Double-joint variable-cross-section soft-body hand with wedged transverse-pattern structure

A double-joint, variable-section technology, used in manipulators, chucks, manufacturing tools, etc., can solve the problems of large differences in human fingers, inability to adjust posture, unstable grasping, etc., to achieve large grasping force and grasping range. , grab stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

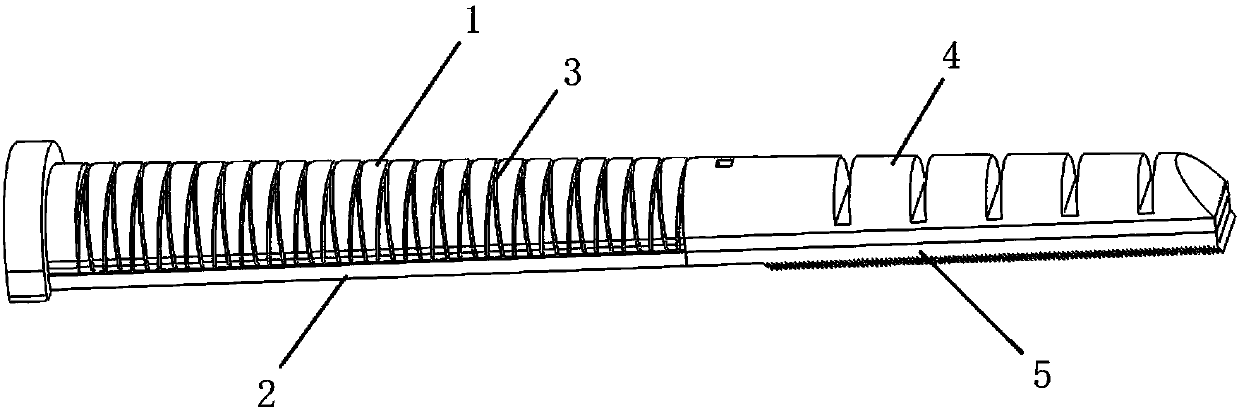

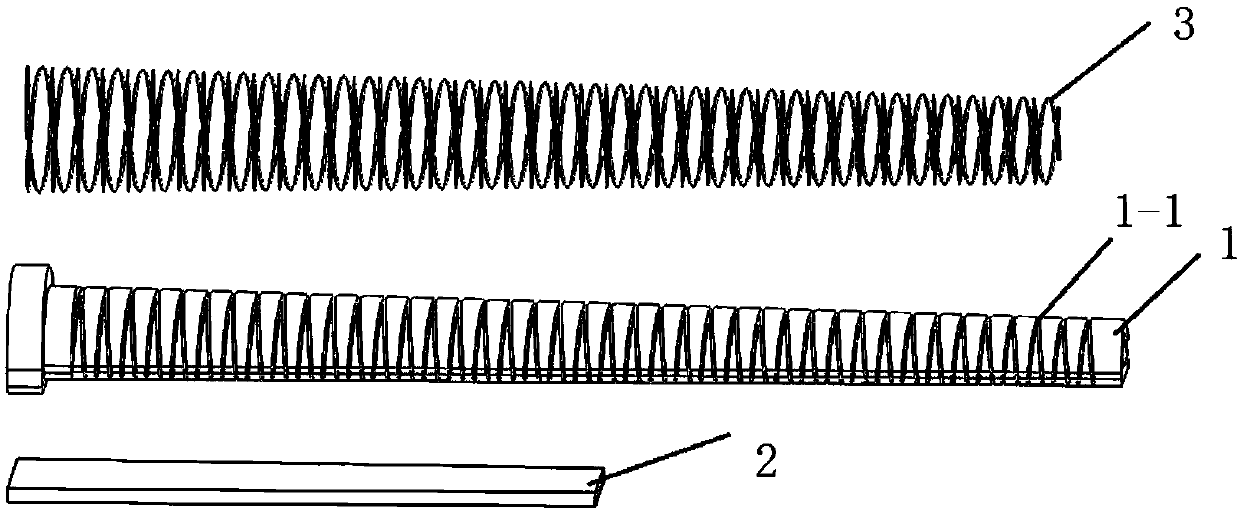

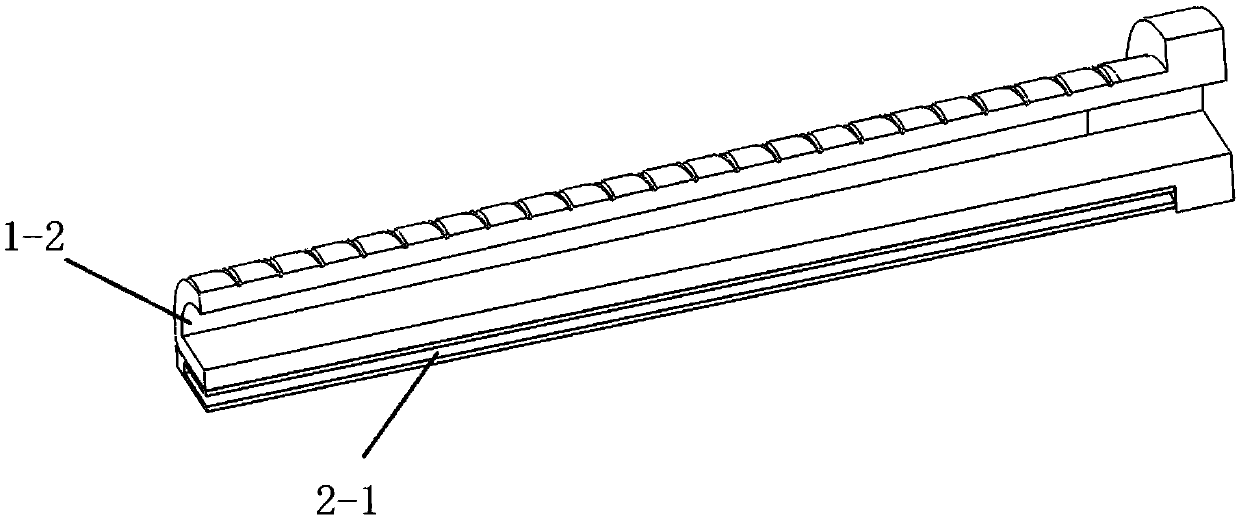

[0038] A double-joint variable-section soft hand with a wedge-shaped cross-stripe structure, the soft hand includes three identical soft fingers and a support, the soft fingers include a first joint and a second joint, wherein the first joint includes a first base 1. The first inextensible layer 2 arranged under the first base and the Kevlar wire 3 wound outside the combination of the first base and the first inextensible layer. The first base is provided with a first gas channel with one end open 1-2. The second joint includes a second base body 4 and a second inextensible layer 5 arranged under the second base body. The joint protrusion 4-3 is separated by the separation groove 4-2 on the second base body. The inside of the joint protrusion Gas chambers 4-5 are formed, and each gas chamber communicates through a second gas channel 4-4, and the second gas channel extends to the upper surface of the second base body in contact with the first base body to form an air inlet hole ...

Embodiment 2

[0043] When a soft finger described in the above technical solution is in use, compressed air enters the first gas channel 1-2 of the first joint of the soft finger through the gas chamber channel, and the air pressure in the first gas channel 1-2 The Kevlar wire 3 constrains the radial expansion of the first gas channel 1-2, and the first non-extensible layer 2 constrains the axial elongation of the first gas channel 1-2 on the plane side, so the first gas channel 1-2 The axial elongation of the arc surface of a gas channel 1-2 becomes the dominant factor, which makes the first joint bend to the plane side as a whole to realize the bending action. When the first joint is bent, the ground coffee powder filled in the first particle-filled cavity 2-1 of the first inextensible layer 2 is squeezed and interfered, which increases the stiffness of the first joint.

[0044] Compressed air enters the second gas channel 4-4 through the air inlet 4-1, and then enters the five gas chambe...

Embodiment 3

[0046] Three soft fingers cooperate to bend to grasp and pick up objects. Two air sources respectively control the first joint and the second joint. When grabbing a small object, the first joint ventilates first and bends inward. When approaching the object, the second joint inhales air first, bends in the opposite direction to increase the grabbing space, and then ventilates and bends inward to grab the object; When it comes to large objects, the second joint inhales air first, bends in the opposite direction to increase the grasping space, then the first joint and the second joint ventilate at the same time, bends inwards, and grasps the object. Depending on the gripping situation, the ventilation sequence can be changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com