Patents

Literature

118results about How to "Won't rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

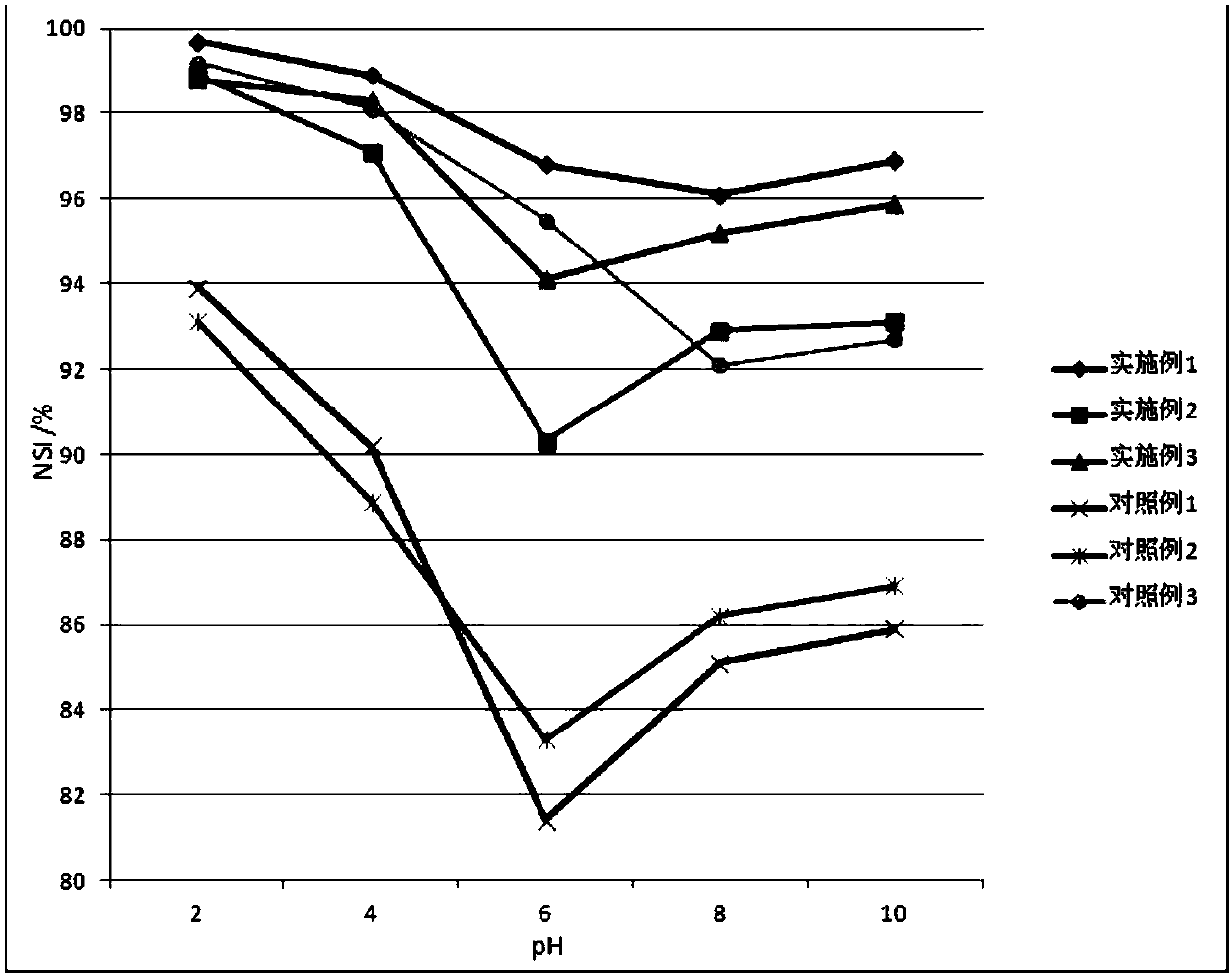

Sewage treatment agent and method for treating black and odorous water body by sewage treatment agent

PendingCN108502963AEfficient governanceNo damageWater/sewage treatment by irradiationWater treatment compoundsWater qualitySewage treatment

The invention discloses a sewage treatment agent. The sewage treatment agent is prepared from a high molecular polymer flocculating agent, an inorganic flocculating agent, a fungus nutrient substance,an aerobic complex microbial flora, a facultative complex microbial flora, an anaerobic complex microbial flora and an inorganic nano-material; a method for treating a black and odorous water body comprises the following step: directly adding the sewage treatment agent into the black and odorous water body or adding a coating treatment agent prepared from the sewage treatment agent into the blackand odorous water body. The sewage treatment agent provided by the invention can be used for effectively managing the black and odorous water body, has an ideal management effect and does not cause damages to the environment and the water quality does not rebound after management. The method for treating the black and odorous water body is simple and efficient to operate and is green and environmentally friendly.

Owner:苏斌

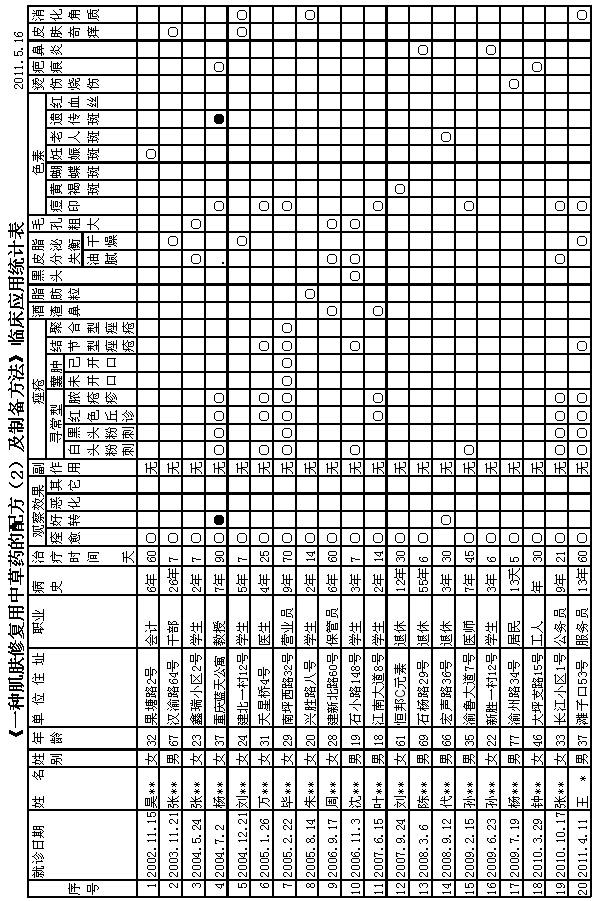

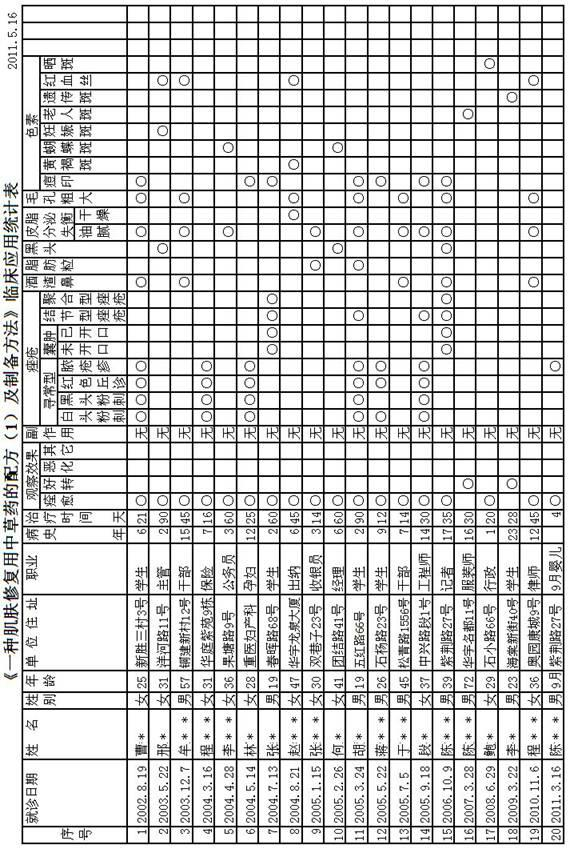

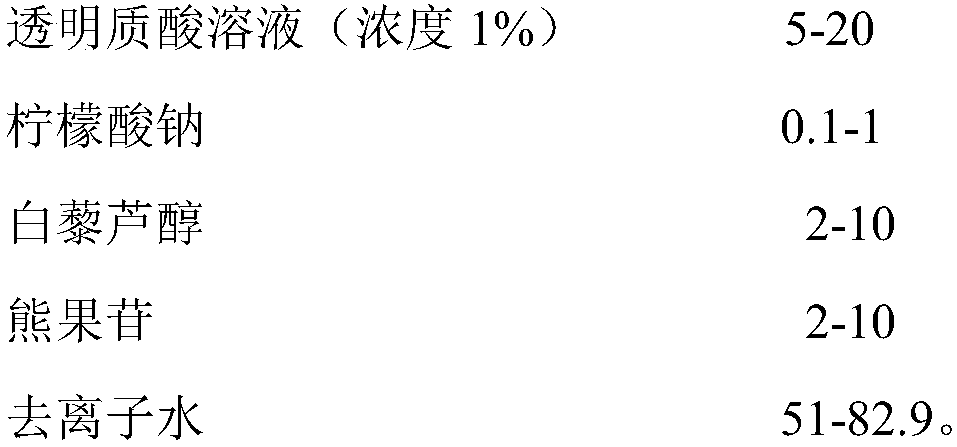

Medicament for repairing skin and preparation method thereof

InactiveCN102205055AReduce oxidationReduce formationAnthropod material medical ingredientsDermatological disorderDiseaseMedicinal herbs

The invention discloses a medicament for repairing skin and a preparation method thereof. The medicament comprises the following raw materials in part by weight: 0.9 to 150 parts of ginseng, 5 to 295 parts of bletilla, 20 to 300 parts of tree poney, 10 to 250 parts of Chinese angelica, 15 to 120 parts of cassia bark, 0.8 to 150 parts of glossy ganoderma and 0.5 to 150 parts of pollen. The preparation method comprises the following steps of: putting the raw materials into a container; adding water to flood the raw materials; decocting for 30 to 80 minutes hermetically or evaporating and decocting for 60 to 120 minutes; taking decoction out; adding the water to flood the raw materials; decocting hermetically or evaporating and decocting for the second time and the third time; mixing the decoction at three times; and packaging to form the medicament. The medicament achieves the effect of treating diseases such as skin allergy pruritus, blain scars, chloasma, butterfly rash, cyasma, senile plaque, sunburn, genetic freckles, fat granules, imbalance in sebum secretion, blackhead trichopore and the like which are caused by acnes, tinea corporis, acne rosacea, blood streak, hormone and the like safely and quickly under the synergistic action of the Chinese medicinal herbs.

Owner:王明全

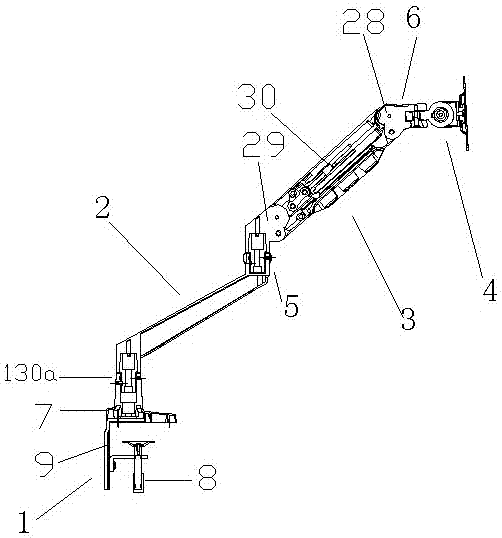

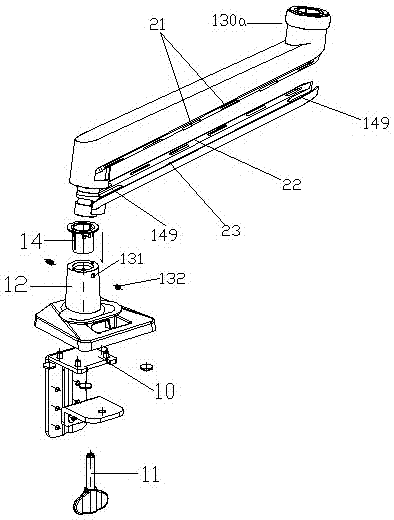

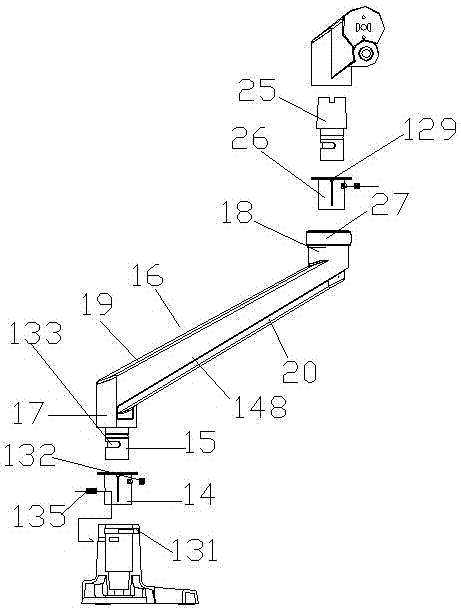

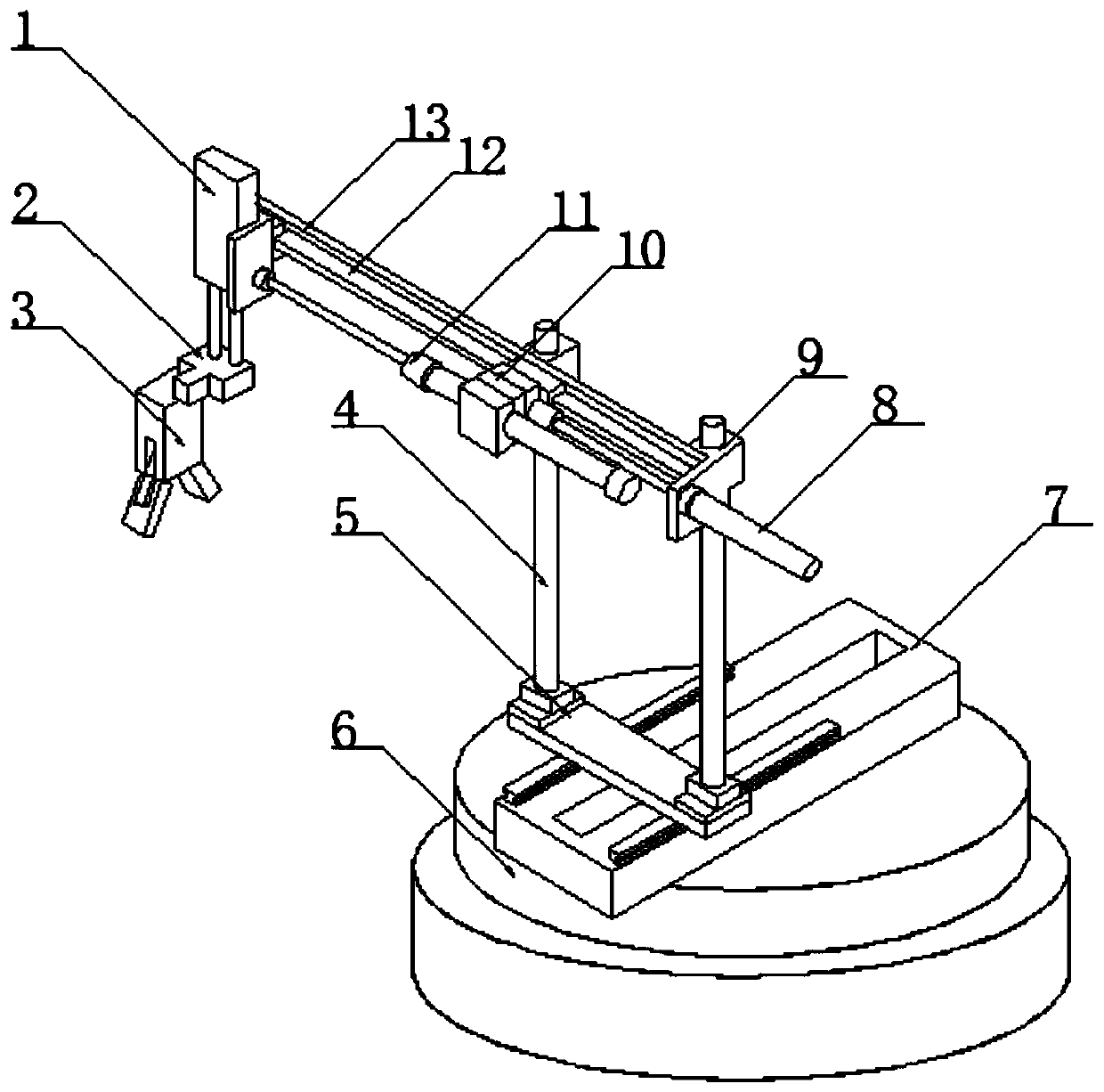

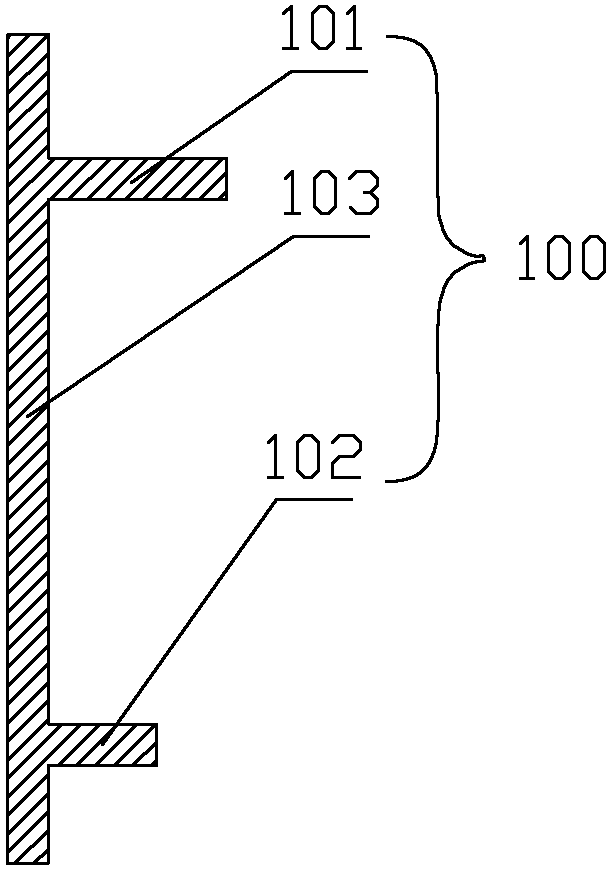

Novel telescopic spring supporting frame

The invention relates to the field of display screen supporting frames, in particular to a novel telescopic spring supporting frame. The novel telescopic spring supporting frame comprises a base, an extension arm, a lifting supporting arm and a display screen hanging tool. The base is provided with the extension arm. An extension arm connecting joint is arranged at the top end of the extension arm and provided with the lifting supporting arm. A swinging head is arranged at the head end of the lifting supporting arm. The display screen hanging tool is arranged at the top end of the swinging head. The extension arm, the lifting supporting arm and the display screen hanging tool are upwards arranged in an oblique angle manner (the display screen hanging tool can be adjusted in a pitching manner), the lifting supporting arm conducts universal rotation with the extension arm connecting joint as the axis, and the lifting supporting arm conducts universal rotation with the swinging head as the axis.

Owner:徐和云

Flakeboard and method of manufacturing the same

InactiveCN101244579AReduce releaseLong-lasting effectFlat articlesDomestic articlesChemical reactionAdhesive

The invention relates to a particle board with low formaldehyde emission and the preparation method, wherein, the preparation method comprises the following steps: grinding the tea waste into fibrous or powder material; well mixing the fibrous or powder material and wood chips; applying adhesive to form mixture; forming the mixture into billets and pressing into particle boards. Ammonia or alkaline salt solution can be sprayed on the tea waste before being ground for activating treatment. The preparation method has the advantages that the tea waste and the wood chips are mixed for use; formaldehyde emission in the particle board is fundamentally reduced through the chemical reaction of the tea waste and the formaldehyde, the effect is obvious, permanent and free from rebound; the mechanical property of the prepared particle board is not reduced, but increased somewhat.

Owner:BEIJING FORESTRY UNIVERSITY

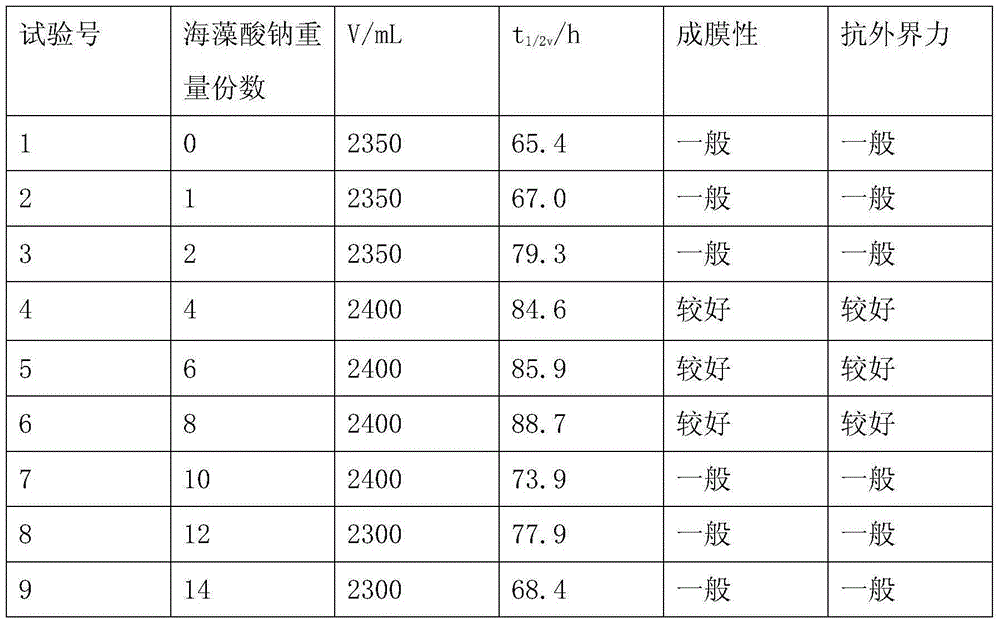

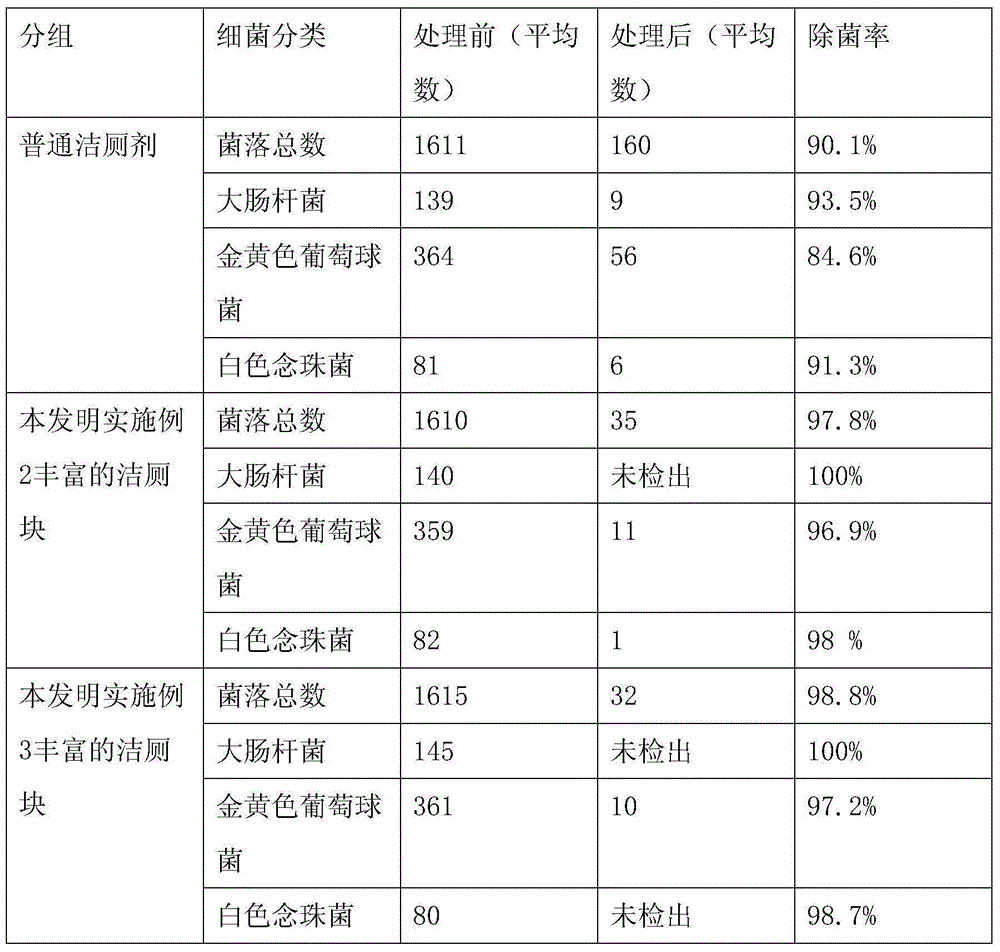

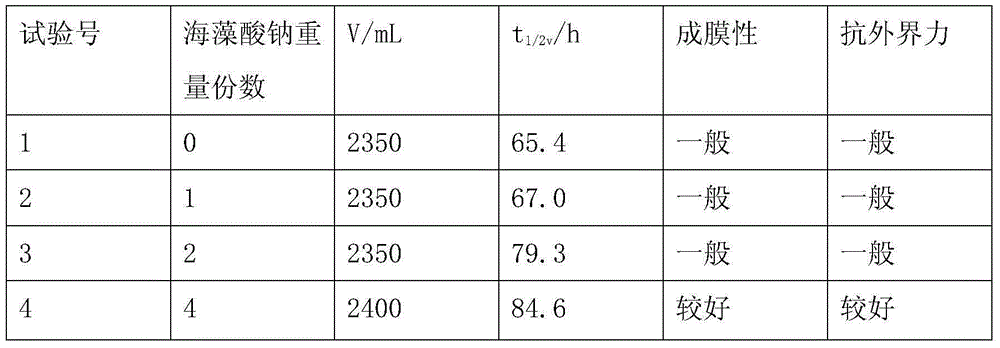

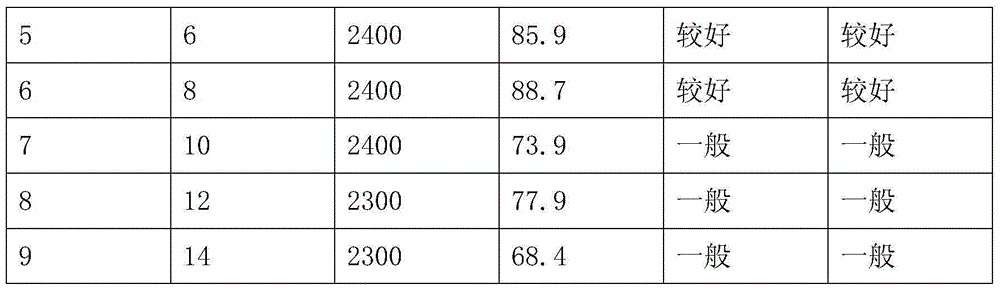

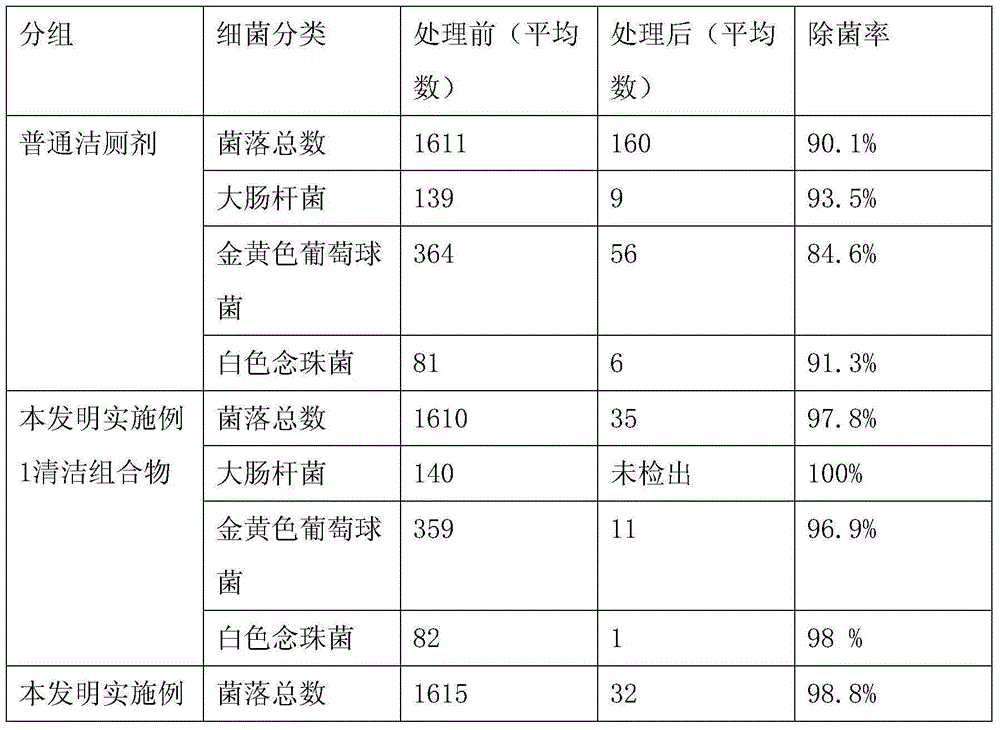

Rich-foam toilet cleaning block

InactiveCN105154247AImprove washing abilityStrong foaming powerInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemistryFood science

The invention provides a rich-foam toilet cleaning block which comprises an anionic surfactant, a nonionic surfactant, tea saponin, sodium alginate, sodium citrate, a bactericidal deodorant, sodium chloride and the like. The bactericidal deodorant used in the rich-foam toilet cleaning block is one or mixture of more of broadleaf holly leaf extract, cloven extract, phellodendron bark extract and mint extract. The rich-foam toilet cleaning block has excellent foaming and foam stabilizing capacities, and can effectively remove yellow scales, urine scales and water scales. By adopting the pure plant extracts, the rich-foam toilet cleaning block can efficiently decompose peculiar smell, has the bactericidal and deodorizing functions, and is harmless to the human body and environment. The rich-foam toilet cleaning block can emit a natural fresh plant odor on the premise of deodorization.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Green slimming tea

The invention relates to green slimming tea which is characterized by comprising the following raw materials in parts by weight: 10-30 parts of green tea, 3-6 parts of poria cocos, 5-12 parts of dutchmanspipe roots, 2-10 parts of folium mori, 3-12 parts of honey and 3-12 parts of polygonum multiflorum. Compared with the prior art, the green slimming tea has the advantages that firstly, the whole raw materials adopted according to the technical scheme are relatively low in cost, the production process is simple, and the operation is easy; secondly, the green slimming tea has no side effect on the digestion and absorption system and can promote normal metabolism of human bodies; thirdly, the green slimming tea has the effects of reducing the blood fat and the cholesterol when the weight is reduced, can detoxify the body and beautify the skin, as well as whiten the skin, and can also prevent diseases such as arteriosclerosis; fourthly, the weight loss effect is remarkable, the taking of the green slimming tea can be stopped after for 6-8 months later, the weight does not rebound after the taking aloe slimming tea is stopped, and thus the green slimming tea is safe and healthy and is applicable to popularization on a large scale.

Owner:黄介兰

Foam cleaning composition

InactiveCN105154251AStop splashPrevent spillageAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBedpanDeodorant

The invention provides a foam cleaning composition which comprises an anionic surfactant, a nonionic surfactant, tea saponin, sodium alginate, sodium citrate, sodium chloride, a bioenzyme, betaine and the like. The foam cleaning composition can also comprise a bactericidal deodorant, an essence and a colorant. The foam cleaning composition is suitable for cleaning bedpans, and has the characteristics of high foaming speed, fine and abundant foam, long duration time and the like. The bactericidal deodorant is a pure natural antibacterial deodorant, can remove peculiar smell, has favorable bactericidal action, and is harmless to the human body and environment.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

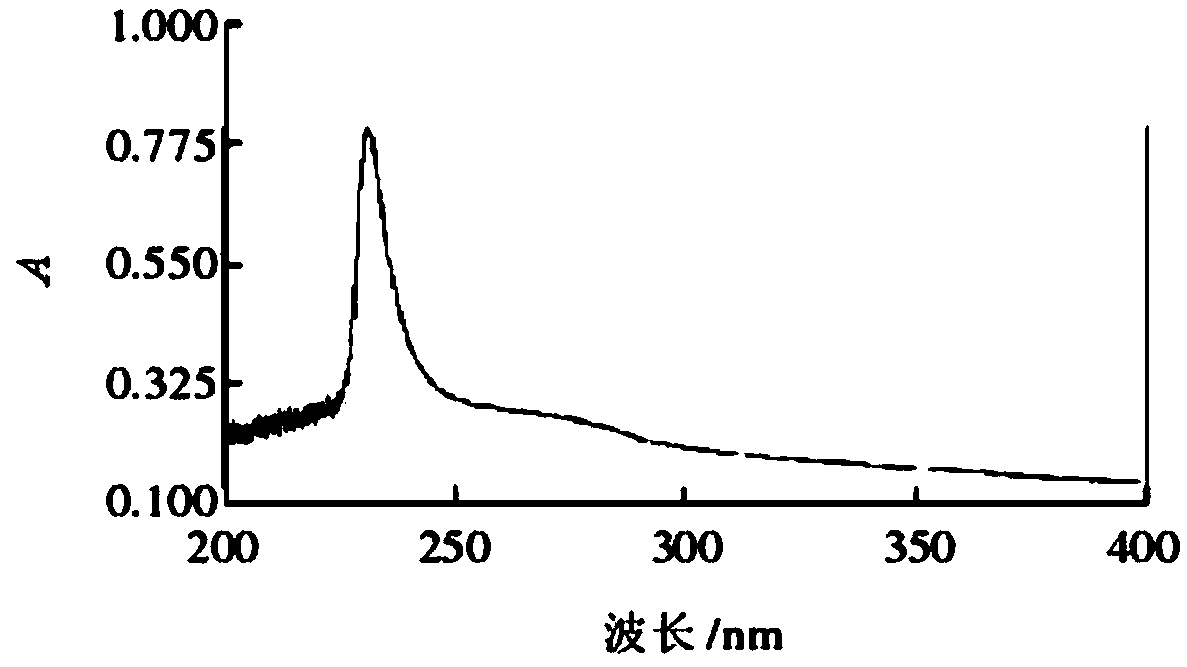

Extraction method and application of high-activity collagen

InactiveCN107929091AMaintain natural biological traitsIncrease vitalityCosmetic preparationsHydroxy compound active ingredientsCutinSkin color

The invention discloses an extraction method and application of high-activity collagen, and belongs to the fields of biotechnology and cosmetics. The collagen is extracted by adopting a combined extraction method, so that the extraction time is shortened, the extraction rate is improved, the purity is improved, the environmental pollution is avoided, and the natural biological character of the collagen is maintained to the maximum degree. On that basis, the invention further provides a fishskin collagen anti-wrinkle essence. The adjustment of skin cutin can be helped, the cutin is smooth, theskin is whitened in an orienteering manner, the activity of face cells is stimulated, darkness is decomposed in multiple layers, the essence is antioxidant, the skin color is balanced, and damaged cells caused by ultraviolet rays or other cosmetics are repaired.

Owner:大美生物科技有限公司

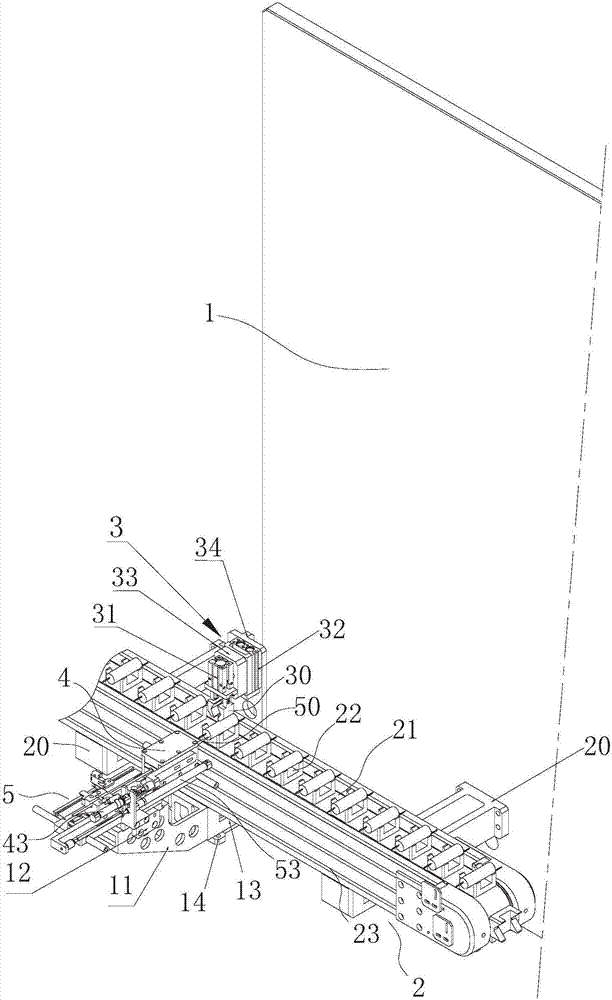

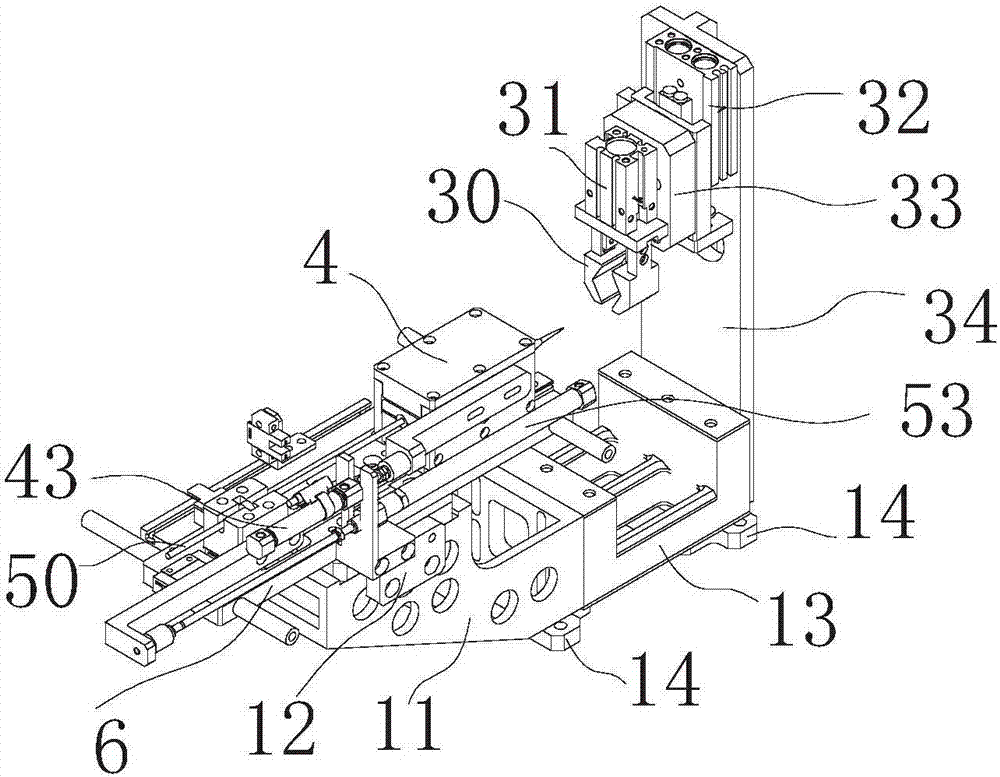

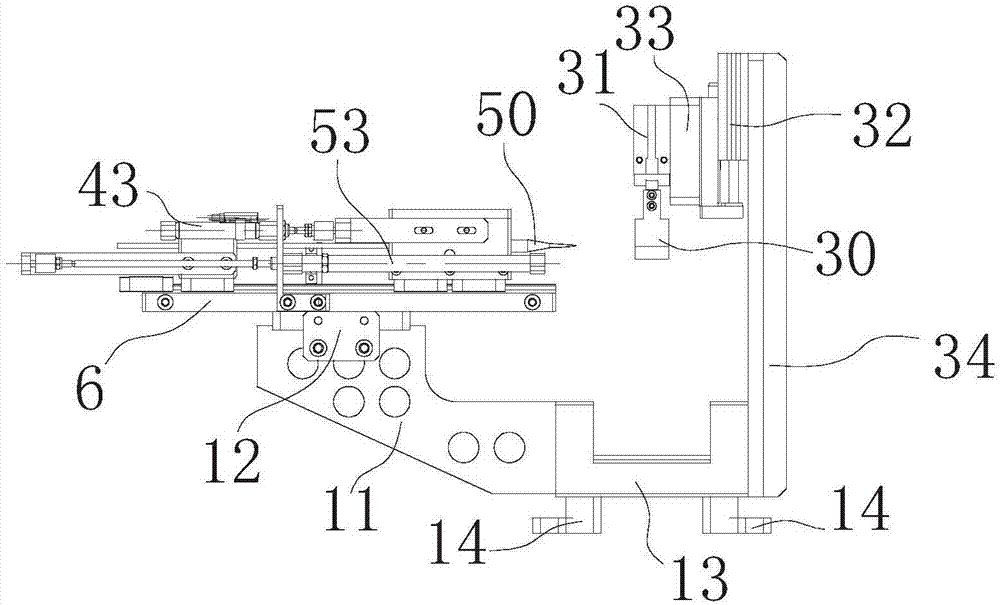

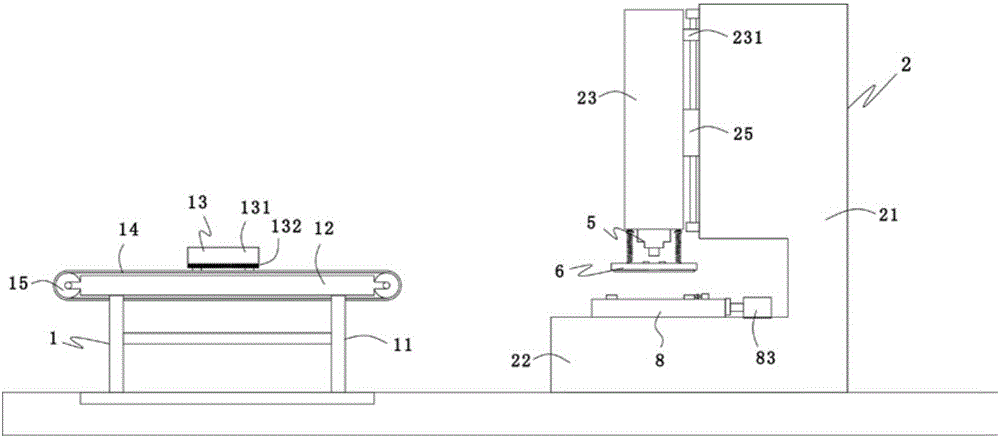

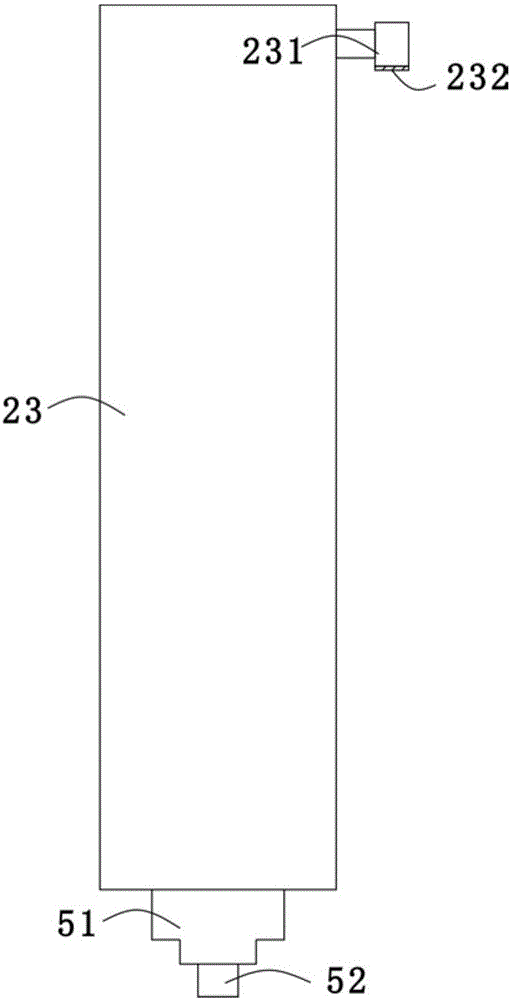

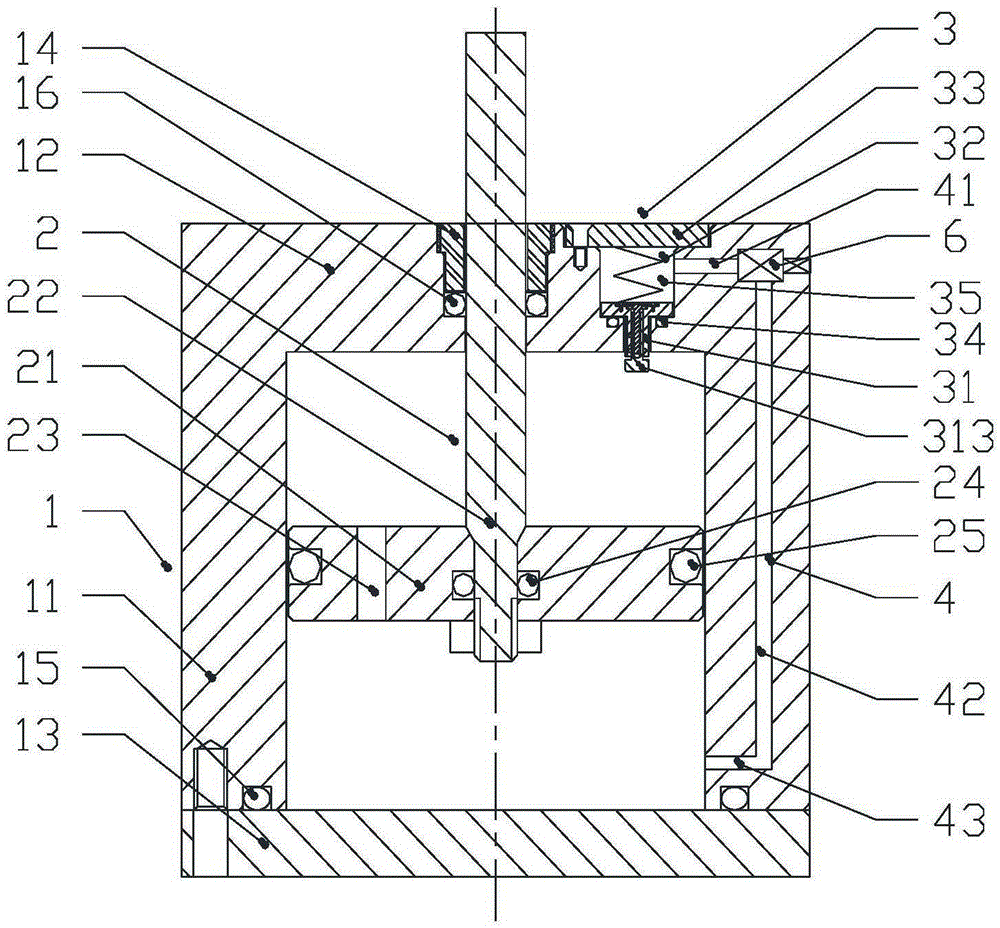

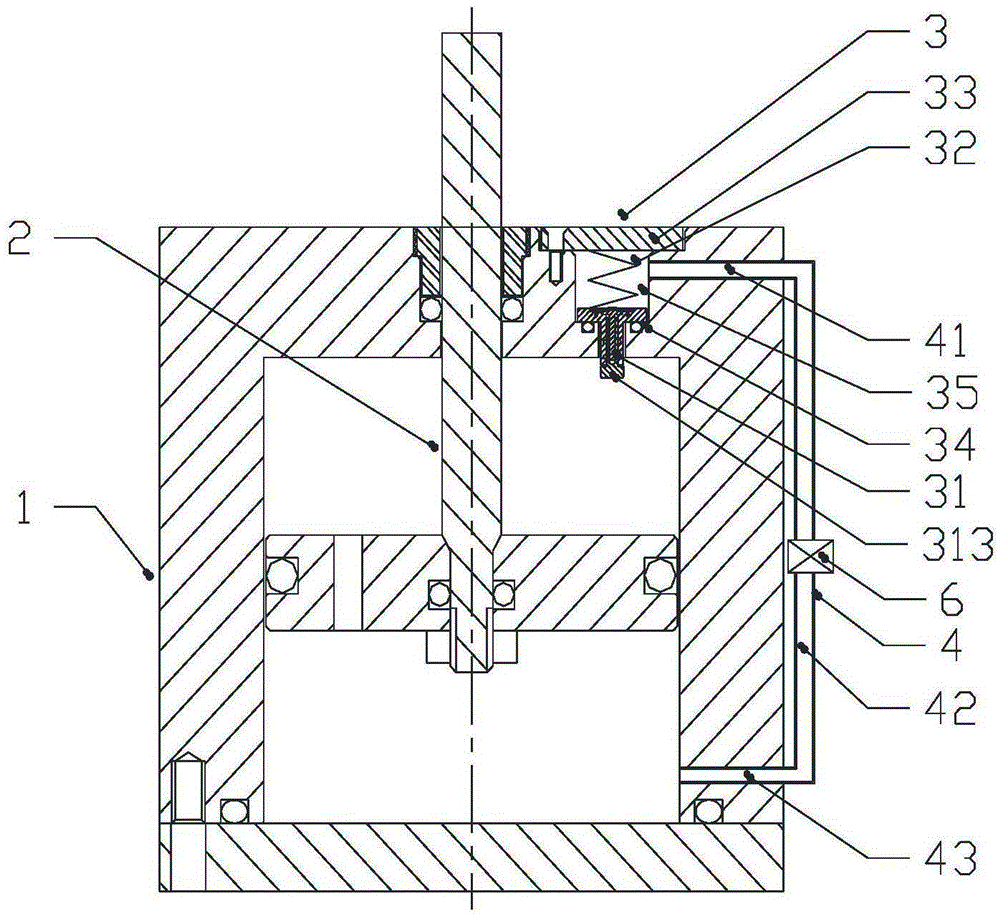

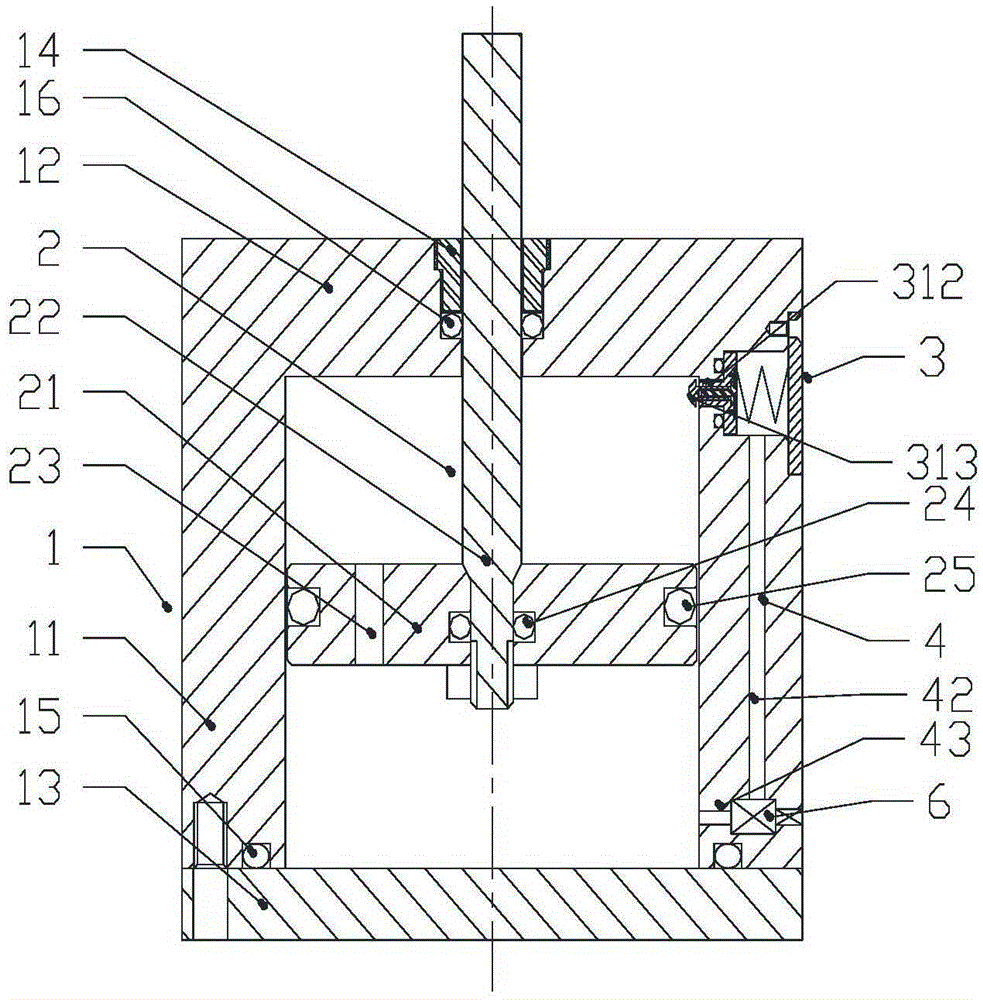

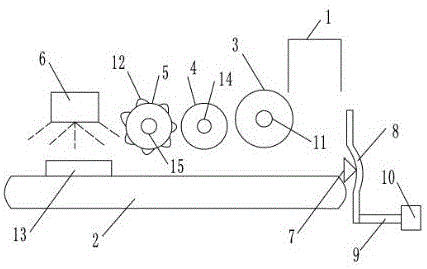

Battery cell hole ironing mechanism and winder thereof

ActiveCN107069071ASolve bad reamingSolving Elasticity ProblemsAssembling battery machinesFinal product manufactureMechanical engineeringBattery cell

The invention provides a battery cell hole ironing mechanism which comprises a baseplate. A battery cell conveying portion for conveying batter cells one by one in order is arranged on the front side of the baseplate, and a battery cell clamping and positioning portion for clamping and positioning each battery cell conveyed on the battery core conveying portion, an ironing needle heating portion and an ironing needle feeding portion for iron a round hole in the center of each battery cell clamped and fixed by the battery cell clamping and positioning portion are arranged on each of two sides of the battery cell conveying portion; each ironing needle feeding portion comprises a hole ironing needle, a sliding rail, a slider seat arranged on the sliding rail and convenient for mounting and fixing the ironing needle hole and an ironing needle feeding cylinder, and each ironing needle feeding cylinder pushes the corresponding slider seat and the corresponding hole ironing needle to move forwards along the corresponding sliding rail to be inserted into the center of the corresponding battery cell clamped by the corresponding battery cell clamping and positioning portion or move backwards to exit the center of the corresponding battery cell for resetting; each heating displacement cylinder pushes a heating block to move forwards along the corresponding sliding rail to the edge of the center of the corresponding battery cell for hole ironing to heat the front portion of the hole ironing needle inserted into the corresponding battery cell to accelerate hole ironing at the center of the battery cell. The invention further provides a winder adopting the battery cell hole ironing mechanism.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

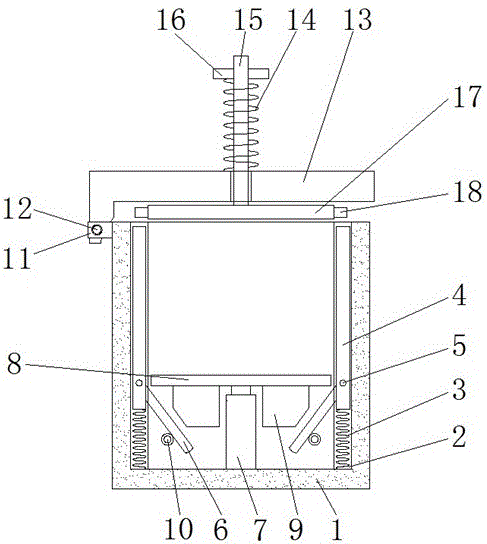

Garbage can with garbage compression function

ActiveCN106144333AHas the function of compressing garbageWon't reboundRefuse receptaclesPressesLap jointEngineering

The invention discloses a garbage can with a garbage compression function. The garbage can comprises a can cylinder. Sliding grooves are formed in the inner wall of the can cylinder. A first spring is arranged at the bottom of each sliding groove. One end of each first spring is fixedly connected with one end of a pressing rod. The pressing rods are located in the sliding grooves. A connecting shaft sequentially penetrates the bottom of the surface of each pressing rod and one end of a prying bar. The other end of each prying bar extends to the bottom of an inner cavity of the can cylinder. Bar shafts penetrate the front face of the box cylinder. The middle of the surface of each prying bar is in lap joint to the surface of the corresponding bar shaft. A telescopic rod is arranged in the middle of the bottom of the inner cavity of the can cylinder. The top end of the telescopic rod is fixedly connected with the bottom of a bottom plate. According to the garbage can with the garbage compression function, the bottom plate is arranged in the garbage can, when the garbage can is filled with garbage, a pull rod on a cover plate is pressed so that a pressing plate can descend to extrude the garbage in the garbage can, the pressing plate can drive the prying bars to pry the bottom plate when descending, and the garbage which is large in size and easy to compact in the garbage can is compacted through vertical extrusion of the bottom plate and the pressing plate.

Owner:无锡智高点技术研发有限公司

Moisture neck cream

ActiveCN103690446AComponents are environmentally friendlyLittle side effectsCosmetic preparationsToilet preparationsLanosterolSide effect

The invention discloses moisture neck cream and relates to the technical field of a neck skin care product. The moisture neck cream comprises the following components in percentage: 2 percent of sunflower seed oil, 8 percent of jojoba oil, 8 percent of shea butter, 2 percent of macadamia oil, 2 percent of olive oil, 2 percent of soybean oil, 1 percent of lanosterol mixed ester, 10 percent of collagen, 4 percent of emulsifier, 6 percent of antioxidant, 5 percent of neutralizer, 10 percent of skin care silicon oil, 10 percent of seaweed extract, 10 percent of hyaluronic acid, 5 percent of vitamin A, 10 percent of matrixyl and 5 percent of essence. The moisture neck cream adopts the environmental-friendly components, has small side effects, is suitable for people at any age, has no rebound phenomenon, and has strong practicality.

Owner:GUANGZHOU MEIZIHE COSMETICS CO LTD

Hot press molded melamine foam prepared by hot press molding and preparation method thereof

The present invention discloses a hot press molded melamine foam, and the melamine foam comprises, by weight, 100 parts of melamine resin, 1-10 parts of a surfactant, 5-40 parts of a foaming agent, 0-20 parts of an assistant, 5-20 parts of a catalyst, 0-30 parts of water, and 5-30 parts of hot pressing rubber powder particles. The invention also discloses a preparation method for the hot press molded melamine foam, and the method includes following steps: preparation of the melamine resin; preparation of a semi-finished product of the melamine foam: mixing raw materials uniformly to form a foaming solution, and subjecting the foaming solution to microwave action to obtain the semi-finished product; and preparation of a melamine foam finished product: spraying a liquid formed by dispersion of the hot pressing rubber powder particles during the moving of the semi-finished product of the melamine foam, and press-forming the dried foam by a thermo-compressor to obtain the melamine foam finished product. Reticular layer structures of the melamine foam are adhered together through melting of the hot pressing rubber powder particles in the method, and the melamine foam has good mechanical properties and flame retardance, and does not increase the formaldehyde content. The method is capable of continuous production.

Owner:成都玉龙超聚新材料有限公司

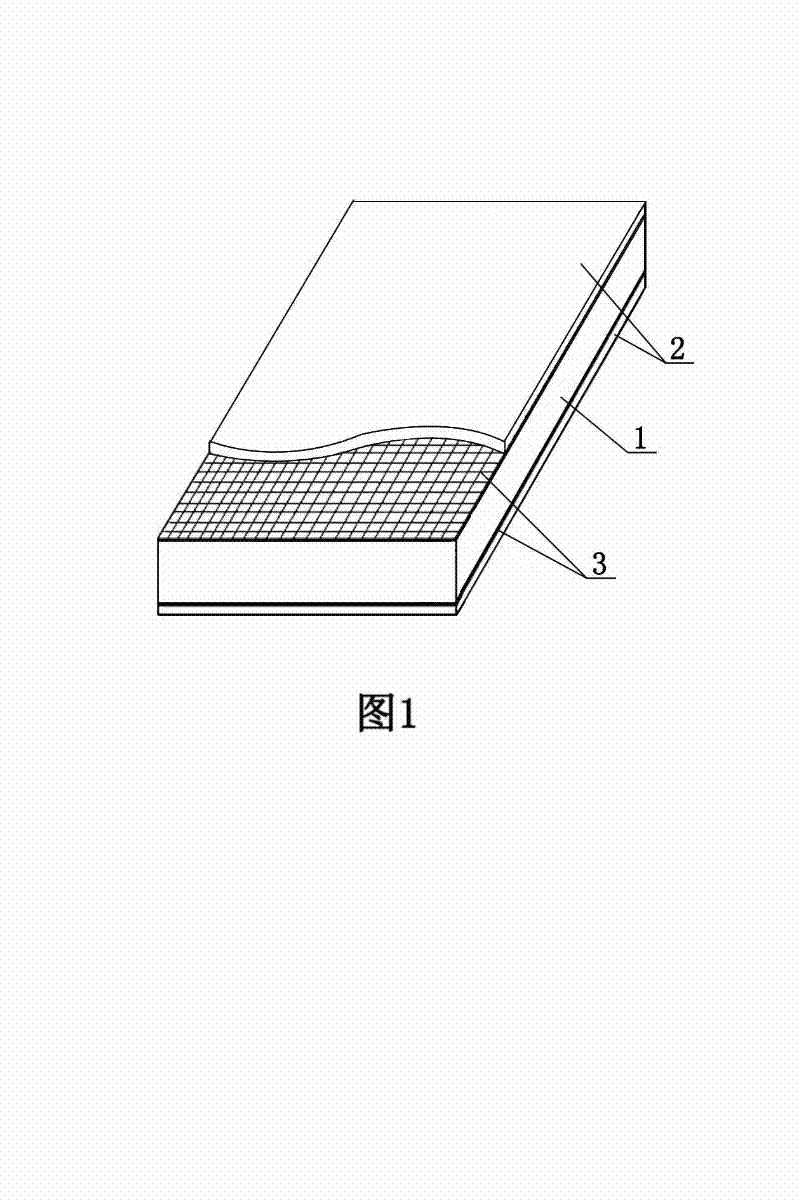

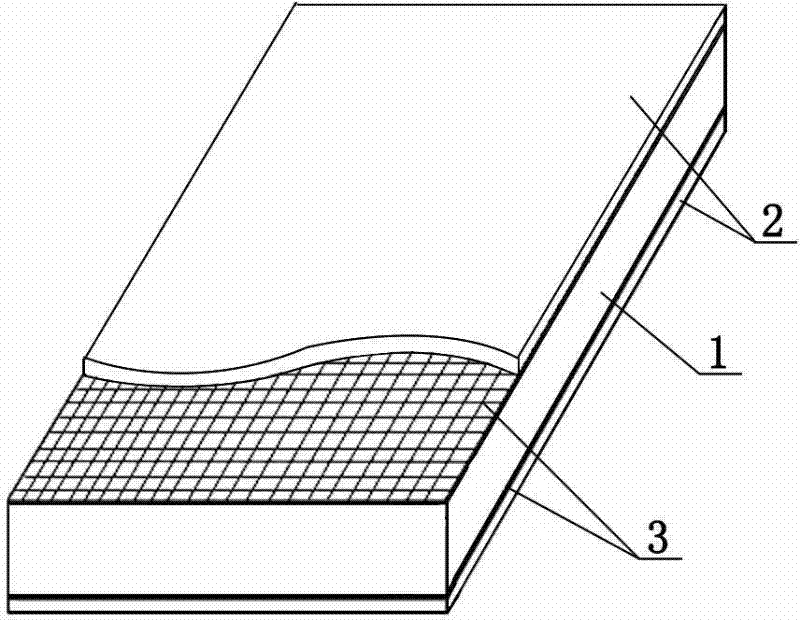

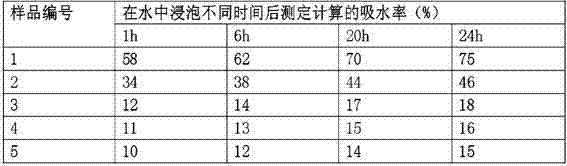

Environmentally-friendly super hydrophobic glazed hollow bead grade A fireproof composite insulation board and production method thereof

InactiveCN102392495AGlossy smoothStable physical and chemical propertiesCeramic shaping apparatusHeat proofingEmulsionNonwoven fabric

The invention discloses an environmentally-friendly super hydrophobic glazed hollow bead grade A fireproof composite insulation board and a production method thereof. The insulation board comprises an insulation layer, a mortar layer and non-woven cloth, wherein the insulation layer is a super hydrophobic glazed hollow bead board which is formed by uniformly stirring super hydrophobic glazed hollow beads, injecting an aid, extruding at the low temperature, extruding and shaping with a mold, cooling and cutting; the non-woven cloth is paved on the two faces of the super hydrophobic glazed hollow bead board, and is compounded with the mortar layer; the super hydrophobic glazed hollow beads are obtained by soaking glazed hollow beads with a bi-component water repellent, filtering and drying;and the bi-component water repellent is a 0.1-0.6 percent aqueous solution obtained by mixing a mono-methylsiloxane organic waterproof agent with a reactive dimethyl siloxane aqueous emulsion in the weight ratio of 1:1.5. By adopting the composite insulation board, the problem that glazed hollow beads cannot be applied to external thermal insulation of outer walls due to high water absorbing capacity; and the composite insulation board contributes to saving energy, is environmentally-friendly, can reach the grade A1 fireproof index, and can be widely applied to insulation work of outer walls and roofs of buildings.

Owner:宁宝柱

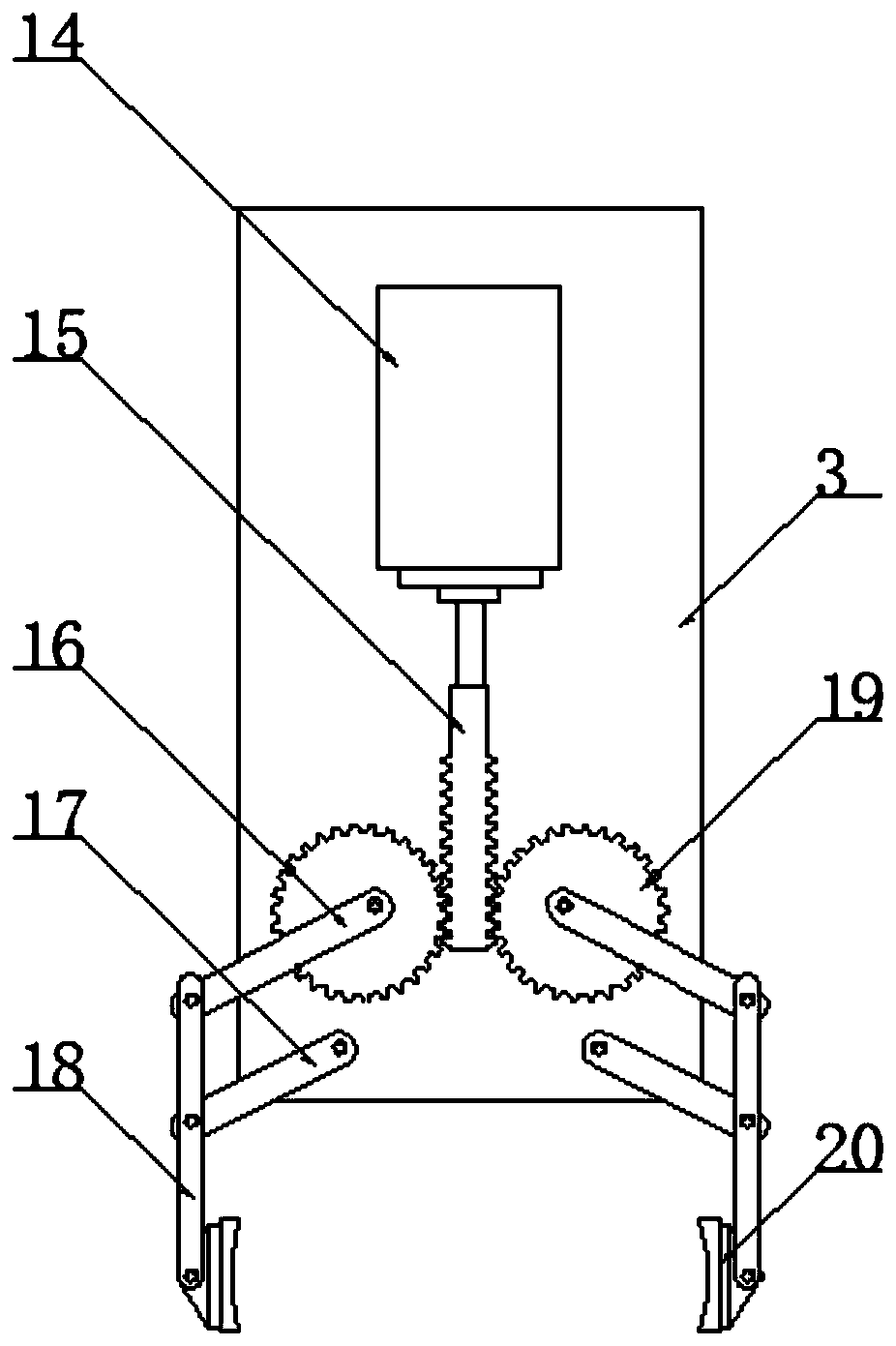

Intelligent grabbing device for automobile part production

InactiveCN111070181ALarge grabbing rangeImprove practicalityProgramme-controlled manipulatorArmsProduction lineEngineering

Owner:浙江华威设备制造有限公司

Urea formaldehyde condensate additive agent, production method and urea formaldehyde condensate adhesive agent

InactiveCN101245172AReduce formaldehyde emissionGood effectNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesScrapChemistry

The invention relates to a urea resin additive used in hard boards and a urea resin binder which comprises the additive and a preparation method thereof; the additive comprises substances which are dipped in and extracted from tea scraps and can eliminate formaldehyde; the extracting steps comprise steps of dipping and extracting the tea scraps by utilizing alkaline solution, filtering the tea scraps to obtain a filtrate and adjusting the ph value of the filtrate. By mixedly using the extracts of the tea scraps and the urea resin gel, the tea scrap extracts is led to be chemically reacted with the formaldehyde in the heat pressing process of the hard board, thus reducing the releasing amount of the formaldehyde of the hard board and having remarkable and durable effect without rebound; furthermore, the mechanical property of the prepared hard board is improved instead of being reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Traditional Chinese medicine weight loss powder and preparation method thereof

InactiveCN104840832AResolve side effectsChange your physiqueMetabolism disorderPlant ingredientsSide effectBetel

The invention discloses a traditional Chinese medicine weight loss powder and a preparation method thereof. The traditional Chinese medicine weight loss powder is prepared by the following materials in parts by weight: 5 to 15 parts of Pinellia ternata, 5 to 15 parts of dried Lotus leaf, 10 to 25 parts of Poria cocos, 10 to 25 parts of rhizoma alismatis, 5 to 15 parts of charred triplet, 5 to 10 parts of pharbitis seed, 5 to 10 parts of betel nut and 10 to 25 parts of rheum officinale. The traditional Chinese medicines are ground and mixed, fresh lotus leaf juice or rheum officinale decoction and traditional Chinese medicine powder are mixed to be ointment-shaped, so as to form the traditional Chinese medicine weight loss powder. The traditional Chinese medicine weight loss powder is especially suitable for weight loss of people with phlegmatic hygrosis intrinsic type obesity, spleen deficiency wet yang type obesity and fatigue type obesity, and is outstanding in weight loss effect and free of side effect and rebound phenomenon.

Owner:龙兰

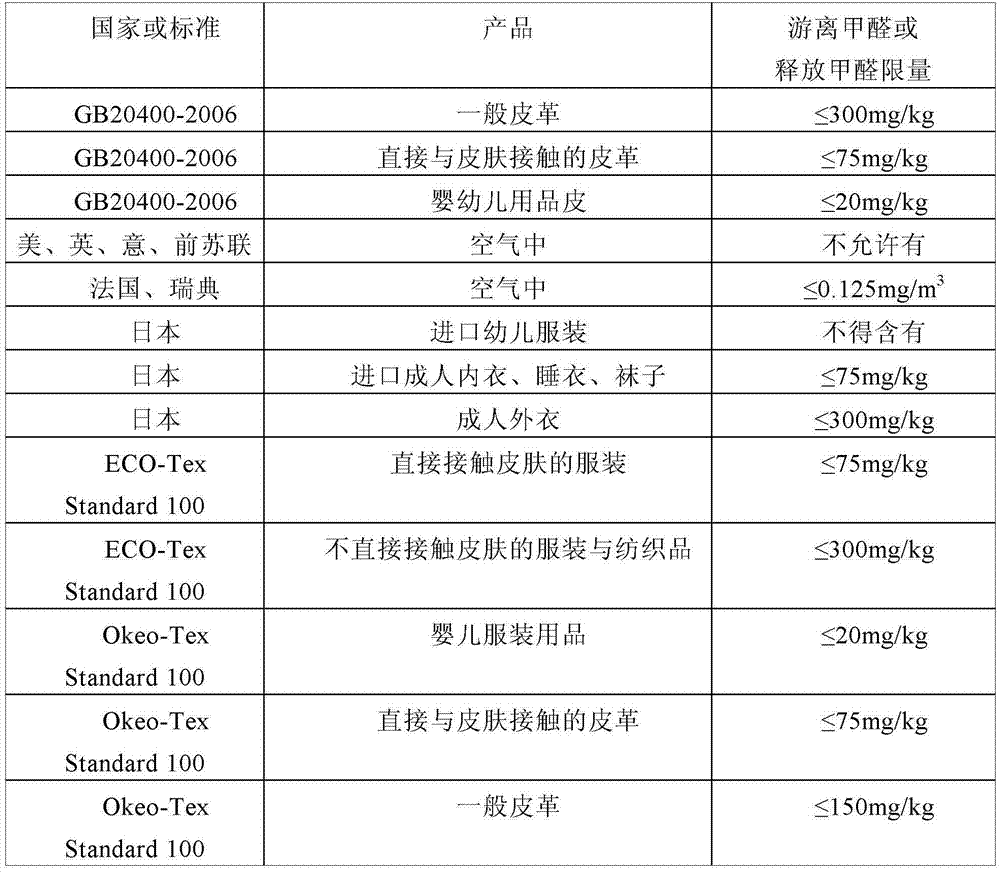

Fur free formaldehyde content reducing method

InactiveCN104726621AHelp removeImprove the effect of removing free formaldehyde in furTanning treatmentDyeing processChemistryAldehyde

The invention discloses a fur free formaldehyde content reducing method which comprises the following steps: 1) taking fur for weighing, and determining fur free formaldehyde content; 2) retanning for formaldehyde removal; 3) capturing to remove free formaldehyde; 4) washing to remove the free formaldehyde; 5) dye fixing; and 6) aldehyde fixing. The method can reduce the fur free formaldehyde content from about 450 mg / kg to 70 mg / kg or less, or even 20mg / kg or less, and the fur free formaldehyde content may not significantly rebound within three months.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +1

Chinese medicinal composition for treating chronic gastritis and peptic ulcer and preparation method thereof

InactiveCN102139080AImprove securityWon't reboundAmphibian material medical ingredientsAnthropod material medical ingredientsSide effectAmomum villosum

The invention relates to the field of traditional Chinese medicines in medicines, in particular to a Chinese medicinal composition for treating chronic gastritis and peptic ulcer and a preparation method thereof. The Chinese medicinal composition is a medicament prepared from the following Chinese herbal medicines in part by weight: 50 to 250 parts of sandalwood, 600 to 1,000 parts of Chinese fever vine, 300 to 600 parts of rhizoma corydalis, 700 to 1,300 parts of dandelion, 200 to 300 parts of alpine salamander, 150 to 500 parts of golden thread, 100 to 300 parts of heterophylly falsestarwort root, 50 to 250 parts of amomum fruit, 50 to 250 parts of pseudoginseng root, 100 to 250 parts of largehead atractylodes rhizome, 100 to 300 parts of white paeony root, 300 to 700 parts of root of red-rooted salvia, 150 to 350 parts of immature bitter orange, 100 to 250 parts of medcinal evodia fruit, 100 to 250 parts of bupleurum and the like. The Chinese medicinal composition has an obvious curative effect of treating the chronic gastritis and the peptic ulcer, has high safety, and does not have toxic or side effects and adverse reactions.

Owner:张伯华

Formaldehyde absorptive reagent and preparation process thereof

InactiveCN101125212AToxicity does not produceMeet environmental protection requirementsDeodrantsSoftened waterPhosphoric acid

The present invention discloses a formaldehyde absorptive reagent and the preparation method; the weight match of materials of formaldehyde absorptive reagent includes: softened water: 0.9 to 1.7; phosphoric acid: 0.3 to 0.5; carbamide: 0.6 to 1.3; activator: 0.003 to 0.009. The formaldehyde absorptive reagent is prepared with the polymerization of phosphoric acid and carbamide with the help of the activator. The preparation method of the formaldehyde absorptive reagent of the present invention is easy and rapid, convenient and low in cost. When being applied with urea-formaldehyde resin adhesive, the excessive free formaldehyde is absorbed during the heat press, the formaldehyde absorption is remarkable and perennial without bounce. During the manufacture and the application, the formaldehyde absorptive reagent generates no toxin, bringing no harm to human and environment and meeting the environmental demands.

Owner:BEIJING FORESTRY UNIVERSITY

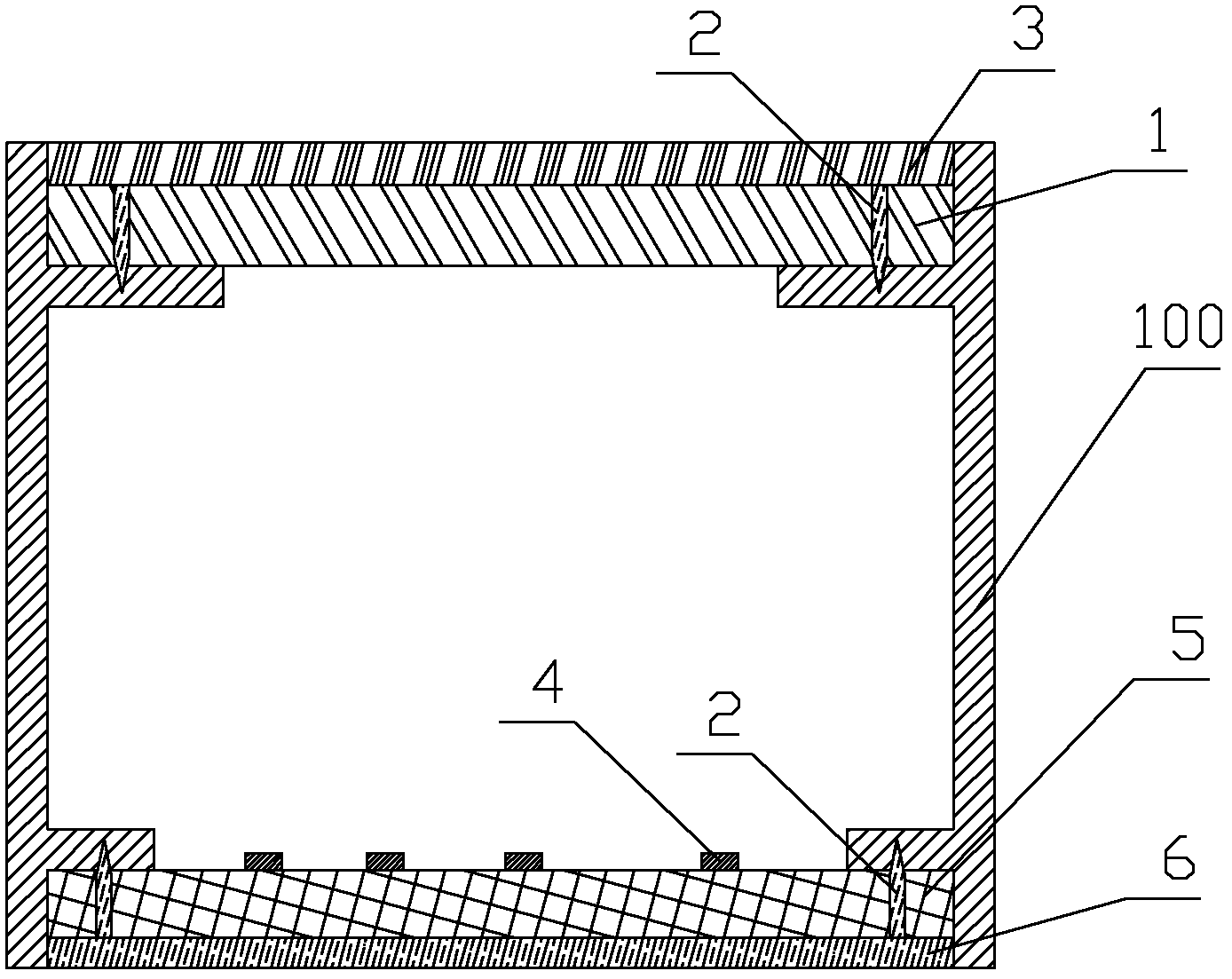

Resin stereoscopic light-emitting character and manufacturing method thereof

InactiveCN102509526AImprove sealingAvoid crackingIlluminated signsLight fasteningsEngineeringLED lamp

The invention discloses a resin stereoscopic light-emitting character which comprises a panel, a character edge, a bottom plate and an LED (light-emitting diode) lamp, wherein the panel comprises a panel auxiliary board and a panel resin layer covered on the panel auxiliary board; the bottom plate comprises a bottom plate auxiliary board; the character edge is formed by enclosing the edge of the character by using an edge strip; the edge strip comprises an edge strip body, a panel riveting rib and a bottom plate riveting rib; the panel auxiliary board is fixedly connected with the panel riveting rib through nails or screws; the bottom plate auxiliary board is fixedly connected with the bottom plate riveting rib through nails or screws; and the bottom plate auxiliary board is provided withthe LED lamp. The resin stereoscopic light-emitting character has the advantages of high structural strength, long service life, low manufacturing cost and the like. The invention also discloses a manufacturing method of the resin stereoscopic light-emitting character, which comprises the following steps: sculpturing the panel auxiliary board and the bottom plate auxiliary board, making grooves in the edge strip, enclosing the character edge and fixing the panel auxiliary board, installing the LED lamp, installing the bottom plate auxiliary board, casting resin to form the panel, and casting resin to form the bottom plate. The manufacturing method has the advantages of short manufacturing time and high processing efficiency.

Owner:ZHEJIANG UNIV

Paste for waist, leg, shoulder and neck

InactiveCN101869671AExtensive sources of raw materialsReduce manufacturing costAnthropod material medical ingredientsAntipyreticArterial insufficiencyVertebra

Owner:刘小杨

Method for preparing weight-reducing chewing gum

InactiveCN101642181ANo side effectsDoes not affect appetiteChewing gumFood preparationSalvia miltiorrhizaSide effect

The invention belongs to the field of nutritional health-care foods, which in particular relates to a method for preparing weight-reducing chewing gum. The weight-reducing chewing gum comprises the main components of green tea, cassia seed, hawthorn, salvia miltiorrhiza, rivier giantarum and lotus leaf. The method comprises the following steps: mixing the green tea, the cassia seed, the hawthorn,the salvia miltiorrhiza, the rivier giantarum powder and the lotus leaf in a certain amount, adding into hot water, refluxing, clarifying, filtering, concentrating, then adding dextrin and xylitol, mixing, preparing wet granules, drying, tabletting and sterilizing. The product adopts a purely natural traditional Chinese medicine formula, has no side effect on a human body, has the functions of facilitating digestion, promoting urination and relaxing bowels, is used as a nutritional health-care product, can not cause relapse after being stopped taking, is similar to chewing gum and has convenient carrying and taking.

Owner:HANGZHOU LIUYI TECH

Pumpkin tea capable of losing weight

The invention relates to a pumpkin tea capable of losing weight. The pumpkin tea is characterized by comprising the following raw materials in parts by weight: 15-30 parts of pumpkin, 3-6 parts of folium artemisiae argyi, 5-12 parts of sterculia scaphigera, 2-8 parts of dried ginger, 5-10 parts of honey and 5-10 parts of watermelon peels. Compared with the prior art, the pumpkin tea has the advantages that firstly, according to the whole technical scheme, the raw material cost is relatively low and a production process is simple and easy to perform; secondly, the weight-losing tea does not have any side effect on digestion and absorption systems and can promote normal metabolism of a human body; thirdly, the weight-losing tea has the effects of reducing blood fat and lowering the cholesterol level while reducing weight, and can remove toxic materials, maintain beauty, whiten skin and prevent diseases such as arteriosclerosis; fourthly, the weight-losing tea has a remarkable weight-losing effect, is safe and healthy weight-losing tea and is convenient for large-scale popularization, the use of the weight-losing tea can be stopped after the weight-losing tea is drunk for 6-8 months, and the weight cannot be increased after the use of the weight-losing tea is stopped.

Owner:黄介兰

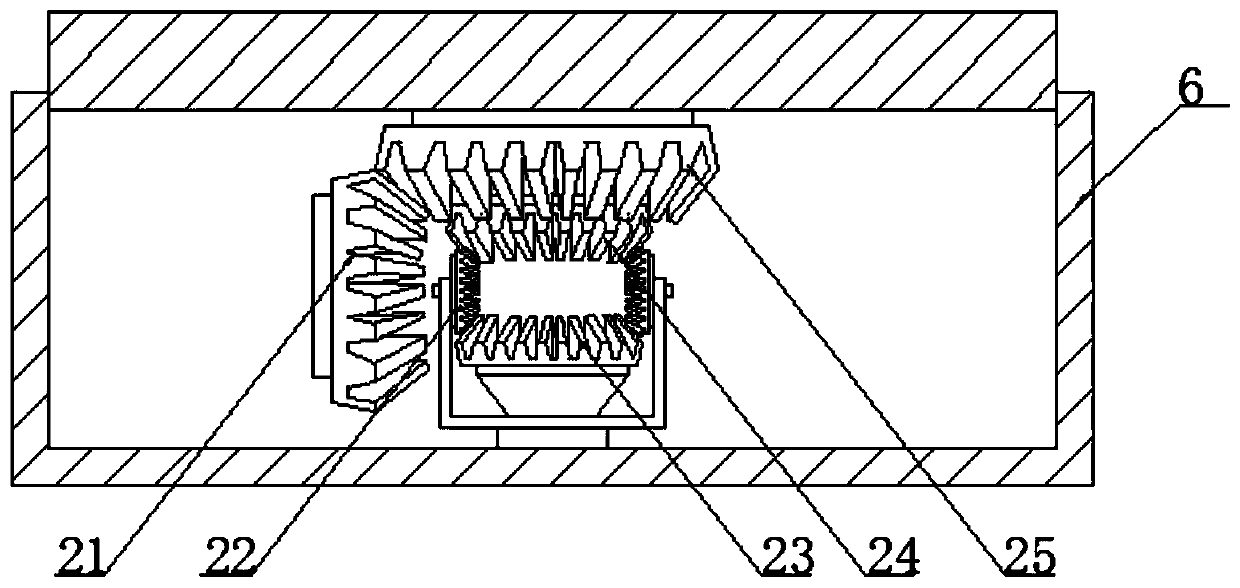

Preparation method of nature sodium base bentonite for precise casting

InactiveCN102974750AImprove reusabilityWon't reboundFoundry mouldsFoundry coresSodium BentoniteReusability

The present invention discloses a preparation method of nature sodium base bentonite for precise casting. The method comprises mining, drying, coarse crushing, sodium content adjustment, sodium modification, drying, crushing and other steps. The preparation method has the following advantages that: no bounce is generated when the bentonite obtained through the method contacts a high temperature of more than 300 DEG C, and the obtained bentonite has characteristics of good high temperature resistance, good weathering resistance, molding sand bonding, good reusability, low addition, and good air permeability.

Owner:董宪姝

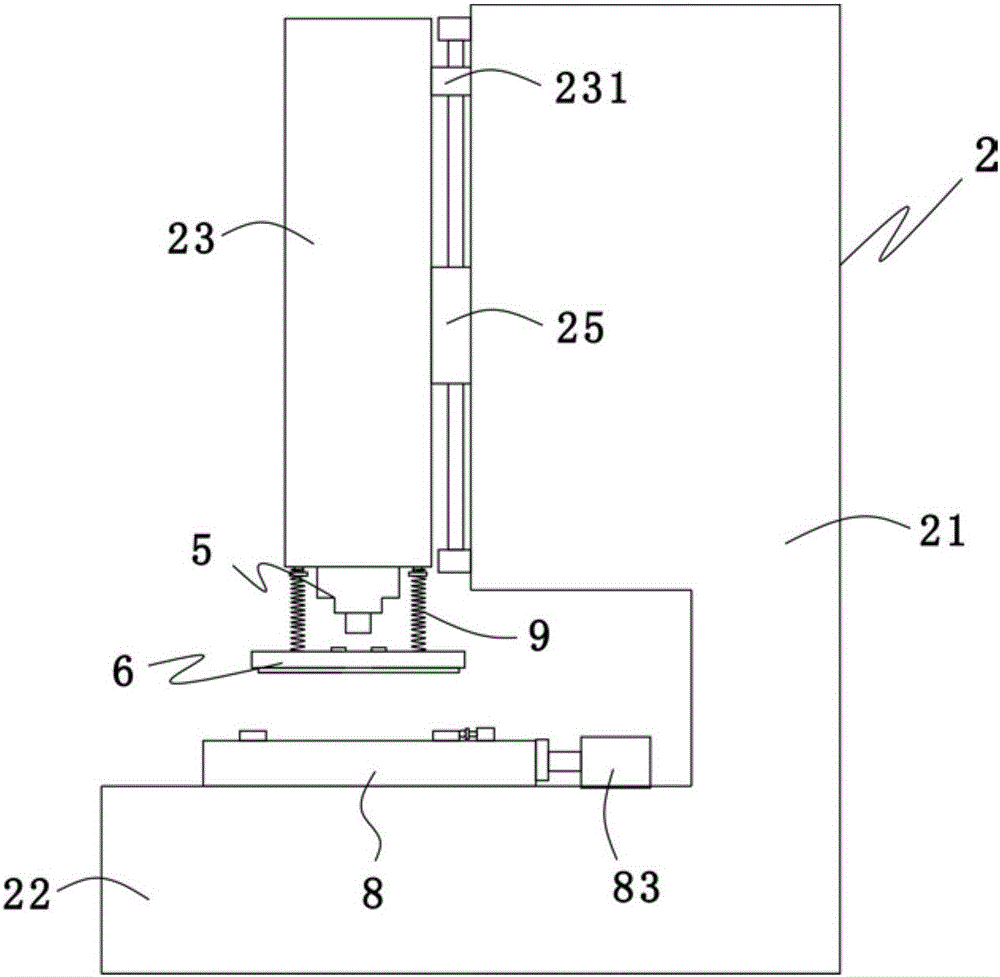

Novel pressure welding system

The invention discloses a novel pressure welding system. The novel pressure welding system comprises a cleaning unit for cleaning impurities on surfaces of to-be-machined workpieces and a pressure welding unit for performing pressure welding operation on the workpieces, wherein the pressure welding unit comprises a rack, a workbench arranged on the rack, a pressure welding power arm capable of acting along the rack up and down, a pressure welding assembly connected with the pressure welding power arm, a heating structure for heating the pressure welding assembly as well as a first drive part for driving the pressure welding power arm to act up and down; the pressure welding assembly comprises a pressure welding head and a pressure dispersion part connected to the pressure welding power arm through an elastic part, and in the initial state, the pressure dispersion part is located below a pressure welding head and above the workbench. The novel pressure welding system can effectively disperse pressure applied by the pressure welding head to the workpieces, prevent workpiece deformation or damage caused by over-high pressure on to-be-welded positions and reduce the scrap rate of the workpieces; the pressure welding position is accurate and the welding quality and efficiency are improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Buffer device and mechanical switch

InactiveCN105351427ADecelerate fastPrevent reboundSpringsShock absorbersCylinder blockMechanical engineering

The invention discloses a buffer device and a mechanical switch. The device comprises a cylinder, a piston, a piston rod and a pressure relieving device, wherein one end of the piston rod penetrates through a first end cover, and extends into the cylinder to be fixed with the piston in the cylinder; a cavity of the cylinder is divided into a first cavity and a second cavity at the sides of the first end cover by the piston; the pressure relieving device is assembled on the cylinder, and a valve core rod part of a pressure relieving valve rod in the pressure relieving device extends into the first cavity; an extension rod is positioned in the pressure relieving valve core for adjusting a pressure relieving trigger travel; and the pressure relieving device and the second cavity are communicated through a channel provided with an adjusting valve. The mechanical switch comprises a single-pole switch; the single-pole switch is axially connected with the buffer device; the buffer device relieves the damping force before switching on; the switching-on bounce of a moving contact is reduced; the damping releasing strength is adjusted; and the buffer device and the mechanical switch are in synergistic effect to optimize the switching-on performance. The pressure relieving device is arranged on the cylinder, and is convenient for installation, maintenance and adjustment of the pressure relieving trigger travel of the pressure relieving valve core.

Owner:陈鸽

Nicotinamide stoste with performance of improving dark and dull skin and preparation method of nicotinamide stoste

InactiveCN109464315AFragrant and elegantSmell aromatic fragrance elegantCosmetic preparationsToilet preparationsSkin complexionYellow complexion

The invention relates to nicotinamide stoste with the performance of improving dark and dull skin and a preparation method of the nicotinamide stoste, and relates to the technical field of cosmetics.The nicotinamide stoste in the formula is prepared from 3.5-5 parts of a raw material group A, 93.5-96 parts of a raw material group B and 0.4-1.5 parts of a raw material group C. The invention further provides the preparation method of the nicotinamide stoste with the performance of improving the dark and dull skin. The stoste prepared with the method has the self-repairing capability of improving and enhancing skin from inside to outside, so that dark lines are smoothed and the skin is whitened under self-repair of the skin in cooperation with the stoste. The nicotinamide stoste is aromaticand elegant in smell, has good use effect, repairs and brightens complexion, improves dark and dull yellow complexion and has good moisturizing property, the skin is enabled to be in a moistened statefor a long time, and skin peeling and aging caused by dry skin and other reasons are avoided.

Owner:广东天源生物科技有限公司 +1

Weight-reducing honeysuckle tea

InactiveCN104247844ALow raw material costSimple production processTea substituesChemistryBlood lipids

The invention relates to weight-reducing honeysuckle tea which is characterized by comprising the following raw materials in parts by weight: 18-29 parts of honeysuckle, 3-6 parts of radix isatidis, 5-12 parts of siraitia grosvenorii, 2-8 parts of asarum, 5-10 parts of honey, and 5-10 parts of watermelon peel. Compared with the prior art, the weight-reducing honeysuckle tea has the advantages as follows: (1) the whole technical scheme is low in cost for raw materials, simple in production technology, and easy to operate; (2) the weight-reducing tea has no side effect to digestion and absorption systems, and promotes normal metabolism of a human body; (4) besides reducing weight, the weight-reducing tea has the effects of reducing blood lipid and reducing cholesterol, and can expel noxious substances, beautify and whiten skin, and prevent arteriosclerosis and other diseases; (5) the weight-reducing tea is obvious in weight-reducing effect, people can stop drinking after taking the tea for 6-8 months, no rebound appears after the stop, and the weight-reducing tea is safe and healthy weight-reducing tea convenient to popularize in a large scale.

Owner:黄介兰

Plastic bottle flatting method

InactiveCN106738461AWon't reboundQuality improvementPlastic recyclingEngineeringMechanical engineering

The invention belongs to the field of plastic pressing methods and particularly discloses a plastic bottle flatting method. A plastic bottle falls to a conveying belt and topples toward a first high-temperature roller. The first high-temperature roller rotates to flat the plastic bottle. A rotating second high-temperature roller flats the plastic bottle once more. A rotating rotary roller continues to fully flat the plastic bottle. The plastic bottle which is fully flatted moves to the position below a water spraying device. The plastic bottle is cooled through water sprayed out of the water spraying device. Cutting-up work of the next step can be conducted on the cooled plastic bottle. By means of the plastic bottle flatting method, the plastic bottle can be fully flatted, and the flatted plastic bottle has brittleness.

Owner:重庆市永川区玉江塑料厂

Agrimonia pilosa ledeb weight reducing tea

The invention relates to agrimonia pilosa ledeb weight reducing tea which is characterized by being prepared from the following raw materials in parts by weight: 10-35 parts of agrimonia pilosa ledeb, 3-6 parts of amomum tsao-ko, 5-12 parts of pawpaw, 2-11 parts of eupatorium, 3-12 parts of brown sugar and 2-15 parts of dandelion. Compared to the prior art, the agrimonia pilosa ledeb weight reducing tea has the advantages that 1) according to the whole technical scheme, the raw materials are relatively low in cost, and the production process is simple and easy to operate; 2) the weight reducing tea is free of any side effects to digestion and absorption systems and can be used for promoting normal metabolism of human body; 4) the weight reducing tea further has the effects of reducing blood fat and cholesterol while is used for reducing weight, can be used for detoxifying and maintaining beauty and whitening skin, and can be further used for preventing diseases such as arteriosclerosis; and 5) the weight reducing tea is obvious in weight reducing effect, can be stopped administration if being eaten for 6-8 months, and weight is not rebounded if the weight reducing tea is stopped, so that the weight reducing tea is safe and health weight reducing tea which is convenient for large-scaled promotion.

Owner:袁海忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com