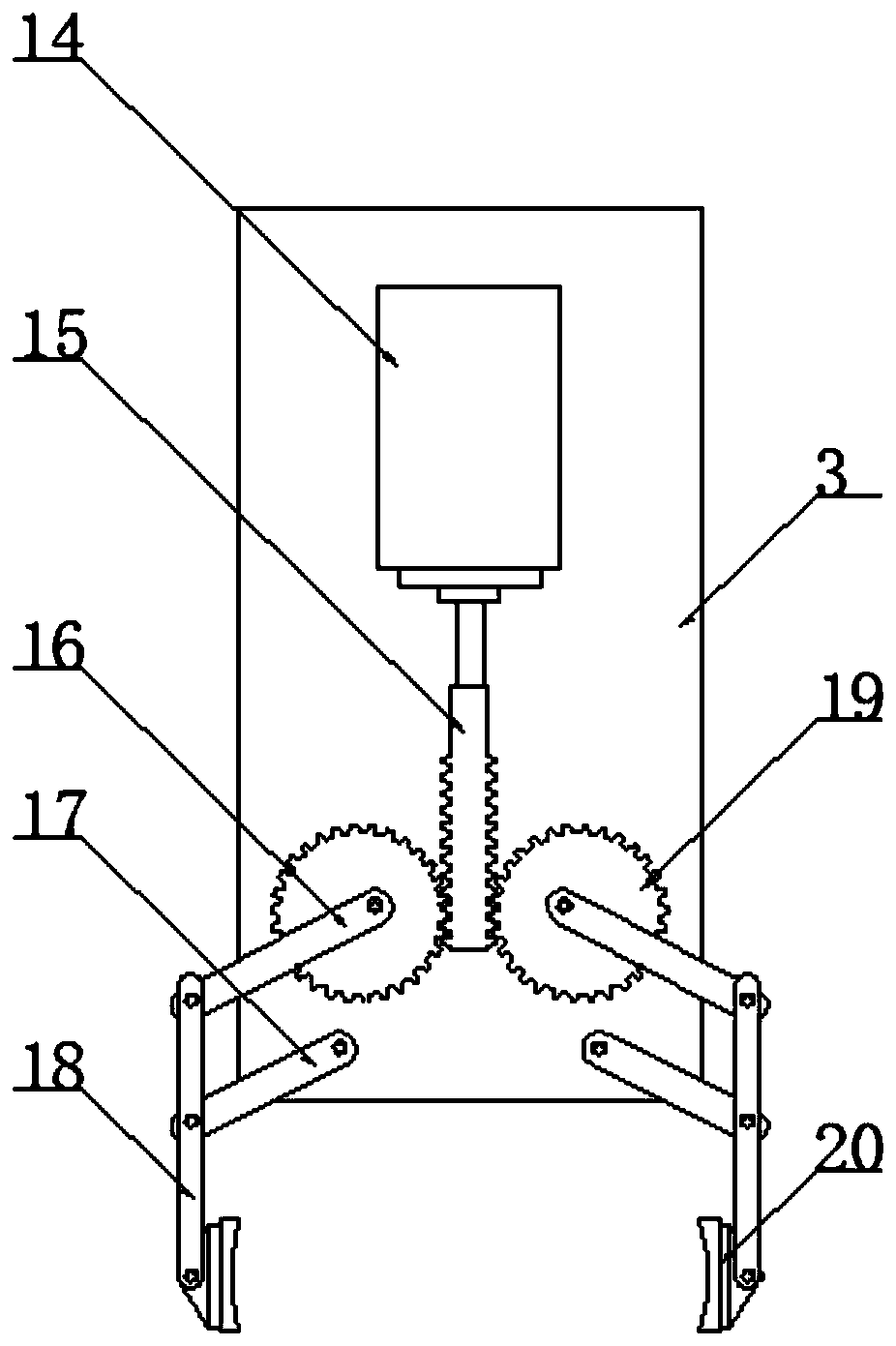

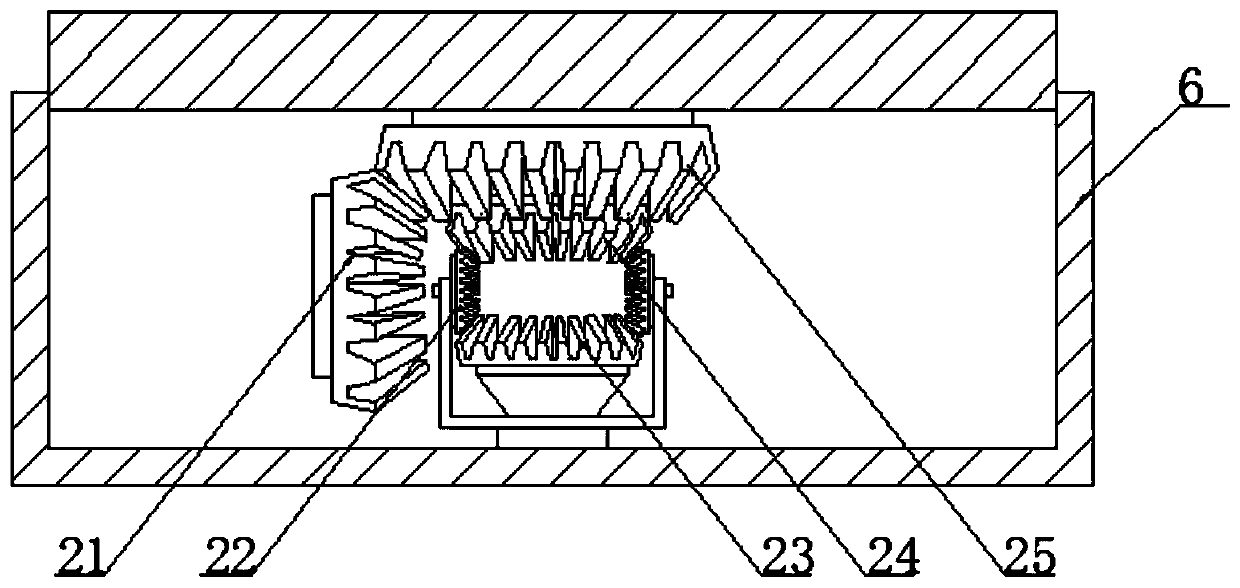

[0021] see Figures 1 to 4 , in the embodiment of the present invention: an intelligent grabbing device for the production of auto parts, comprising a turntable 6, the top of the turntable 6 is overlapped with a sliding table 7, and the top of the sliding table 7 is slidably connected with a sliding plate 5, A set of vertical rods 4 are erected on the top, and the top of the vertical rod 4 is provided with a fixed plate 9, and the fixed plate 9 is welded with a connecting plate 13, the connecting plate 13 is connected with a slider 12, and the slider 12 is slidably connected with a slider 10. , and the rear end of the slider 10 is connected with a second cylinder 8, and the second cylinder 8 is fixed on the fixing plate 9, the slider 10 is provided with a third cylinder 11, and the output end of the third cylinder 11 is connected with the first cylinder 11. Cylinder 1, a clamp 3 is installed on the output end of the first air cylinder 1, and a sensor 2 is installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com